Understanding Rubber Seals and Gaskets

In oil and gas or any industry that involves machinery or systems that transport fluids or gases, rubber seals and gaskets play a pivotal role in ensuring everything runs smoothly.

But what exactly are rubber seals and gaskets, and what functions do they serve?

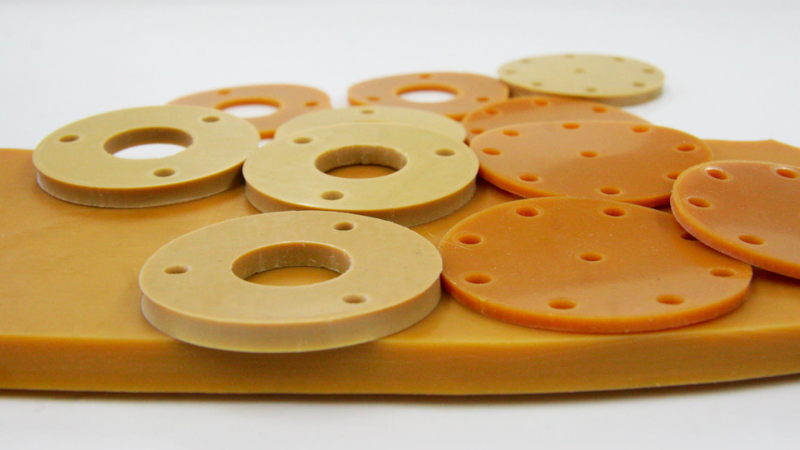

Defining Rubber Seals and Gaskets

At their core, rubber seals and gaskets are flexible components designed to prevent the leakage of fluids or gases between two connecting parts of a system.

They are made from various rubber materials, which give them the resilience and elasticity to withstand high pressure, high temperatures, and potential corrosive substances they might come into contact with.

The Essential Function of Seals and Gaskets

The primary function of rubber seals and gaskets is to maintain a tight seal between connecting parts, effectively preventing the escape or entry of fluids or gases.

This is crucial for maintaining system pressure and efficiency, as well as preventing potential contamination in sensitive applications like food processing or pharmaceutical manufacturing.

Whether it’s a car’s braking system, a heating and cooling system in a building, or a food processing machine, rubber seals and gaskets contribute significantly to the overall performance and safety of the systems.

Understanding the essential role of these components is the first step in selecting the right ones for your industrial applications.

Global Market Insights on Rubber Seals and Gaskets

The global rubber seals and gaskets market continues to expand in 2025, fueled by demand from automotive, oil & gas, and renewable energy industries.

The global gaskets and seals market size was estimated at USD 63.09 billion in 2024 and is projected to reach USD 95.13 billion by 2033, growing at a CAGR of 4.8% from 2025 to 2033. The global market is expected to be driven by the growth of the aerospace and automotive industries.

Asia Pacific dominated the market with a revenue share of 45.4% share in 2024 and is further expected to witness growth at the fastest CAGR over the forecast period.

Types of Rubber Materials for Gaskets and Seals

Rubber gaskets play a vital role in creating reliable seals between two surfaces across many industries. Each gasket material performs differently under heat, pressure, chemicals, and moisture.

Finding a perfect seal may be tough, but choosing the right gasket material makes all the difference.

Let’s look at the most common types and what makes each one unique.

Natural Rubber (NR)

Natural rubber offers excellent mechanical properties, including high elasticity and tensile strength. It’s highly resistant to abrasion and tear and is often used in applications involving dynamic stresses.

However, its resistance to heat and oil is quite limited.

Nitrile Rubber (NBR)

Nitrile rubber is known for its excellent oil and fuel resistance. It also provides good resistance to heat, wear, and abrasion, making it an ideal choice for sealing applications in the automotive and industrial sectors.

Silicone Rubber

Silicone rubber provides superb resistance to high and low temperatures, ozone, and UV light. Although not as strong as other rubber types, its non-reactive nature makes it suitable for medical-grade and food-grade applications.

Fluorocarbon Rubber (FKM)

FKM rubber offers excellent chemical and heat resistance. It’s highly valued in the aerospace, automotive, and energy industries where components need to withstand harsh conditions.

Ethylene Propylene Diene Monomer (EPDM)

EPDM is characterized by its superior resistance to ozone, weathering, and aging. It’s extensively used in outdoor applications and for sealing hot water and steam.

Choosing the right gasket material is crucial as it ensures optimal performance based on environmental conditions. The wrong material can cause a seal or gasket to fail resulting in equipment damage, production delays, shorter product life, or even injury.

Material selection should always begin with an assessment of the application in which the seal or gasket will be utilized to ensure it meets your specific needs.

Choosing the Right Gasket or Seal for Your Specific Application

When selecting a rubber seal or gasket for your specific application, there are several important factors to consider.

These factors will ensure that you choose the right material that can withstand the demands of your particular environment.

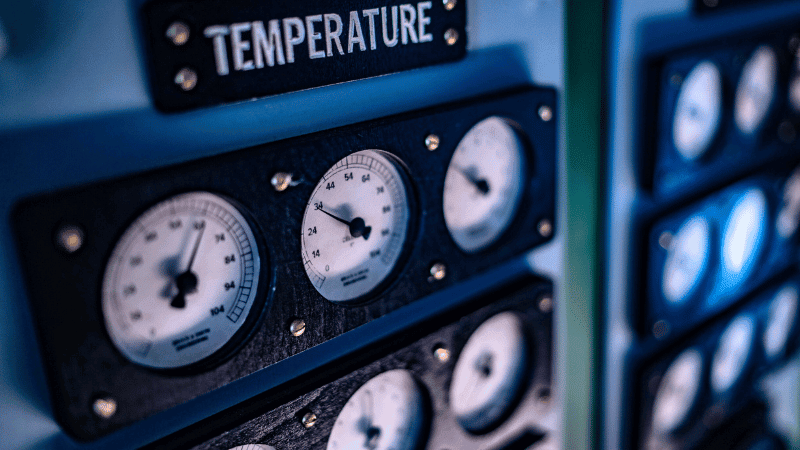

- Temperature Range and Pressure Requirements:

- Evaluate the temperature range in which the seal or gasket will be exposed.

- Consider the pressure requirements of your application.

- Choose a material that can handle both the temperature and pressure conditions effectively.

- Chemical Exposure:

- Assess the compatibility of the seal or gasket material with different fluids and gases it may come into contact with.

- Determine if there will be exposure to any chemicals or corrosive substances.

- Select a material that is resistant to chemical degradation.

- Operating Conditions:

- Evaluate any specific operating conditions such as vibration, UV exposure, or mechanical stress.

- Ensure that the chosen seal or gasket material can withstand these conditions without deteriorating.

Choosing the right rubber seal or gasket is key to keeping your equipment running smoothly and leak-free. Consider factors like temperature, pressure, chemical exposure, and operating conditions to ensure top performance and durability.

With the right material, you’ll get a seal that lasts — protecting your machinery and improving reliability.

Tips for Maintaining and Replacing Rubber Seals and Gaskets

Rubber seals and gaskets, though often overlooked, play a crucial role in ensuring the optimal operation of various equipment and machinery.

To extend their lifespan and ensure they continue to function effectively, it’s essential to understand how to properly maintain and replace these components.

Use Appropriate Cleaning Agents

Some cleaning agents can cause the deterioration of rubber materials. Always ensure the cleaning agents used are compatible with your specific rubber material. Avoid using harsh chemicals that can degrade the rubber.

Regular Inspection

Perform regular inspections of your rubber seals and gaskets. Look for signs of wear, deformation, hardening, or cracking. These could be early indicators that the seal or gasket is failing and needs replacement.

Avoid Over Compression

Over-compressing a rubber seal or gasket can cause it to deform, leading to leaks or failures. Ensure the seal or gasket is correctly fitted and that there’s sufficient compression to create a seal without deforming the component.

Regular Replacement

Even with optimal maintenance, rubber seals and gaskets have a finite service life. It’s important to have a regular replacement schedule based on the manufacturer’s guidelines or the specific demands of your application.

Temperature and Storage

Extreme temperatures can degrade rubber material. Therefore, when not in use, rubber seals and gaskets should be stored in a cool, dry place away from sunlight, ozone, and extreme temperature changes.

Seek Professional Assistance

If you’re uncertain about the state of your gasket or seal, seek advice from the manufacturer. They possess the necessary expertise to guide you on maintenance or when a replacement is necessary.

Conclusion

Choosing the right rubber seals and gaskets is a crucial aspect of maintaining operational efficiency and reliable performance in your industry.

Understanding key differences in materials and maintenance requirements enables you to make a well-informed selection. This directly improves operational performance and lowers maintenance expenses.

Trust Hongju Silicone for Top-Quality Rubber Seals and Gaskets

Partnering with Hongju Silicone means benefiting from our expertise and commitment to quality. Bring your custom designs to market faster with 3–5 day prototyping, flexible quantities, and 20 years of craftsmanship. We deliver dependable silicone parts that fit your goals.

Request your free consultation today!

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.