Material’s hardness is an important factor for the viability of an application material. But how can we measure flexible materials like rubber and plastic? The shore hardness scale provides a definitive answer.

This post fully explains the mystery of it and discusses the Shore A, Shore D, and Shore OO scales in detail. Let’s get started!

What Is Shore Hardness Scale?

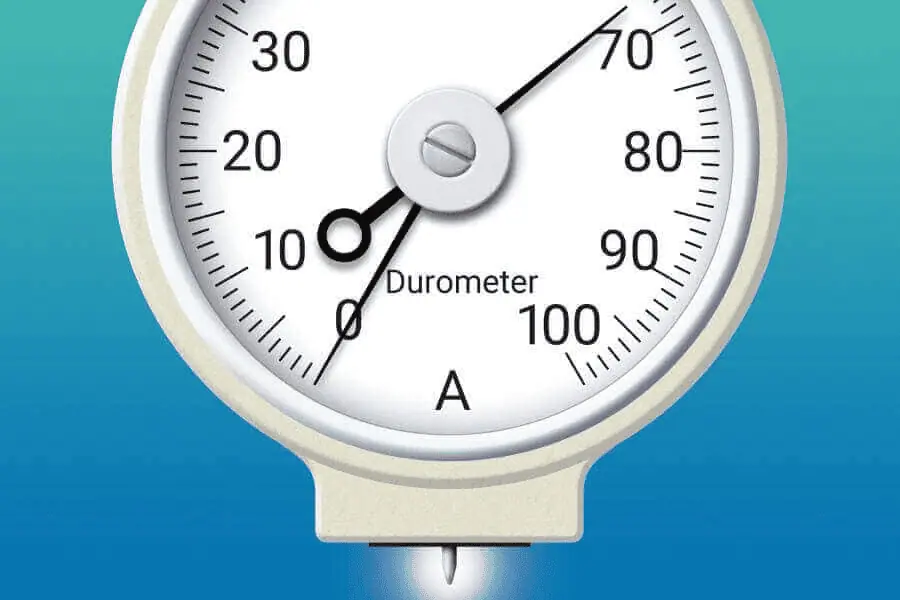

The device used to carry out the shore hardness test is called a shore durometer, or shore hardness scale.

The Shore durometer is an instrument used for measuring the material’s hardness, generally rubbers, semi-rigid plastics, hard plastics, and thermoplastic elastomers.

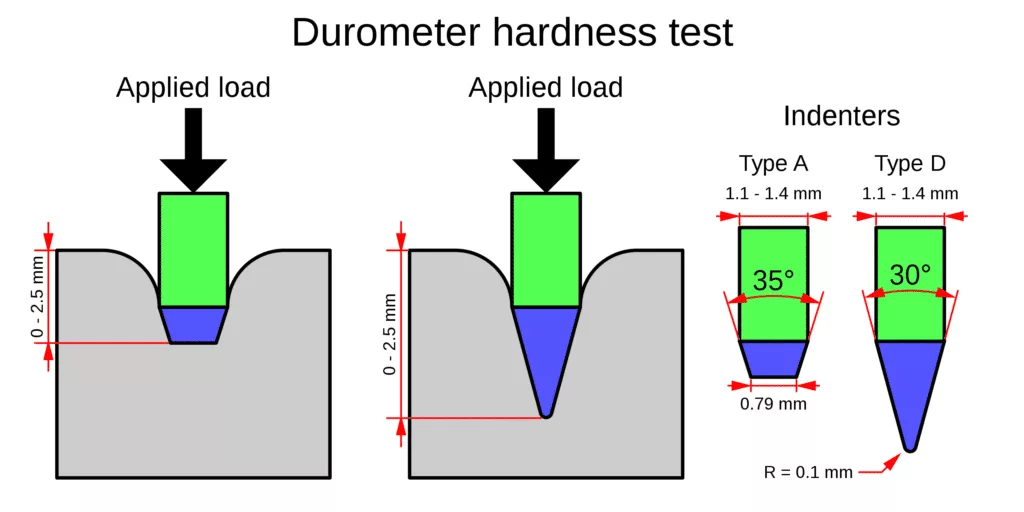

The hardness value is determined by how far the durometer’s indenter presses into the sample.

The Shore hardness scale is a system of letters and numbers used to classify the hardness of flexible materials like rubber and plastic.

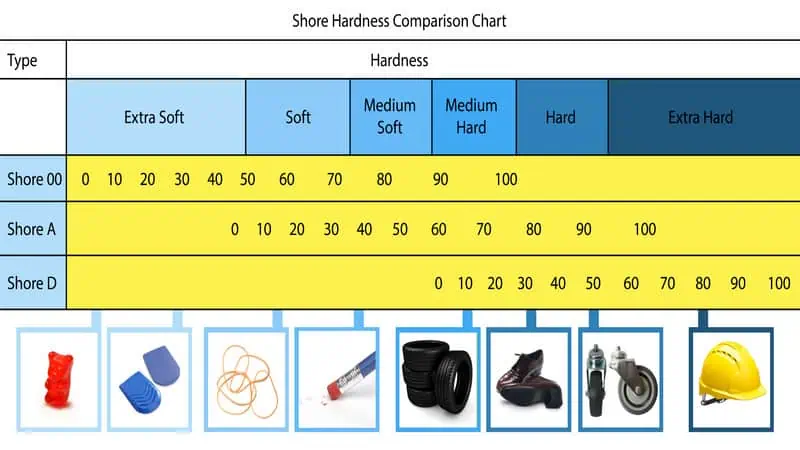

From super-soft gels to very rigid plastics, these materials vary greatly in their firmness, so different Shore scales came out.

This standardized system provides a common standard for everyone to measure and discuss the relative hardness of materials.

How do you Calculate Shore A Hardness?

A durometer is the tool used to measure material hardness. According to the American Society for Testing and Materials (ASTM) D2240 standard, the Shore durometer test is internationally recognized for measuring the indentation hardness of rubber, thermoplastic elastomers, and some plastics.

It works by pressing a spring-loaded metal rod with a cone-shaped tip into the surface. The deeper the rod indents, the softer the material is.

And the hardness is rated on a scale from 0 to 100. For instance, softer materials in lower numbers are great for low-pressure seals that need to conform to uneven surfaces. And harder materials in higher numbers are better for high-pressure seals.

Following are the testing criteria for the shore durometer hardness test.

- Steel Rod Diameter: 1.1 mm to 1.4 mm

- Rod Tip Angle: 35°

- Tip Diameter: 0.79 mm

- Applied Force: 8.064 N (822 g)

The format for shore scale labeling is a number first, then the word “shore,” and finally, the type of testing. For example, a standard O-ring has a durometer value of 70 Shore A.

“70” shows the relative hardness of this material compared with other materials tested. “Shore” represents the test methodology, and “A” shows the sub-type of shore testing.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Shore Hardness Scales

The numbers on a shore hardness scale are directly linked to material hardness. Here, higher numbers indicate a higher hardness value. And the letters are an indication of the test method.

There are 12 shore hardness scales, represented by the letters A, B, C, D, E, M, O, OO, DO, OOO, and OOO-S. Shore OO, O, B, C and H are rare within the plastics and rubber industry.

Shore A and Shore D are the two most commonly used scales for measuring rubber hardness. The numbers on a shore scale are directly linked to material hardness. Here, higher numbers indicate a higher hardness value.

While the letters are an indication of the test method. There are 12 shore hardness scales, represented by the letters A, B, C, D, E, M, O, OO, DO, OOO, and OOO-S.

Shore or Type A and Type D are the two most prominent scales for measuring material hardness for rubbers, plastics, and nonmetals.

Shore A

Shore A scale is used for soft materials with relatively high flexibility, like semi-rigid plastics or soft silicone rubber. This scale uses a gram force of 822 g (~1.8 lbs) to push a steel rod into the test sample.

You need to use an appropriate force for softer materials, as too much force will pierce through the material.

Commercially, you will find durometer scales with Type A printed on them. These are shore A scales and will give you a shore rating when you press them against a material surface.

Example:

- A rubber band generally has a durometer hardness rating of 25 Shore A scale.

- A tire tread has a hardness of 70 A while a leather belt can have a hardness of 85 A.

- A Soft wheels of roller skates & skateboards 75 Shore A

Shore D

The Shore D classification is used for determining the hardness of more rigid materials with little flexibility. Common materials associated with the Shore D scale include hard vulcanized rubbers, semi-rigid plastics, and rigid plastics.

This scale uses a gram force of 4536 g (~10 lbs) to push a steel rod into the test sample.

Example: Truck tires have a standard durometer hardness rating of 55 Shore D.

Shore OO

Shore OO is one of the less common scales for measuring shore hardness. It measures the softest materials like rubber gels and soft-touch rubber.

Materials tested on the Shore OO scale are so soft that any large force would damage the test samples. Hence, this test is conducted using a small gram force of 113 g (~0.25 lbs).

Example: Bubble gum has a durometer hardness rating of 20 Shore.

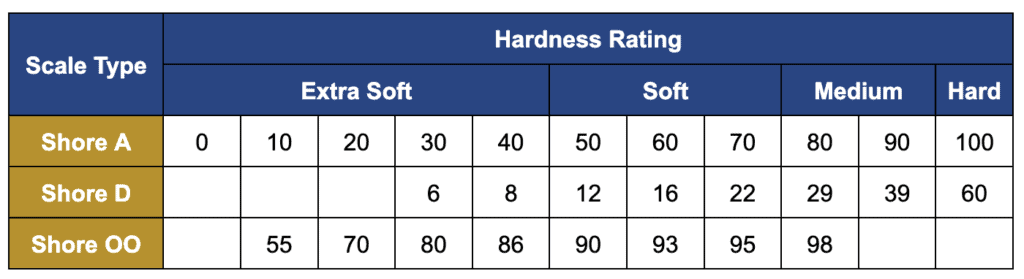

Shore Scale Conversion

Some materials that lie between soft and rigid can be tested using both Shore A and Shore D scales.

In such cases, you can use a simple conversion table to determine the Shore A scale value corresponding to the Shore D scale.

This conversion can also be applied to all the shore hardness scales, though compatibility is more limited.

These hardness scales were created so that everyone could discuss these materials and have a common point of reference for them.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Importance of Shore Hardness

The Shore Hardness Scale is a vital tool for evaluating soft materials like rubber and plastic. It provides a clear way to measure and categorize materials for a range of applications.

Engineering and Manufacturing: With so many types of rubber and plastic available, the Shore scale provides a consistent, scientific way to distinguish between them. This helps engineers and manufacturers choose the right material for different products.

Material Strength and Flexibility: The Shore hardness rating directly relates to a material’s strength and flexibility. Higher numbers on the scale mean the material is stronger but less flexible.

This is essential because silicone rubber is often chosen for its flexibility, but many products also require a certain level of firmness to ensure durability.

Product Longevity: Generally, harder materials are more durable. Materials rated 50 Shore D or higher can last for decades.

Research published in the Polymer Degradation and Stability journal indicates that silicone rubber with a Shore A hardness between 50-70 exhibits optimal resistance to compression set (less than 25% after 22 hours at 150°C), a key factor in maintaining seal integrity and product longevity under sustained stress.

However, this isn’t suitable for all products.

Product Safety: Product safety is crucial. For example, children’s toys must be safe. A soft rubber toy should be made from flexible rubber that ranks around 50 Shore A, which is similar to a pencil eraser. This ensures the toy is safe and soft enough for kids.

Shore Hardness Scale Examples

Shore OO: Shore OO is used for very soft materials, and it is commonly used as a reference for foods.

Soft food and snacks like marshmallows or gummy bears hover around 10 Shore OO on the durometer scale. Non-food products like gel insoles are around 30 Shore OO.

Shore A: Shore A scale has a much more comprehensive range of products under its umbrella. Food products like bubble gum are made from soft materials on a 20 Shore A scale.

A material with a hardness of 50 Shore A feels like a firm, pencil-top eraser or the surface of a golf ball.

While leather belts can go up to 80 Shore A scale. Ebonite rubber is at the peak of the type A scale, with an average rating of 100 Shore A scale.

Shore D: Shore D also has a wide range of products and materials. But unlike type A, many more plastics are listed here.

Plastic materials like HDPE are often used for manufacturing hard hats. They have an average value of 75 Shore D.

Additionally, you will find that many wood and paper products are also measured using the Type D scale. Textbook covers are 40 Shore D. A material with a hardness of 70 Shore D is very hard.

It’s difficult to indent with a fingernail, similar to a hard hat or a wooden ruler.

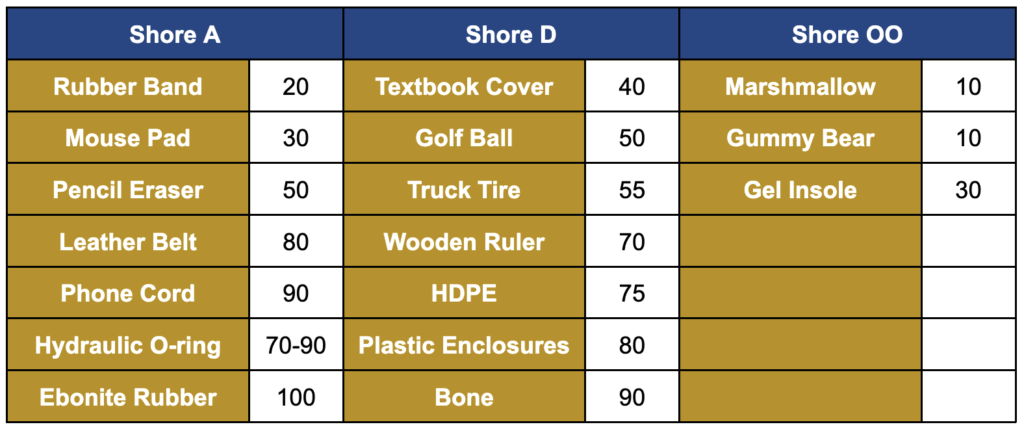

The following is a simple table of standard shore hardness scales and their associated materials and products.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

A Guide to Choosing the Right Hardness

The following is a simple checklist to help you choose the correct Shore hardness for your product or specific application.

Step 1: Consider the Application and Feel

First, think about how the product will be used and the desired feel your need.

- For a soft, flexible feeling: Choose a lower Shore A hardness. This is ideal for products like children’s toys, gel insoles, or soft gaskets that need to conform to an irregular surface.

- For a firm, durable feeling: Go with a higher Shore A or even a Shore D value. This is better for products that require rigidity, such as hard protective cases or industrial parts.

Step 2: Consider Pressure and Stress

The amount of pressure a material will experience is a critical factor in selecting the right hardness.

- For low-pressure applications: A softer material with 50 Shore A, is perfect for seals that need to fill small gaps and require minimal force to create a tight seal.

- For high-pressure applications: A harder material with 70 Shore A or higher is necessary to withstand more pressure without deforming.

Step 3: Consider Environmental Factors

The environment the product will be used in affects the necessary material hardness and type.

- For chemical resistance: Choose a material that can resist specific chemicals or cleaning agents. The hardness may also need to be higher to maintain its shape when exposed to these substances.

- For high-abrasion environments: Select a harder material with 50 Shore D that can resist cuts, tears, and abrasion from repeated uses, prolonging the product’s life.

Conclusion

The Shore Hardness Scale is essential for measuring material hardness and firmness in manufacturing.

From soft gels (Shore OO) to rigid plastics (Shore D), this system helps manufacturers to select the right materials to ensure product reliability, safety, and functionality across medical, automotive, and consumer applications.

Partner with Hongju for High-Performance Silicone Rubber Solutions!

At Hongju, we combine advanced manufacturing expertise with customer-centric flexibility to deliver precision rubber products tailored to your exact needs. Our comprehensive capabilities include compression molding, injection molding, die-cutting, and rapid CNC prototyping.

Request a free project consultation and quote! Experience Hongju’s exceptional quality and fast turnaround today!

FAQs

Q1:What is the Shore Hardness Scale and why is it used?

The Shore hardness scale is an industry-standard method for measuring the resistance of elastomers and plastics to indentation. This provides a critical, objective metric for comparing material flexibility and softness.

Q2:How is Shore A Hardness calculated?

Shore A hardness is not calculated but directly measured using a calibrated durometer. The device applies a defined force with an indenter; the depth of penetration correlates to a hardness value on a 0-100 scale.

Q3:How do I choose the right hardness for a sealing gasket?

For static seals, choose a softer material (Shore A 30-50) to ensure proper compression and sealing; for dynamic seals, a harder grade (Shore A 60-80) may be needed for durability.

Q4:How can Hongju help with my specific hardness requirement?

Hongju offers tailored silicone rubber formulations and expert consultation to match the exact Shore hardness your project demands, ensuring optimal performance and reliability.