Rubber and Polyvinyl Chloride (PVC) are versatile materials due to their innovative properties.

Rubber is known for its flexibility, durability, and chemical resistance. These qualities make it the best choice for various applications, like automotive parts.

The choice between PVC and rubber depends on your needs and applications. Both offer various advantages due to their unique features but have some limitations.

In this blog, we will compare PVC and rubber. This comparison will help you choose between both materials with confidence.

What is PVC?

Polyvinyl Chloride (PVC) is a widely used synthetic plastic polymer thermoplastic material.

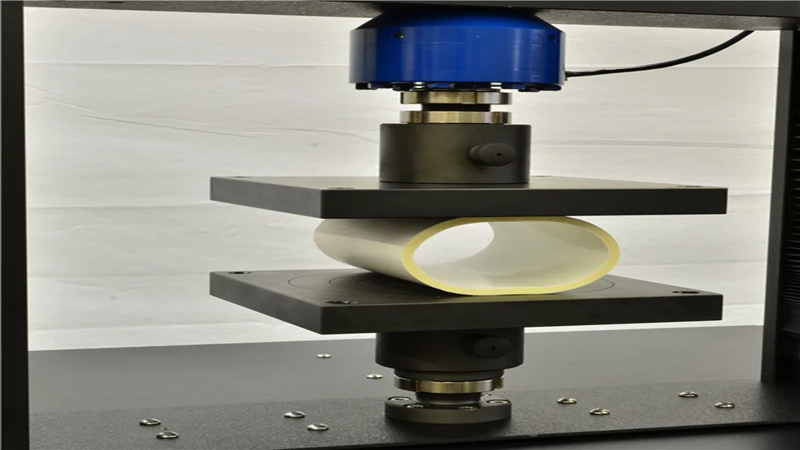

According to ASTM D1784, PVC compounds are classified by their tensile strength, modulus, and Izod impact resistance.

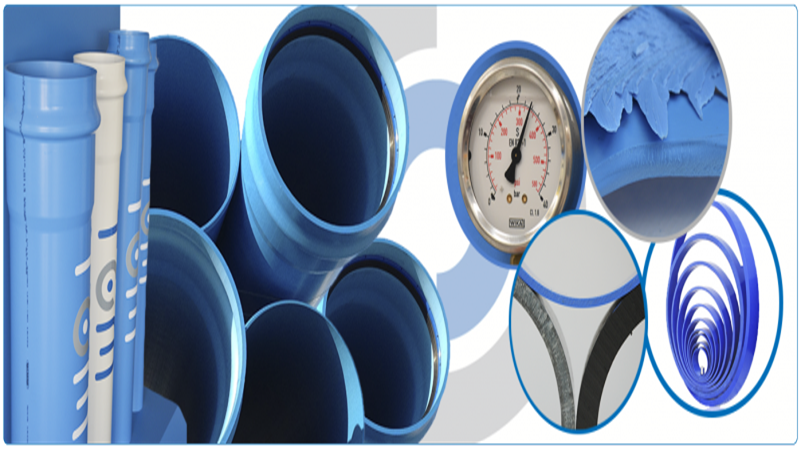

It has unique features like easy processing, affordability, and lightweight. These versatile properties make it suitable for construction, insulation, medical devices, pipes, etc.

Properties and Characteristics

PVC is a versatile with the following properties and characteristics:

- This white solid powder can stick to metal surfaces and not dissolve in hydrocarbon solutions.

- PVC’s melting point is about 100 °C. It reaches the glass transition at 80 °C. This high melting point enables it to withstand extreme conditions.

- It is a lightweight but tough material with 1.3 to 1.45 g/cm³ density. PVC offers durability, strength, and flexibility.

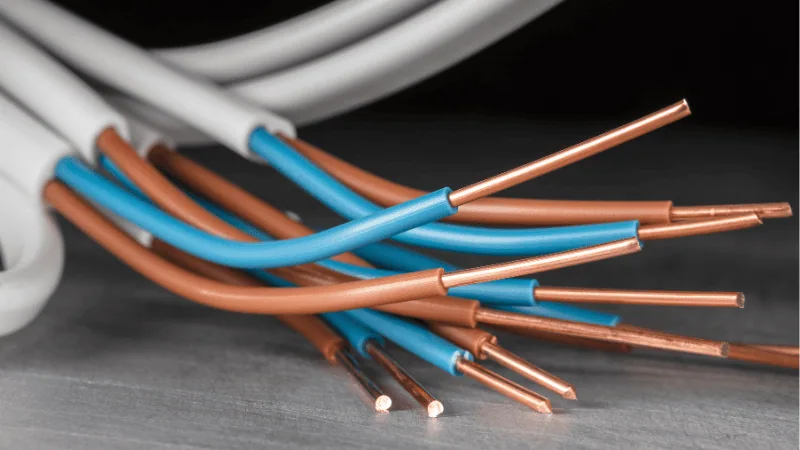

- PVC is an excellent insulator that prevents electricity from passing through. That’s why it is one of the best materials for insulating electrical wires.

- It is weather, corrosion, and chemical-resistant. The shock and abrasion-resistant qualities make it the best choice for outdoor activities like water pipes and PVC flooring.

Applications

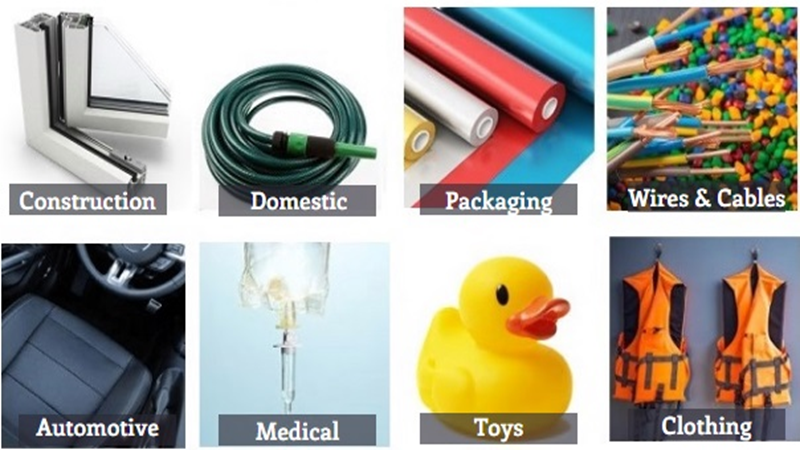

The wide range of uses makes PVC ideal for various industries. The applications of PVC are:

- This synthetic material has applications in the construction industry. The applications include fittings, frames, PVC flooring, pipes, and PVC soles. PVC is cheaper than synthetic rubber or latex.

- Another application of PVC is its use for making packaging materials. It is flexible and transparent, which makes it best for preserving and protecting different materials and products.

- It is excellent for insulating wires and cables. The moisture and chemical-resistance properties protect electrical wires from damage.

- PVC plays an important part in the automated industry. Manufacturers use it to make various components due to impact-resistant quality and durability. These include dashboard covers, door panels, flooring, and wire harnesses.

- Synthetic plastics like PVC have various uses in the medical field, such as making medical tubing, medical devices, blood bags, and more. Their flexibility and easy-to-mold features suit these applications.

- PVC is easy to mold into different shapes and colors. It makes various consumer goods, including shoes, toys, work boots, household items, inflatable structures, and flooring.

Advantages and Limitations

PVC has become an integral part of various industries due to its versatility. It offers advantages but also has limitations.

Advantages

PVC brings the following advantages:

- Versatile: It is waterproof and weather-resistant. That makes it suitable for outdoor activities like furniture or garden fencing. Its lightweight property gives it extra marks to use for various applications!

- Fire Resistant: PVC is inherently fire resistant because it contains about 50% chlorine. On exposing PVC to fire, thermal cracking produces hydrogen gas and makes an outer layer. This process slows the burning process down.

- Availability: It is cheaper than the other materials. That’s why it is a budget-friendly option for matting. The best thing about PVC is that it is available in various colors, shapes, and textures. It increases its application criteria according to individual needs.

- Chemical Resistant: PVC is highly resistant to chemicals, acids, and oxidizing agents. This property makes it perfect for chemical storage tanks and piping.

- Abrasion Resistant: The excellent tensile strength gives PVC abrasion resistance and toughness. Due to these properties, it has become a popular choice for underground piping.

Limitations

PVC has various advantages but with some limitations. These limitations are:

- Difficult to Recycle: It can not easily recycled due to its complex composition. PVC contains plasticizers. They become very toxic if you want to recycle them. So, recycling PVC is costly and not environmentally friendly.

- Harmful for the Environment: PVC releases harmful substances like hydrochloric acid while recycling. It can have serious health and environmental impacts from production to disposal.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What is Rubber?

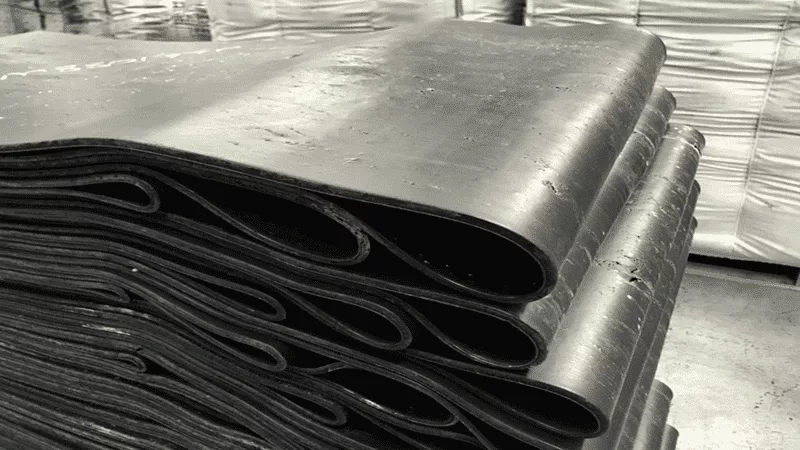

Rubber is a polymer that is easy to shrink and stretch.

It naturally comes from rubber trees, creating a milky fluid from wood called latex. That’s why it is also named as latex.

Moreover, it is best for various applications in daily use and gadget manufacturing.

Properties and Characteristics

Natural or synthetic rubber offers numerous uses to various industries due to their unique properties. These properties and characteristics are below:

- It occurs naturally soft with the most significant elastic properties. It returns to its original shape without deforming upon stretching. This quality makes it perfect for applications requiring flexibility without compromising strength.

- Rubber matting is excellently resistant to wear and abrasion. Its shock absorption power prevents friction’s impact. These qualities make it perfect for manufacturing components that face consistent wear. Examples include work boots, shoes, soles, tires, rubber flooring, and matting.

- Another amazing characteristic of natural rubber is its high resistance to chemicals and other solvents. It is ideal for manufacturing gloves and chemical tubes.

- It is a great insulator. The resistance against electricity makes it the best insulator for wires and cables. It helps prevent short circuits and electrical shocks.

- Natural material rubber can withstand -100 °C and up to 250 °C higher temperatures. It is best for manufacturing seals, gaskets, and soles.

Applications

It is famous for its elasticity and durability against low and high temperatures. These features make it excellent for various applications, including:

- The resistance to temperature and friction makes it the perfect choice for tires, soles, gaskets, and rubber bellow seals.

- It carries excellent waterproof and oil-resistance properties. These properties make it ideal for rubber matting, rubber flooring, sealant, and floor covering compared to other synthetic rubber.

- It is popular for insulation in the electronic industry due to its flexibility and easy molding properties. It is widely used to insulate components and cables to ensure electrical safety.

- Elasticity and easy molding technique makes it best for making gloves, pipes, and other pharmaceutical devices.

- It is highly resistant to chemicals and solvents. So, it is best to manufacture chemical containers, pipes, and other chemical-handling objects.

Advantages and Limitations

Here are the advantages and limitations of rubber, Let’s take a look!

Advantages

- Durable: It is more durable than other synthetic materials. On top of that, it also requires low maintenance and is flexible. This makes it an easy-to-install natural product.

- Slip Resistant: It provides friction in wet conditions. The slip-resistant quality makes it perfect for manufacturing tires, shoe soles, and work boots to increase safety.

- Shock-Resistant: Rubber soles or shoes can absorb impact while walking and keep feet dry. Rubber tires are also the best example of their shock-absorbing and impact-absorbing features.

- Reduce Noise: Rubber flooring creates less noise than the other options, making it better for mating. However, the noise-controlling ability depends on the thickness of the rubber matting.

- Insulating Properties: It offers excellent insulation against high and low temperatures, electricity, and water.

Limitations

Here are some potential weak spots of natural rubber:

- Expensive: Synthetic rubbers are usually expensive. However, the price may vary according to its thickness and quality.

- Decoloration: Over time, it may fade in color and cannot withstand liquids like oil, grease, and detergents. It may swell and damage if prone to these liquids for a long time.

- Smell: Newly bought rubber matting may have a distinctive smell. It can cause allergies for some consumers. Although it may fade with time, it still causes discomfort.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

PVC VS. Rubber: Key Differences

Here are some differences between PVC and rubber, let’s take a look!

| Feature | PVC | Rubber |

| Material Composition | Synthetic (white powder); lightweight and durable. | Natural source; slightly heavier, flexible, and comfortable. |

| Environmental Impact | High; non-biodegradable, may pollute environments and disrupt ecosystems. | Low; biodegradable and has less environmental impact. |

| Key Resistance | Excellent fire resistance (due to high chlorine content). | Excellent slip resistance and waterproof capabilities. |

| Decoloration | Resistant; will not decolorize even when exposed to chemicals. | Prone to fading; may decolorize when exposed to oil, grease, or harsh solvents over time. |

| Price | Generally the more affordable option. | Typically higher cost (though varies by grade and thickness). |

1. Material

The main difference is the material. PVC consists of white powder, which is lightweight and durable. While rubber comes from a natural source. It is slightly heavier, flexible, and comfortable.

2. Environmental Impact

Rubber is a natural material that is biodegradable and may have less environmental impact. However, PVC may not degrade over time and may cause serious issues.

It can pollute the environment and disrupt natural ecosystems.

3. Resistance

Rubber has excellent slip-resistant and waterproof qualities.

On the other hand, PVC is excellent fire-resistant due to its high chlorine content. Each has its advantages regarding specific resistance in a given condition.

4. Decoloration

PVC will not decolorize even if it is prone to chemicals and other solvents. However, rubber may decolorize when it is prone to oil, grease, and other harsh solvents for a long time.

5. Price

PVC is a more affordable option than rubber. However, the final price might vary depending on the grade and thickness of the materials.

Selection Considerations

PVC and rubber offer different benefits and are best for various industrial and daily applications.

Both are used in the construction, automotive, and electrical industries. They are known for their durability, ease of use, and flexibility.

But which one should you choose for the best results?

It only depends on your needs. If you are looking for an affordable option, PVC is the best option. It is more cost-effective than natural rubber.

European Commission studies note PVC has environmental impacts, yet modern closed-loop recycling can achieve over 90% recovery for specific waste streams, challenging views of its complete non-recyclability with proper systems.

Both materials have different applications, needs, and budgets. So before making any decision, it is good to consult with professionals to make an informed decision.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

PVC vs. rubber, which one to choose is ultimately a call based on the application. Both offer various benefits for different industrial applications, from weight to flexibility and durability.

Rubber and PVC have many similarities, as they are the best insulators, perfect for automotive parts, and provide durability.

However, key differences like slip resistance, fire resistance, and, more importantly, the price difference set them apart. Both are good, but the choice is only yours.

Get Premium Quality Rubber Products by Hongju

Confused about choosing the right material for your project?

Hongju provides more than just products—we deliver solutions. With rapid prototyping in 3-5 days, flexible low-MOQ production, and over 20 years of material expertise, we help you navigate the PVC vs. rubber decision confidently.

Learn more about us and trust us to meet your product requirements.

FAQs

Q1:What are the main differences between PVC and rubber in practical applications?

PVC is cost-effective and fire-resistant, ideal for pipes and insulation. Rubber offers superior elasticity and temperature resistance, perfect for seals and automotive parts.

Q2: Which material is more environmentally friendly, PVC or rubber?

Natural rubber is biodegradable and eco-friendlier. PVC is less sustainable due to recycling challenges and potential environmental impact during disposal.

Q3: Is PVC or rubber more cost-effective?

PVC is generally more affordable and offers a lower initial cost. Rubber, while often more expensive initially, provides superior durability and longevity, potentially offering better long-term value.

Q4: Which material is better for outdoor use: PVC or rubber?

Rubber is ideal for outdoor use due to its excellent waterproofing, slip resistance, and shock absorption, whereas PVC’s superior UV and chemical resistance make it suitable for long-term outdoor exposure.