In this guide, we will delve deep into the features of silicone fabric, shedding light on its unique attributes and uses.

Introduction to Silicone Fabric

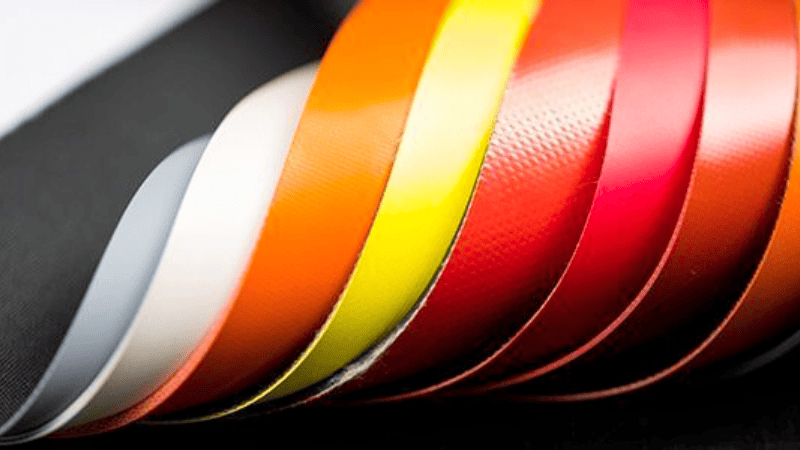

Silicone fabric, as the name suggests, is a composition where textile fibers are integrated with or coated by silicone rubber. The excellent performance of silicone and the combination of leather gets maximized by the Hongju.

- On the surface layer, it is composed of 100% silicone material.

- It also utilizes fabric bases such as microfiber, polyester, and spandex as basic fabrics.

Silicone rubbers are used in a wide variety of everyday items, from supplying the medical profession with high-performance, hypoallergenic materials to sealing off dust and moisture in our electronic devices.

Silicone rubber is a special type of rubber made from a mix of silicon, carbon, hydrogen, and oxygen. People like using it because:

- It can handle very high and very low temperatures without melting or freezing.

- It does not react with many chemicals, so it stays safe in different conditions.

- It’s resistant to water, which means it doesn’t get wet easily.

- It remains flexible for a long time and doesn’t break down quickly.

- It’s safe for food, which means you can use it in kitchen tools.

Because of all these characteristics, silicone fabric is one of the most desired polymers for constructing several paraphernalia as non-slip material is used in lingerie, intelligent textiles, and athletic clothes. They are also used in medical applications for several purposes.

Knowing how silicone rubber is made and how beneficial it is would make it easy to understand how to work with it with all the conditions being met. As said by the professionals, “Knowing the nature of your material will help produce the desired result.”

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Characteristics of Silicone Fabric Derived from Silicone Rubber

Silicone fabric, as an innovative material, gains its unique characteristics primarily from the silicone rubber that constitutes it. Here’s a dive into those attributes:

Temperature Resistance:

- Silicone fabric, imbued with the traits of silicone rubber, showcases remarkable thermal stability.

- This fabric can endure both high and low temperatures, making it ideal for diverse applications.

Weather Resistance:

- Just like silicone rubber, silicone fabric stands strong against the challenges posed by ozone and ultraviolet rays.

- This fabric’s inherent resilience to various weather conditions ensures products made from it have a longer lifespan even in challenging environments.

Low Surface Tension:

- Thanks to the properties of silicone rubber, silicone fabric offers a naturally hydrophobic (water-repelling) surface.

- This feature, along with its stain resistance, is particularly valued for numerous professional applications.

Odorless and Non-toxic:

- Mirroring the eco-friendliness of silicone rubber, silicone fabric is also non-toxic.

- Its absence of any offensive odors makes it a preferred choice in the creation of various consumer-friendly materials.

In essence, silicone fabric inherits its robust and versatile attributes from silicone rubber, allowing it to be an adaptable, durable, and preferred material for myriad applications.

Understanding the Composition of Silicone Fabric

Silicone fabric is a unique and versatile material that’s grown in popularity for a range of applications due to its robust characteristics. Let’s delve into its composition and understand what makes it special.

- Base Fabric: At its core, silicone fabric is usually a woven textile made from materials like polyester, nylon, or fiberglass. This base fabric provides the structural integrity and the initial strength of the final product.

- Silicone Coating: The key characteristic of silicone fabric comes from its silicone rubber coating. Silicone rubber is synthesized from siloxane polymers, made from a chain of alternating silicon and oxygen atoms combined with carbon and hydrogen.

- Characteristics Derived from the Composition: Flexibility and Strength: The base fabric (like polyester or nylon) provides the material’s initial strength and flexibility. When combined with silicone, this strength is amplified, and the fabric becomes even more durable.

Characteristics Derived from the Composition

- Water-Resistance: Silicone, being inherently hydrophobic, offers excellent water resistance. Thus, when the base fabric is coated or impregnated with silicone rubber, it becomes resistant to water and moisture.

- Temperature Resistance: The silicone coating allows the fabric to resist both high and low temperatures. This means that silicone fabric can endure extreme weather conditions without degrading.

- Chemical Resistance: Silicone is chemically inert in most environments, providing the fabric with resistance to various chemicals, solvents, and oils.

Different Applications of Silicone Fabric

The silicone fabric is becoming more and more applicable in a rather extensive assortment of frameworks, and it tends its use from backwoods to the retainers.

- Outdoor Equipment: Used in tents and tarps due to its water resistance.

- Protective Clothing: Ideal for fire-resistant outfits and weatherproof jackets.

- Medical: Found in hospital beddings, curtains, and equipment covers because of its sanitizable nature.

- Aerospace & Automotive: Used for thermal insulation and in gaskets and seals.

- Home Use: Employed in weatherproofing materials and outdoor furniture upholstery.

- Industrial: Seen in heat-resistant conveyor belts and protective machine covers.

- Electronics: Serves as insulation and protective layers in devices.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Comparing Silicone Fabric to Other Synthetic Materials

The comparison between silicone fabric and other synthetic materials is enormous. All fabrics have different properties that need to be considered before using them.

| Property/Feature | Silicone Fabric | Polyester | Nylon | Polyethylene | PVC |

|---|---|---|---|---|---|

| Water Resistance | Excellent (inherently hydrophobic) | Good (with treatment) | Good (with treatment) | Excellent | Very Good |

| Durability | Very High (UV and temperature resistance) | High | Very High | High | High |

| Breathability | Low (due to rubber coating) | Medium | Medium | Low | Low |

| Flexibility | High | High | Very High | Medium | Medium |

| Temperature Tolerance | Very High (resistant to extreme temperatures) | Moderate | High | Low-Medium | Moderate |

| UV Resistance | High | Moderate | Moderate | Low | Moderate |

| Chemical Resistance | High (chemically inert) | Low-Medium | Medium | High | Very High |

| Environmental Impact | Moderate (more durable, but can be challenging to recycle) | Low (microfiber pollution, but recyclable) | Low (similar issues as polyester) | Moderate (recyclable, but derived from petrochemicals) | Low (contains chlorides, can release toxins when burned) |

| Common Uses | Outdoor gear, medical applications, protective clothing | Clothing, home textiles | Outdoor gear, clothing | Packaging, containers | Pipes, cables, faux leather |

How to Choose and Buy Silicone Fabric

Choosing and buying silicone fabric involves considering several factors to ensure you get a product that meets your needs. Here’s a guide to help you make an informed choice:

1. Determine Demand:

- Purpose: Consider the primary end-use within your company or by your customers. Will it be for outdoor gear, medical applications, protective wear, or another niche? With the limitless possibilities of silicone fabric, there’s a broad range of potential applications.

2. Assess Weight and Thickness:

- Select fabric specifications that align with your requirements. For instance, outdoor apparel might need lighter, thinner silicone fabric, while interior protective covers could require something more robust, especially when considering the tastes and preferences of interior designers.

3. Ensure Quality Consistency:

- As a buyer, receiving consistent quality in every batch is crucial. Especially when compared to natural fiber which can sometimes have variances.

4. Evaluate Cost-effectiveness:

- Ensure you’re getting value for money. This doesn’t necessarily mean going for the cheapest option, but rather ensuring a balance between cost and quality. Also, take into account the added value of resistance to the extreme heat that silicone fabric offers.

5. Supplier Relationship and Reliability:

- Building a trustworthy relationship with suppliers is essential. Research potential suppliers for their track record, timely delivery, and responsiveness to issues.

Conclusion

silicone fabric has proved to be one of the best polymer materials for various products, and it provides protection and durability because it is the most desired fabric for crafting multiple things.

Looking for Silicone Fabric? Hongju Silicone Can Help You

Your trip can undergo an immediate improvement with the help of silicone fabric provided by Hongju. Make changes to make your life easier with the help of Hongju’s silicone fabric. Participate, learn, and flourish. Only then you will be able to acquire the knowledge of having a better experience and have a promising future with your products.