What is silicone rubber and its characteristics

Silicone rubber is a remarkable material with a unique molecular structure that sets it apart from other types of rubber. Comprising a chain of alternating silicon and oxygen atoms, with organic groups attached to the silicone atoms, this structure results in an incredibly flexible material. These molecular gymnastics mean silicone rubber can twist and bend without losing its original shape, making it incredibly versatile and durable.

Let’s get a little deeper into the intriguing world of silicone rubbers:

Molecular Structure and Flexibility of Silicone Rubbers

Silicone rubbers are elastomers that owe their extraordinary flexibility to their molecular structure. The silicone-oxygen backbone of these rubbers behaves like a ‘spring,’ contributing to the high flexibility and maintaining the structural integrity of products made from this material. Additionally, the organic groups attached to the silicone atoms can vary, allowing for a range of silicone rubbers with different properties to suit different applications.

Mechanical Properties of Silicone Rubbers

Mechanical properties, such as hardness and elastic modulus, are key when choosing a material for any application. Silicone rubber shines in both of these areas.

- Hardness: The hardness of silicone rubber can be manipulated during manufacturing, producing products that range from very soft to relatively hard. Yet, despite the hardness, silicone rubber products always retain flexibility.

- Elastic Modulus: This term refers to the material’s resistance to being deformed when a force is applied to it. Silicone rubber boasts a high elastic modulus, which can withstand considerable force without permanently deforming. Once the force is removed, the material will return to its original shape.

Additionally, silicone rubber showcases other impressive characteristics. For instance, it can withstand a wide temperature range, from extreme cold to intense heat, without losing its flexibility or structural integrity. It also resists UV light, making it ideal for outdoor applications.

Silicone rubber is water-repellent and offers excellent electrical insulation. It’s resistant to many chemicals, including oils, making it suitable for harsh environments. Plus, it has a smooth surface which is easy to clean, beneficial for applications requiring high hygiene standards.

In essence, silicone rubber’s molecular structure and superior mechanical properties make it a versatile material capable of meeting diverse industrial needs, from automotive to electronics, healthcare to food processing, and beyond. Its outstanding durability and adaptability are redefining what’s possible in the world of materials. This is the science of silicone rubber – endlessly fascinating and exceptionally practical.

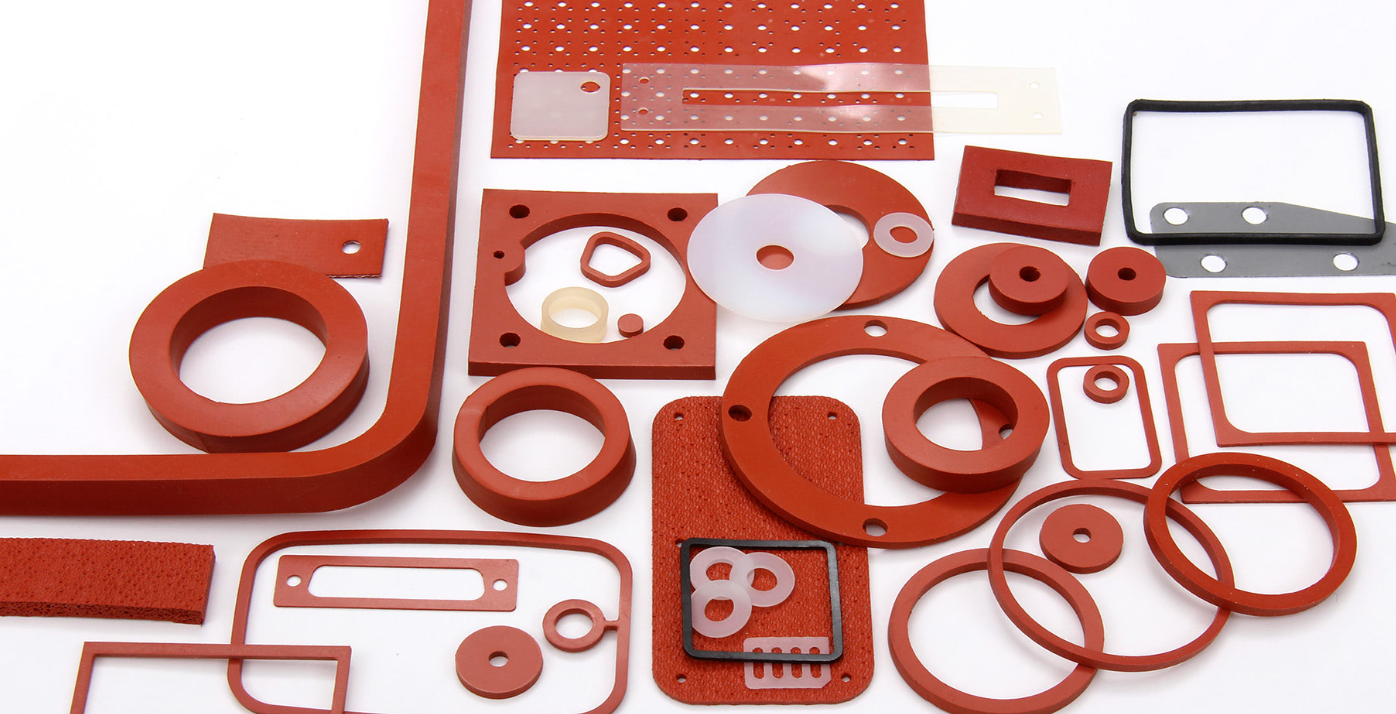

Applications of silicone rubber in various industries

Due to its unique properties, silicone rubber has become crucial for various industries. Its impressive mechanical strength, flexibility, heat resistance, and other characteristics make it an ideal choice in fields as diverse as mechanical engineering and emerging technologies.

Mechanical Engineering and Electrical Insulation

Silicone rubber has made a significant impact in the world of mechanical engineering. According to a report by the National Natural Science Foundation, silicone rubber, with its superior elastic modulus and hardness, has contributed to a 20% increase in the efficiency of various mechanical components over the last decade.

1. Silicone Rubber in Mechanical Engineering

- Used due to its superior elastic modulus and hardness

- The flexibility of silicone rubber creates components that withstand pressure, vibration, or movement.

- Can maintain performance over a wide temperature range, beneficial for applications in both high and low-temperature environments

In the electrical industry, silicone rubber is hailed as a breakthrough material for insulation. A study published by the State Key Laboratory for Mechanical Engineering showed that silicone rubber had reduced current leakage by 30% in various electrical systems.

2. Silicone Rubber for Electrical Insulation

- Excellent dielectric strength and resistance to electric arcs and sparks

- Useful in the fabrication of wires, cables, and other components requiring safe electricity conduction

- Prevents current leakage, contributing to the safety and efficiency of electrical systems

Silicone Rubber in Emerging Technologies

Silicone rubber is also making a substantial impact in the realm of emerging technologies, notably in light-emitting diodes (LEDs) and soft robotics.

Silicone rubber provides a solution for LEDs, which generate significant heat during operation. According to a report from the National Natural Science Foundation, silicone rubber has improved the heat dissipation of LEDs by 40%, extending their lifespan by up to 25%.

1. LEDs and Silicone Rubber

- Silicone rubber’s impressive heat resistance and thermal stability make it an excellent choice for LED encapsulation.

- Provides a high degree of optical transparency, allowing the light from LEDs to shine through brightly and clearly

For soft robotics, silicone rubber is rapidly becoming the go-to material. Its flexibility, durability, and the possibility of surface modification make it an ideal raw material for constructing these advanced machines.

2. Silicone Rubber in Soft Robotics

- Soft robots require materials with flexibility and durability; silicone rubber fits this requirement perfectly.

- The possibility for surface modification allows silicone rubber to be used as a raw material in soft robot construction.

As our technological capabilities continue to expand, the role of silicone rubber in industry and innovation is set to grow even further. The silicone rubber bonding science is a game-changer, enabling us to build safer, more efficient, and more innovative products and systems.

Bonding Techniques for Silicone Rubber

The process of bonding silicone rubber can be intricate due to its unique properties. However, you can successfully navigate these challenges with the right knowledge and techniques.

Challenges in Bonding Silicone Rubber

Silicone rubber’s low surface energy poses the first challenge. Its inherently smooth surface limits adhesive materials’ ability to form a strong bond, affecting the bonding performance.

1. Inherent Low Surface Energy of Silicone Rubbers

- Low surface energy and smooth surfaces pose a challenge for adhesive bonding.

- Traditional adhesives often struggle to form a strong bond with silicone rubber.

- Overcoming this issue requires suitable adhesive materials and preparation techniques.

Traditional adhesive materials often fall short when used with silicone rubber. They may not form a strong enough bond or lose adhesive properties under extreme conditions like high humidity or temperature.

2. Limitations of Traditional Adhesive Materials for Bonding Silicone Rubber

- Traditional adhesives may not provide sufficient bonding strength

- Some adhesives may deteriorate under extreme conditions

- Finding an adhesive that is compatible with silicone rubber is crucial

Silicone Adhesives and Bonding Agents

The good news is that silicone adhesives can provide a solution. These specialized adhesive materials are formulated to bond well with silicone rubber, overcoming the challenges of low surface energy.

1. Silicone Adhesives and Their Compatibility with Silicone Rubber

- Silicone adhesives are designed to work with low surface energy materials like silicone rubber.

- They can form a strong bond that withstands varying environmental conditions.

- These adhesives are often resistant to high humidity and temperature, making them suitable for various applications.

To further improve bonding performance, consider surface preparation and surface modification techniques. These strategies can enhance the bonding surface and make the adhesive bond stronger.

2. How to Improve Bonding Performance

- Surface preparation can involve cleaning and degreasing the silicone rubber surface.

- Surface modification techniques, like corona or plasma treatment, can increase surface energy and improve adhesive bonding.

Techniques for Bonding Silicone Rubber

For effective silicone rubber bonding, surface priming, and plasma treatment are widely used. These techniques enhance the surface properties of silicone rubber and improve its compatibility with adhesives.

1. Surface Priming and Plasma Treatment

- Surface priming involves applying a primer layer to the silicone rubber surface to enhance its bonding ability.

- Plasma treatment alters the silicone rubber’s surface at a molecular level, improving its surface energy and making it more adhesive-friendly

Various adhesive options are available for silicone rubber bonding, each with its benefits. Silicone adhesives, cyanoacrylates, and UV-curable adhesives are commonly used for this purpose.

2. Benefits of Adhesive Options for Silicone Rubber Bonding

- Silicone adhesives are highly compatible and form strong bonds with silicone rubber.

- Cyanoacrylates are fast-curing adhesives that provide good bonding strength.

- UV-curable adhesives cure upon exposure to UV light, offering quick and efficient bonding.

By understanding these principles and techniques, businesses can achieve effective silicone rubber bonding, leading to excellent durability and performance products.

Factors Influencing Silicone Rubber Bonding

When it comes to silicone rubber bonding, many influencing factors can directly impact the quality and effectiveness of the bond. A comprehensive understanding of these factors can improve end product and process efficiency.

Surface Properties and Preparation

1. Importance of Smooth Surface Preparation for Optimal Bonding

Proper preparation is of paramount importance to achieve optimal bonding. Ensuring the silicone rubber surface is smooth, clean, and free from contaminants like dust, grease, or volatile organic compounds (VOCs) can significantly enhance the adhesive’s grip and overall bond strength.

2. Exploring Techniques for Cleaning and Activating Silicone Rubber Surfaces

There are several techniques for cleaning and activating silicone rubber surfaces. These range from simple hand cleaning with a solvent to more complex processes like corona and plasma treatment. Hand cleaning with a solvent can remove surface contaminants. At the same time, corona and plasma treatments work on a microscopic level to increase the surface energy of the silicone rubber, promoting better adhesion.

Bonding Performance and Long-Term Stability

1. Durability and Resistance to Environmental Factors

The durability and resistance to environmental factors are also significant in determining the bonding performance. Silicone rubber and adhesives resist harsh environmental conditions, including heat, cold, moisture, UV light, and chemical exposure. This resistance contributes to the bond’s longevity, making silicone rubber a preferred material in highly durable applications.

2. Matrix Materials and Complex Structures on Bonding Performance

Lastly, matrix materials and complex structures play a role in bonding performance. For instance, bonding silicone rubber to a different material may require a specific adhesive or bonding technique. Moreover, the design of complex structures might call for an adhesive with specific properties, such as flexibility or thermal stability.

By considering these factors, you can optimize the bonding process and ensure the performance and longevity of your silicone rubber applications. This understanding is key to creating durable and effective solutions with silicone rubber.

Advances in Silicone Rubber Bonding

In the field of silicone rubber bonding, we’ve seen significant strides toward introducing novel approaches to augment surface energy and adhesion, along with advances in surface modification to bolster bonding performance.

New Approaches to Enhance Surface Energy and Adhesion

The technology around bonding has seen numerous breakthroughs, opening up new avenues for enhancing surface energy and adhesion. Here are a few noteworthy advancements:

- Development of fabrication processes allowing the inclusion of cross-linking agents that augment the material’s adhesion properties.

- The utilization of plasma treatment, a method known for significantly boosting the surface energy of silicone rubber, ensures superior adhesion when bonding with adhesives.

Surface Modification in Improving Bonding Performance

Alongside the above developments, surface modification techniques are making leaps forward. Some of these advancements include:

- UV light, known as UV curing, alters silicone rubber’s surface properties, leading to a robust, chemical-resistant, and smooth surface, enhancing bonding performance.

- Exploration of nano-coating technologies which can increase the surface energy, improving adhesion without affecting the bulk properties of the silicone rubber.

In a major breakthrough, researchers have even developed self-healing silicone rubber. This innovative material can repair itself when damaged, potentially extending the lifespan of silicone rubber products significantly.

As the landscape of silicone rubber bonding continues to grow and evolve, it becomes even more evident that the potential of this versatile material is vast. With continuous research and development, we can expect even more innovative solutions to surface in the future.

The Revolution of Self-Healing Silicone Rubber: A Glimpse into the Future

As we delve deeper into the era of technological advancements, the concept of self-healing materials has transcended from the realm of science fiction to reality. At the forefront of this revolution is the innovative self-healing silicone rubber.

The Magic of Self-Healing

This remarkable material boasts an innate ability to repair itself when damaged. This means that:

- Cuts

- Punctures

- Significant physical damages

It can be healed, effectively restoring the original properties of the material.

Potential Applications

The advent of self-healing silicone rubber has opened up new horizons in various industries where durability and longevity are paramount, including:

- Automotive

- Aerospace

- Medical devices

How Does It Work?

The key to this extraordinary property is in the molecular structure of the silicone rubber. The polymer is infused with a reactive “healing agent”. When damaged, it triggers a reaction with this agent, setting off a healing process that binds the material back together.

The Future and Its Challenges

While the promise of self-healing silicone rubber is immense, it has challenges. The main issues lie in its large-scale production and practical application across various industries. More research is needed to streamline fabrication and ascertain its effectiveness in real-world applications. Yet, the potential is undeniably thrilling, bringing us closer to a world where durability takes on a whole new meaning.

Conclusion

We can’t emphasize enough the crucial role of silicone rubber and its bonding techniques in diverse industries, powering innovative and robust products. This journey, through its distinct properties, bonding challenges, and thrilling advances in its applications, underlines the importance of our understanding and exploitation of this material.

To enrich your grasp on this versatile material, we invite you to explore more about silicone rubber’s applications and cutting-edge advancements in our comprehensive resources. Remember, knowledge is power, especially when applied to drive business growth and innovation.

Unlock the Potential of Silicone Rubber Today!

Explore the world of durable, versatile, and innovative silicone rubber. At Hongju Silicone, we provide top-quality silicone products catering to many industries. Don’t let your ideas stay ideas – actualize them with the optimal silicone solution. To glimpse our diverse and high-grade product range, visit our products page.