We will delve into the unique characteristics that make it suitable for use in diverse manufacturing systems across the food industry landscape.

So let’s dive into the world of polyurethane gaskets and seals designed specifically for safe contact with consumable goods!

What is Polyurethane?

In the realm of polymers natural rubber and plastics, one-star player stands out due to its versatility and resilience – polyurethane.

Breaking Down Polyurethane

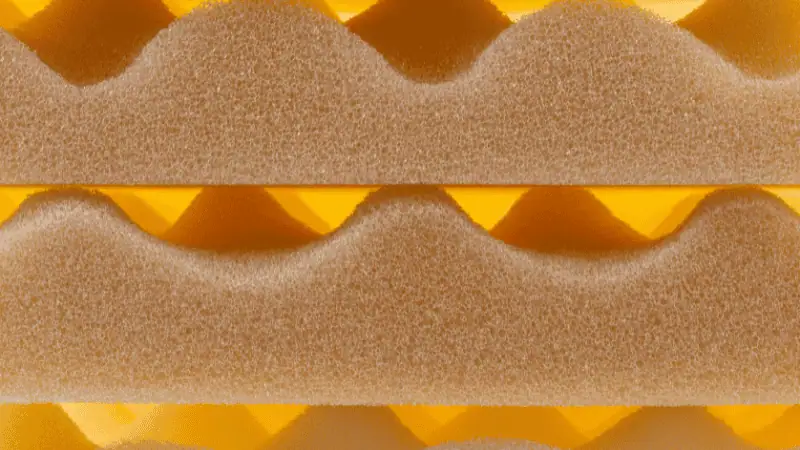

Polyurethane, commonly abbreviated as PU, is a type of polymer composed of organic units linked by urethane links. These polymers are part of a broader class of compounds known as elastomers, which exhibit rubber-like flexibility and resilience.

The Chemistry Behind Polyurethane

Polyurethanes are synthesized by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives.

The process produces a material that’s incredibly versatile and can be as hard as fiberglass, squishy as upholstery foam, protective as varnish, bouncy as silicone rubber bottom, or sticky as glue.

From Liquid to Solid: Polyurethane Transformation

In its raw form, polyurethane is a liquid. However, it transforms into a solid material when it reacts with other chemicals.

This change allows it to be molded into various shapes and sizes, making it an incredibly adaptable material suited to a wide range of applications.

How Does Polyurethane Make Good Food-Grade Seals or Gasket Materials?

Sealing materials play a pivotal role in food processing and packaging applications. To understand why polyurethane fits the bill perfectly, we need to delve deeper into its key attributes.

The Resilience of Polyurethane

A major advantage that sets polyurethane apart is its impressive resilience. With the capability to withstand regular wear and tear during machine operations, polyurethane helps reduce the frequency of seal and gasket replacements, thus promoting operational efficiency.

High-Temperature Tolerance

Another factor that cements polyurethane’s position as a preferred material is its high-temperature tolerance. Polyurethane can easily resist hot liquids or high-temperature processing and sterilization procedures, making it ideal for demanding applications.

Chemical Resistance

A unique trait of polyurethane is its remarkable resistance to chemicals, oils, and other substances commonly encountered in food processing environments. This assures the longevity and integrity of the seal or gasket, even in harsh conditions.

Compliance with Food Safety Regulations

Is Polyurethane Food Safe? One cannot overlook polyurethane’s compliance with food safety regulations. It does not leach harmful substances into the food product and is resistant to microbial growth.

This makes polyurethane a safe choice for food processing applications, that have direct contact with food.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

The Benefits of Choosing Polyurethane for Food-grade Applications

Transitioning our focus from the characteristics of polyurethane, we delve into the tangible benefits of using this versatile material in food-grade applications.

- Prolonged Equipment Lifespan: The first benefit of choosing polyurethane is the extended lifespan it offers to your equipment. The inherent resilience of polyurethane reduces the wear and tear on your seals and gaskets, which can greatly extend the useful life of your machinery.

- Operational Efficiency: Given its high-temperature tolerance, polyurethane allows for seamless operations even under extreme conditions. This leads to fewer disruptions and downtime, enhancing overall operational efficiency and productivity in your food processing or packaging operations.

- Cost-Effective: Polyurethane’s superior chemical resistance means fewer replacements due to damage caused by harsh substances. This, in turn, reduces maintenance costs and makes polyurethane a cost-effective solution in the long run.

- Adherence to Safety Standards: Lastly, and importantly, polyurethane complies with food safety regulations, ensuring the safety of your consumers. Its resistance to microbial growth prevents contamination, making polyurethane a safe and reliable choice for food-grade applications.

In summary, the benefits of choosing polyurethane extend beyond its desirable material properties.

It offers an array of advantages from operational efficiency to cost-effectiveness, and crucially, it ensures adherence to food safety regulations, providing peace of mind for both producers and consumers.

Boosting Polyurethane Performance with Additives

Polyurethane is a top choice for food-grade gaskets, but its versatility doesn’t end with its inherent properties. One of the significant benefits of polyurethane lies in its compatibility with various additives.

These can further enhance its performance, making it an even more attractive choice for food-grade gaskets.

Antimicrobial Additives

In the context of food-grade gaskets, antimicrobial additives are crucial. When incorporated into polyurethane, these substances can inhibit the growth of bacteria and other microorganisms, promoting food safety and extending the lifespan of the gasket.

Flame Retardant Additives

Certain food and beverage applications may require the gasket material to withstand higher temperatures without degrading or releasing harmful fumes. With the addition of flame-retardant substances, polyurethane gaskets can safely function in these high-heat scenarios.

Wear and Abrasion Resistance

Additives that improve wear and abrasion resistance are particularly beneficial in the food processing industry, which often involves abrasive materials and high-pressure environments.

These additives extend the lifespan of polyurethane gaskets, ensuring reliable service even under rigorous conditions.

In summary, the customizability of polyurethane via additives is another factor that contributes to its status as a top choice for food-grade gaskets.

It underscores the versatility and suitability of polyurethane in meeting the diverse and stringent requirements of the food and beverage industry.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Are there any Potential Drawbacks to this Application?

In the realm of material selection, understanding potential constraints is just as vital as recognizing the advantages.

Although polyurethane is indeed a top choice for food-grade gaskets, it’s essential to acknowledge that no solution is without its limitations. Let’s delve into some aspects where polyurethane might face challenges.

Limitations with Extreme Temperature

One thing to bear in mind is the temperature tolerance of polyurethane. While this material has excellent heat resistance, its performance might decline under exceedingly high or low temperatures, however.

Therefore, for applications requiring tolerance to extreme temperature conditions, some other specialty materials might be more appropriate.

Chemical Resistance

Polyurethane stands out with its remarkable resistance to a wide range of common chemicals. However, in settings involving specific aggressive chemical substances, polyurethane might not be the ideal choice.

Even though additives can enhance this excellent chemical resistance, it’s critical to consider the exact chemical environment the gasket will be exposed to.

Cost Implications

Undeniably, polyurethane, especially food-grade quality, might come with a higher price tag than other synthetic rubber materials. For businesses operating on a tight budget, this could be a potential drawback.

Nonetheless, the superior performance, longevity, and reduced maintenance needs of polyurethane often justify the initial investment, yielding significant cost savings in the long run.

In essence, while polyurethane certainly offers numerous advantages for food-grade gaskets, understanding its potential drawbacks allows for informed decision-making, ensuring the final selection perfectly suits the application’s unique demands.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How Long Will They Need to be Replaced or Serviced Again?

The durability of a material directly impacts its maintenance cycle and service life, thus affecting the overall cost of the application.

When it comes to polyurethane gaskets, their lifespan is impressively long, but this largely depends on the conditions of usage.

The durability of Polyurethane

The unique composition of polyurethane grants it exceptional durability, making it resistant to wear, tear, and aging.

These properties significantly enhance the lifespan of polyurethane food-grade gaskets, and they require replacement less frequently than many other gasket materials. However, it’s important to note that this doesn’t mean they can be neglected in terms of routine maintenance.

Maintenance and Replacement

Although polyurethane gaskets exhibit excellent durability and longevity, maintaining a regular service schedule is crucial.

Routine inspections can help detect and address any potential issues early, ensuring the gasket performs optimally and the machinery it supports runs smoothly.

Timely replacement is crucial. As polyurethane gaskets age or degrade, there is an increased risk of contamination due to compromised seals. Contaminants could potentially enter the food production process, leading to health hazards or product recalls.

To mitigate these risks, it is important to monitor the condition of gaskets regularly and replace them as needed.

Polyurethane in the Food and Beverage Industry

The food and beverage industry is an integral part of global infrastructure, catering to billions daily. This sector has a responsibility to use materials that won’t compromise the safety and integrity of its products.

The deployment of polyurethane gaskets and seals in this industry enhances product safety. Known for their resistance to bacteria and a variety of contaminants, these components help preserve the quality and extend the shelf life of food and beverage items.

Polyurethane gaskets and seals serve multiple roles in the food and beverage industry, from canning and bottling to packaging.

They’re incorporated into food processing equipment and machinery such as conveyor belts and mixers and find utility in commercial kitchens and eateries. The presence of these components contributes to maintaining high standards of safety and hygiene.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

In conclusion, the use of polyurethane as a material for food-grade gaskets and seals stands as an optimal choice for the food and beverage industry. Owing to its superior properties like durability, resistance to bacteria, and adaptability to various applications.

However, it’s essential to monitor for potential wear and consider regular replacement or servicing to maintain these benefits. Thus, polyurethane is indeed a top pick for food-grade gaskets and seals.

Are You Looking for Polyurethane Gaskets and Seals? Hongju Can Help You

At Hongju Silicone, we understand the crucial role that high-quality food-grade gaskets and seals play in the food and beverage industry. We specialize in manufacturing customized polyurethane gaskets and seals that meet strict industry standards.

Contact us in Hongju Silicone’s expertise to help you meet your operational goals.