Injection molding has evolved into a highly advanced manufacturing process with specialized techniques for precision, complexity, and efficiency. From thermoplastic and thermoset molding to LSR, micro molding, multi-component, two-shot, and insert molding, each method offers unique advantages for specific applications.

This guide breaks down 7 key injection molding technologies to help you choose the best fit for your product. Keep reading now!

Thermoplastic Injection molding

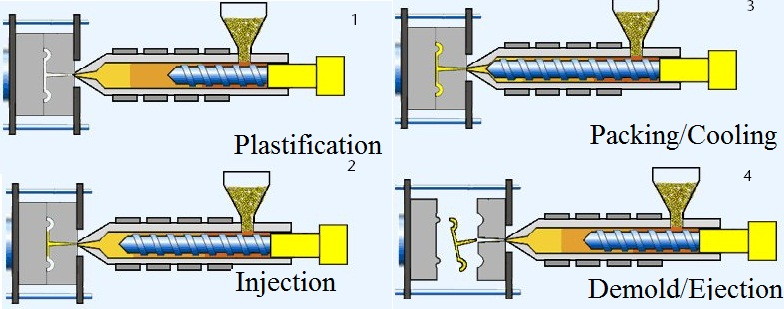

It is a reversible injection molding process during which thermoplastic materials are turned into a liquid state and then injected into a mold cavity in an injection molding machine.

When melted plastic material is inside the mold cavity in the injection molding process machine, the material cools down so that it takes the desired shape.

This popular plastic injection molding process is highly used to create fully functional parts. This method is used to create anything that requires top-level surface finish and accuracy. It offers high tolerance and accuracy for molded parts.

When you compare it with other plastic manufacturing processes, you realize it is a cost-effective and efficient molding technology due to its high production output rate. This fast processing method is helpful in manufacturing plastic parts, which are identical.

Thermoplastic injection molding is used to create a wide variety of consumer products such as toys, electronic casings, and storage containers. It has good use in automotive components such as bumpers, dashboard parts, and interior trim.

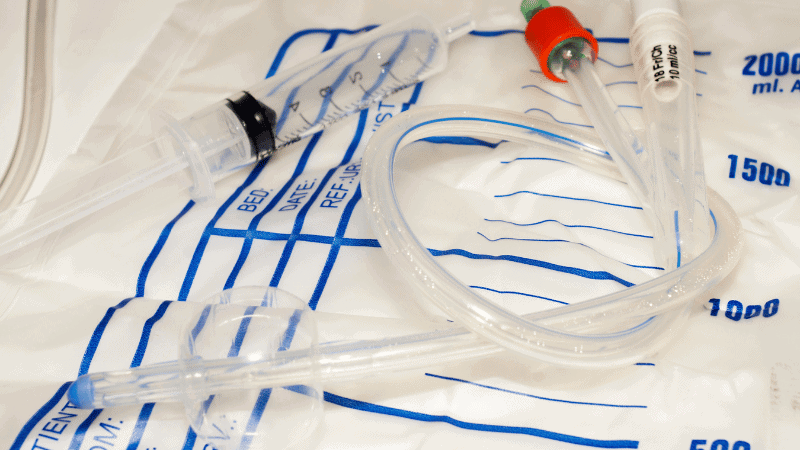

When you look into the medical industry, you find out that the thermoplastic injection molding technique has a good use in this industry as well.

It is employed to create different medical devices and equipment such as IV components, syringes, and surgical tools. These components are highly bio-compatible and are quite easy to sterilize.

The most common use of thermoplastic resin can be seen in packaging industries, where this technique is helpful in producing lightweight and recyclable food containers, bottles, and caps.

Since this procedure produces molded parts with high chemical resistance, it is quite useful in manufacturing construction materials such as pipes and fittings.

Both thermoset and thermoplastic injection molding offer unique advantages and are chosen based on the material properties and application needs.

Thermosets offer heat resistance and chemical stability, while thermoplastics provide versatility and recyclability.

Advantages

Let’s explore 5 benefits you can get from thermoplastic injection molding:

Precision and Consistency: When your project involves the creation of complex and intricate parts at high volumes, accuracy, and consistency levels, you can achieve desirable results with the thermoplastic injection molding method.

Since it makes it easy to achieve tight tolerance and high-quality finish. That means you can produce identical molded parts with exact specifications in every batch of production.

Cost Savings: Every industry wants to achieve the goal of cost-effectiveness. And thankfully, you can go with mass production with this plastic injection molding technique.

It allows you to produce large quantities quickly. Its initial tooling cost is offset quickly with high-volume production and then you get low per unit cost.

Customization: You can get it with this method when you need top-notch injection molding design flexibility. It lets you integrate different features into molded parts during the molding process.

There won’t be any need to go with a secondary operation when the first operation can do it all. During the injection mold and design process, designers can incorporate textures, threads, and inserts into the thin wall injection molding part.

In other words, it’s easy to produce complex designs with thermoplastic injection molding.

Wide Material Selection: You can select a wide variety of materials with this technique. It allows you to pick a material as per your application specification.

Whether you are looking for flexibility, strength, or too much shear heat resistance properties, everything such property is covered well with this technique.

Reduced Material Waste: Everyone tries his best to reduce waste during the manufacturing process. Fortunately, the thermoplastic method helps you achieve sustainability goals.

If there is any excess material after the molding is done, then this material can be reused and recycled to reduce overall environmental impact.

Material Selection

Here’s a list of commonly used thermoplastic materials for plastic injection molding:

- Polystyrene (PS)

- Polyvinyl chloride (PVC)

- Polyvinylidene fluoride

- Nylon Polyethylene (PE)

- Polypropylene (PP)

- Polyethylene terephthalate

- Polyurethane (PU)

- Acrylonitrile-butadiene-styrene (ABS)

- Polycarbonate (PC)

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Thermoset injection molding

It is an irreversible manufacturing process during which cold material is injected into a hot mold of an injection molding machine to create a final part. This injection cooling process also cures the part that can never be melted again.

This process is commonly used to create parts that can withstand high temperatures. The best example is medical parts. For example, dental tools with metal parts must withstand the claving process and sanitization, so they can be used over and over again.

Thermoset materials are stronger than thermoplastic materials. Parts made of thermoplastic injection molding can be melted, but thermoset parts can’t be re-melted.

This technique of plastic injection molding is quite suitable for those industries that require strong and durable plastic parts.

Since thermoset material undergoes a chemical reaction to create a strong bond, thermoset molded parts are highly resistant to chemicals, electrical conductivity, and temperature.

Thermoset materials are used for manufacturing connectors, housing, and electrical insulators. The best example of this technique in the automotive industry is the creation of brake parts, distributor caps, and ignition components.

The best example of this technique is found in our kitchen where you can see cookware handles and knobs. Thermoset plastics are used to produce heat-resistant handles and knobs, which don’t melt or deform if temperatures go high.

This technique is also applied in the Aerospace industry where thermoset materials are used to produce engine parts and electrical connectors. These components are highly durable and show great resistance against temperature.

Advantages

Here are the key benefits of employing thermoset injection molding:

Withstand Heat: The best thing about thermoset molded parts is that they won’t soften or deform regardless of how high a temperature level is.

They are quite ideal for an object that needs to be used in extreme heat conditions such as electrical insulators, under-the-hood automotive parts, etc.

High Chemical Resistance: Another plus of thermoset molded parts is they can withstand a wide range of chemicals. Therefore, they are quite suitable for application in industries where chemical exposure is constant.

For example, when you need to create parts for chemical processing like oil and gas, thermoset parts seem like a good option.

Precision: There are certain industries where you must have to create parts with top-notch dimensional stability. The best example is electrical connectors, which are usually created with this method.

Electrical Insulation: Thermoset molded parts usually remain electrically non-conductive. So, they are designed to work under extreme conditions.

Strength: Thermoset injection molding parts can withstand mechanical stress and loadbearing. These specifications make them the most suitable structural components.

Material Selection

Here is a list of commonly used materials for thermoset injection molding:

- BMC (Bulk Molding Compound)

- Phenolic Resin

- Epoxy Resin

- DAP (Diallyl Phthalate )

- Polyester Resin

- Silicone Resin

- SMC (Sheet Molding Compound)

- Urea Formaldehyde Resin

- Bakelite

- Melamine Formaldehyde Resin

- Epoxy Phenolic Resin

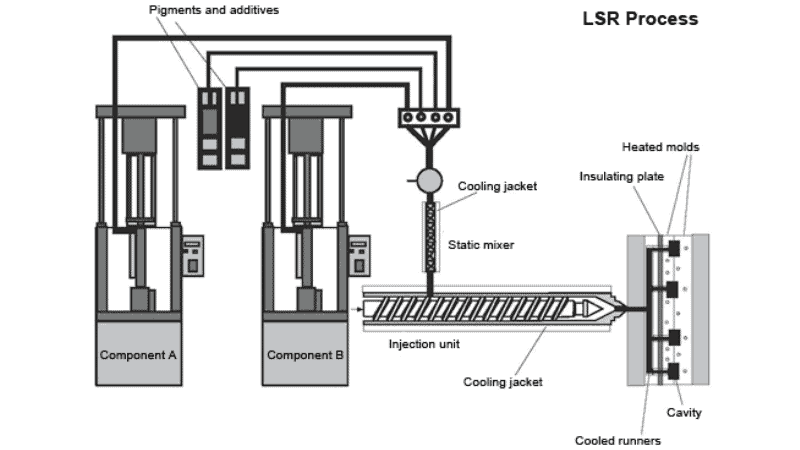

Liquid Silicone Rubber (LSR) injection molding

The producers of rubber-based products make the most of LSR Injection molding because this technique allows them to enjoy a high level of automation and almost 24/7 production run.

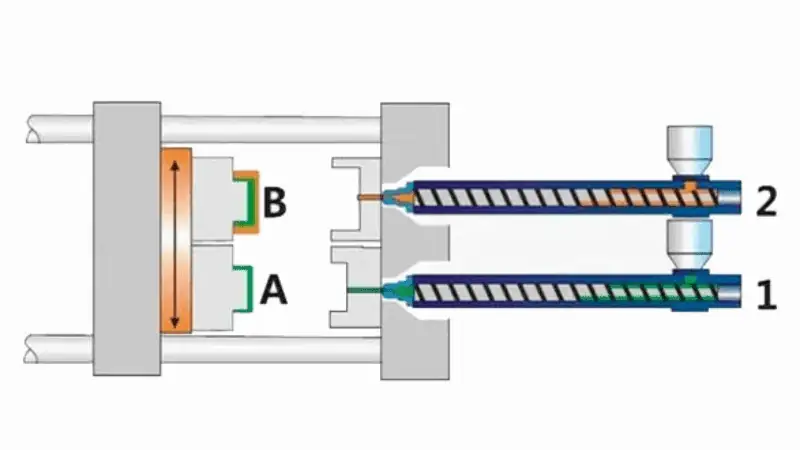

During (LSR) injection molding method, a two-part platinum-cured silicon compound is mixed and injected into the mold in the injection molding machine. Once this material is inside the mold, it cures into a flexible and solid rubber part.

The liquid Injection mold technique has revolutionized rubber industries. Because this method allows producers to create versatile products while maintaining a high level of precision.

They can create highly detailed and intricate rubber components via this method.

The common application of LSR injection molding is in medical industries. This technique is quite effective in the creation of medical-grade silicone parts such as tubes, seals, and gaskets.

Since silicone rubber is quite safe and durable, this technique is effective in manufacturing baby bottle nipples and pacifiers.

The role of LSR injection molding is big in the automotive Industry. This plastic injection molding method is used to produce automotive gaskets and seals. These components are highly resistant to shear heat burning and chemicals.

Advantages

Here are some benefits that you can only achieve with Rubber injection molding:

Fast Production: The biggest advantage manufacturers can achieve with this technique is quick production. It is made possible with the short cycle of this process.

It is cured after the cooling process and then you get the molded part more quickly with LSR as compared to other traditional methods.

Biocompatibility: The LSR injection mold process is biocompatible. Thereby manufacturers can produce medical and health care products through this method.

This technique is safe for the production of medical devices, components, and implants that come in contact with the human body.

Withstand Temperature: The injection molded parts from this technique can withstand high levels of temperature from too cold to too hot.

That means the part won’t lose its physical properties regardless of how extreme the temperature will be. So, you can use this technique for applications in extreme temperature conditions.

High Precision: Industries where products must have high precision and accuracy can make the most of this technique. It helps them produce highly detailed parts with tight tolerances.

Flexible and Durable: The injection Molded parts from LSR injection molding are highly durable and flexible. So, they are quite an ideal choice for applications that need to level performance and resilience such as gaskets and seals.

Material Selection

Here is some commonly used material for this molding process.

- General-Purpose LSR (GP-LSR)

- Fluorosilicone LSR (F-LSR)

- Transparent LSR

- LSR for Electronics

- LSR for Seals and Gaskets

- High-Temperature LSR (HTV-LSR)

- Medical-Grade LSR

- Electrically Conductive LSR

- Self-Lubricating LSR

- Food-Grade LSR

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Micro Injection Molding

This process is widely used for the production of incredibly small and complex plastic parts with as much accuracy and precision as possible.

This technique takes miniaturization to the next level because it allows manufacturers to produce plastic with a weight of around 1 to 0.1 grams with tolerance levels of 1 to 100 microns.

As far as applications of micro injection molding are concerned, you will be surprised to know this technique is widely used for the production of parts and components in the automotive, electronics, medical, and pharmaceutical industries.

The best example of micro-injected molded parts is tiny gear created for delicate watches or microfluidic devices for advanced medical diagnostics.

Manufacturers can expect outstanding precision with micron-level tolerances through this technique. This method is quite suitable for low-volume manufacturing and prototyping.

When it comes to material choice, you can have diverse options from thermoplastic to bioresorbable polymers.

Advantages

Here are 5 main advantages of Micro injection molding

Complex Geometries

This versatile technique enables the production of miniature components with highly intricate designs. It merges innovation and accuracy, making it the ideal choice for creating tiny parts with complex geometry.

Precision

Microplastic injection molding delivers exceptional precision, making it indispensable for industries such as medical devices and microelectronics, where micro-objects must meet exact specifications.

Sustainability

The process supports sustainable manufacturing by generating minimal waste and efficiently utilizing molten materials, significantly reducing its environmental impact.

Consistency

For industries requiring repeated production of identical micro-parts, this method ensures exceptional consistency in every batch, maintaining dimensional accuracy and enabling products to pass rigorous quality control.

Material Versatility

Engineers benefit from a wide material selection, as the process is compatible with diverse polymers. This allows the choice of the most suitable material for specific performance and application needs.

Material Selection

Here is a list of materials commonly used for micro-injection molding:

- Bioresorbable Polymers

- Micro-Metal Alloys

- Thermoplastic

- High-Performance Engineering Plastics

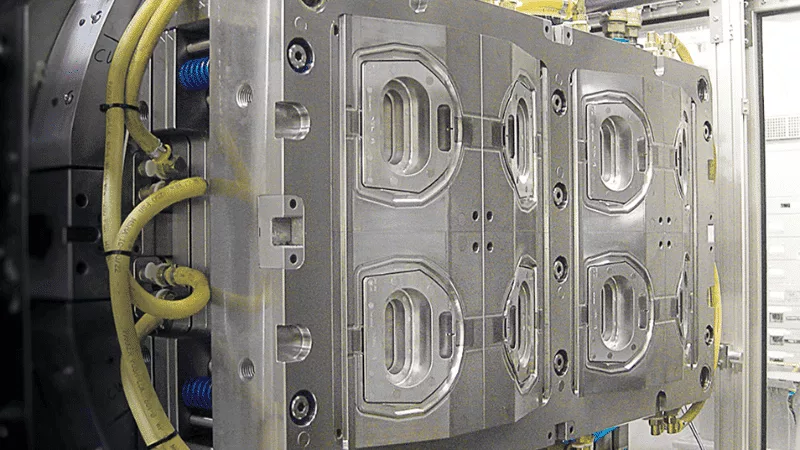

Multi-Component Injection Molding

Do you want to create eye-catching multi-colored or multi-material plastic components? What could be a better option than multi-component injection molding?

It is also known as the multi-material molding (MMM) technique, during which two or more resins are injected to form a multi-material part.

This process combines different colors and materials to create high-quality plastic parts through molten plastic. The best example of MMM is a colorful and super soft smartphone case, which offers a comfortable grip.

Since you can combine various materials and colors into one product, it allows you to create aesthetically pleasing functional products.

When it comes to its application in consumer products the best example is toothbrushes with rubber grips. It is an ideal technique for the creation of electronic enclosures, especially the ones that are usually integrated with gaskets.

Multi-component injection molding has great use in the medical industry. It allows manufacturers to create medical-grade equipment with different materials.

It’s easy to combine material with varied flexibility, strength, and biocompatibility.

Advantages

Here are 5 advantages you can avail yourself with the Multi-component injection Molding technique.

Cost Savings: This process allows molders to create a product in one go. There is no need for additional processing that reduces cycle time and material waste.

You can produce products quickly and without wasting material.

High-Quality Parts: Just like other injection molding techniques, multi-component processes also deliver high-quality parts with utmost precision and accuracy.

It ensures that every component is positioned and bonded precisely. So, you can expect the production process of well-structured parts through it.

Creative Design: Since it allows you to play with diverse colors, textures, and plastic materials, it facilitates you to create innovative designs with utmost flexibility.

You are free to combine soft and hard plastic into one visually appealing product.

Eco-Friendly: There is no need to have a secondary assembly step, so it reduces material waste. This eco-friendly manufacturing process reduces environmental impact.

Manufacturing Efficiency: This process allows you to create a strong and reliable bond between multiple materials and components. This molding happens in a single operation.

There won’t be any secondary step, as a result, cycle time is reduced and you can achieve high volumes and manufacturing efficiency.

Material Selection

Here is some common plastic material used for Multi-Component Injection Molding:

- Liquid Silicone Rubber (LSR)

- Thermoplastic Polyurethane (TPU)

- Polyolefins

- Polyesters

- Polyvinyl Chloride (PVC)

- Thermoplastics

- Thermoplastic Elastomers (TPE)

- Engineering Plastics

- Styrenic Polymers

- Acrylics

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Two-shot Injection Molding

Two-Shot Injection Molding is an advanced manufacturing process that integrates two different materials or colors into a single production cycle.

It enables the creation of multi-functional components in a single piece, making it ideal for applications requiring combined properties or striking visual contrasts.

During the process, two distinct molten plastics are sequentially injected and permanently bonded within the same mold.

This allows the formation of a single integrated part with layered or segmented structures, eliminating the need for secondary assembly.

A typical application can be found in the automotive industry, where dual-material dashboards combine soft-touch surfaces with rigid supports.

In medical device manufacturing, it is widely used to produce syringe plungers that integrate a rigid core with a flexible seal in one seamless component.

Advantages

Here are five main advantages you can get from Two-Shot injection molding:

Time and Cost Savings: There is no need for a secondary process when you can create an amazing product with only one step.

There is no secondary assembly process that reduces material waste and your cost. You save time by producing a dual-shot product in one step.

Innovative Design: You can integrate different materials, textures, and colors into one product. Therefore, creating a product that is highly functional and aesthetically pleasing is not a goal.

Designers are free to use their creative skills to make some really amazing designs.

High-Quality Parts: You can produce high-quality parts through this technique. It lets you combine soft and hard plastic in one product, thus creating a highly useful item.

Manufacturers can bond complex materials through this process. With dual-shot, you can craft a visually appealing product with dual texture, color, or material.

Efficient Production: You can achieve manufacturing efficiency via dual-shot injection molding. The production cycle time is reduced because there is no need to run a secondary assembly process.

Reduced Environmental Impact: By minimizing material waste and eliminating the need for additional assembly steps, two-shot injection molding aligns with sustainable manufacturing practices.

This also promotes eco-friendliness in production processes.

Material Selection

Here are some common materials used in the two-shot injection molding process.

- Thermoplastics

- Thermoplastic Elastomers (TPE)

- Liquid Silicone Rubber (LSR)

- Thermoplastic Polyurethane (TPU)

- Engineering Plastics

- Polyolefins

- Styrenic Polymers

- Acrylics

- Polyesters

- Overmolded Metals

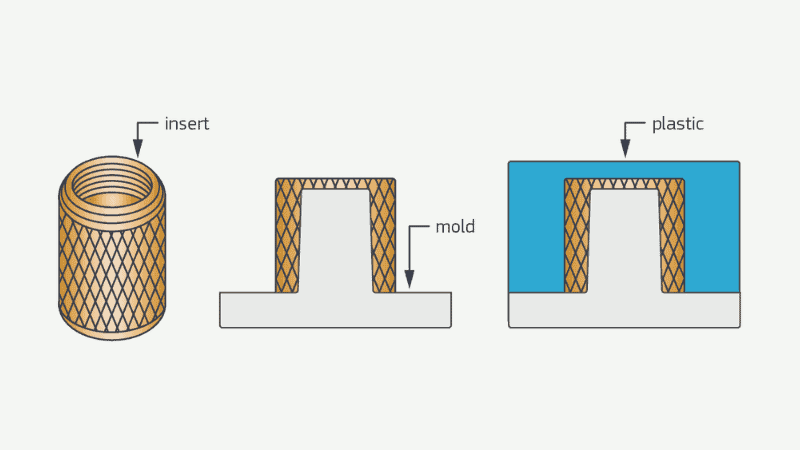

Insert Molding

It is another technique of injection molding during which an insert is introduced in the process. This technique is useful in combining metal or non-metal inserts with plastic material.

This process is quite similar to traditional injection molding but with an additional step where an insert is added to a mold filled with melted plastic.

The best example of this technique is catheters. In this medical device, soft tips are usually molded onto rigid bodies. Another good use of this technique is metal pins and connectors within plastic housing.

You always use a screwdriver that has a plastic handle. Well, it is also a good example of a product created through insert molding, which is a process of making plastic components around other non-plastic parts or inserts.

Advantages

Here are the main advantages you can get from this process.

Complex Design: When your project involves complex assemblies into a single molded part, you can make the most of insert injection molding. It allows you to enhance overall design and create a product with precision.

Versatile Applications: It is quite an innovative technique. Thereby, it has diverse applications in various industries such as consumer goods, medical devices, automotive, and electronics. Normally, when a project requires a nice combination of precision and durability, this technique seems like a great deal.

Strong Bond: This method creates a secure and durable bond between the plastic and non-plastic parts. So, when an industry requires durable products then this technique is quite useful for them.

Design Freedom: It allows designers to combine plastic with other materials such as ceramics, metals, etc. This unique combination unlocks endless design possibilities for aesthetics and functionality.

Reduces Size and Weight: It is an effective technique for creating lightweight small components. There is no need to use connectors and fasters to create a bond because metal inserts and resins make a strong bond during molding.

Material Selection

Here’s a list of commonly used materials for this molding process:

- Thermoplastics

- Thermosetting Plastics

- Metals (e.g., steel, brass, aluminum)

- Ceramics

- Glass

- Electronics Components (e.g., PCBs)

- Rubber and Elastomers

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Injection molding includes several specialized technologies—thermoplastic, thermoset, LSR, micro, multi-component, two-shot, and insert molding. Each molding is designed to meet specific production needs.

Understanding their strengths helps companies achieve better precision, durability, and manufacturing efficiency. By choosing the right injection molding method, businesses can improve product performance and reduce costs for high-quality, scalable results.

Upgrade Your Injection Molding Projects with Hongju Expertise

Accelerate your product development with Hongju’s 3–5 day rapid prototyping, flexible low-MOQ production, and 20+ years of expert craftsmanship.

Whether you’re exploring new injection molding technologies or scaling up, we deliver precision, speed, and reliability.

Contact us today to discuss your project and get a fast, competitive quote!