Ensure safety and quality with the perfect silicone partner! This guide explores the booming food-grade silicone industry, highlighting crucial selection factors like FDA compliance and platinum-curing.

We reveal the top 10 manufacturers in China, helping you source premium, non-toxic silicone for cookware and medical products. Read on to find your reliable manufacturing leader!

An Overview of the Food-Grade Silicone Industry

Before we examine the different manufacturers and suppliers of medical-grade silicone products, it’s important to understand what this material and industry are all about.

The food-grade silicone industry is a rapidly growing sector, leveraging the unique properties of silicone to meet stringent health and safety standards required for food-related applications.

Recent research shows that the global food grade silicone market was valued at USD 1.5 Billion in 2024 and is estimated to reach USD 2.9 Billion by 2033, growing at a CAGR of 7.8% from 2026 to 2033. It is driven by demand for safe, non‑toxic kitchenware, bakeware, and food‑contact components.

Here’s an overview focusing on aspects relevant to SEO and readability, tailored for a B2B audience in the silicone industry.

What is Food-Grade Silicone?

Food-grade silicone is a material used for products that come into contact with food. This differentiates it from ordinary-grade silicone manufactured with industrial applications in mind.

Food-grade silicone is ideal for its applications because it is considered non-toxic.

How is Food-Grade Silicone Made?

To manufacture silicone, quartz is heated with coal (carbon) to high temperatures, converting it to elemental silicon. The resulting silicon is crushed into a powder and taken through various chemical processes where it fuses with hydrogen, oxygen, and carbon.

Other elements can be added depending on the desired properties of the final silicone products.

The result of these chemical processes is called Polydimethylsiloxane. This raw silicone can have a fluid-like consistency and is called liquid silicone rubber. This polymer can be converted into products through a process called curing.

For the silicone to be considered food-grade, the curing process must only use platinum as the catalyst.

What Do People Choose Food-Grade Silicone?

- Silicone can withstand extreme temperatures better than other polymers and is even used for bakeware.

- Food-safe silicone is resistant to many chemicals including animal fat.

- Silicone isn’t easily contaminated thanks to its antifungal properties.

- The material is easy to shape and can seal customer profiles in many applications.

- Food-grade Silicone is non-toxic.

- Silicone is durable and doesn’t degrade or wear as easily as plastic.

- Doesn’t produce unpleasant odors.

Applications of Food-Grade Silicone

Food-grade silicone is used in many food and beverage-related applications including:

- Silicone tubing used to transfer food

- Tubing used to handle edible liquids including milk in the dairy industry and alcohol in the beverage industry

- Seals for commercial ovens

- Gaskets used in machines used for food processing

- Spatulas, brushes, and bakeware used in homes

- Pacifiers for babies

Food Grade Vs. Medical Grade Silicone

The main difference between these two types of silicone is that medical-grade silicone is subjected to higher standards of purity and manufacturing. Medical-grade silicone must also be biocompatible since it can be used to make implants worn inside the body.

Medical-grade silicone can be used for food-grade applications but can also be used for medical devices and other sensitive medical applications.

Factors to Consider When Choosing a Food-Grade Silicone Manufacturer

When choosing a food-grade silicone manufacturer, several critical factors must be considered to ensure high-quality, safe, and compliant products.

1. Certification

Due to the intended applications, you need a manufacturer who has certifications that prove their manufacturing is up to the desired standard.

Certifications should be from reliable third-party organizations, government agencies such as the FDA, and other regulatory authorities.

2. Scale of Operations

Depending on your needs, you may be better served by either a large or small manufacturer. Large manufacturers may be able to handle larger orders, but working with them can be challenging if they have a backlog of client orders or high minimum order quantities.

3. Quality Control

For food-safe products, it is important to work with a manufacturer with a quality control process that is proactive. Manufacturing products using food-grade silicone is a tightly controlled process and certain quality standards must be maintained to avoid contamination.

4. Experience

If a medical-grade silicone manufacturer has been around for a long time, they have likely been serving customers well enough to survive that long. The experience of the personnel is also important since they’ll have good knowledge of the process.

Manufacturers that have experience working with foreign clients understand the needs of these clients and the quality standards their products must meet to be considered food or medical grade in other parts of the world.

5. Reputation

Due to the high stakes of food and medical-grade applications, it’s a good idea to steer clear of manufacturers with poor reputations.

6. Overall Service Experience

It’s not enough for manufacturers to produce the right product. You need a manufacturer whose services come with peace of mind. This means not having to worry about late deliveries, slow communication, rude representatives, and similar issues.

Top 10 Food Grade Silicone Manufacturers and Suppliers in China

| Position | Company Name | Year Established | Location (City) | No. of Employees |

|---|

As the global food grade silicone market continues to grow, many international brands now source kitchenware, baby products, and food‑contact seals from certified Chinese manufacturers to balance cost, quality, and production capacity.

This table is a summary of the top 10 food-grade silicone manufacturers and suppliers in China. These companies are the key players in the industry right now and are gaining reputations for producing high-quality food and medical-grade products for clients throughout the world.

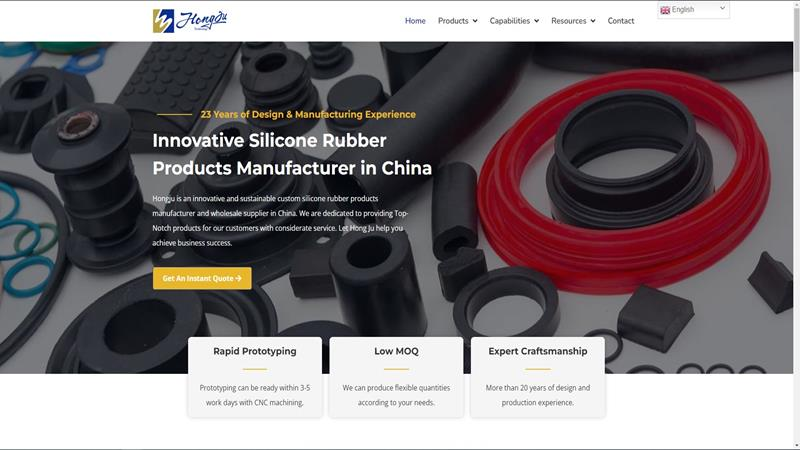

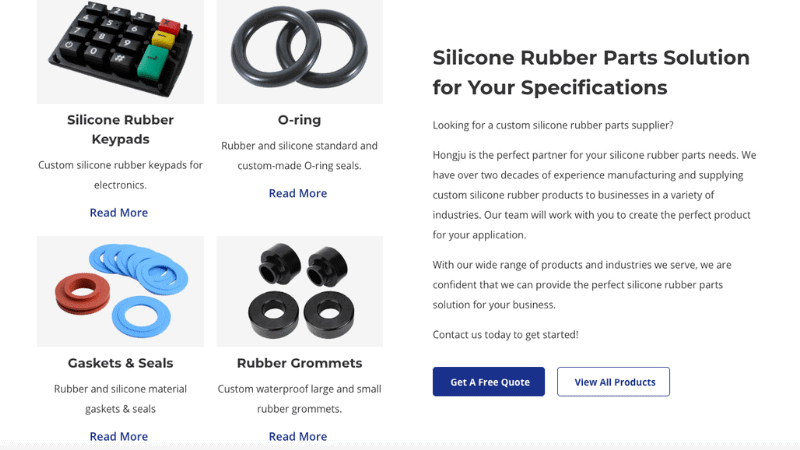

1. Hongju Silicone Co. Ltd

Company Overview

Hongju Silicone is located in Dongguan City. Since its start in 1999, the company has established itself as one of the key manufacturers of silicone rubber products with a product range that includes gaskets, swimming caps and goggles, kitchenware, and O-rings.

Its low minimum order quantities give smaller customers an advantage. Their 20-plus years of experience mean quality is not sacrificed in their process. The company uses a variety of manufacturing processes including injection molding, compression molding, and die cutting.

The food-grade silicone products the company makes have attained both CE and FDA approval. The company has also ventured into the use of processes and materials that are environmentally friendly.

Pros

- Rapid Prototyping (3-5 work days)

- Low MOQ

- Expert Craftsmanship (more than 20 years)

- Good reputation in foreign markets

- Short company’s production cycle as low as 9 workdays

- Multiple manufacturing methods

Cons

- Quotes can take 1 to 3 days

Inquire About Our Silicone and Plastic Products!

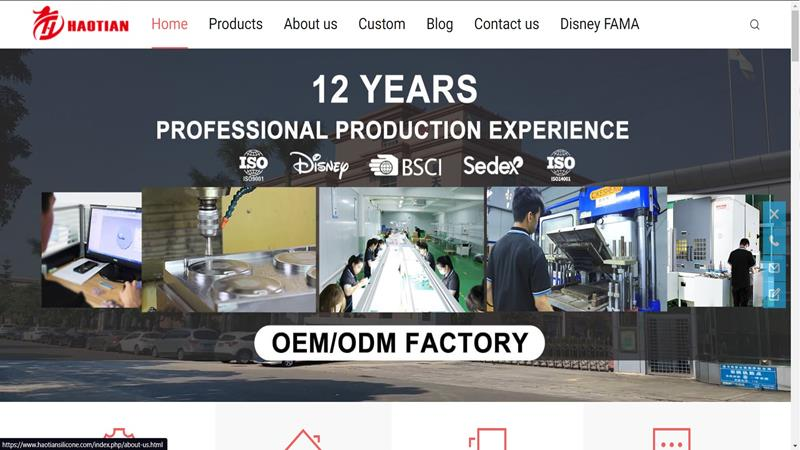

2. Dongguan Haotian Silicone Co. Ltd

Company Overview

Haotian Silicone has become an excellent supplier of all types of silicone products including molds, kitchenware, toys, and custom liquid silicone rubber products. The company has an excellent research and development team which includes 6 engineers.

The manufacturing services offered by Haotian Silicone are well-rounded and incorporate the design of parts for manufacturing and surface treatment of molded parts.

The company pays particular attention to quality control to ensure their products always meet the standard. It has worked with big-name corporations in the past including Disney. The company is ISO-certified and allows 3rd party inspections.

Pros

- The company has experience working with well-known Chinese and American companies.

- Haotian Silicone has experience manufacturing a wide range of consumer products.

- Robust quality control system including 100% product inspection

- Post-processing options are available if needed

Cons

- The company is relatively young having been founded in 2015

3. Shenzhen Tenchy Silicone & Rubber Co. Ltd

Company Overview

Tenchy Silicone & Rubber has been around since 2008. Today, the company exports as much as 90% of the products it makes. Its markets include North and South America, Eastern and Western Europe, and the Middle East.

The company manufactures a wide range of silicone products including gaskets, medical-grade tubing, seals, foam tubing, and food-grade containers. Tenchy Silicone & Rubber is ISO 9001 certified. It also has certifications from various countries including Italy, Germany, and the EU.

The company follows an 11-step manufacturing process from mold design to delivery. It has one factory for extrusion of silicone parts and another for molded products.

Pros

- The company already has a system to service customers all over the world.

- Different delivery options are available.

- The company is certified by several bodies.

- The company offers customization services for clients with unique projects or product use cases.

Cons

- Customers may be overwhelmed by product options.

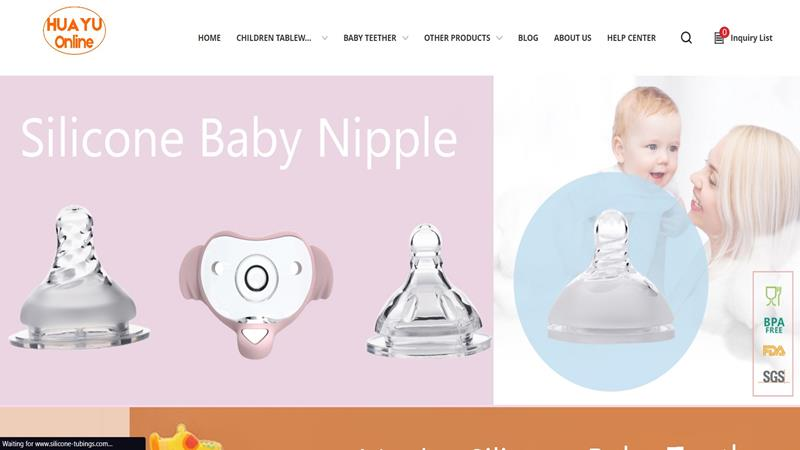

4. Huayu Silicone Co. Ltd

Company Overview

Huayu Silicone boasts a customer base that extends to all parts of the world. This company was set up in 2010 and it produces both OEM and ODM parts. Their product line now includes silicone teethers, nipples, feeding plates, pacifiers, and other baby accessories.

Its manufactured products are utilized for several industries across the USA, such as construction, plumbing, and maintenance.

This manufacturer works with top-of-the-line equipment that now includes block presses and liquid silicone forming machines. Their commitment to quality is demonstrated by their product testing center where products are subjected to VOC testing, bite tests, flow tests, etc.

The company has attained certifications that include ISO 9001, and they have worked with international companies such as Starbucks.

Pros

- Past clients include well-known corporations in the food and beverage industry.

- The company has a well-equipped product testing lab.

- The company is an excellent source of silicone products for babies and children.

Cons

- They may not be the ideal manufacturer for the non-infant silicone product market.

- Most of their certification is local.

5. Honychem Co., Ltd

Company Overview

Honychem is one of the youngest companies on this list having been founded in 2015. Even so, it has distinguished itself as a manufacturer of food-grade silicone products in recent years. In 2019 its products received both FDA and LFGB certifications.

The company offers a diverse range of silicone solutions, including medical-grade silicones and silicone additives for various industries. Honychem has invested in both its team and equipment to be able to manufacture high-quality silicone rubber products.

Its products now include liquid silicone rubber baby bibs, plates, bottles and cups, and food-grade rubber tubing.

The company utilizes its in-house design team to develop new products. The company also produces specialty plastic products.

Pros

- The company’s products have attained both FDA and LFGB certifications.

- The company has a good line of products made using food-grade silicone.

- The company’s offerings now include eco-friendly rubber

Cons

- The company has limited experience.

- Their website makes for a poor customer.

6. GOFAI Rubber Co., Ltd

Company Overview

GOFAI Rubber is a major rubber manufacturer located in Qingdao City. The company was established in 2013 but was founded by individuals with years of experience in the manufacture of silicone-based products.

The company produces a long list of products requiring both ordinary and food-grade silicone material. These include suction cups, rubber bumpers, boots and bellows, and food-grade tubing.

These products have ideal applications in various industries, including construction, automotive, aerospace, and electronics.

GOFAI Rubber has attained various certifications including ISO 9001 and RoHS. Their operations are supported by 21 vulcanizing machines, 5 extruders, 9 injection molding machines, and 7 CNC machines.

Pros

- The company can deliver a wide range of products since it works with many different materials.

- The company produces both extruded and injection-molded food-grade silicone rubber products.

- They have experience manufacturing OEM and ODM products.

Cons

- Their operations are not centered around food or medical-grade silicone products

7. Neway Rubber & Plastic Co., Ltd

Company Overview

Xiamen Neway Rubber and Plastic Products Co., Ltd was started in 2002. The company specializes in the fabrication of plastic, metal, and silicone rubber products. It’s one of the most important market players on this list.

At this company, silicone rubber parts can be manufactured using different processes including injection molding, transfer molding, die cutting, and extrusion molding. The company puts its raw materials through many tests and has many certifications including FDA and LFGB.

The company produces various epoxies, urethanes, and silicones for use in bonding, casting, encapsulating, and mold making. Neway Rubber uses food-grade silicone to make products including teething toys for babies and food molds. They also offer accessories made using medical-grade silicone.

Pros

- Neway Rubber has experience manufacturing products for the food industry and the medical industry.

- The company has many manufacturing processes for food-grade silicone including injection molding.

- The company has many certifications relevant to food and medical-grade silicone.

Cons

- The scope of the company’s operations may make it challenging to get personalized service.

8. Zhongshan Xinyuan Silicone Rubber Ltd.

Company Overview

Zhongshan Xinyuan Silicone Rubber was started in 2009 in the city of Zhongshan. The company mainly exports its silicone products to the USA, Europe, Canada, Brazil, and Australia.

Zhongshan Xinyuan is a manufacturer of silicone solutions like elastomers, polyethers, and emulsions, as well as lubricant additives and specialty chemicals for various industrial applications.

The company has experience manufacturing silicone products for various industries and has thousands of molds at hand. They test every product before delivery and delivery is usually within 7 days.

The company has an MOQ of 30 pieces for in-stock models and 1000 pieces per color for custom products. The company’s products include silicone kitchenware, wristbands, food bibs, etc.

Pros

- The company is experienced in the manufacture of products using silicone elastomers

- They have successfully delivered products to different continents

- The company has ISO 9001 certification

Cons

- The company’s website isn’t very informative

- The company has a minimum order quantity

9. Xiamen Xingluan Industrial Co. Ltd.

Company Overview

Xiamen Xingluan was launched in 2008. The company has been focused on the manufacture of plastic and silicone rubber products. The company has a system that starts from product design to sales.

Xingluan Industrial works with an experienced technical team that includes engineers. It utilizes the latest manufacturing systems and strict quality control to produce high-quality products. The company’s production operations now cover 12000 square meters.

Its silicone rubber products include baby toys, toothbrushes, spoons, bowls, and cups. They also manufacture breast pumps. The company has attained various certifications including ISO 9001 and 14001, plus IATF 16949.

Pros

- The company has years of experience manufacturing food-grade silicone products.

- Xingluan Industrial has multiple certifications

- The company uses different manufacturing methods including injection molding, die cutting, and liquid forming.

Cons

- Their website can be difficult for customers to navigate.

10. Shenzhen Onequan Silicone Rubber Products Co., Ltd

Company Overview

Onequan Silicone Rubber Products was founded in 1997 in Shenzhen. The company is only 40 minutes away from Hong Kong. The factory currently has a footprint of 4800 square meters and is supported by 8 curing machines and six glue production lines.

Onequan Silicone has produced a wide range of silicone products including baby products, wristbands, and belts. The company also has its own brand of products.

The company manufactures products using a wide range of plastic and rubber materials. It has served customers from all over the world and has several certifications.

Pros

- Extensive experience manufacturing food-grade silicone rubber products.

- The company has produced products for international brands

- They have a well-trained and experienced staff

Cons

- The website doesn’t help the customer experience

- The Manufacture of food-grade silicone rubber products is just one of many manufacturing operations.

Conclusion

Food-grade silicone products cost more to produce. Some manufacturers may be tempted to cut corners to keep their costs down and this is one of the industry’s major challenges.

When you need a product for the food, medical, or pharmaceutical industries, it is important to confirm that the manufacturer’s products meet the standard. This list of the top 10 food-grade silicone manufacturers and suppliers in China is the right place to start your search today.

Choose Hongju as Your Trusted Food-Grade Silicone Manufacturer

With over 20 years of manufacturing expertise, Hongju Silicone helps you confidently source certified food-grade silicone. From expert material guidance and rapid prototyping to low MOQs and strict quality control, we make compliance and reveals simple.

Contact our team today. Request samples, validate performance, and move to production faster.

Inquire About Our Silicone and Plastic Products!

FAQs

Q1: How does food-grade silicone outperform plastic or rubber in durability?

It resists stains, odors, and degradation from oils or acids, maintaining flexibility and hygiene through repeated sterilization and daily use.

Q2: What certifications validate true food-grade silicone safety?

Look for FDA, LFGB, and EU 10/2011 compliance, which certify material purity and safety for direct food contact under high temperatures.

Q3: Can you support OEM & ODM projects with custom requirements?

Yes. We offer full OEM & ODM services, from design assistance to mass production, helping you turn ideas into market-ready products efficiently.

Q4. Do you require a high minimum order quantity?

No. We support low MOQ orders, allowing you to test the market or develop new products with lower risk and greater flexibility.