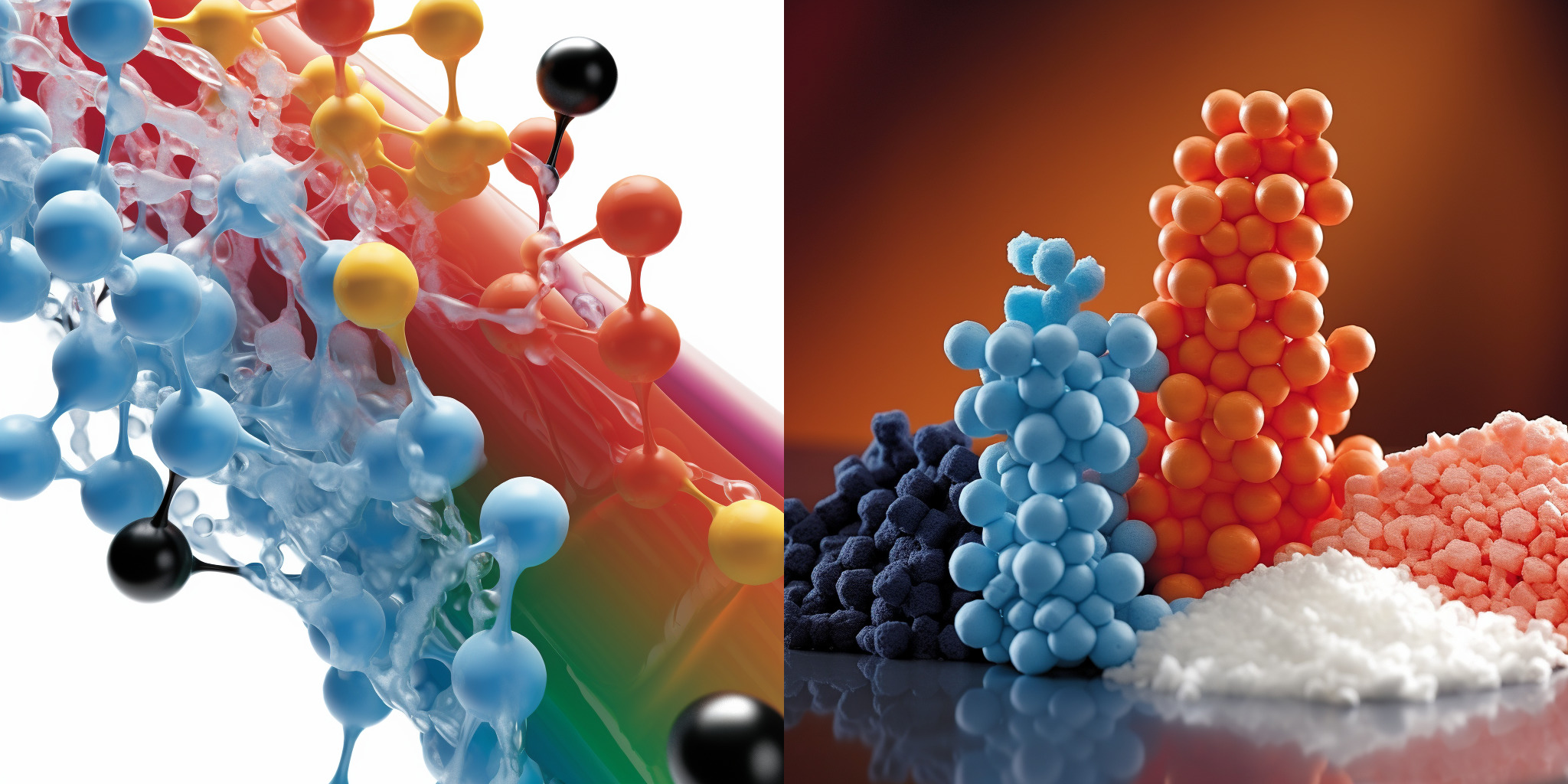

That’s why we’ve crafted this comprehensive guide. We’ll explore the chemistry behind these materials, including the role of liquid polymers and chemical powder. We’ll also delve into their manufacturing processes, where blowing agents like carbon dioxide gas and nitrogen gas come into play.

You’ll learn about the unique properties of closed-cell sponge rubber, open-cell sponge rubber, flexible foam rubber, and rigid foam rubber for your project and improve your business.

What is Foam Rubber?

Have you ever wondered about what form rubber is? You’re not alone. Let’s delve into the fascinating characteristics of this unique material. Prepare to delve into its chemistry, manufacturing process, and what sets it apart from sponge rubber.

The result? Gain valuable insights to empower your business decisions. Stay tuned for more! Foam rubber, a versatile material formed by combining polymers with gas bubbles, finds widespread use across various industries.

Its exceptional blend of flexibility, resilience, and insulation properties makes it a preferred choice. The production process involves mixing synthetic rubber with foaming agents and additives in a polymerization procedure.

Subsequent heating triggers the release of gases from the foaming agents, thereby giving rise to the foam structure. According to a scientific study published in Australian Critical Care, foam rubber is widely used in healthcare for medical cushions and mattress pads, offering both comfort and support.

Its closed-cell materials make it resistant to water absorption, making it ideal for applications where hygiene is a priority. So why should you, as a B2B customer, care?

Well, at Hongju, our mission is to provide top-notch products with considerate service. We specialize in various eco-friendly silicone products, including foam rubbers, that align perfectly with the needs of your industry.

What is Sponge Rubber?

Alright, let’s switch gears and talk about sponge rubber, another heavyweight in the world of industrial materials. Sponge rubber has an open or closed cellular structure, unlike foam rubber, making it incredibly versatile. This unique feature allows it to excel in cushioning, sealing, and insulation applications.

The sponge rubber manufacturing process involves using blowing agents during vulcanization. This results in a material that’s not just durable but also flexible and lightweight. It’s like the Swiss Army knife of rubbers—equally adept at sealing gaps as it is at providing cushioning in medical devices.

According to research by Digital Journal, sponge rubber has gained significant popularity in the automotive sector due to its exceptional sound-dampening properties. Moreover, its resistance against environmental elements like UV rays and ozone has made it the preferred choice for various outdoor applications.

If you’re involved in the manufacturing or healthcare sectors, understanding the unique properties of sponge rubber can greatly benefit you. It empowers you to make informed decisions that align with your specific needs.

Inquire About Our Silicone and Plastic Products!

For example, whether you require a reliable seal for machinery components or desire comfortable medical cushions, sponge rubber offers tailor-made solutions.

The Chemistry of Foam Rubber and Sponge: Base Polymers and Additives

The chemistry is where the magic happens when it comes to the nitty-gritty of foam and sponge rubbers. At Hongju, we’re committed to providing you with top-notch, eco-friendly silicone foams, and part of that commitment is helping you understand what you’re using.

- Base Polymers: The backbone of foam rubber is typically a polymer matrix, often derived from synthetic rubbers like styrene-butadiene rubber (SBR) or natural sources like isoprene. Sponge rubber, conversely, frequently utilizes a blend of both natural and synthetic rubbers to achieve its unique set of properties.

- Additives: But the base polymer is just the start. A variety of additives, including curing agents, flame retardants, and fillers, are integrated into the mix. These additives serve to enhance specific mechanical properties and safety features. For instance, zinc oxide and sulfur are commonly employed as curing agents, fortifying the rubber’s resilience and durability.

Why This Matters?

A thorough understanding of chemistry significantly influences the process of selecting materials. Whether you are involved in healthcare and designing medical devices or manufacturing and creating automotive parts, the chemical composition of rubbers plays a crucial role in determining the success of your project.

The power of chemistry should not be underestimated. It goes beyond the sensory aspects of materials, encompassing their molecular functions that impact everything from durability to safety.

Inquire About Our Silicone and Plastic Products!

How They Are Made: Manufacturing Techniques

Understanding the manufacturing techniques behind foam and sponge rubbers can provide valuable insights into their quality and performance. Let’s delve into foam rubber. The journey commences with polymerization, where base polymers like styrene-butadiene rubber (SBR) or natural rubber undergo synthesis.

Additives such as antioxidants and curing agents are subsequently incorporated. The mixture then undergoes mechanical frothing or chemical reactions to generate the foam structure, followed by vulcanization to enhance its mechanical properties.

On the contrary, sponge rubber frequently begins with expandable rubber types like EPDM or neoprene. The rubber compound is then supplemented with a chemical blowing agent, which, upon heating, decomposes and releases gases. This process leads to the expansion of the rubber and the formation of a sponge-like structure.

Both manufacturing processes are highly specialized and strictly follow rigorous quality control measures. Important factors such as low density, cell structure, and tensile strength undergo comprehensive testing to guarantee that the final product meets industry standards.

So, the next time you encounter foam or sponge rubber in your operations, you’ll appreciate the intricate science and engineering that go into making these versatile materials.

Property Differences: Foam Rubber vs. Sponge Rubber

| Property | Foam Rubber | Sponge Rubber |

|---|---|---|

| Cell Structure | Closed-cell, impermeable to air and moisture | Open-cell allows air and moisture to pass through |

| Ideal Applications | Insulation, buoyancy, thermal protection | Cushioning, compression, sand sealing |

| Durability | High resistance to wear and tear | Moderate resistance due to open-cell structure |

| Cost | Generally more expensive | More cost-effective |

| Environmental Impact | Challenging to recycle | Easier to recycle |

So, there you have it! Whether you’re looking for insulation, buoyancy, cushioning, or cost-effectiveness, understanding these property differences will guide you in making the best choice for your needs.

Inquire About Our Silicone and Plastic Products!

Foam vs. Sponge in Real-World Applications

Regarding real-world applications, foam and sponge rubbers have carved out indispensable roles, especially in the manufacturing and healthcare sectors. Let’s get down to how these materials are making waves in various industries.

- Foam rubber, known for its resilience and durability, is a go-to material for automotive seating, industrial gaskets, and even some medical prosthetics. Its closed-cell structure makes it an excellent choice for water resistance applications and thermal insulation.

- On the flip side, sponge rubber, with its open-cell structure, excels in applications requiring high compressibility and air permeability. It’s widely used in healthcare for wound care and in manufacturing for sealing applications, particularly where irregular surfaces are involved.

According to a study by the National Center for Biotechnology Information, chemicals used in the manufacturing of synthetic rubber can induce lung cell injury when inhaled, highlighting the importance of safety measures in industrial applications.

So, whether you’re in manufacturing or healthcare, understanding the unique properties of foam and sponge rubber can guide you in selecting the right material for your specific needs.

And remember, at Hongju, our mission is to provide you with top-notch, eco-friendly silicone products backed by considerate service.

How to Choose Between Foam and Sponge Rubber

Choosing between foam and sponge rubber is more than a coin toss; it’s a decision that could impact the efficiency and cost-effectiveness of your operations. Whether you’re in healthcare or manufacturing, the material you choose needs to align with your specific requirements.

- First, identify the primary function of the material in your application. If you need water resistance and thermal insulation, foam rubber is your best bet. For cushioning and air permeability, sponge rubber takes the cake.

- Durability is another key factor. Foam rubber tends to outlast sponge rubber in wear-and-tear scenarios, making it a wise choice for long-term applications.

- Budget constraints? Sponge rubber is generally more cost-effective, but don’t forget to factor in longevity and performance.

For those who want to dive deeper, resources like ScienceDaily offer comprehensive guides on material selection, or you can contact Hongju’s experts now for more helpful information.

Inquire About Our Silicone and Plastic Products!

In essence, your choice between foam and sponge rubber should be a calculated decision based on application needs, durability, and cost. And remember, we at Hongju are always here to offer expert advice and top-notch, eco-friendly products.

Conclusion

Choosing between foam and sponge rubber depends on your specific needs, such as durability, cost, or application. The right choice can greatly impact your project’s success.

Get Top-Of-The-Line Products From Hongju

Don’t leave your project to chance. Contact Hongju today for a consultation and discover how Hongju’s eco-friendly silicone products can elevate your business.

Contact us now and get the free consultation. Please remember, we at Hongju are always here to help you make the best choices for your business needs.