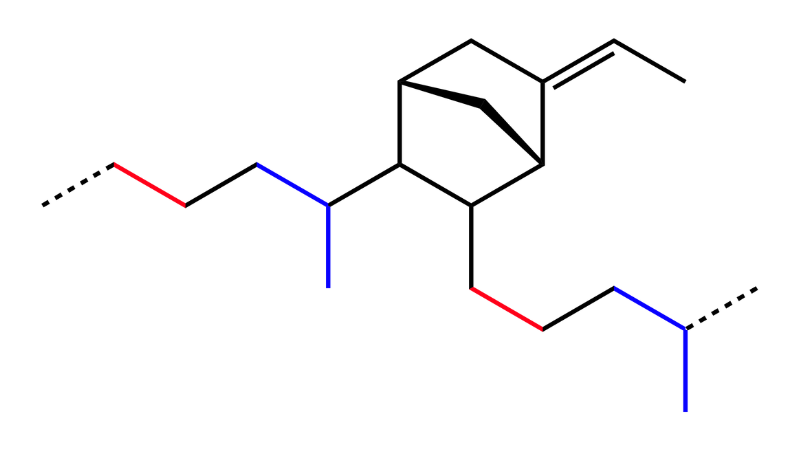

EPDM is a synthetic rubber known for its excellent resistance to weather, ozone, and heat. It is a durable choice for the construction industry and automotive parts manufacturing. It ensures long-lasting performance and extreme resistance to harsh conditions.

Below, we are going to discuss the EPDM injection molding process in detail, along with its benefits, applications, and more.

Benefits of EPDM Rubber Injection Molding

As already stated, EPDM injection molding is widely used across different industries. Thanks to the unbeatable advantages it offers.

A top benefit of using EPDM injection molding is its flexibility and elasticity. It allows molded parts to maintain their shape and perform well under pressure.

Parts molded using this technique can perform well even under repeated compression or movement. This explains why EPDM molding is widely used to produce seals and gaskets.

EPDM can easily withstand heat, UV exposure, and chemical reactions. This enables it to endure extreme temperatures without experiencing any change in its composition or shape.

EPDM’s resistance to harsh environmental conditions also makes it ideal for automotive components and applications.

The growing demand for lightweight and durable plastic products across the automotive, packaging, and consumer goods sectors is fueling the injection molding market.

As per stats, the injection molding market size is expected to reach $462437.7 million by 2033, showing a CAGR of 5.0% from 2025 to 2033.

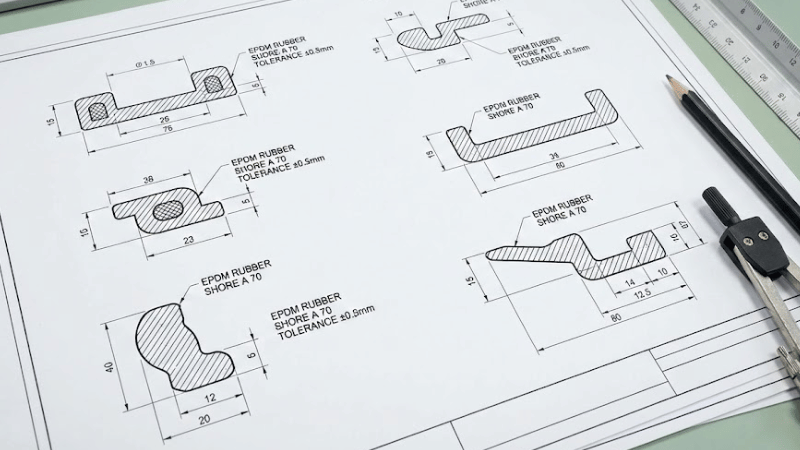

Using EPDM injection molding, one can produce complex products with precision compared to simple transfer moulding or closed metal molding. This property also sets it apart from other rubber molding methods, where intricate geometries are not easy to achieve.

EPDM injection molding also helps ensure consistent quality during mass production. This increases production efficiency and reduces defects and scrap rates.

Automated ethylene propylene diene monomer injection systems are capable of delivering uniform results. This makes this method highly reliable and widely practiced for large-scale manufacturing.

Speed and precision in automated production are some of the main advantages of EPDM. Compared to compression and transfer molding methods, EPDM injection molding is suitable for high-volume production.

It is ideal to use where efficiency and speed are critical.

EPDM rubber molding techniques are now widely utilized by various industries. Common examples include its use in the production of automotive door seals, gaskets, and O-rings. It is also used to make HVAC gaskets and electrical housings.

EPDM injection molding is also crucial in the production of modern vibration dampers in industrial machinery. Thanks to its durability and flexibility, EPDM is becoming extremely popular across multiple sectors.

Material Properties to Understand Before EPDM Rubber Molding

Below, we will be discussing a few material properties that can help you understand EPDM rubber in a better way. This can help ease the understanding of the step-by-step process of EPDM injection molding. So, read on.

1. Hardness Range and Part Design

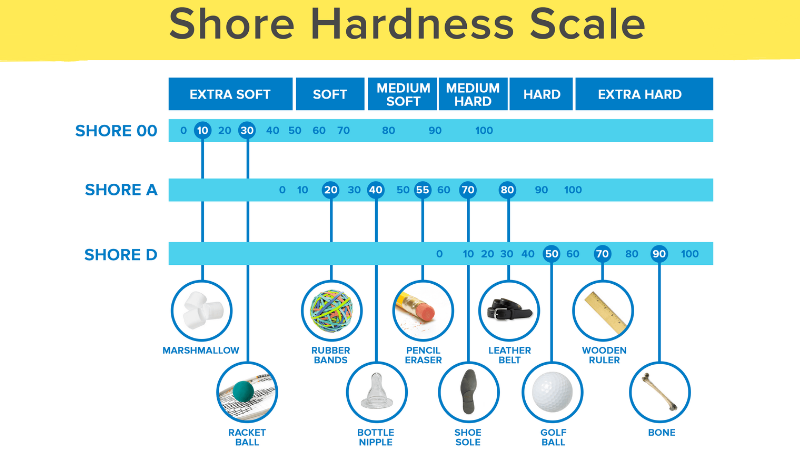

There are different types of EPDMs used in injection molding. Their hardness typically ranges between 40 and 90 on the Shore A scale. This ensures that manufacturers have options ranging from soft to firm. They can pick one depending on their needs.

A soft and less firm ethylene-propylene-diene monomer is a bit difficult to work with. This is because it is hard to feed into the mold. It often sticks during injection, too.

On the other hand, harder grades of EPDM are easier to work with. This is because they flow more easily, provided that higher injection pressures are maintained.

For manufacturers who want to prevent defects and issues in manufacturing processes, it is better to consider using proper draft angles, surface texture, and wall thickness adjustments for a smoother injection and consistent production quality of the final product.

2. Compression Set Resistance or Elastic Memory

EPDM comes with a noticeable compression set resistance quality under high pressure. In other words, EPDM can return to its original shape even after it has been compressed for a long time.

This elastic memory is what makes EPDM the gold standard raw material for the production of dynamic seals, O-rings, and weatherstripping.

It is also important to know that poor processing or improper curing of EPDM rubber products can often lead to the loss of the material’s elastic memory. This makes it essential to ensure proper control during molding and vulcanization to preserve the elastic memory of EPDM.

3. Thermal and Weathering Performance

Products manufactured from EPDM can perform great across wide temperature ranges, typically ranging from minus 50 degrees to plus 150 degrees.

This makes it highly suitable for several outdoor applications, as well as the production of under-the-hood automotive components. Most of the modern weather-resistant and long-lasting industrial parts are manufactured entirely using EPDM.

4. Bonding Behavior Overmolding and Insert Molding

Regardless of its excellent durability, EPDM is chemically inert. This means that its bonding with rigid substrates like metal or plastic can often become challenging.

To ensure successful adhesion between EPDM and other substrates, manufacturers often use primers, adhesives, or mechanical interlocks like grooves and holes.

For some applications, there are modified forms of EPDM that can be used, as they offer enhanced chemical bonding. Such specialized and modified EPDM grades make over-molding and insert molding applications possible.

A Quick Breakdown of the EPDM Injection Molding Process

Contrary to popular belief, the process of EPDM injection molding is quite simple. You just have to break it down into steps and approach it correctly. Below are the steps to ensure seamless injection molding, depending on your project.

Step 1: Material Preparation

The raw form of the ethylene propylene diene monomer often has to be properly formulated into a usable compound. You often require fillers, stabilizers, and accelerators to develop a proper and usable EPDM compound.

Depending on your requirements and process, you might need to preheat or pelletize your compound. This helps improve its flow and the uniformity of the injection process. Proper material preparation beforehand helps prevent critical defects in production.

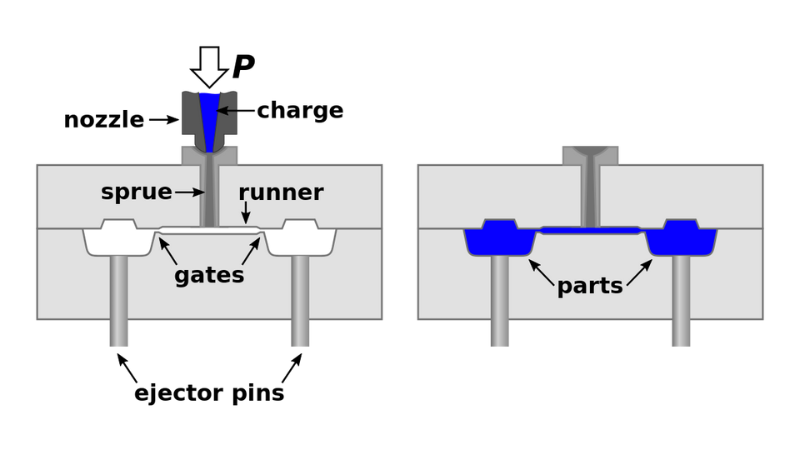

Step 2: Injection Phase

Now that the compound is ready, you have to inject it into the mold cavity. Here, it is important to note that EPDM rubber requires careful temperature and pressure control. It helps ensure proper curing and prevents its degradation.

It is also essential to fix and adjust the injection parameters based on the part geometry and hardness. This way, the mold is completely and uniformly filled with the EPDM rubber.

Step 3: Vulcanization or Curing

Once it is injected, the EPDM rubber will undergo vulcanization or curing. In this step, the heat from the mold will interlink the polymer chains. This sets the product’s final elasticity.

The curing time varies depending on the material thickness and the properties of the compound you have used. It can take anywhere between a few minutes to a few hours.

Step 4: Cooling and Ejection

Once everything is cured and cooled down, you have to eject it from the mold. Cooling helps ensure dimensional accuracy. In high-grade industries, automated ejection systems are used. These maintain consistent results and avoid product damage.

Step 5: Post-processing

Once the molded parts are ejected, they have to undergo post-processing. In this step, the products may be flash-trimmed or attached to other components. This is done to ensure proper finishing and give them their final aesthetic appeal.

Post-processing helps ensure that the final product you get is clean, ready for shipment, and use.

What EPDM Parts Can Be Injection Molded?

Various industries now use EPDM injection molding for the production of their respective parts and products.

Some common examples include:

- Automotive: Seals for doors, grommets, under-the-hood components, vibration dampers, wire harnesses

- Electrical Industry: Cable boots, terminal caps

- Industrial Machinery: Vibration isolation mounts, valve components

- Consumer Goods: Appliance seals, waterproof covers

- HVAC: Gaskets, O-rings, insulators

Injection Mold EPDM vs. Other Rubber Molding Methods

Sometimes, you’d have to choose only one suitable rubber molding method. It’s important that you understand compression molding and transfer molding, and how they differ from each other. Pro manufacturers also know their differences from the injection molding EPDM technique.

Compared to injection molding, compression molding is slower and steadier. This makes it more preferable in the manufacturing processes of large and simpler products. It is also ideal to use only if you’ve more manual labor.

Transfer molding, on the contrary, is better to adopt when you’ve to manufacture parts with mid-range complexity. It is slower compared to injection molding and can’t offer the precision of injection molding.

| Feature | Injection Molding | Compression Molding | Transfer Molding |

|---|---|---|---|

| Cost (High Volume) | Moderate | Low | Moderate |

| Precision | High | Moderate | Moderate |

| Speed | Fast | Slower | Moderate |

| Part Complexity | Complex | Simple | Moderate |

Conclusion

EPDM is the safest and most flexible rubber compound available to industries at present. More and more businesses are now opting for EPDM injection molding.

It gives precise and reliable production quality across genres like HVAC, automotive, and others. We suggest you also reach out to a reliable rubber manufacturer to source high-quality EPDM in bulk.

Explore EPDM Customization With Hongju Today!

The experts at Hongju Silicone are here to help you ace your EPDM rubber injection molding projects with speed. We offer the best blend of our rapid prototyping abilities, expert craftsmanship, and low minimum order quantities. Moreover, we can also bulk produce and deliver customized solutions that meet your needs.

Reach out to us today to take advantage of our 25 years of experience in producing high-quality rubber. Offering items produced with advanced technology and precision guaranteed.

FAQs

1. What products are typically made with EPDM injection molding?

It’s widely used for seals, gaskets, O-rings, automotive components, and industrial rubber parts.

2. What are the advantages of injection molding EPDM over other methods?

Injection molding provides precise dimensions, consistent quality, and efficient production for complex EPDM parts.

3. What is your production time?

The average production cycle for our products is 9-15 workdays, but this can vary according to the quantity of orders, the complexity of our products, and the different seasons.

4. What certifications does your factory have?

We are ISO 9001 certified silicone rubber products manufacturer. And we have CE and FDA certificates for our products. We can also apply for you if you have specific certification needs for your market.