So next time you hit the road in your electric ride, remember that behind the scenes, silicone is working hard to keep you moving smoothly and safely. Let’s dive deeper into how this remarkable material fuels the future of transportation.

But first, let’s take a closer look at why silicone has become such a game-changer for electric vehicles.

Advantages of Silicone for EV Safety

Silicone is a game-changer. Its unique properties make it an ideal material for electrical systems in EVs. Let’s take a closer look at the advantages of silicone for EV safety:

- Excellent thermal stability: Silicone offers remarkable thermal stability, which is crucial for the safe operation of electrical systems in EVs. This means that even during demanding conditions, such as high temperatures generated by the battery or motor, silicone can withstand without compromising its performance.

- Superior resistance to extreme temperatures: In the world of EVs, extreme temperatures are a constant challenge. However, silicone rises to the occasion by providing exceptional resistance to both high and low temperature extremes. This reduces the risk of overheating or short circuits that could potentially lead to accidents or damage.

- High dielectric strength: Electrical leakage can be a significant concern in any vehicle, especially in EVs where advanced electronics play a vital role. Fortunately, silicone has a high dielectric strength that helps prevent electrical leakage. Minimizing this risk enhances overall safety and ensures the smooth functioning of critical systems.

Silicone helps make electric vehicles safer by withstanding extreme temperatures and preventing electrical mishaps. It is an important component for keeping EVs reliable and secure on the road.

Advanced Silicone Materials for EV Applications

Advanced silicone materials are a promising area of research and development in the field of electrical vehicle (EV) components. Silicones have unique properties that make them valuable in various automotive applications, such as gaskets and seals, and more recently in the rapidly growing EV market.

EV Gaskets and Seals

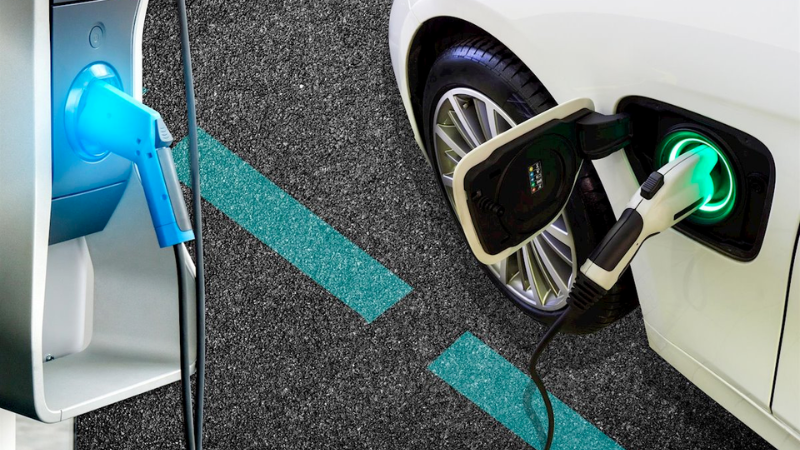

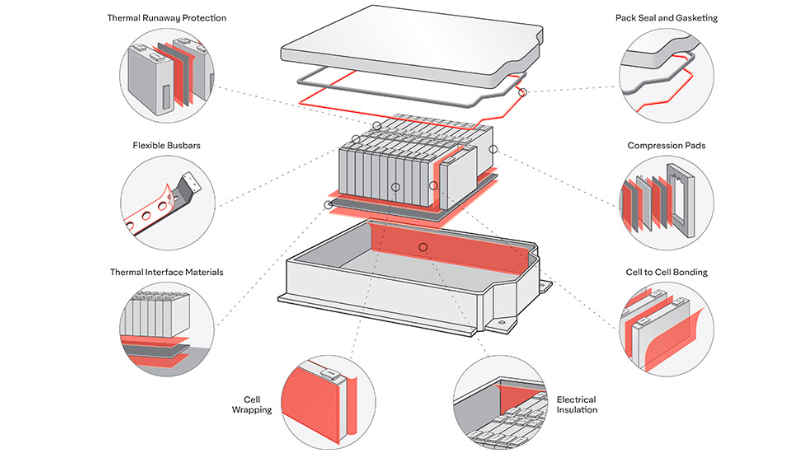

One application of advanced silicone materials for EV applications includes electric vehicle (EV) gaskets and seals. EVs have a variety of different requirements compared to traditional internal combustion engine vehicles, including higher voltage systems and more extreme operating temperatures. Because of these unique requirements, high performance gaskets and seals are needed for EVs.

Silicone materials offer excellent chemical and thermal resistance, as well as high voltage sustainability, making them a valuable material choice for these applications.

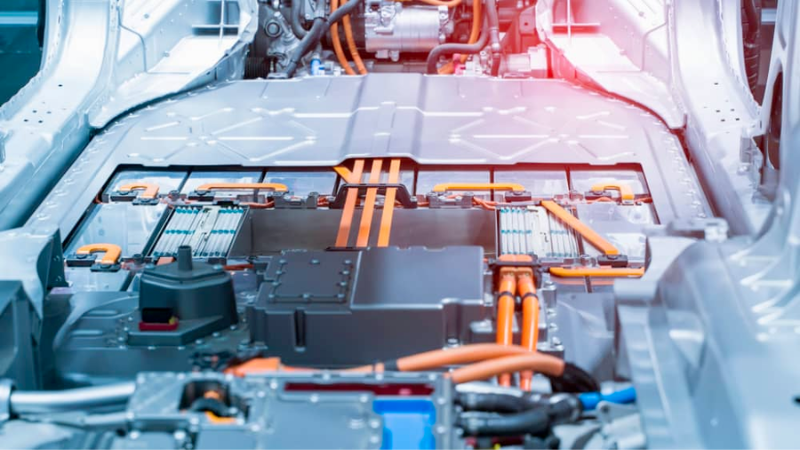

Silicone in EV Batteries

Because the EV batteries thermal management solutions evolve all the time, it’s vital you stay current and updated on how they are now making a difference in multiple markets through various applicational uses.

Advanced silicone materials have also been developed for use in EV batteries. For example, silicone rubber materials are used as separators in lithium-ion batteries. These separators are designed to prevent short circuits and ensure safe battery operation.

When dealing with the thermal conductivity of EV batteries, the temperature has a direct bearing on the EV battery’s performance. The better thermal management material that’s used helps keep temperatures drops to a minimum, which means you have optimum battery performance. Silicone materials have excellent mechanical and thermal properties, making them a desirable option for use in EV batteries.

Advanced silicone materials are also being developed for use in EV charging ports and connectors. These applications require materials that can withstand high voltage and temperature conditions, while also providing excellent electrical insulation properties.

In short, advanced silicone materials have demonstrated excellent potential for use in various EV applications. These materials offer excellent chemical, thermal, and electrical resistance, making them a valuable option for EV component design.

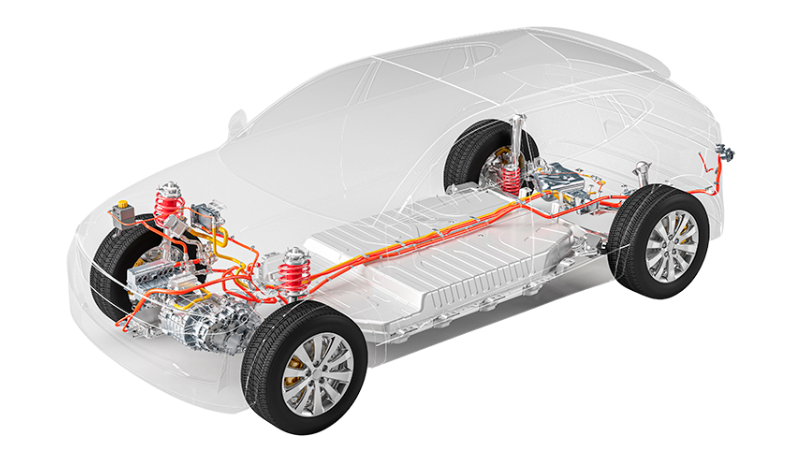

Thermal Management and Assembly In Electric Vehicles

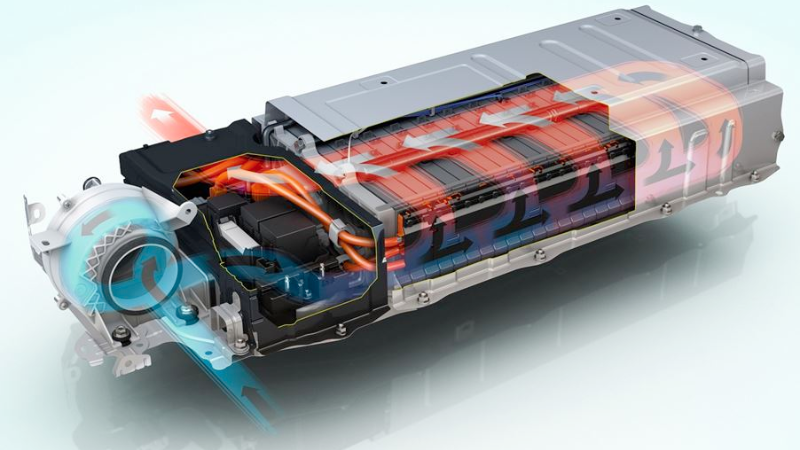

Silicone-based thermal interface materials (TIMs) play a crucial role in ensuring efficient heat transfer within electric vehicles (EVs). By facilitating the dissipation of heat between electronic components and heat sinks, these TIMs prevent overheating issues that can impact the performance and lifespan of EVs.

Here are some examples of leading technologies of silicone materials in EVs for thermal management:

Silicone gel

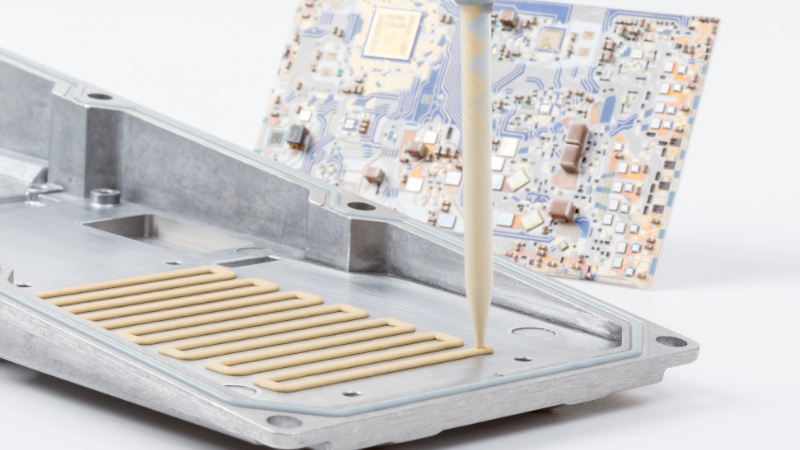

Silicone gel is a non-liquid form of silicone that has excellent heat transfer properties and can be used as a thermal interface material (TIM) in EVs. The gel can be applied between components to provide effective heat dissipation and reduce thermal hot spots, which can improve battery performance and extend battery life.

Silicone rubber

Silicone rubber is a material that offers excellent chemical resistance, durability, and heat resistance, making it a valuable material for EV thermal management applications. It can be used as a thermal spacer or gasket in various components to provide a secure and leak-free seal and improve thermal conductivity.

Silicone adhesive

Silicone adhesive is a material that can provide an excellent moisture barrier and thermal conductivity, making it suitable for use in EV battery packs and other thermal management components. It can be used to bond and seal components, providing a secure and efficient thermal management system in EVs.

Silicone adhesive tape

Silicone adhesive tape is a material that offers excellent adhesive properties and flexibility, making it suitable for use in various thermal management applications in EVs. It can be used to bond and seal components, providing a secure and efficient thermal management system in EVs.

Silicone-coated thermal management materials

Silicone-coated thermal management materials, such as heat sinks and cooling fans, are a leading technology used in EV thermal management. These materials provide an excellent combination of heat dissipation, moisture protection, and ease of installation, making them ideal for use in EV thermal management systems.

The use of silicone materials in thermal management and assembly processes reflects the growing significance of this versatile compound in the automotive industry. As the electric vehicle market continues to expand rapidly, manufacturers rely on silicone’s exceptional thermal stability to address challenges associated with high-performance batteries and other electrical components.

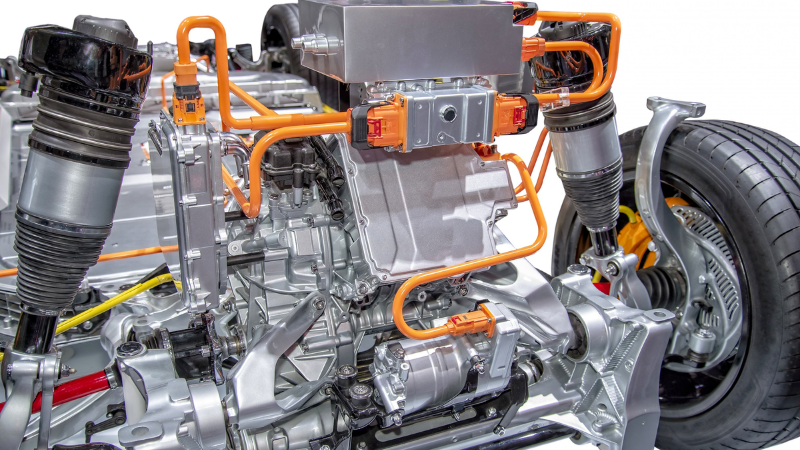

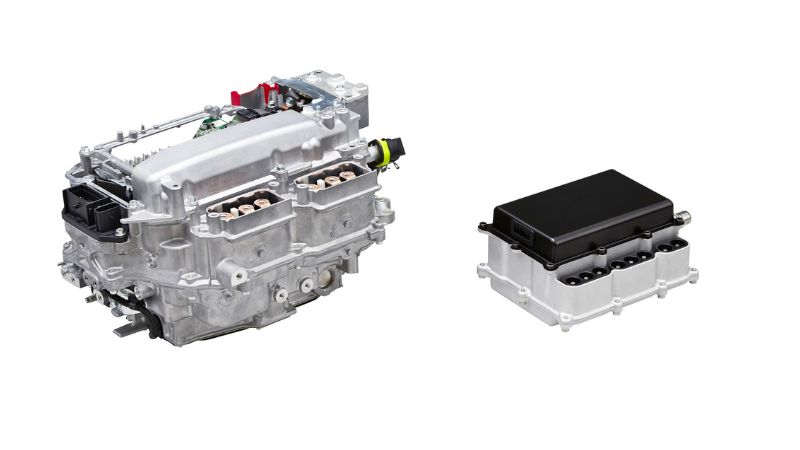

Power Control Unit (PCU) Thermal Management with Silicone

By utilizing silicone-based solutions for PCU thermal management, several benefits can be achieved:

- Effective heat dissipation: Silicone gap fillers efficiently dissipate heat within PCUs, preventing overheating.

- Component protection: Silicone encapsulants safeguard PCU components from moisture, dust, and other environmental factors.

- Reliable insulation: Silicone thermal pads offer reliable insulation properties for power semiconductor devices in PCUs.

Silicone in EVs improves their power control units, enhancing performance and durability. This optimization leads to increased overall functionality and longevity of electric vehicles.

The Impact of Silicone in Electric Vehicles

Silicone’s use in electric vehicles brings about several significant benefits. It contributes to improved safety standards, enhanced performance, and extended lifespan of critical components. Moreover, its versatility and reliability make it an indispensable material for the advancement of electric vehicle technology.

The advantages of silicone in electric vehicles can be summarized as follows:

Enhanced Safety:

- Silicone materials provide insulation and protection against electrical hazards.

- They help minimize the risk of short circuits or electrical fires.

Improved Performance:

- Silicone-based coatings enhance the efficiency of battery systems.

- It facilitates smoother movement of mechanical parts, reducing friction and energy loss.

Extended Component Lifespan:

- Silicones offer excellent resistance to extreme temperatures, moisture, and environmental factors.

- They protect critical components from degradation over time, increasing their durability.

Conclusion

Silicone is important for electric vehicles (EVs) because it improves safety. It can withstand high temperatures and prevent fires, extending its lifespan. In light of these advantages, it is clear that incorporating silicone into electric vehicle manufacturing is essential for maximizing safety and efficiency.

Discover the Perfect Silicone Products for Your EV Business with Hongju

As a global supplier of silicone products, Hongju Silicone offers a wide range of products specifically designed for the EV market, such as insulation seals, gaskets, electrical insulation, and more.

With expertise and experience in silicone technology, Hongju Silicone is poised to support the growing demand for high-quality silicone products in the EV market.