The integration of elements like carbon nanotubes and nano-silica into the polymer matrix has broadened LSR’s applications. From injection molding processes to the fabrication of medical devices, this material’s low glass transition temperature and high thermal conductivity make it an industry favorite. As we journey through this article, we will explore the intricacies of LSR, its nanotech applications, and its burgeoning value for silicone rubber producers.

What is Liquid Silicone Rubber?

Liquid Silicone Rubber, commonly abbreviated as LSR, is a type of two-component elastomeric material that cures or vulcanizes rapidly under heat. Unlike conventional high-consistency rubber (HCR), LSR is more fluid, making it exceptionally suitable for injection molding processes.

At its core, the chemical structure of LSR is primarily composed of silicon, oxygen, carbon, and hydrogen. This unique combination imparts LSR with low surface energy, allowing it to maintain resilience and flexibility over a broad temperature range. Its low glass transition temperature ensures that even under cold conditions, it remains flexible and does not become brittle.

Another noteworthy aspect of LSR is its impressive mechanical properties. Its tensile strength speaks of its capability to withstand stretching forces without tearing, and its thermal stability and chemical resistance make it suitable for various challenging environments.

Furthermore, LSR’s inherent properties of air permeability and high thermal conductivity make it stand out in applications requiring heat dissipation or breathability. Reinforcing fillers can be introduced to enhance specific properties, making LSR even more versatile in meeting industry-specific demands.

In essence, LSR is more than just a rubber. It’s a cutting-edge material with properties that can be tailored to fit a myriad of applications, and with the inclusion of nanotechnology, its potential is further magnified.

LSR Properties Beneficial for Nanotechnology

Liquid Silicone Rubber (LSR) stands as a beacon in the convergence of traditional materials and the wonders of nanotechnology. This integration brings forth applications that were once considered theoretical or overly ambitious. Here’s a deep dive into the key properties of LSR that synergize beautifully with nanotechnology:

- Radiation Shielding: LSR’s composition makes it an exemplary matrix material for radiation shielding endeavors. Its inherent characteristics efficiently attenuate detrimental radiation, safeguarding both equipment and users.

- Graphene Integration: LSR’s adaptability with graphene is noteworthy. This compatibility allows it to be incorporated into state-of-the-art nanoscale apparatus, amplifying their electrical faculties and overall efficiency.

- Electrical Insulation: One of LSR’s paramount qualities is its superior electrical insulation capabilities. When introduced to nanotech applications, it ensures that electrical interferences are minimal, leading to optimized device performance.

- Low Surface Energy: This property of LSR paves the way for a plethora of applications that require hydrophobic or non-stick attributes, making it versatile in the realm of nanotech.

- Thermal Stability: LSR’s capacity to retain its characteristics across an extensive temperature spectrum, when paired with nanotechnology, leads to solutions that can withstand extreme thermal variations.

The melding of LSR with nanotechnology is a testament to the limitless potential of materials science. LSR’s remarkable array of attributes makes it a linchpin in the rapid evolution and expansion of nanotechnological applications.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Use 1: Nanocomposites and Enhanced Materials

Liquid Silicone Rubber (LSR) stands as a pivotal component in the creation of advanced nanocomposites. When integrated with nanoscale materials, LSR transforms into a composite with properties that far exceed those of traditional materials. Here’s how this synergy manifests:

- Carbon Nanotube Reinforcement: By infusing LSR with carbon nanotubes, a remarkable increase in the material’s tensile strength and mechanical properties is observed. These nanotubes act as a reinforcing filler, strengthening the polymer matrix of the LSR and making it more robust and resilient to external forces.

- Nano Silica Integration: Incorporating nano silica into LSR enhances its thermal stability and resistance. This not only boosts the material’s heat resistance but also improves its overall thermal conductivity, making it more adept at handling and dissipating heat.

- High Thermal Conductivity Applications: The addition of materials with high thermal conductivity, such as certain metal nanoparticles, transforms LSR into a material that can efficiently conduct and distribute heat. This has crucial implications for industries where heat management is paramount.

- Chemical Structure Enhancement: On a molecular level, the inclusion of nanomaterials can tweak and optimize the chemical structure of LSR. This offers improved chemical stability, resistance to corrosive agents, and extended longevity.

- Improved Air Permeability: By manipulating the LSR at the nanoscale, its air permeability can be fine-tuned. This means the material can be tailored for specific applications, from those requiring high breathability to those where airtightness is essential.

In essence, the marriage of LSR and nanotechnology births nanocomposites with superior attributes. These enhanced materials cater to a diverse range of industries, offering solutions that are more durable, efficient, and versatile than ever before.

Use 2: Microfluidics and Lab-on-a-chip Devices

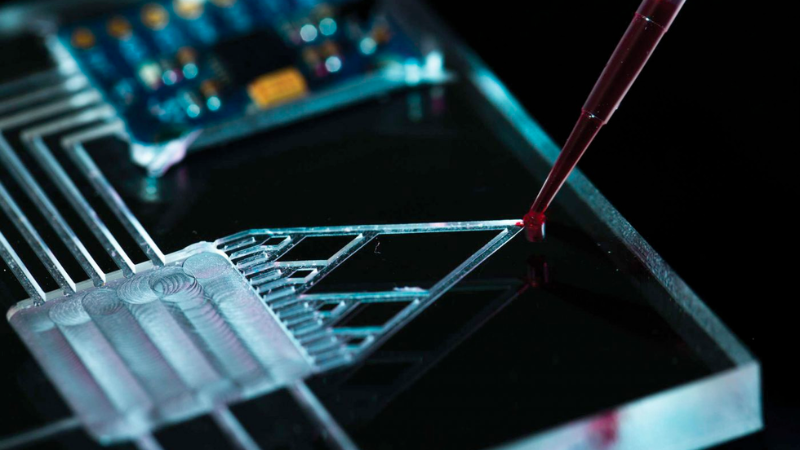

Microfluidics and lab-on-a-chip technologies have significantly transformed diverse sectors, notably medical diagnostics. A primary player in this transformation is Liquid Silicone Rubber (LSR), which offers several distinct advantages for these applications. Here’s a closer look at why LSR has become a cornerstone material for such devices:

- Biocompatibility: One of LSR’s standout properties is its exceptional biocompatibility. When we think about microfluidic devices specifically crafted for medical diagnostics, they often come into intimate contact with biological specimens like blood or saliva. LSR’s non-reactivity ensures that these samples remain uncontaminated, facilitating accurate diagnostics and ensuring patient safety.

- Transparency: A significant attribute that makes LSR indispensable in lab-on-a-chip devices is its inherent transparency. This clarity offers researchers the invaluable ability to monitor fluid dynamics in real time, observe cellular behaviors, and track potential reactions. Such visual insights greatly enhance experimental accuracy and overall efficacy.

- Precision in Fluid Manipulation: Microfluidic devices crafted from LSR are renowned for their impeccable control over minuscule liquid volumes. This precision allows researchers to conduct intricate experiments with heightened efficiency, conserving precious reagents and minimizing waste. Such meticulous control ensures unparalleled reproducibility and accuracy in results.

Beyond these primary advantages, the versatility of LSR has catalyzed the evolution of multifunctional lab-on-a-chip systems. By harnessing LSR’s properties, scientists have seamlessly integrated microfluidics with ancillary technologies, such as electronics or optics. This symbiosis paves the way for avant-garde platforms capable of performing multifaceted experimental tasks.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

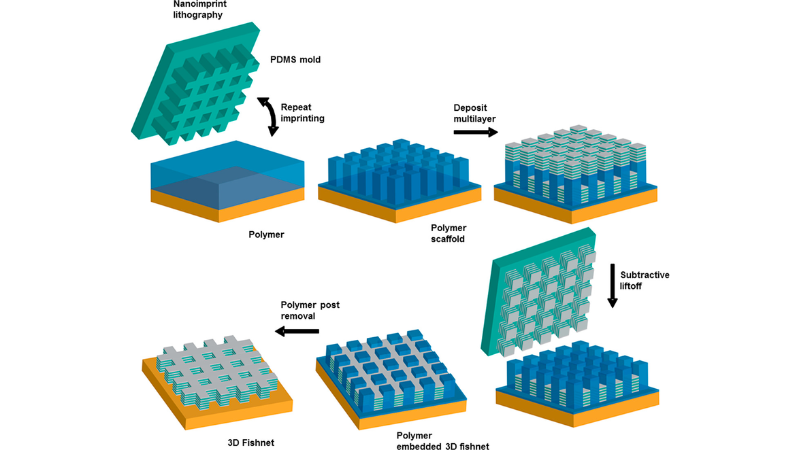

Use 3: Precision Nanomolding and Nano-imprinting

Liquid Silicone Rubber (LSR) stands as a cornerstone in the arena of precision nanomolding and nano-imprinting, thanks to its unparalleled properties. Here’s a deep dive into its transformative role:

- High-resolution Replication: The low viscosity of LSR is pivotal for achieving precise, high-resolution replication of intricate nanostructures. Whether through molding or imprinting, this trait ensures the production of modified nanopatterns that boast unmatched dimensional accuracy at the nanoscale level.

- Intricacy in Nanomolding: Precision nanomolding harnesses LSR to capture complex patterns in minute detail. The process involves channeling LSR into a mold that houses a master pattern, leading to the birth of refined nanostructures that mirror the master’s intricacies. This meticulous technique is pivotal for crafting sophisticated micro-optical components, be it lenses or nuanced diffractive optical elements.

- Precision in Nano-imprinting: LSR’s versatility shines in nano-imprinting, where it’s tasked with transferring detailed patterns from a master template onto a chosen substrate. This transfer relies on calibrated pressure and heat, with LSR’s low viscosity ensuring a snug fit against the template, resulting in a faithful replication of nano intricacies.

- Diverse Nanotechnology Projects: LSR’s adaptability is showcased in myriad nanotechnology ventures, spanning various materials and objectives. For instance, innovative projects have seen LSR married with tungsten oxide (WO3) nanoparticles to birth ceramic composites flaunting enhanced electrical attributes. Techniques such as ball milling have been deployed to achieve minuscule particle dimensions, culminating in ceramics that offer superior yield and complex capacitance dynamics.

By marrying traditional molding methodologies with the unique capabilities of LSR, scientists, and researchers can craft exact replications of sophisticated nanostructures. This spans a gamut of nanotech applications. From reproducing intricate nano designs to manufacturing micro-optical components with unrivaled precision, LSR’s role in precision nanomolding and nano-imprinting is truly transformative.

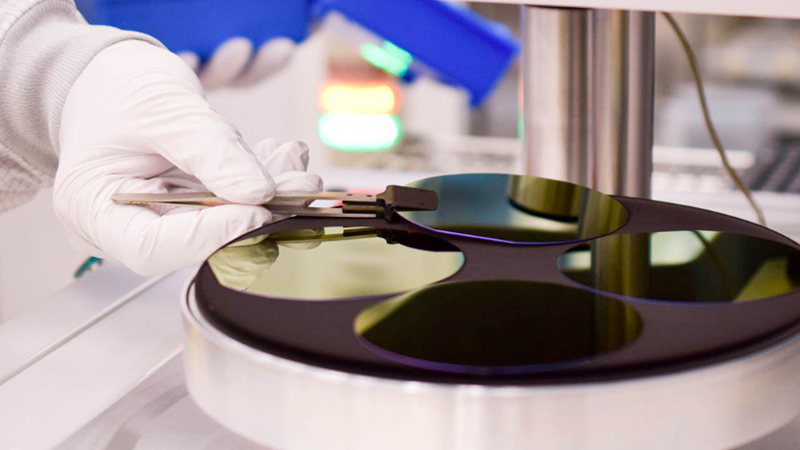

Use 4: Biomedical Nanodevices

In the rapidly advancing field of biomedical research, Liquid Silicone Rubber (LSR) is making significant strides, particularly in the domain of nanodevices. These devices, operating at the nano-scale, hold immense potential for revolutionizing healthcare and diagnostics. Here’s a closer look at LSR’s pivotal role in biomedical nanodevices:

- Biocompatibility: At the heart of biomedical applications lies the essential requirement of biocompatibility. LSR stands out for its innate compatibility with biological systems, ensuring that nanodevices made from it don’t elicit harmful reactions when introduced into the human body.

- Medical Devices Integration: LSR’s compatibility with a wide range of materials, combined with its superior mechanical properties, makes it an ideal choice for integrating with other components in medical devices. Whether it’s sensors, microfluidic channels, or drug delivery systems, LSR provides a reliable and flexible matrix.

- Enhanced Drug Delivery: With the integration of nano silica and other nanoparticles, LSR can be used to create controlled drug delivery systems. These nanodevices can effectively target specific cells or tissues, releasing therapeutic agents in a controlled manner, thus maximizing efficacy and minimizing side effects.

- Diagnostic Advancements: Thanks to its transparency and chemical stability, LSR-based nanodevices can be utilized in real-time diagnostic applications. From detecting pathogens to monitoring cellular interactions, these devices offer heightened sensitivity and quicker response times.

To conclude, LSR is not just a material but a transformative agent in the realm of biomedical nanodevices. Its unique properties make it indispensable for developing devices that are more efficient, precise, and patient-friendly. As we continue to push the boundaries of medical science, LSR is poised to play a central role in shaping the future of healthcare

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Challenges and Considerations in Integrating LSR with Nanotechnology

Blending the domains of Liquid Silicone Rubber (LSR) with the precision of nanotechnology promises transformative applications. However, this fusion is not without its challenges. Delving deep, we unravel the technical and environmental considerations that researchers and manufacturers must address:

Technical Hurdles:

- Precision and Scaling: While LSR is renowned for its flexibility and adaptability, maintaining consistent properties at the nano-scale is challenging. Factors such as molecular weight distribution or even minute impurities can significantly impact outcomes.

- Material Interactions: LSR’s interaction with various nanoparticles, like carbon nanotubes or nano-silica, might not always yield predictable results. This can pose difficulties in achieving the desired reinforcement or property enhancement.

- Curing Complications: Nanoparticles can affect the curing process of LSR. Ensuring uniform curing without compromising the material’s desired properties requires careful optimization of process parameters.

- Quality Control: With the integration of nanotechnology, stringent quality control becomes paramount. Any inconsistencies can have magnified effects when dealing with nano-scale applications.

Environmental and Safety Concerns

- Nano Waste Management: As nanotechnology enters more sectors, concerns about nanoparticle waste have grown. Efficiently capturing and recycling or disposing of these minute particles to prevent environmental contamination is a challenge.

- Biological Impact: There are concerns about the long-term effects of nanoparticles on human health, especially when used in medical or consumer products. It’s imperative to conduct thorough biocompatibility and toxicity studies.

- Ecosystem Interactions: The release of nanoparticles into ecosystems could impact flora and fauna. The potential for bioaccumulation and the consequent effects on the food chain necessitate rigorous environmental impact studies.

- Resource Utilization: The extraction and processing of materials for nanotechnology can have significant environmental footprints. Considerations related to sustainable sourcing and minimizing

Public Perception and Regulation

- Transparency and Education: As with most emerging technologies, there’s a need for transparent communication about the benefits and risks associated with LSR-based nanotech products. Educating stakeholders, from consumers to regulators, is crucial.

- Navigating Regulatory Frameworks: As the field evolves, so does its regulatory landscape. Manufacturers and researchers must stay abreast of changing regulations to ensure compliance and address safety and environmental concerns proactively.

In conclusion, while the fusion of LSR and nanotechnology promises innovative solutions and applications, it’s equally important to address the accompanying challenges head-on. By balancing innovation with responsibility, the industry can chart a sustainable path forward, harnessing the best of both worlds.

Conclusion

Liquid Silicone Rubber (LSR) stands as a beacon in nanotechnology, promising transformative applications. Yet, this fusion isn’t without challenges. Addressing technical and environmental hurdles is paramount. As we harness LSR’s potential in nanotech, a responsible, balanced approach will dictate the path forward, ensuring innovation aligns with safety and sustainability.

Discover Next-Gen LSR Solutions with Hongju

Dive into the cutting-edge world of nanotechnology powered by Liquid Silicone Rubber with Hongju Silicone. Experience transformative solutions, groundbreaking innovations, and the next chapter in industry excellence. Together, let’s shape tomorrow’s possibilities. Embark on this journey with Hongju today!