What Is Silicone Rubber? Key Properties Explained

Before we jump into the protective features of silicone rubber for electronics, let’s first understand silicone rubber. In minute quantities, it is a synthetic elastomer made from elements, including oxygen, hydrogen, carbon, silicon, etc.

We often see the use of silicone in the manufacturing industry. For instance, automotive parts, sensitive electronics, medical devices, and general household items.

Hence, it is safe to say that the scope of silicone rubber is beyond electronic products. Nonetheless, for the professional degree of the article, we will only focus on the electronic bits to fully understand it.

As for the properties of silicone, you get a great deal. For starters, it has excellent resistance to heat and moisture. Moreover, silicon resists UV radiation and harsh environmental conditions pretty well. Even if an application has oils, solvents, or chemicals, silicone can defend electronic devices just fine.

As a result, manufacturers often use silicone elastomers in electronic products to avoid exposure to harmful external elements. Moreover, silicone is known for its durability and long life, thanks to good abrasion resistance.

Hence, it’s an economical choice for many industries compared to other rubber materials.

6 Advantages of Using Silicone Rubber In Electronic Protection

We have briefly touched on the properties of silicone. However, let’s have a look at each advantage separately to understand the purpose of silicone in these devices fully:

UV Resistance: In recent years, solar panels and outdoor lighting have become more common. However, these devices are often exposed to UV radiation, which can cause problems like fading, discoloration, and reduced performance over time.

That’s where silicone comes in. It offers excellent UV resistance, meaning it can endure prolonged sun exposure without cracking, warping, or losing its properties. By protecting electronic components, silicone helps extend their lifespan and even prevents bacterial growth that could further damage the devices.

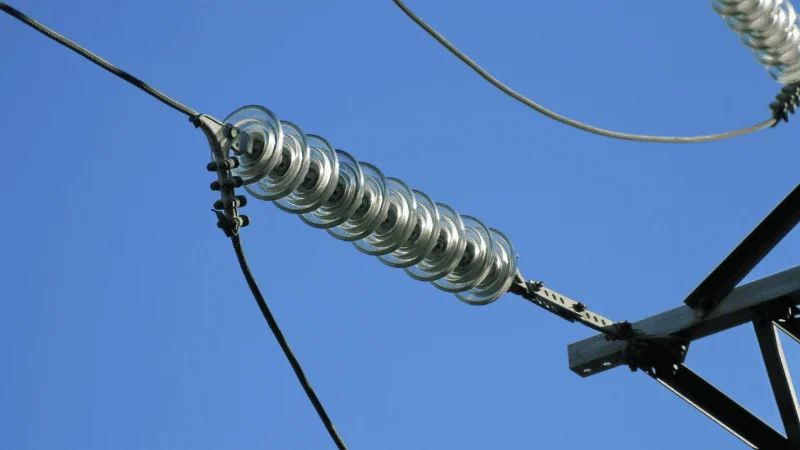

Insulation: High-voltage applications are often prone to electrical shocks and short circuits. Without the presence of protective material, these threats can damage electrical equipment. Since silicone has good insulation properties, it works as a barrier between short circuits and electric devices, preventing damage.

Water Resistance: Electric devices and water never make a good match. So, there is always a need to protect sensitive components from water and moisture. Silicone does this job well, thanks to its sealing and waterproof properties. It keeps the water away from critical electrical components, ensuring smooth functioning over the long run.

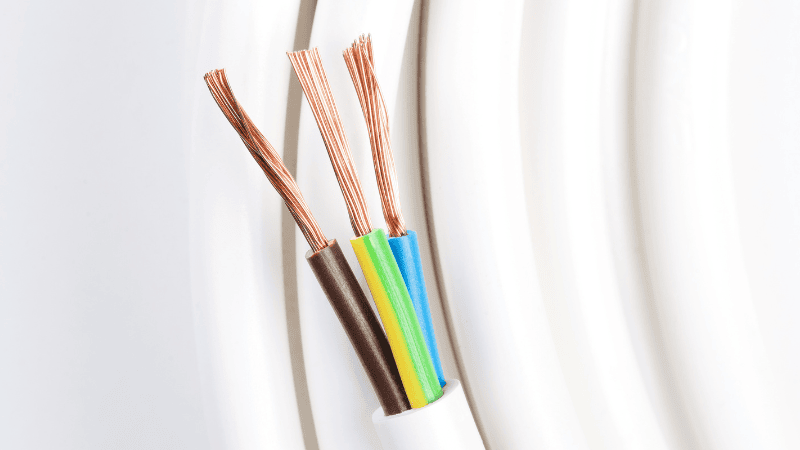

Temperature Resistance: Electrical devices often generate heat. These include electrical motors, transformers, and even cables. Fortunately, silicone rubber tends to retain its properties in extreme temperatures. As a result, it is ideally used in electronic products that experience high heat.

Flexibility: Electrical equipment, such as oversized speakers that experience shocks and vibrations, needs a flexible material to protect them. Silicone also does this job well since it’s highly elastic.

Chemical Resistance: silicone successfully resists various chemicals, including acids and solvents. These can potentially damage electrical devices, but not if silicone is there acting as a shield against them. Hence, a lot of industrial electronic equipment uses silicone rubber.

How Does Silicone Rubber Protect Electrical Devices?

How does silicone protect power electronics? What’s so special about it? Well, silicone depicts a unique set of properties. Manufacturers can also tweak these properties with vulcanization and additives to give you silicone compounds with specific electrical properties and molecular structures.

Superior Electrical Insulation

Also, silicone tends to work as an excellent electrical insulator. Thus, the use of silicone components in electrical devices with high-voltage applications proves beneficial.

Defending Against Environmental Threats

In the particular electronics case, these devices are threatened by high temperatures, chemicals, and moisture. Thus, the dangers posed by these threats call for a material that can protect them. That is where silicone enters with its versatile mix of properties.

Biocompatibility for Medical Applications

Lastly, FDA-approved silicone is highly suitable for use in electric medical devices. These include not only external medical devices but also those that are implanted.

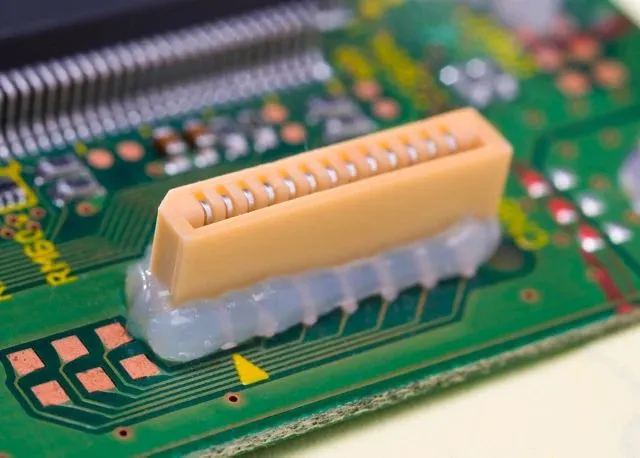

Exceptional Material Compatibility

Another vital aspect of silicone elastomers is their compatibility with various materials. This makes silicone components in electrical devices that use plastics, other elastomers, or even metals much more manageable.

As a result, the versatility of the rubber material, thanks to high compatibility, allows it to protect power electronics in various applications.

Applications of Silicone Rubber In The Electronics Industry

Once again, Silicone has popular demand in the electronics industry thanks to its versatile properties. Here are some of the most common applications of silicone rubber in the electrical industry:

Insulation: Silicone rubber is often used to insulate electrical connectors and wires. It protects the electrical equipment from high-voltage shocks and currents.

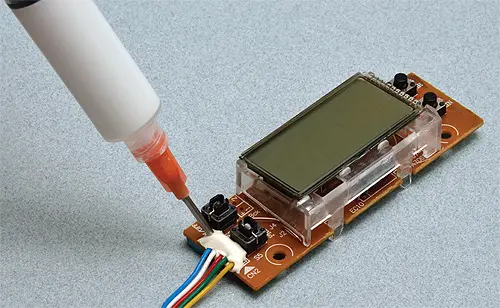

Conformal Coatings: Silicone conformal coating is a thin protective layer applied to printed circuit boards (PCBs). It effectively insulates conductors, guarding against moisture, dust, chemicals, and high temperatures.

Applied during the final manufacturing stage using liquid silicone rubber, it forms a flexible, durable barrier that doesn’t interfere with electrical function. This extends PCB life and improves reliability in harsh environments.

Buttons/Keypads: Remember the old keypad mobile phones and telephones? The buttons used on them and many computers are made from silicone. This stays true even today, as electrical devices such as remote controls and industrial equipment use silicone buttons for their excellent properties.

Thermal/Heat Dissipation: Silicone potting compounds protect delicate electronics like transformers, sensors, and power supplies. They offer excellent heat resistance and flexibility, dissipating internal heat while blocking moisture and contaminants. This improves thermal stability and extends device life in demanding environments.

Sealing: Silicone linings, seals, and gaskets are widely used to protect electrical devices from water and moisture. A common example is modern smartphones with IP67 or IP68 ratings, which rely on liquid silicone rubber linings to form a tight seal.

Silicone sealant is also used in computers and medical electronics due to its flexibility, durability, and reliable performance in preventing liquid ingress.

Silicone Rubber vs. Alternative Materials

Here is a comparison of silicone with other rubber materials used for electronics. The table below clearly indicates how silicone performs better in almost every aspect:

| Property | Silicone Rubber | Neoprene | Nitrile Rubber | EPDM Rubber |

| Electrical Insulation | Excellent | Good | Good | Good |

| Tear strength | Excellent | Good | Good | Good |

| Oil resistance | Excellent | Good | Excellent | Poor |

| Temperature range | -55°C to 200°C | -30°C to 120°C | -40°C to 100°C | -50°C to 130°C |

| Chemical resistance | Excellent | Good | Good | Good |

| UV resistance | Excellent | Good | Poor | Good |

| Flexibility | Excellent | Good | Good | Poor |

| Water resistance | Excellent | Good | Good | Good |

As the table above shows, silicone offers better electronic properties than other rubber materials used for the same purpose. Hence, manufacturers often prefer silicone for its unique properties and exceptional performance.

When to Choose Silicone Rubber for Electronics Protection

Given the properties of silicone, you should use it to protect electronics in specific conditions. But what are these particular conditions? Even though we have practically discussed each already, there is a different way to view it.

For Elasticity

We already know silicone has high flexibility and elasticity. Hence, any application that will put electronic devices under pressure and extension uses silicone to protect them. The rubber material retains its properties even after being stretched for prolonged periods.

For Water Resistance

Silicone tends to protect electrical devices from water and moisture better than any other synthetic rubber. Hence, any medical or telecommunication industry application requiring water-resistant sealing must use silicone rubber.

For UV Resistance

Outdoor applications in the form of lights and solar panels can significantly benefit from silicone. It helps keep the UV rays at bay, ensuring your investment is protected correctly and increasing the overall lifespan.

For Low Flammability

Silicone has high-temperature resistance. Hence, any application where things can get heated up quickly can use silicone well. Even if things get out of hand with extra high temperatures, silicone still does not release any toxic materials.

For High Voltage Resistance

Any application that will put the electrical device through high voltage must use silicone as a protective layer, coating, potting, or encapsulation.

FAQs

Q1:Is silicone safe for electronics?

Yes, silicone is a highly versatile rubber material with a combination of properties. These include chemical resistance, temperature resistance, water resistance, and insulation. All of this help make silicone a safe material for electronics.

Q2: Does silicone rubber conduct electricity?

Silicone is an electrical insulator. Hence, it can withstand high currents and shocks without losing stability. As a result, it won’t conduct electricity or let it pass through and damage the electrical equipment.

Q3: What kind of silicone is used for electronics?

The most common electronic silicone forms include liquid silicone rubber and thermally conductive silicone. This helps ensure that it serves the purpose of equipment protection while ensuring things stay calm around it.

Q4: What are the advantages of using silicone rubber?

Low compression set, high flexibility, and temperature resistance are some of the advantages of silicone. Moreover, the rubber material has a proven record of high durability, making it a cost-effective investment for long-term applications.

Conclusion

To conclude, silicone does an incredible job protecting electronic components. Its unique properties ensure stability and safety against external damage. For businesses, the key to long-term reliability lies in selecting high-quality silicone materials and products.

This is a worthwhile investment that ensures superior performance and fosters customer trust.

Accelerate Your Business with Hongju’s Custom Silicone Rubber Solutions!

At Hongju Silicone, we deliver reliable silicone rubber products backed by over 20 years of craftsmanship. With rapid prototyping in just 3–5 days, low MOQ for flexibility, and expert CNC precision, we ensure efficiency, quality, and customization.

Contact Hongju today for a tailored solution that meets your exact business needs!