The seal construct includes an elastomer sprung leading sealing lip with which it’s in contact area with the shaft. Seals are designed with a wide range of sealing lip configurations to maximize oil retention and contaminant prevention.

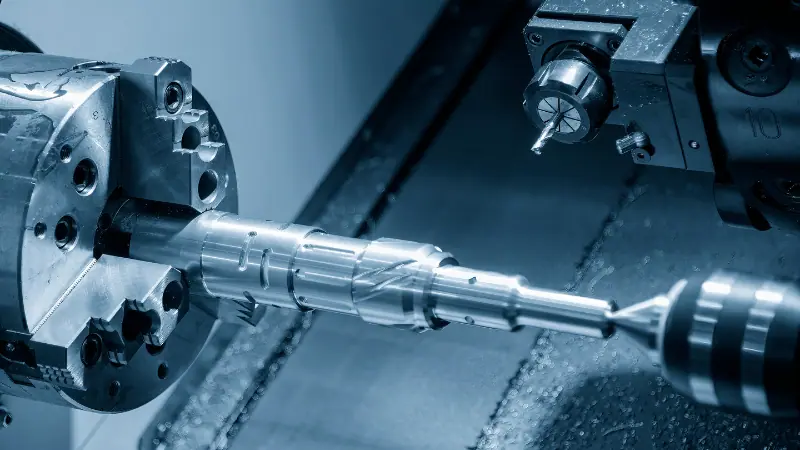

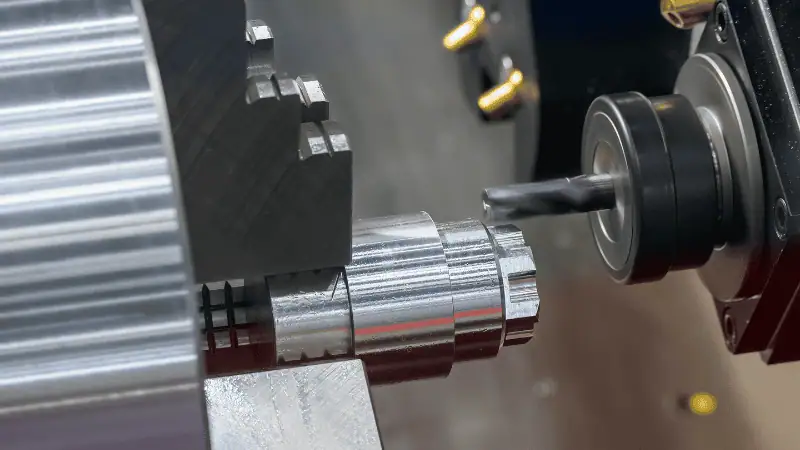

They are made in different shapes and sizes depending on the intended purposes. They can either be tapped or untapped with holes for axial mounting, grooved to allow snap rings and channeled for keyways; examples have been hydraulic pump seals and axle seals.

Other shafts are solid or hollow, while others come in male and female pairs like power steering and valve stem seals.

What are Rotary Shaft Seals?

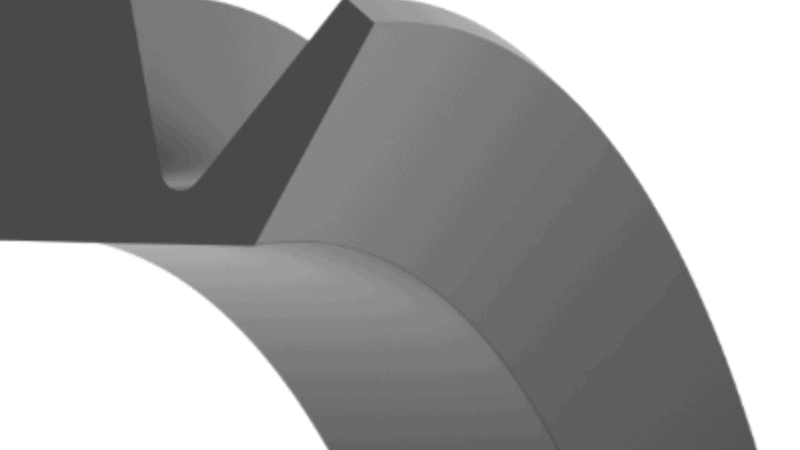

Rotary shaft seals are achieved by bringing both the seal, now called the lip seal, together in a line contact such that an axial angle is formed.

To ensure this angle has formed, the air or the outer part of the seal is usually smaller than the oil or the inside part, this angle difference creates a valve concept, but with the rotary sealing edge, nothing goes in or comes out.

This angle is usually altered with different types of rotary shaft seals because the air side is thinned further to create a pressure distribution at the seal contact area, depending on the workforce delivered to the shaft.

Keep in mind that the steeper the slope on the oil side of the shaft, the wetter the seal will be.

Application of Rotary Shaft Seals

Shaft seals have been used in most if not all, industrial or home installations that perform their duties with an initiation of a rotary or rotation motion.

These will require rotating equipment or seals specifically where liquids, oil, or electricity cross by proximity while the installation maintains its rotary motion.

Kitchen Uses

Shaft seals are used in blenders, ribbon blenders, and mixers. These machines mix, process, and convey liquids, gels, powders, and slurries.

Industrial Uses

With the heavy industrial application, we have hydraulic pumps, axel seals, stem valve seals and strut seals, power steering seals, and much more.

You could categorize the application of rotary shaft seals by the position, role, or state of the installation device or equipment. These could be:

- Submerged installation systems like with the tidal turbines and water controlled environment.

- The centrifugal installation is mainly the rotary elements.

- Propulsion installation covers radial shaft seal applications like ferries, cargo vessels, and many other heavy installations.

Rawhide Adopting Products

There are so many applications of rotating shafts, and with time, they have also improved the efficiency of the rotary shaft seals.

Most products that usually adopt rawhide materials from tanneries have been replaced with the garter spring. This has significantly helped with the changes in elastomeric materials and lip seal wear compared to rawhide.

Types of Rotary Shaft Seals

We could say there are no types since they all deal with rotary elements, which is true but depending on their application use and the intensity of their intended task will require a variety of rotary shaft seals to choose from.

Types are mainly achieved by varying the axial angle of the outside sealing lip and inside seal angles.

There are other factors and sealing effects that determine the type of shaft seal to be used:

- Condition with which the rotary shaft seal installation will operate, like temperature, pressure difference, and RPM

- The suitable lubricant used inside the installation device will also determine the kind of shaft seal. The lubricant could be petroleum, grease, or water.

- The nature of the material used in the installation system will also determine the type of radial shaft seal used, like rough or smooth surface materials.

- Above all, the surrounding environment will also determine the types of radial shaft seals. Desert, tropical, or swampy environments will highly contribute to the type of rotary shaft seal used to ensure optimum efficiency of the rotating shaft and the whole installation system.

Oil Seals

They prevent installation system fluids from being contaminated from the outside or any leakage towards the outside. They have three main components: a garter spring, a metal case (insert), and a polymer seal.

A garter spring always ensures the efficiency of the rubber sealing, while the metal case or insert holds the seal to the recessed groove or bore. Still, it enhances the seal’s rigidity and strength, preventing leakages and contaminations.

IM Seals

Their primary function is to guide the piston rod and a piston cylinder in an installation system by absorbing all transverse force and chemical attacks.

They have a high tolerance to high-pressure environments and are deemed to last longer than all radial shaft seals. The materials used for their inner components are available in numerous instances:

- Long life and low friction types

- Two dynamic peaks

- Channel for oil reserve, which increases life and eliminates torque

- Long-term sealing and enhanced low pressure

- Zero compression energizers

- Numerous sealing points for rotary elements

PTFE Lip Seals

These are formed from wear-resistant polymers and the composite of low friction, poor lubricated environment, soft shafts, high-speed surface, and long life.

A supporting O-ring on the seal prevents the seal from rotating hence an improvement from elastomeric seals compared to mechanical face seals.

V-Ring Seals

They are made purely of elastomers without fabric or any metal sheet reinforcement. They can be stretched and pushed over other components of a device in question; hence very easy to install.

Their thin, tapered lip seals are generally mounted on a shaft surface against a “counterface” at exact right angles to the shaft.

Even though the V-ring can tolerate misalignment forces on the shaft, it is very reliable on eccentric rotation or out-of-round shafts.

Material Specifications for Rotary Shaft Seals

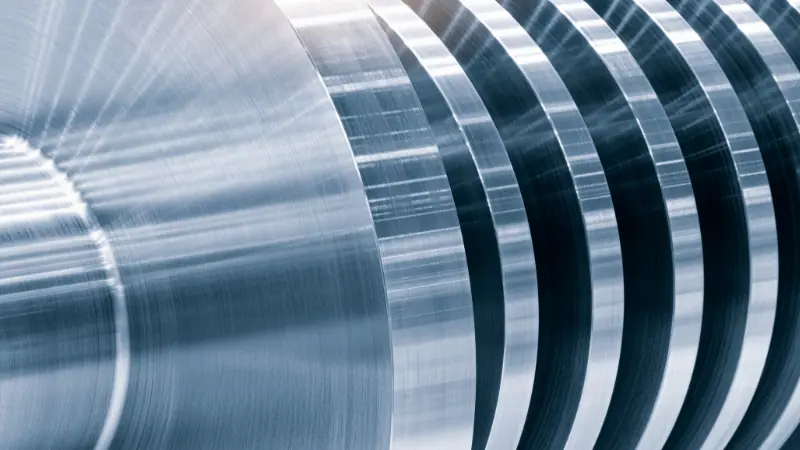

The most reliable way to achieve the efficiency of a rotating shaft seal is by coating with PTFE, also known as polytetrafluoroethylene. This is highly resistant to tear and wear and provides low friction on the rotary shaft.

This property also allows being stretched or pushed through the highest or thinnest shaft surface and device with no or less abrasion and torque.

Most rotary seal material is:

- Carbon steel

- Composite materials

- Plastics

- Alloy steel and stainless steel

- Aluminum

Merits and Demerits of Rotary Shaft Seals

Merits

PTFE advantages generally exhibit the best properties in rotary seals with their flexibility with high temperatures and tensional forces.

User-Friendly

They are user-friendly because you will not require an expert to repair your installation.

Long Lasting

Their long life is an advantage but also an added value to your resources since you won’t be replacing them often compared to other seals; hence cost-friendly.

Easy Availability

High user-friendly, and efficiently provided rotary seals make them more readily available in the market than other unknown shafts.

Drawbacks

Precision is usually required when preparing and installing rotary seals despite their tendency to tolerate misalignment. They can also pose a problem to the shaft surrounding the surface or elements and the whole installation device.

Seal Failure

Their effectiveness can be harmed when sealing countenances is not done smoothly. This can also cause pivotal end play the shaft lining vital to the whole installed system.

Choosing the Right Rotary Shaft Seal

The main factor one should always consider while choosing the rotating shaft is usually the shaft seals’ properties which should counter the surrounding hazards of the installation device. These are;

- Lubrication state of the installation system

- Temperature and pressure exhibited by the installation

- Environmental factors include the surroundings, such as sea, freshwater, or desert.

- The texture of the installation surface is its roughness or smooth surface.

- The shaft and installation system material used, whether complex or tender.

- Above all, maybe you should consider pricing depending on your budget.

Conclusion

Rotary shaft seals are used in our daily life routines and applications and have evolved from hiding skin to synthetic rubbers and polymers in their components. This has increased the efficiency and longevity of rotary shaft seals.

Even though their behavior of wear and tear is still unpredictable, even after considering the most factor that favors the installation, this comes with high maintenance costs and environmental pollution.

Keep yourself updated with the best shaft seals available at Hongju.

Contact Hongju for the Best Rotary Shaft Seals

If the above article was not enlightening enough, get a free consultation on your best rotary shaft seal work by an expert at Hongju. Hongju is a legend in the business and has been collaborating with numerous businesses.

Contact us to ensure that the rollout of Rotary shaft seals is streamlined and effective.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.