You’ve probably heard of Teflon — that slick, nonstick stuff on your favorite frying pan. But did you know it’s actually called PTFE and is used far beyond the kitchen?

From medical devices to airplane parts, PTFE’s unique properties make it super useful in all kinds of industries. In this article, you’ll learn the top 7 reasons why PTFE is so popular and how it could be the right material for your next big project.

So, let’s dive in!

What is PTFE?

Polytetrafluoroethylene, or PTFE, is an artificial material made from tetrafluoroethylene. This puts it in a family of per- and poly-fluoroalkyl substances, or PFAS. PTFE might be a bit tongue-twister, but you are likely more familiar with it under the brand name Teflon.

What makes PTFE, or Teflon, so special is its status as one of the most famous types of PFAS, often talked about as “forever chemicals.” These chemicals are called “forever” because they don’t break down in the environment, making them extremely durable and long-lasting.

Composition of PTFE

PTFE is a solid form of fluorocarbon, meaning it is made up entirely of carbon and fluorine bonds. It is a very high molecular weight substance, contributing to its unique chemical and physical properties.

PTFE has a hydrophobic nature, which means it repels water. Water and substances that contain water do not stick to PTFE surfaces because fluorine, the element that gives PTFE its hydrophobic quality, has a very low ability to polarize.

This means it doesn’t easily allow charges to distribute asymmetrically, leading to weak attraction forces between molecules, known as London dispersion forces. Additionally, this molecular structure results in PTFE having one of the lowest friction coefficients of any solid.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

7 Key Benefits of PTFE

Here are the top 7 key benefits of PTFE that make it stand out from other materials:

Number 1. High-Temperature Resistance

PTFE is known for its exceptional ability to resist high temperatures. It can easily endure temperatures ranging from about 260 degrees Celsius (500 degrees Fahrenheit) to 290 degrees Celsius (554 degrees Fahrenheit).

This unique quality means that PTFE does not degrade or lose its inherent properties, even when exposed to such intense heat levels.

This remarkable heat resistance renders PTFE perfectly suitable for various high-temperature applications. For example, it is widely used in baking utensils and industrial processes where materials are required to maintain integrity, thermal stability, and performance despite being subjected to high temperatures.

Number 2. Nonstick Properties

Thanks to its low coefficient of friction, substances don’t stick to surfaces made with PTFE coatings, making PTFE a popular choice for coating cookware.

Foods don’t stick to pans or pots, allowing them to slide off effortlessly, making cooking and cleaning significantly easier. This nonstick quality is beneficial for culinary purposes and extends to various applications where preventing material adhesion is needed.

Number 3. Low Friction

PTFE’s low coefficient of friction enables surfaces in contact with one another to glide smoothly with minimal resistance. These low friction properties are incredibly beneficial in scenarios where parts move or rotate against each other, such as bearings and gears.

PTFE’s ability to reduce friction and wear significantly extends the life and efficiency of these components. Furthermore, PTFE’s self-lubricating features mean it can keep things moving smoothly without needing additional lubricants.

Number 4. Chemical and Corrosion Resistance

PTFE’s outstanding resistance to oxidation and chemical corrosion places it in a league among engineering materials. PTFE can withstand continuous exposure to several chemical compounds and fluids without degradation.

Its innate ability to resist most chemical attacks is further increased when combined with other fluoropolymers such as FEP (fluorinated ethylene propylene) and PFA (perfluoroalkoxy alkane), significantly extending the operational lifespan of components.

As a result, many chemical processing plants depend on PTFE to provide reliable protection against corrosive chemicals.

Number 5. Electrical Insulation Properties

Another noteworthy property of PTFE is its ability to maintain excellent insulation properties even when subjected to high voltages and frequencies. The material has a high dielectric strength, making it an ideal insulator for electronic components.

PTFE also exhibits exceptional resistance to arc tracking and electrical discharge, making it a preferred choice in manufacturing wires, cables, and other electrical equipment.

Number 6. Biocompatibility

PTFE’s ability to maintain its integrity during and after implantation makes it biocompatible. This characteristic ensures that PTFE can be utilized safely within medical applications, where maintaining the function and form of implant materials is critical.

Its compatibility with biological tissues means that PTFE doesn’t cause adverse reactions when used for medical implants or as part of devices that interact directly with the human body. This property is especially valuable in designing medical devices requiring long-term bodily fluids or tissue exposure.

Number 7. UV Resistance

PTFE stands out for its exceptional UV resistance, largely thanks to its powerful carbon-fluorine bonds. These bonds are nearly 30% stronger than the carbon-hydrogen bonds found in many other materials, providing a solid shield around the carbon backbone of PTFE in a helical structure.

This unique configuration ensures that the material is well-protected against the damaging effects of ultraviolet or UV rays from the sun.

Additionally, PTFE and most other fluoropolymers lack certain impurities known as light-absorbing chromophores in their structure. These impurities can start photo-oxidation, where light exposure leads to material degradation.

PTFE’s absence of these impurities further enhances its resistance to UV radiation, making it an ideal choice for applications exposed to sunlight for extended periods without experiencing deterioration.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Uses of PTFE

After considering all the above benefits, you should not doubt PTFE’s reputation as a unique material. Because of all these benefits, PTFE’s uses are virtually endless, and there is a growing demand for it in various sectors.

Here are just some of the most common applications or uses of PTFE:

1. Electrical Industry

In the electrical industry, PTFE helps in things like soldering, sticking stuff together with heat (heat sealing), and putting electronic parts together (component assembly). Imagine trying to solder without PTFE – it would be a sticky mess because the solder would cling to everything.

But with PTFE, the solder doesn’t stick where it is not supposed to, making the job clean and the connections reliable. Plus, when sealing stuff with heat, PTFE’s ability to take the heat without sweat ensures things go smoothly and efficiently.

2. Medical Industry

Here, PTFE helps in implants like blood vessel grafts and artificial joints. This is because it is kind to our bodies. As mentioned earlier, PTFE is non-toxic and doesn’t harm us internally.

Even more impressive, our bodies don’t freak out when they come into contact with it. In other words, PTFE doesn’t trigger an immune response, which is a big win for keeping replacement parts working nicely inside us.

This property makes PTFE ideal for long-term medical implants and devices that need to interact with our biological tissues.

3. Printing and Packaging Industry

In the printing and packaging industry, PTFE-coated sheets and transport belts are instrumental in various processes, including heat sealing, drying ink, and transferring or conveying printed materials throughout the production line.

Here, again, the nonstick property of PTFE plays a key role in avoiding unwanted adhesion of ink or adhesives to machinery, thus streamlining the printing process and maintaining the cleanliness and efficiency required for high-quality outputs.

Beyond this, PTFE’s heat resistance characteristic proves indispensable for effectively sealing and drying packages, safeguarding the integrity of the packaged goods.

Additionally, PTFE’s low friction quality facilitates the smooth and effortless movement of materials during transport, enhancing the overall efficiency and productivity of the printing and packaging industry.

4. Aerospace and Automotive Industries

It is a big deal in the automotive industry because it can handle heat well and doesn’t get eaten away by nasty chemicals. This is super important for parts like fuel lines, the bits that keep everything sealed tight, like head gaskets, and ensuring wires don’t get damaged. It even helps parts move together without wearing out, acting as a slippery coating.

Moving up to the sky, the aerospace industry loves PTFE for similar reasons. Spacecraft and things exploring other planets have wires coated in PTFE to protect against extreme temperatures and the sun’s harsh rays.

Gaskets, fuel lines, and even fasteners on aircraft get the Teflon treatment to ensure they can handle the crazy conditions up there. Also, it helps reduce wear and tear between moving parts, which is crucial when flying high or zooming through space.

5. Cookware Industry

Perhaps one of PTFE’s most familiar and appreciated applications is in the kitchen, where its non-stick properties shine. PTFE is the key ingredient behind the non-stick surfaces of various cookware items, such as frying pans, pots, and baking sheets.

Thanks to its low coefficient of friction, PTFE ensures that food doesn’t cling to the surface. This drastically enhances the cooking experience by making both the cooking process and subsequent cleaning far more manageable and time-efficient.

This attribute saves considerable effort and cooking oil and supports healthier cooking practices by allowing for less reliance on fats and oils to prevent sticking.

6. Semiconductor Industry

In the precise world of semiconductor production, PTFE is again a real game-changer, making things a lot easier and safer. Everything needs to be super clean and free from any nasty chemicals that might mess things up when making stuff like computer chips. PTFE comes to the rescue here with its awesome chemical resistance.

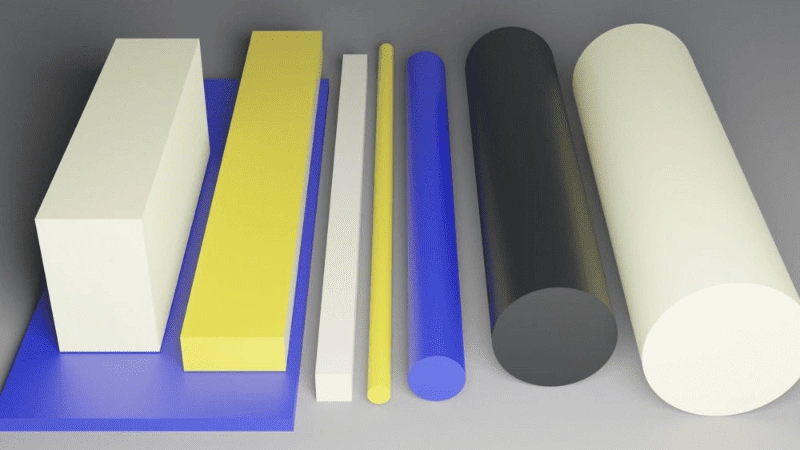

This means it can handle all sorts of harsh chemicals without getting damaged or allowing those chemicals to pollute the super-clean spaces where chips are made. PTFE shows up in many forms, like resin, coating, or film, and plays a part in many products used to create semiconductor materials.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

These are some of the key benefits and uses of PTFE, making it an invaluable material for various industrial applications. It offers unique properties that enhance performance and efficiency and helps support more sustainable practices by reducing the need for harmful chemicals and promoting product longevity.

As technology advances and new challenges arise, PTFE will continue to evolve and adapt, proving essential in the modern world. Whether in the medical industry or outer space, PTFE will undoubtedly play a crucial role in shaping the world around us.

Choose Hongju for Innovative Solutions & Sustainable Success!

Looking for a trusted partner to elevate your project with eco-friendly, durable silicone rubber products? Look no further than Hongju. With 23 years of design and manufacturing experience, Hongju is a pioneering manufacturer and wholesale supplier of innovative silicone rubber products in China.

Join us and contribute to a sustainable future while ensuring your products’ highest quality and reliability.