A tactile keypad offers a responsive, satisfying touch that enhances user control and precision. Commonly made from silicone, these keypads are used in electronics, medical devices, and industrial equipment.

This guide explores how tactile keypads work, their types, benefits, and applications, plus tips to help you choose the right one for your needs.

Tactile Keypad: What is It?

Tactile keypads, as the name implies, provide tactile feedback, a physical sensation felt when a key is pressed. This happens because of how the keys are constructed.

They usually have a small dome-shaped structure that collapses when pressed and snaps back into place when released, creating a noticeable “click.”

Tactile keypads can be made from various materials, with silicone being a common choice due to its durability and flexibility.

The key benefit of tactile keypads is the immediate feedback they provide to the user, enhancing the user experience and helping to improve typing accuracy.

How Tactile Keypad Works?

Understanding the operational mechanics of a tactile keypad requires a close look at its construction and the subsequent interaction of its components. Let’s delve into its intricacies:

The Construction of a Tactile Keypad

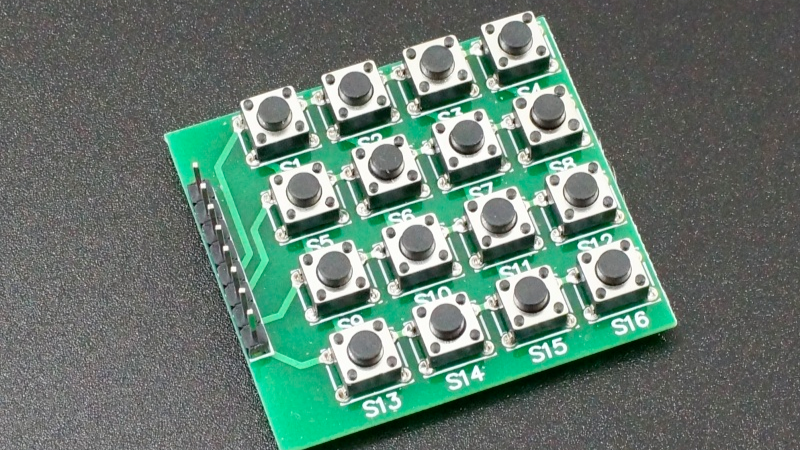

A tactile keypad comprises several layers, each serving a specific function. Typically, there’s a top layer—made of a durable material like silicone—with embossed keys. Underneath this, you’ll find a layer that houses the conductive fingerprints or circuits, which act as sensors.

The base layer is often a rigid surface, such as a circuit board, which provides support and stability for different switches.

The keys, switches or buttons on the tactile keypads often feature a metal or conductive rubber dome, which, when pressed, completes contact with the circuit underneath.

Tactile switches are a type of switch that focus on producing a tactile bump and a relatively quiet audible click with each keystroke. This key-to-circuit interaction is what enables the keypads or switches to generate the desired command or input.

The Working Principle

When a key is pressed on the tactile keypad switch, the conductive membrane keyboard dome flexes, making contact with the circuit beneath the switch itself.

This action closes the circuit, creating a pathway for the electrical current. The electrical signal is then sent to the connected device, which interprets it as the correct action—such as showing a character on the screen, executing a command, or triggering a device function.

The tactile feedback, often experienced as a tactile pressure, bump or a sound ‘click’, is produced by the dome springing back to its original position once the force is removed. This immediate physical response is what assures the user that their input has been successfully registered.

The tactile keypads are a marvel of user-centric engineering, combining physical sensation with electronic functionality for a seamless naturally enjoyable, and intuitive user experience.

Its widespread use across various devices stands testament to its effectiveness and efficiency.

Types of Tactile Keypads

The versatility and adaptability of tactile keypads have led to their incorporation into a diverse range of devices. Each application may call for a slightly different design or material, resulting in several keyboards available on the market.

Let’s examine some basic functionality of the common types:

Silicone Rubber Keypads

One of the most widely used types of tactile keypads, silicone rubber keypads are prized for their durability, resilience, and excellent tactile feedback. They’re used in a wide range of applications, from remote controls and computer keyboards to industrial machinery and medical equipment.

Their weather-resistant properties make them a great choice for outdoor or harsh environment applications.

Capacitive Keypads

Capacitive keypads, often seen in modern touch-screen devices, use the human body’s natural conductivity to detect when and where the keypad is touched.

While these keypads offer less physical feedback compared to other types, they’re sleek and responsive, offering their users a modern, high-tech feel.

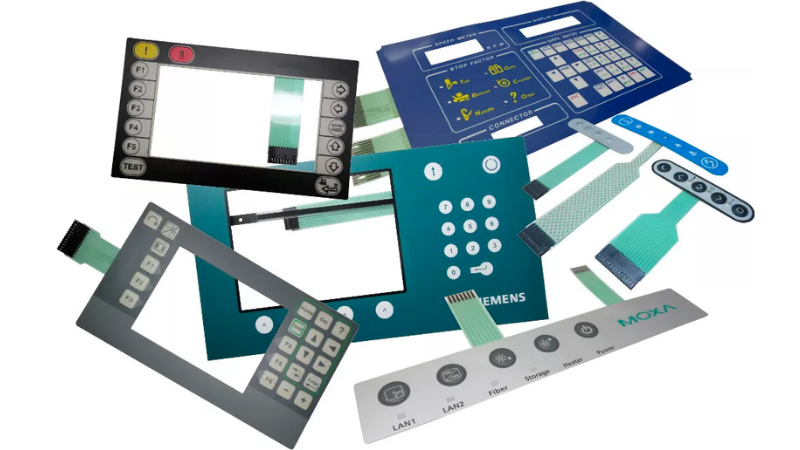

Membrane Keypads

Membrane keypads are thin, lightweight, and flexible, with a flat surface that can be easily cleaned. The keys on these keypads are small bumps often less pronounced than on other types of keypads and switches, but they still offer tactile feedback.

Membrane keypads with metal domes are frequently used in applications where cleanliness or space is a critical factor, such as in medical devices or compact electronic equipment.

Mechanical Keyboards

Mechanical keyboards, often used by typists and gamers, utilize individual mechanical switches underneath each key to provide a strong tactile response and produce an audible ‘click’ sound.

These keyboards are known for their longevity and customizability, with various mechanical switch types varying in tactile strength and noise level.

Each of these tactile keypads brings unique advantages to the table, and the choice often depends on the specific needs and requirements of the application.

On some mechanical keyboards, you may find a tactile switch, a clicky switch, and even a linear switch. Because of their tactile bump, they provide reasonable feedback when a key is pressed.

From the tactile switch to the soft, robust keys of silicone keypads to the sleek touch of capacitive ones, tactile keypads have revolutionized the way we interact with our devices.

Applications of Silicone Tactile Keypads

Silicone tactile keypads have carved a niche for themselves in several industries due to their durability, versatility, and exceptional tactile switch feedback.

A tactile switch is an ideal solution in a specific application where physical feedback is essential for the product’s operation. Let’s explore a few notable ones:

Consumer Electronics: Tactile keyboard switches are used for many household devices, like remote controls and appliances.

In the realm of consumer electronics, silicone tactile keypads find extensive use. Its ability to withstand frequent use while offering a pleasant touch experience makes it ideal for such applications.

Medical Devices: Cleanliness and reliability are of utmost importance in medical devices.

Silicone keypads, being resistant to water, chemicals, and temperature fluctuations, are often chosen for devices such as medical monitors, diagnostic equipment, and hospital beds.

Industrial Equipment: Industrial environments demand equipment that can withstand harsh conditions while maintaining functionality.

Silicone tactile keypads, known for their durability and resistance to adverse conditions, are extensively used in machinery controls, safety systems, and communication devices within industrial settings.

Automotive Industry: Within the automotive industry, silicone tactile keypads are commonly used for various controls on the dashboard, as well as in-car entertainment systems.

Given their high durability and ability to endure temperature variations, they are an excellent choice for such applications.

The Benefits of Using Tactile Keypads in Various Applications

Tactile keypads are becoming increasingly popular in a wide range of applications. These innovative input devices offer numerous benefits that greatly enhance the user experience.

Let’s dissect these benefits further:

Enhanced User Experience: One of the primary advantages of tactile keypads is the enhanced user experience they offer.

The tactile feedback provided when a key is pressed confirms to the user that the action has been registered, eliminating the need for visual confirmation and allowing for faster and more efficient operation.

Durability and Reliability: Tactile keypads, especially those made of silicone, are incredibly durable.

They can withstand a significant amount of use and resist damage from environmental factors such as water, temperature fluctuations, and chemicals. This makes them reliable for applications in demanding environments.

Cost-Effectiveness: Tactile keypads are generally inexpensive to manufacture, particularly when produced in large quantities. This makes them a cost-effective choice for applications ranging from consumer electronics to industrial machinery.

Design Flexibility: Tactile keypads offer significant design flexibility.

They can be custom-designed to fit a wide range of applications and can incorporate various features such as switching colors, backlighting, logos, or unique key shapes.

Ease of Maintenance: Tactile keypads, particularly those made from silicone, are easy to clean and maintain. This makes them a suitable choice for environments where hygiene is critical, such as in medical or food processing applications.

Optimizing User Experience with Tactile Keyboards

The use of tactile keyboards, due to their design and functionality, inherently enhances the user experience. But there’s much more that can be done to optimize this interaction further. Let’s delve into a few strategies:

Intuitive Design: The layout and design of the tactile keyboard should be intuitive and easy to understand. Often, this means adhering to conventional layouts—numbers are laid out like a calculator, for example.

However, it can also involve grouping keys by function or make frequently used keys larger or differently shaped.

Quality Material: Using quality materials in the construction of tactile keyboards can make a significant difference.

Silicone, for instance, offers a soft yet firm feel under the fingers, which most users find satisfying. Additionally, it’s durable, resisting wear and tear even after extensive use.

Clear Markings: Key markings should be clear and durable. Whether they’re printed, laser-etched, or molded directly into silicone, they need to withstand frequent use without fading or wearing off.

This not only ensures longevity but also aids in user comprehension, particularly in low-light conditions.

Sensible Tactile Feedback: The ‘click’ or response of a tactile keyboard should be tuned to the preferences of the user base.

For instance, gamers might prefer a strong click to ensure precise control, whereas office workers might prefer a softer click to reduce noise. Understanding the user’s needs and preferences can significantly enhance their experience.

How to Choose the Right Silicone Tactile Keypads for Your Needs?

Choosing the right silicone tactile keypads for your needs can be a daunting task, given the variety of options available. However, by taking into account certain critical factors, you can ensure that you select the most suitable keypad for your specific requirements.

Here’s a guide to help you through the selection process:

Consider the Application Environment: The environment where the keypad will be used is another important factor.

For instance, a keypad used outdoors or in an industrial setting will need to be more durable and weather-resistant than one used in a controlled indoor environment.

Evaluate Tactile Response: The tactile response of a keypad is a crucial factor in user experience. Consider whether the keypad needs to have a soft or hard press, and how much tactile feedback is necessary for the user to be comfortable and efficient.

Check the Durability: Silicone keypads are typically durable, but the level of durability required can vary depending on the application.

If the keypad will be used frequently or in harsh conditions, opt for a high-durability model.

Cost Consideration: Finally, consider your budget. While silicone keypads are generally cost-effective, prices can vary based on factors such as durability, design flexibility, and customization options.

Choose a keypad that fits your budget without compromising on the necessary features.

By considering these keyboard customization options, you can create a keypad that not only meets your functional requirements but also adds visual appeal and user-friendly features.

Conclusion

Tactile keypads, particularly those made from silicone, have revolutionized the way we interact with numerous devices in our daily lives.

Their robustness, adaptability, and enhanced user experience make them an optimal choice for a broad spectrum of applications, ranging from consumer electronics to industrial machinery.

Customize Perfect Silicone Keypads from Hongju

Hongju Silicone excels in crafting high-quality tactile keypads tailored to your unique needs. We offer quick prototyping, low MOQs, and trusted craftsmanship built over 20 years. Whether you need small runs or mass production, we deliver precision and speed.

Request your personalized quote today!