Lip seals are small but essential components used to prevent fluid leaks and protect machinery from contaminants. Also known as oil seals or shaft seals, they help maintain pressure and retain lubricants in everything from automotive engines to industrial equipment.

In this article, we’ll explore the function, types, applications, and selection tips for lip seals. Whether you’re sourcing for manufacturing, repair, or OEM projects, this guide will help you make informed decisions.

Introduction to Lip Seal

By delving into the definition of a lip seal and comprehending its pivotal role, we can better appreciate its contribution to ensuring optimal functionality and longevity of machinery.

So let’s dive deeper into the exploration of the definition and the role that a lip seal plays in industrial applications.

What is a lip seal?

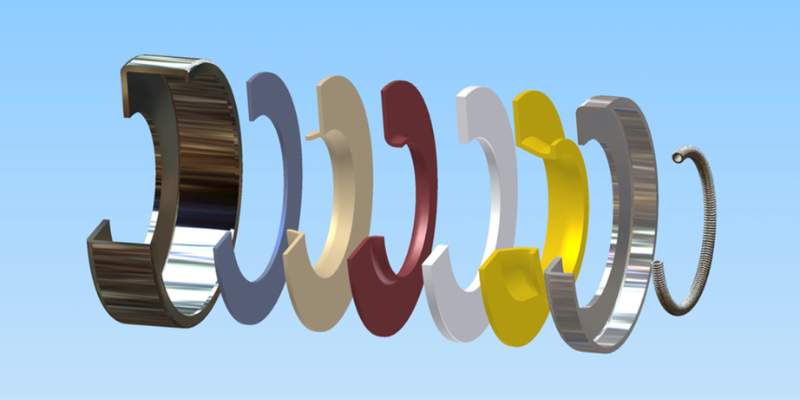

A lip seal, also known as a lip gasket or lip sealing ring, is a type of seal that is used to provide a tight, leakproof seal between two mating surfaces. The lip is the part of the seal that is in direct contact with the surface it is sealing.

The lip seal works by creating a tight fit between the surface it is sealing and the mating surface. This tight fit is achieved by using a lip material that is elastic and can be compressed to create a tight seal.

Lip Seal‘s Function

The primary functions of a lip seal can be broadly categorized into two:

- Retention of Lubricants: One of the main purposes of a lip seal is to keep the lubricant, which is essential for the smooth running of the machinery, within the components where it’s needed. The flexible lip of the seal forms a barrier that helps contain the lubricants, reducing friction and wear, thus ensuring the efficient and uninterrupted operation of the machinery.

- Protection Against Contaminants: Apart from retaining lubricants, lip seals also provide a protective shield against external contaminants. This includes preventing dust, dirt, moisture, and other environmental elements from infiltrating the machinery and causing potential damage.

How is a Lip Seal Different from Other Types of Seals?

Lip seals stand out from other types of seals due to their unique design and functionality.

Unlike mechanical face seals or labyrinth seals, lip seals have a flexible sealing element that directly contacts the shaft or rod, providing an efficient seal. Let’s delve deeper into what sets lip seals apart!

| Seal Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Lip Seals | Made of rubber or other soft materials, designed to create a tight seal between two surfaces | Provide a tight seal that can withstand high temperatures, pressures, and chemicals | Can wear out over time, resulting in leaks |

| O-Rings | Circular cross-section, used for sealing between pipes, hoses, and other components | Provide a reliable seal that can withstand high temperatures and pressures | Limited to applications with limited space |

| Gaskets | A ring or disk-like shape, used for sealing engine components, plumbing, and other applications | Can seal in a wide range of shapes to fit a variety of applications | Requires proper installation and maintenance to maintain the seal |

Overall, each type of seal offers some protection with its own unique advantages and drawbacks, depending on the application and sealing requirements.

Lip seals are particularly effective at creating tight seals in applications requiring high temperatures, pressures, and chemical resistance, and can be customized to fit a wide range of geometric profiles.

Types of Lip Seals: Applications and Varieties

Lip seal plays a crucial role in preventing fluid leakage in various applications. There are several types of lip seals available, each designed for specific purposes. Let’s explore some of the common varieties and their applications.

Radial Shaft Seals

Radial shaft seals are commonly used in cars to stop oil from leaking out of the engine crankshaft. They have a metal casing with a rubber lip that touches the spinning shaft.

This lip block oil from getting out and keeps dirt away. These radial seals are important for keeping engines running smoothly.

Radial shaft seals are used in industries like manufacturing, agriculture, and aerospace, besides automotive. They are used in pumps, gearboxes, and rotary equipment to seal against fluids.

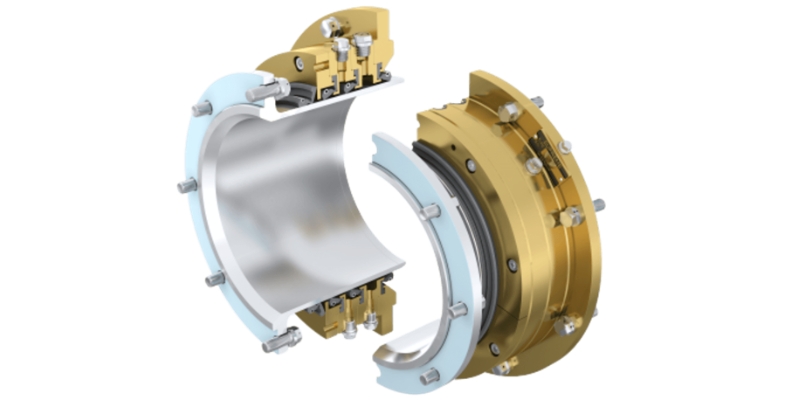

Axial Face Seals

Axial face seals are used in hydraulic cylinders to stop fluid from leaking along the piston rod. They have two metal rings with precise faces that touch when pressure is applied.

This creates a strong seal to keep the fluid inside the cylinder. Hydraulic systems need these seals to maintain pressure and prevent leaks. They are used in construction machinery, industrial equipment, and aircraft landing gear systems.

V-Rings

V-rings are secondary lips that work with oil seals to make them seal better. They have a V-shape and fit tightly against rotating shafts or bores. V-rings are good at keeping out dirt and moisture and keeping lubricants in.

They are used in many industries, like pumps, motors, gearboxes, and washing machines.

Rotary Shaft Oil Seals

Rotary shaft oil seals stop fluid from leaking while the shaft rotates. They have a metal outer case and an elastomeric lip that touches the shaft surface.

Rotary shaft oil seals are important in many machines, like cars and factories. They keep things lubricated and clean.

Factors Affecting Lip Seal Performance

Lip seals are important in many industries to seal moving parts. But factors can affect their performance and the system’s efficiency.

1. Material Choice Matters

The material used for lip seals affects how well they work. For example, nitrile rubber works well with many substances and can handle moderate heat.

Fluoroelastomers are even better at resisting chemicals and can handle higher temperatures. Choosing the right material is important for getting the best seal.

2. Installation Techniques and Surface Finish

Choosing the right material is important, but how you install it matters too.

The surface finish of the shaft and bore or rod needs to be smooth to keep the seal working well. Proper installation, like using enough lubrication and not fitting too tightly, helps prevent problems like leaks or early failure.

3. Environmental Influences

Environmental factors like dust, dirt, moisture, and UV radiation can harm lip seals. They can cause abrasion, reduce effectiveness, and degrade materials. So, choosing a lip seal that can withstand these influences is important for long-term reliability.

4. Temperature, Pressure, Speed, and Media Compatibility

Temperature and pressure can impact the performance of a lip seal. Extreme temperatures can cause the seal material and surfaces to expand or shrink, potentially leading to leaks or increased friction.

Fast movement can generate more heat and friction, so selecting materials that can withstand these conditions is crucial. Additionally, the seal should be resistant to any chemicals it may come into contact with to prevent damage.

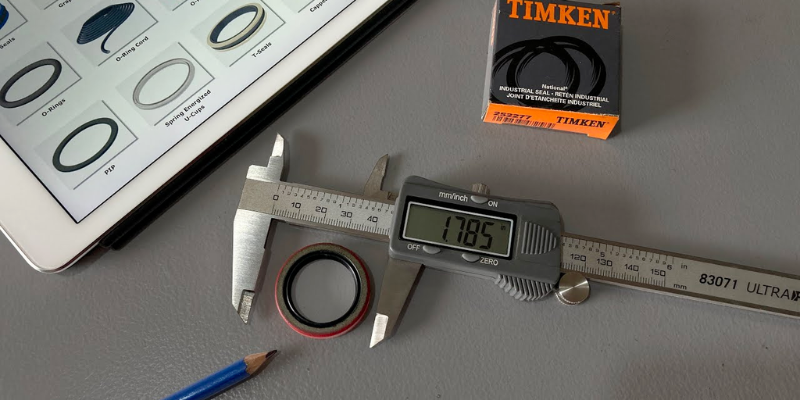

How to Select a Lip Seal?

Selecting the right lip seal ensures efficient sealing and prevents fluid leakage in various applications. To make an informed choice, several factors need to be considered. Let’s explore these factors in detail:

Operating Conditions

The first step in selecting a lip seal is to assess the operating conditions under which it will be used. Factors such as temperature, pressure, speed, and media compatibility play a significant role in determining the appropriate seal material.

For example, if the application involves high temperatures or aggressive chemicals, materials like Viton or PTFE may be more suitable for such seals because PTFE or Viton rubber seals have excellent heat and chemical resistance.

Application Requirements

Understanding the specific requirements of your application is essential when choosing a lip seal. Consider factors such as shaft movement (rotary or reciprocating), direction of fluid flow (inward or outward), and expected service life.

Different lip seals are designed for different types of applications. Radial shaft seals are commonly used for rotary motion sealing, while axial face seals are ideal for reciprocating motion applications.

Compatibility with Fluid

The compatibility between the lip seal material and the fluid being sealed is critical for long-term performance. Some fluids can degrade certain seal materials over time, leading to premature failure.

It’s important to ensure that the chosen lip seal material is compatible with the specific fluid it will come into contact with regularly.

Proper Fitment

To achieve optimal sealing effectiveness, it is crucial to select a lip seal size that matches the shaft bore, diameter, or rod size accurately. A loose-fitting seal may result in leakage, while an excessively tight fit can cause excessive friction and wear on both the seal and mating surface.

Manufacturers usually provide guidelines on how to determine the correct size based on shaft dimensions.

Once you have considered these factors, consult manufacturers’ guidelines or seek expert advice if necessary to choose the most suitable lip seal for your needs. Manufacturers often provide detailed specifications and recommendations based on their experience and expertise.

Troubleshooting Common Issues with Lip Seals

Lip seals are essential components in various industrial applications, providing a reliable barrier to prevent leaks and contamination. However, like any mechanical part, lip seals can encounter issues that affect their performance.

1. Leakage due to Improper Installation or Damage to the Sealing Element

One of the primary issues faced with lip seals is leakage, which can be attributed to improper installation or damage to the sealing element itself.

During installation, it is crucial to ensure that the seal is correctly positioned and aligned with the mating surfaces. Any misalignment or distortion can compromise its effectiveness and lead to leaks.

Damage to the sealing element can occur due to mishandling or excessive force during installation. This can result in deformities such as tears or cuts in the seal material, creating paths for fluid or gas to escape. To troubleshoot this issue:

- Carefully inspect the lip seal for any visible signs of damage.

- If damage is detected, replace the seal with a new one.

- Ensure proper alignment during installation by following manufacturer guidelines.

- Use appropriate tools and techniques when installing lip seals.

2. Excessive Friction or Heat Generation Leading to Premature Wear and Failure

Another common problem encountered with lip seals is premature wear and failure caused by excessive friction or heat generation within the system.

When a seal experiences high levels of friction due to inadequate lubrication or misalignment between rotating parts, it can lead to accelerated wear on both the sealing element and mating surfaces.

To troubleshoot this issue:

- Check if there is sufficient lubrication present around the sealing area.

- If lubricant levels are low, replenish them according to manufacturer recommendations.

- Verify that rotating parts are properly aligned and balanced.

- Consider using lubricants specifically designed for high-temperature applications.

- Monitor operating conditions to ensure they do not exceed the recommended temperature limits.

3. Contamination from Foreign Particles Causing Abrasion or Loss of Sealing Effectiveness

Contamination is another significant factor that can compromise lip seal performance.

Foreign particles such as dirt, debris, or abrasive substances can enter the sealing area and cause abrasion on the sealing element or mating surfaces. This can lead to reduced sealing effectiveness and potential leaks.

To troubleshoot this issue:

- Regularly inspect the surrounding environment for potential sources of contamination.

- Implement effective filtration systems to minimize the entry of foreign particles into the system.

- Clean and maintain equipment regularly to prevent the buildup of contaminants.

- Consider using protective covers or shields to shield lip seals from external elements.

Identifying these common issues early on and taking appropriate troubleshooting measures is crucial for maintaining optimal lip seal performance.

By addressing problems related right oil seal due to improper installation, damage, excessive friction, heat generation, and contamination, you can ensure that your lip seals operate effectively and contribute to a reliable sealing solution.

Remember, proper maintenance practices including regular inspections, lubrication checks, and cleanliness are essential in preventing these issues from arising in the first place.

Tips for Taking Care of Lip Seals

Regular inspection and maintenance are necessary to ensure the proper functioning and long service life of lip seals. Lip seals play a crucial role in preventing leaks and contamination in various machinery and equipment.

By following these tips, you can extend the lifespan of your lip seals and maintain their optimal performance.

1. Maintaining Seal Integrity

To prevent damage to lip seals, it is essential to keep the sealing area clean and free from any debris or contaminants.

Regularly inspect the surrounding environment for dirt, dust, or foreign particles that could potentially enter the seal and cause abrasion or wear. Use appropriate cleaning methods such as wiping with a lint-free cloth or using compressed air to remove any loose particles.

Pay attention to potential sources of contamination like oil spills or chemical splashes near the oil seal sealing area. Promptly clean up any spills and ensure that no corrosive substances come into contact with the lip seal.

2. Maintaining Optimal Conditions

Lip seals are designed to operate within specific temperature and pressure ranges. Exceeding these limits can lead to premature failure of the seal. Regularly monitor these operating conditions and ensure they remain within manufacturer-recommended limits.

Extreme temperatures can cause lip seals to harden or become brittle, reducing their effectiveness over time. Similarly, excessive pressure can deform or rupture the seal, leading to leaks.

By keeping a close eye on these factors, you can identify potential issues early on and take appropriate measures to prevent seal failure.

3. Optimizing Performance with Compatible Lubrication

Lubrication is crucial for minimizing friction and wear on lip seals. It ensures smooth operation by reducing heat generation between moving parts while the lubricating oil also provides a protective barrier against contaminants.

When lubricating lip seals, always use fluids that are compatible with the material of the seal. Different lip seals may require specific lubricants, so refer to the manufacturer’s guidelines or consult with an expert if unsure.

Apply the lubricant evenly and avoid over-lubrication, as excessive amounts can lead to seal degradation.

Regularly check the lubrication levels and replenish them as needed. This will help maintain optimal performance and extend the lifespan of your lip seals.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Lip seals are essential components that provide reliable sealing solutions across numerous industries.

By understanding their function, differences from other seals, types available, factors affecting performance, selection criteria, troubleshooting techniques, and maintenance tips, you can ensure optimal performance and longevity with the best oil seal for your equipment.

Are You Looking for the Perfect Lip Seals? Hongju Can Help You

At Hongju, we offer a wide variety of high-quality lip seals. Our lip seals are made from a range of materials and are available in a range of custom sizes and shapes.

Whether you need a standard or custom-designed lip seal, we have the expertise and experience to help you find the right solution for your application. Contact us now and get a free quote to have a successful future for your business.