What Is Silicone Rubber Tubing?

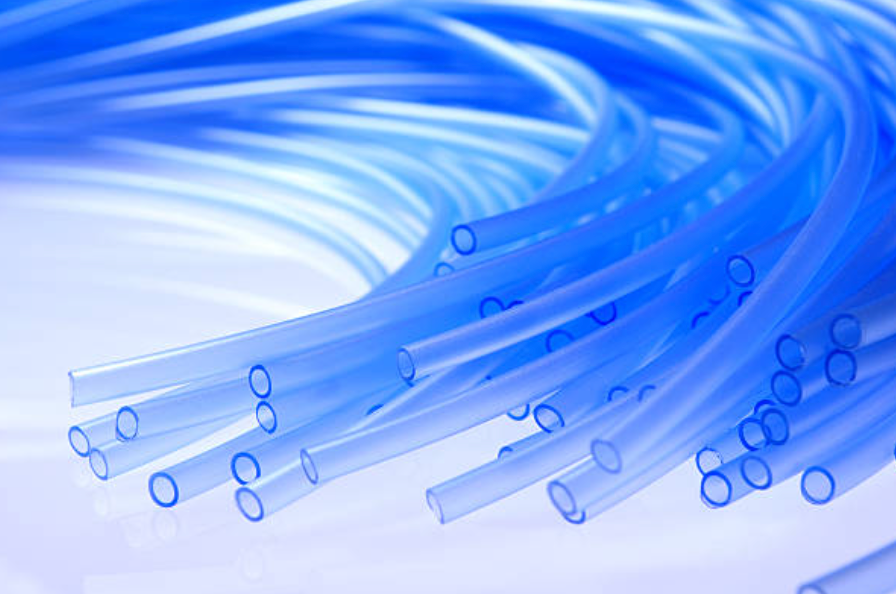

Silicone rubber tubing is, in essence, flexible and sterile equipment constructed from silicone rubber, a material known for its superior qualities. It features a smooth interior surface and comes in various sizes and colors. Notably, this tubing resists high and low temperatures effectively, compression sets, and harmful chemicals, establishing itself as a dependable option for numerous applications.

Transitioning to the importance of silicone rubber tubing, its versatility, and durability stand out. Industries such as healthcare, automotive, and food and beverage extensively employ this tubing, owing to its non-reactive nature and heat resistance.

Effectively, this tubing can endure harsh environments and strenuous use, offering consistent service without degradation. For businesses, selecting silicone rubber tubing signifies choosing a solution that amalgamates efficiency, safety, and cost-effectiveness.

Importance of Silicone Rubber Tubing In Various Sectors

Due to its unique properties, silicone rubber tubing has become vital in many industries. Its importance spans a wide range of sectors, making it a popular choice for various applications. This section will explore its key roles in different industries, backed up by real-life examples.

- Healthcare Sector: medical grade silicone tubing is practically irreplaceable in many medical applications. Its use in peristaltic pumps for precise fluid delivery in IV therapy and dialysis is a testament to its importance. Its flexibility, biocompatibility, and sterilization resistance make it a perfect fit for a sector where safety is paramount. Honestly, patient care wouldn’t be the same without it.

- Food and Beverage Industry: The food and beverage industry leans heavily on silicone rubber tubing in their production lines. Its role in transporting liquids in brewing and dairy processing equipment is crucial. The non-reactive nature ensures no harmful substances taint the products, safeguarding both quality and consumer safety. It’s hard to imagine maintaining these high standards without it.

- Automotive Industry: Silicone rubber tubing is a powerhouse in the automotive world. It’s used extensively in vehicle cooling systems to transport coolants. Its stellar heat and pressure resistance guarantees system integrity and boosts vehicle performance. It’s a key player in delivering the reliable, high-performing vehicles we depend on.

- Pharmaceutical Manufacturing: Silicone rubber tubing shines in pharmaceutical manufacturing, especially in fluid transfer processes. Its non-toxic nature and resistance to bacterial growth are invaluable in maintaining the strict hygiene standards the industry requires. Without it, ensuring product quality and consumer safety would be a far more complex challenge.

- Construction Industry: In construction, silicone rubber tubing is a game changer, used for insulation in electrical wiring and heating systems. Its excellent thermal resistance improves energy efficiency and fire safety in buildings. It’s a clear win for construction businesses, contributing to greener, safer structures.

Properties of Silicone Rubber Tubing

As we delve into the core characteristics of silicone rubber tubing, it becomes clear why this material is favored across various industries. Its unique properties equip businesses with a tool that’s not just functional but also durable and safe. Here are the key attributes that set silicone rubber tubing apart:

- Sterile and Flexible Materials: Silicone elastomers tubing is a sterile, non-reactive, and flexible material. For businesses in the medical and food industries, this is a game-changer. For instance, medical-grade silicone tubing has sterility that ensures safety in medical devices, while its flexibility allows for diverse shapes and sizes in food-grade and medical-grade material.

- Resistance to Elevated Temperatures: One of the standout properties of silicone rubber tubing is its ability to resist high temperatures. This feature is invaluable in industries like aerospace and automotive, where components often endure intense heat. Silicone tubes can withstand these challenging conditions, maintaining their structure and functionality and ultimately ensuring product longevity.

- Mechanical and Electrical Properties: Silicone rubber tubing offers excellent mechanical and electrical properties. For businesses in the electronics sector, this attribute is key. It implies that silicone tubing can protect delicate wires, enhancing the durability and safety of electronic devices. Additionally, its mechanical strength allows it to resist pressure in industrial applications, reducing the risk of failure and increasing operational efficiency.

Silicone Rubbers Vs. Other Materials

Let’s delve into how silicone rubber stacks up against other materials, notably EPDM Rubber and Rigid Rubber material, and understand why businesses often opt for silicone.

EPDM Rubber

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile material known for its outstanding heat, ozone, and weather resistance. However, silicone rubber stands out regarding overall temperature resilience and flexibility. It can operate in more extreme temperature conditions, both hot and cold, making it a go-to choice for businesses in sectors like aerospace, automotive, and medical devices, where such resilience is paramount.

Rigid Rubber Material

More rigid rubber material, including hard rubber, have their place in the industry due to their firmness and durability. Yet, they often lack the elasticity and pliability that silicone rubber offers. Silicone’s flexibility means it can stretch and bend without damage, making it ideal for applications such as seals, gaskets, and various medical devices.

Natural Rubber

Natural rubber offers excellent tensile strength and elasticity. However, it doesn’t stand up to temperature extremes or UV exposure as well as silicone rubber does. Silicone rubber’s superior temperature and weather resistance make it the preferred choice for outdoor applications or those requiring exposure to high heat.

Nitrile Rubber

Nitrile rubber is known for its resistance to oils and chemicals. Despite this, it falls short in terms of temperature resistance compared to silicone rubber. Silicone’s ability to withstand extreme temperatures without degrading allows it to maintain its integrity in high-temperature environments, like engine parts or cooking utensils.

Polyurethane Rubber

Polyurethane rubber boasts impressive abrasion resistance, making it perfect for applications like wheels and casters. However, it lacks the flexibility and temperature resistance of silicone rubber. This limitation can be a disadvantage in applications that require a material to maintain its properties under a wide range of temperatures.

Causes of Silicone Rubber Degradation

Although silicone rubber boasts impressive resilience, it’s not immune to degradation. Several factors can contribute to the deterioration of silicone rubber. By understanding these, businesses can better implement preventive measures, thus extending the product’s lifespan.

Elevated Temperature Issues

One of the culprits causing silicone rubber degradation is excessive heat. While silicone rubber performs exceptionally well at high temperatures, prolonged exposure can still have negative effects.

· Thermal Expansion

Silicone rubber expands when heated. This thermal expansion can lead to stress and eventual degradation if the material is confined or bonded to a rigid structure. For instance, a silicone rubber gasket exposed to repeated heat cycles in the automotive industry can begin to degrade if not designed to accommodate expansion.

· Changes In Chemical Composition

Prolonged exposure to high temperatures can also change the silicone rubber’s chemical composition. This alteration might reduce the material’s elasticity and resistance to tear, affecting its performance over time. A real-life example can be seen in the kitchen, where silicone rubber spatulas exposed to extreme heat over long periods may start to stiffen or crack.

Mechanical Stress Factors

Silicone rubber is also subject to mechanical stress factors. These include constant pressure or repetitive flexing, which may cause the material to wear down over time. For example, in the medical industry, silicone rubber tubing used for fluid transfer may degrade over time due to the constant pressure of the fluids passing through them.

Gas Diffusion Layer And Porosity

The presence of gas diffusion layers and porosity can also accelerate the degradation of silicone rubber. This is particularly relevant in industries like the fuel cell sector, where silicone rubber components are exposed to gases. The diffusion of these gases into the silicone material can lead to swelling and, eventually, degradation.

How to Prevent Degradation, Leakage, And Failure

Understanding the root causes of silicone rubber degradation helps devise strategies to counter these issues. Let’s delve into a few strategies that can enhance the performance and longevity of silicone rubber.

Silicone Coolant Hoses

Silicone coolant hoses, used in industries such as automotive and HVAC, are renowned for their heat resistance. They outperform other materials in extreme temperatures, making them an excellent choice for such applications. However, they can be prone to electrochemical degradation if not properly manufactured or maintained. Therefore, ensuring quality control during production and regular maintenance checks can help mitigate these issues, enhancing the lifespan of these components.

Enhancing Durability With Inorganic Fillers

One way to bolster the durability of silicone rubber is by incorporating inorganic fillers. These fillers can improve the material’s resistance to heat, mechanical stress, and gas diffusion. For instance, adding silica fillers to silicone rubber can enhance its tensile strength, reducing the chances of degradation under mechanical stress. This strategy is beneficial, especially for applications that require robust performance over extended periods.

Optimizing The Manufacturing Process

A well-optimized manufacturing process can significantly reduce the risk of silicone rubber degradation. This includes ensuring precise temperature control during the curing process and maintaining cleanliness in the production environment. By doing so, businesses can prevent the introduction of impurities that might compromise the material’s integrity and performance.

Smoother Surface Finish For Better Performance

Lastly, a smoother outer surface finish can enhance the performance of silicone rubber products. A smoother surface reduces the chances of micro-cracks that can evolve into significant defects over time. It also minimizes the area of contact with potentially damaging substances, reducing the risk of degradation. For example, a smooth surface finish in medical tubing enhances durability and ensures consistent fluid flow.

Applications of Silicone Rubber Tubing

Silicone rubber tubing’s unique properties make it an ideal choice for various industries. Its durability, flexibility, and resistance to extreme temperatures have paved the way for numerous applications, as we will explore below.

Medical Devices And Equipment

In the medical sector, silicone rubber tubing is a staple. For instance, it’s used in equipment requiring sterile and flexible materials like catheters and cannulas, whose non-reactive nature ensures safe patient contact. Its flexibility and durability make it an excellent choice for long-term use, offering comfort and reducing the risk of complications.

In analytical instrumentation, such as blood gas analyzers, silicone tubing’s chemical resistance ensures accurate sample analysis, directly contributing to reliable diagnostics and patient care.

Food And Dairy Processing Equipment

Silicone rubber tubing is also common in food and dairy processing equipment. It’s resistant to frequent sterilization cycles and doesn’t impact the taste or odor of food, making it an ideal choice for food-grade applications. For example, in dairy processing, silicone tubing is used in milking machines, ensuring safe and efficient milk collection without compromising its quality.

Aerospace Industry

The aerospace industry is another significant user of silicone rubber tubing. Given the extreme temperatures that aircraft encounter, the heat resistance of silicone rubber is a major advantage. It’s used in insulation, sealing, and fuel lines, supporting the reliable operation of aircraft and ensuring passenger and crew safety.

Automotive Industry

The automotive sector heavily relies on silicone rubber parts for their excellent heat resistance and durability. From radiator hoses to gaskets, silicone rubber components ensure optimal performance and longevity of vehicles. For example, turbocharger hoses made from silicone rubber can withstand the high temperatures of exhaust gases, contributing to improved engine efficiency.

Electronics Industry

Silicone rubber plays a critical role in electronics manufacturing. Its superior insulating properties make it ideal for wiring and cable applications, providing effective protection against heat and electricity. For instance, silicone rubber tubing is often used to insulate high-voltage cables, enhancing safety and durability.

Chemical Processing

In the chemical industry, silicone rubber hoses are used to resist a wide range of chemicals. They are instrumental in transferring various chemical substances safely, reducing the risk of leaks and spills that could cause serious harm to both personnel and the environment.

Marine Industry

The marine sector also benefits from silicone rubber’s exceptional properties. For example, silicone rubber hoses are used in bilge pump systems owing to their durability and resistance to saltwater corrosion.

Agriculture

In the agricultural sector, silicone rubber is used in various equipment, such as irrigation systems. Its resistance to weather and temperature changes makes it an ideal choice for outdoor applications.

Why Should You Prevent Silicone Degradation, Leakage, And Failure

The importance of preventing silicone degradation, leakage, and failure can’t be overstated. Neglecting these factors can lead to severe consequences for your business, impacting both operational efficiency and customer satisfaction.

Firstly, consider the potential cost implications. Degraded silicone products require replacement, which entails additional materials, labor, and downtime expenses. These costs can quickly escalate, particularly if the issue isn’t identified promptly. Regular maintenance and proactive measures to prevent degradation can significantly reduce these expenses.

Secondly, silicone rubber tubing leakage can lead to operational issues. A single leak can disrupt the entire production line in medical and food processing industries, leading to delays and potential product contamination. Furthermore, a failure in critical applications such as aerospace or healthcare could have serious safety implications, potentially risking lives.

Finally, product failure can significantly damage your company’s reputation. Consumers rely on the durability and reliability of silicone rubber products. A failed component can lead to customer dissatisfaction, negative reviews, and a loss of trust in your brand.

Conclusion

In conclusion, the importance of silicone rubber tubing, especially in preventing degradation, leakage, and failure, cannot be overstated. Its diverse applications across multiple industries underline its worth. By understanding its attributes and taking preventive measures, businesses can optimize efficiency, cut maintenance costs, and avoid system failures. Explore our website further to discover how silicone rubber can positively impact your business operations.

Discover Our Expertise in Silicone Rubber Solutions

Don’t miss the opportunity to benefit from our vast experience in silicone rubber capabilities. Let Hongju Silicone help you develop reliable, high-quality products for your business needs. Visit our capabilities page to learn more and elevate your projects to new heights.