Our comprehensive guide shines a light on the top 10 plastic over-molding companies in China for 2024, celebrated for their mastery of the injection molding process, robust quality control, and innovative mold design. Let’s dive in and find the perfect plastic over-molding manufacturer for your manufacturing requirements!

An Overview of the Plastic Overmolding Industry

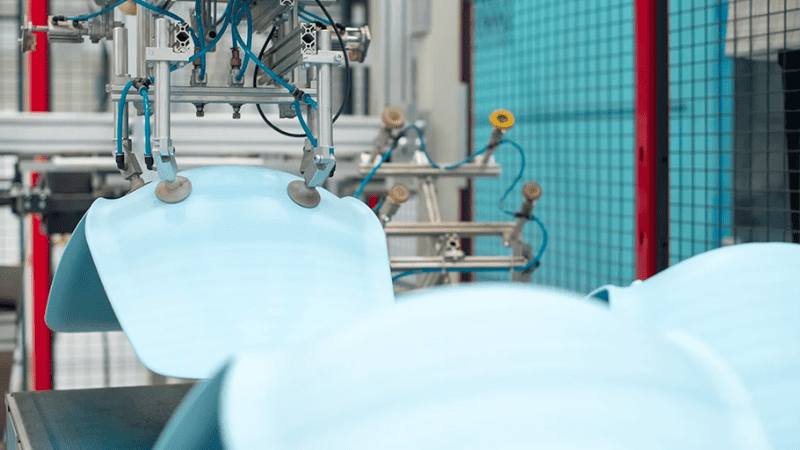

Plastic over-molding, a key technique in the injection molding industry, seamlessly combines different materials to craft products with superior durability, aesthetics, and functionality.

This method is crucial across various sectors, notably automotive and consumer electronics, offering advantages like design versatility and cost-efficiency.

Notably, China’s recent data indicates a production surge, with a 2.8% increase to nearly 7 million tons in December alone, highlighting the method’s growing importance. This growth, part of a 3.0% annual rise to 74.89 million tons, marks a rebound from previous slowdowns, highlighting the sector’s resilience and its significant contribution to the global manufacturing ecosystem.

This trend, reflecting a gradual yet steady resurgence after the pandemic-induced lull, emphasizes the enduring demand and innovation within the plastic over-molding sector.

Key Factors to Consider When Choosing a Plastic Overmolding Manufacturer

Selecting the right plastic over-molding manufacturer is pivotal, blending numerous factors to ensure the success of your project. Here’s a detailed look:

1. Reputable Plastic Injection Molding Company

- Proven Track Record: Choose a manufacturer with a solid history of delivering high-quality plastic injection molding products.

- Positive Client Feedback: Look for manufacturers with glowing reviews, indicative of their commitment to customer satisfaction.

2. High-Quality Material Standards

- Premium Thermoplastic Resins: The durability of your over-molded parts hinges on using top-notch materials.

- Rigorous Injection Molding Process Control: A stringent quality control system is essential to maintain consistency in every product batch.

3. Essential Certifications

- ISO and Other Standards: Certifications like ISO demonstrate a plastic molding company’s adherence to international manufacturing quality and management standards.

- Industry-Specific Approvals: For specialized projects, ensure the plastic injection molding manufacturer holds relevant industry certifications.

4. Cutting-Edge Technology

- Modern Injection Molding Machines: Advanced equipment translates to precision and efficiency in producing plastic injection molds.

- Innovative Manufacturing Processes: Look for manufacturers that leverage rapid tooling or insert molding to enhance product value.

5. Cost-effectiveness and Timeliness

- Competitive Plastic Injection Molding Prices: Quality comes at a cost, but prices should remain competitive within the industry.

- Efficient Turnaround Times: A reliable manufacturer meets deadlines, crucial for maintaining project timelines.

6. After-Sales Service

- Responsive Customer Support: Effective communication post-manufacture indicates a manufacturer’s commitment to their client’s success.

- Warranties and Support: A mark of reputable plastic injection molding company is standing behind its products with robust support services.

Top 10 Plastic Overmolding Manufacturers in China

Explore China’s leading plastic over-molding manufacturers, known for their innovative approaches and quality products.

| Position | Brand Name | Year Established | Location | Employee Size |

|---|

This table ranks these manufacturers based on quality, product range, market share, revenue, and customer service, highlighting their unique strengths in advanced technology, mold design, rapid prototyping, and high-volume production.

Whether catering to specific industries like automotive and electronics or offering a diverse range of plastic products and services, these manufacturers stand out for their innovative solutions and commitment to delivering high-quality molded parts.

1. Hongju Silicone Co, Ltd.

Since its inception in 1999, Hongju has emerged as a leading manufacturer in the silicone molding industry in China, specializing in high-quality silicone rubber products. It is known for its commitment to international quality standards and innovative products.

Hongju serves various industries, including electronic products, home appliances, and the automotive sector, with a comprehensive range of services from mold making to rapid prototyping and mass production.

Pros:

- Exceptional manufacturing capabilities in silicone molding and plastic parts, ensuring tight tolerance and complex shapes.

- Rapid prototype service within 3-5 work days, highlighting their advanced equipment and efficient manufacturing process.

- Strong commitment to environmental sustainability with the use of eco-friendly materials, complemented by responsible after-sales service.

Cons:

- Specialization in silicone might limit options for clients seeking broader plastic molding solutions.

- Custom and low-volume orders might come at a premium, reflecting their niche focus on high-quality, customized products.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

2. Run Sheng Plastic Hardware Co., Ltd.

Run Sheng Plastic Hardware Co., Ltd., located in the industrious city of Dongguan, is a powerhouse in the plastic injection molding world. This company is a one-stop shop, offering everything from CNC machining to die casting, and boasts a suite of plastic injection molds that cater to a wide-ranging clientele. With a hefty workforce and significant market reach, Run Sheng cements its reputation as a go-to source for plastic parts and more.

Pros:

- A broad spectrum of services including rapid injection molding and precision mold design.

- Expertise in high-volume thermoplastic injection molding and liquid silicone rubber products.

- Leverages advanced mold manufacturing techniques to deliver parts that hit the mark every time.

Cons:

- Large-scale operations might mean longer waits for custom projects.

- The extensive product lineup could lead to less focus on niche client needs.

3. Five-Star Tooling

Established in 2006, Five-Star Tooling Ltd has carved its niche as a distinguished provider of injection molds, die casting, and precision components, catering to a global clientele from its bases in Shenzhen and Dongguan, China.

Their commitment to quality is evidenced by ISO 9001 and IATF 16949 certifications, ensuring that every molded part and CNC component adheres to tight tolerances and high-quality standards.

With over 120 skilled employees and a 6000-meter facility equipped with state-of-the-art machinery like DMG 5-axis CNC and Hexagon CMM machines, they guarantee precision within ±0.005mm.

Pros:

- Specialises in a wide array of molds, including multi-cavity and unscrewing molds, catering to consumer products and various manufacturing needs.

- Emphasizes stringent quality management, from raw material inspection to final assembly, ensuring cost savings and numerous client benefits.

- Advanced project management is supported by a customized ERP system for efficient and transparent processes.

Cons:

- The focus on high precision and quality might be reflected in the pricing, potentially higher than in some local Chinese companies.

- The comprehensive quality and project management processes might extend lead times for urgent projects.

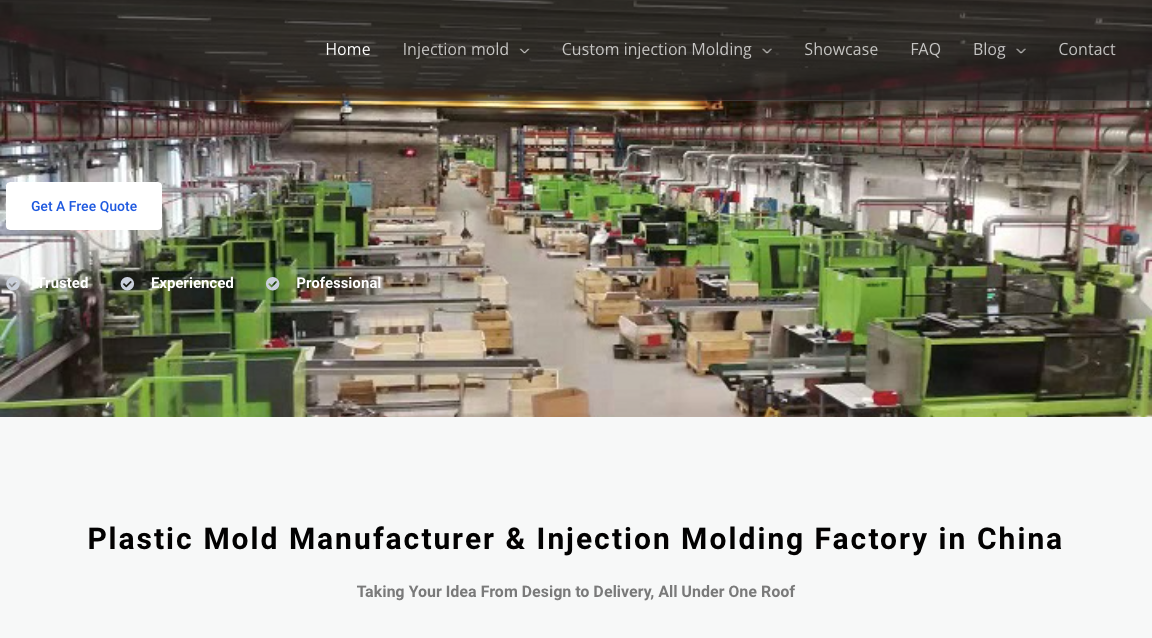

4. Stebro Mold

Stebro Mold, an ISO 9001:2015 certified company, has been a frontrunner in the plastic injection molding industry since its establishment. Specializing in injection molds and plastic injection molding, Stebro Mold offers comprehensive services from design to delivery, ensuring high-quality products at economical prices.

Their expertise spans various consumer products, employing advanced mold-making techniques and thorough research to achieve tight tolerance and innovative products.

Pros:

- Wide range of services including die casting, plastic injection mold making, and liquid silicone rubber molding.

- Commitment to quality with rigorous quality control in manufacturing, ensuring high-quality products.

- Offers injection molding with fast turnaround times, providing cost savings and numerous benefits to clients.

Cons:

- Specialization may limit the diversity of plastic molds available.

- High demand for their precision services could lead to longer wait times for project initiation.

Stebro Mold’s dedication to delivering comprehensive solutions and its ability to service a broad spectrum of industries make it a go-to plastic molding company for businesses seeking reliable and innovative manufacturing partners.

5. TEAM Rapid

TEAM Rapid, renowned for its rapid injection molding and comprehensive plastic molding services, stands out as a leading figure among plastic injection molding companies in China.

With an ISO 9001:2015 certification, this company ensures each plastic injection mold and molded part meets stringent quality standards. Specializing in both low and high-volume production, TEAM Rapid provides cost-effective solutions across various sectors.

Pros:

- A wide array of plastic injection molding services, supporting diverse project requirements with precision and efficiency.

- Notable for rapid prototyping and tooling, allowing for quick market entry and significant cost savings.

- Strong focus on quality control, ensuring high-quality products that adhere to international standards.

Cons:

- The rapid production pace might limit the customization depth for highly specialized projects.

- As a sought-after company, lead times may vary based on the complexity and volume of orders.

6. JMT Automotive Mould Co.

JMT Automotive Mould Co., founded in 2005, has carved out a significant space for itself in the automotive industry as a distinguished plastic injection mold manufacturer. Specializing in a range of molds, including those for home appliances and automotive parts, JMT is committed to European and American standards of excellence.

Pros:

- Renowned for producing high-quality injection molded parts, meeting stringent international criteria.

- Offers comprehensive services from design to manufacturing, backed by a modern management system.

- Competitive prices paired with a global market presence in over 100 countries, showcasing their scale as a trusted Chinese manufacturer.

Cons:

- Specialization in automotive and home appliance molds might limit offerings for other industrial needs.

- The focus on high standards and extensive reach might lead to longer project lead times for customized orders.

JMT’s commitment to precision and customer satisfaction has established them as a reliable partner in mold making and sheet metal fabrication. Their dedication to maintaining a robust OEM client base is evidence of their quality and service.

7. Longxiang Group Limited

Longxiang Group Limited, established in 2000 in Dongguan, has evolved into one of China’s most reputable plastic injection molding companies. With a strong emphasis on quality and innovation, Longxiang specializes in producing plastic injection molds for a wide range of applications, including automotive parts and electrical appliances.

Their commitment to excellence is supported by ISO 9001:2015 certification and a state-of-the-art facility spanning 5000 square meters.

Pros:

- Expertise in diverse plastic parts, serving industries from automotive to consumer electronics.

- A focus on high-quality products, backed by thorough research and advanced manufacturing processes.

- Offers injection molding and other services, ensuring cost-saving solutions for clients.

Cons:

- Specialization in specific mold types might limit variety for some projects.

- The high standard for quality could be reflected in premium pricing for their services.

8. Sositar Mould Co., Ltd.

Sositar Mould Co., Ltd. is renowned for its expertise in plastic injection molding, providing quality molds and parts across various industries. Their dedication to precision and affordability makes them a preferred choice for many.

Pros:

- Specializes in high-quality plastic injection molding, ensuring durable and precise parts.

- Offers comprehensive services from mold design to final production, facilitating seamless project execution.

- A competitive pricing structure provides cost savings for clients without compromising on quality.

Cons:

- Focus primarily on plastic injection molding might limit options for projects requiring broader manufacturing techniques.

- High demand for their specialized services could result in longer wait times for project commencement.

9. Powerjet Plastic Machinery Co., Ltd.

Powerjet Plastic Machinery Co., Ltd., based in Guangdong, China, is a prominent manufacturer and exporter in the plastic machinery industry. They specialize in producing a wide range of injection molding machines, including standard models and specialized IBM (Injection Blow Molding) machines, catering to various manufacturing needs.

Pros:

- Offers a diverse lineup of injection molding machines for different applications.

- Renowned for reliability and efficiency in machinery production.

Cons:

- May have a specialized focus that might not suit all project requirements.

- Details on after-sales support and service responsiveness are not readily available.

10. Ecomolding Co., Ltd.

Ecomolding Co., Ltd. specializes in high-precision plastic injection molded components and assemblies, positioning itself as a key player among plastic injection molding companies. With over a decade of experience, they offer a one-stop service from mold design to plastic injection molding, ensuring cost-effective solutions for custom mold manufacturing.

Pros:

- Focus on custom injection molding, delivering tailored solutions.

- Comprehensive services, from mold design to production, streamline the manufacturing process.

- ISO9001-2008 certified, ensuring high-quality products and services.

Cons:

- Specialization in custom projects might limit options for off-the-shelf solutions.

- The focus on detailed engineering and customization could lead to longer project lead times.

Final Thoughts

Choosing the right manufacturing partner is crucial to the success of your project, so consider all factors, from quality and experience to cost-effectiveness and service scope. Your ideal partner should not only meet your current needs but also support your future growth.

Why Choose Hongju for Your Plastic Overmolding Projects?

In the competitive landscape of plastic over-molding in China, Hongju distinguishes itself with unparalleled quality and affordability. Our expertise spans various industries, delivering custom silicone products designed for optimal performance. Embracing cutting-edge technology, Hongju ensures each product meets rigorous standards, solidifying our market presence.

Discover the Hongju difference on our website, and see why we are the top choice for your next project. Choose Hongju, where innovation meets excellence.