People who like watches often choose silicone and FKM rubber watch bands because of their durability. But which one do you want?

Silicone is known for being cheap and flexible, while FKM rubber claims to be very strong. To help you choose the best strap for your needs, we’ll compare them based on strength, comfort, and value.

What Are FKM Rubber and Silicone Rubber Watch Straps?

Fluoroelastomer, or FKM rubber, is a high-performance synthetic rubber with a lot of fluorine. Because of this, it can withstand high temperatures, chemicals, and oils.

FKM material works great in harsh conditions where other rubbers fail. It is commonly used in airplanes, automobile parts, and industrial seals. It doesn’t break down with ease, making it an excellent choice for watch straps that must last a long.

Silicone rubber is made from siloxane resins and is a bendable elastomer. It is safe and nontoxic, and it can withstand temperatures from -60°C to 230°C better than FKM.

Because it is soft and comfortable, silicone is used in many things, like medical gadgets, cooking, and waterproof watch straps. It is a preferred option to FKM because it doesn’t absorb water and is cheap.

Key Differences Between FKM and Silicone Rubber

FKM and silicone rubber have their benefits, and the way they are made makes them suitable for different watches and wristbands. To help you understand their pros and cons, here is a quick comparison:

| Property | FKM Rubber | Silicone Rubber |

|---|---|---|

| Composition | Fluoroelastomer | Siloxane polymer |

| Temperature Resistance | Up to 300°C | -60°C to 260°C |

| Corrosion Resistance | Strong acids, solvents, and oxidizers | UV, oxygen, and moisture |

| Elasticity | Good | Excellent |

| Electrical Insulation | High | High |

| Biocompatibility | Limited | Excellent (hypoallergenic) |

| Cost | Higher | Lower |

| Applications | Engines, chemical plants | Medical, electronics, and consumer goods |

Why Choose FKM Rubber Strap?

Fluoroelastomer (FKM) strap is a high-quality material that is used in tough situations. It is known for being very durable and works reliably in harsh situations where other elastomers fail. Consider what makes it special and why businesses use it for high-performance tasks.

- Superior Chemical and Corrosion Resistance

FKM rubber exhibits a high resistance to strong acids, alkalis, fuels, and oils. It is more durable than conventional rubbers in hostile chemical conditions. This feature guarantees long-term performance without deterioration, even when exposed to harsh chemicals.

FKM’s dependability makes it ideal for airplane components and automotive systems applications. Industries rely on FKM for everyday wear seals and gaskets.

- Excellent High Temperature Resistance

FKM rubber performs better than other elastomers. It maintains its integrity even at extreme temperatures (250–300°C). Its thermal stability ensures reliable performance. This prevents deformation and failure in high-heat conditions.

Due to these properties, FKM is crucial for heat-resistant engine gaskets. It is also vital for airplane seals and refinery equipment. FKM provides unmatched resilience under temperature stress. It excels in blazing engine bays and harsh industrial operations.

- Low Friction & High Wear Resistance

FKM rubber has a low coefficient of friction. This makes it ideal for moving parts and dynamic sealing applications. The property reduces energy loss and prevents sticking. It ensures smooth operation over long periods.

FKM also offers excellent wear resistance. This allows it to perform well in high-stress conditions. It works reliably in hydraulic systems and rotating machinery.

- Strong Electrical Insulation

FKM rubber provides excellent electrical insulation. It maintains stability in high-voltage and high-frequency environments. This makes it ideal for protecting sensitive electronic components. It prevents electrical interference and short circuits.

FKM is widely used in electrical connections. It is also common in electronic device housings and power transmission systems. Its insulating properties are highly valued. FKM can withstand electrical stress while resisting environmental factors. This makes it a top choice for critical electrical applications.

- Airtight and Durable Sealing Performance

FKM rubber offers superior sealing performance. It maintains airtight integrity in extreme conditions, including vacuums and high pressure. Its molecular structure creates durable, reliable seals that prevent leaks.

FKM is ideal for critical applications. It’s widely used in high-pressure hydraulic systems. The material is also essential for semiconductor manufacturing equipment. Additionally, FKM is preferred for aircraft components due to its exceptional sealing properties.

Types of FKM Rubber and Their Application Areas

FKM (Fluoroelastomer) is a high-performance material. It is known for excellent heat and chemical resistance. Different grades with varying fluorine content meet industrial needs. These grades balance cost and performance.

Below, we highlight two key FKM variants. Their specific applications are also explained.

High Fluorine Rubber (67–70% Fluorine)

This mid-range FKM offers strong chemical resistance. It costs less than premium grades. The material works well for moderate-exposure uses.

Common applications include automotive fuel systems. It’s also used in oil seals. Chemical processing equipment often uses this grade. These applications frequently handle corrosive fluids. The fluorine level of 67-70% ensures an ideal equilibrium between efficacy and cost-effectiveness.

Perfluoroelastomer (>70% Fluorine)

FFKM rubber handles the toughest conditions. It beats all other materials against chemicals, heat, and plasma damage. This super-resistant rubber has extra fluorine of over 70%. It costs much more but works where others fail.

Factories use FFKM to make computer chips. Hospitals need it for sterilizing tools. Oil drillers rely on it deep underground. When failure would be dangerous, FFKM is the best choice.

Why Choose Silicone Straps?

Silicone rubber suits diverse applications, from consumer goods to medical uses. Its unique properties make it ideal for many purposes.

The material offers exceptional elasticity and biocompatibility. It performs reliably in extreme temperatures and harsh environments.

- Wide Temperature Tolerance

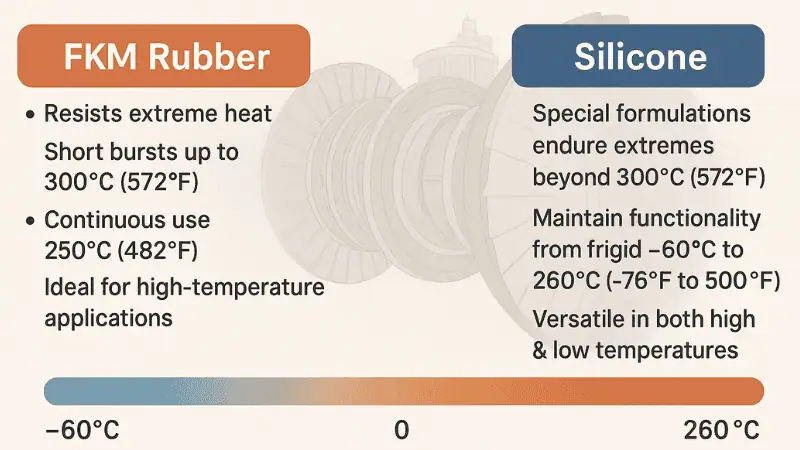

Silicone rubber performs across a broad temperature range (-60°C to 260°C). Special formulations can withstand over 300°C. In cold conditions, it resists cracking. Under extreme heat, it maintains structural integrity.

These properties make it ideal for demanding applications. It’s perfect for electrical insulation. Oven gloves benefit from heat resistance. High-temperature bakeware relies on its ability to handle thermal shocks.

- High Elasticity and Flexibility

Silicone rubber is highly elastic and flexible. It maintains its shape even after repeated stretching or compression.

This durability makes it ideal for long-lasting parts. It’s perfect for cushioning components. The material excels in sealing applications. It’s also excellent for shock absorption.

- Weather and UV Resistant

Silicone rubber offers excellent weather and UV resistance. It remains durable even after prolonged sun exposure. The material withstands harsh outdoor conditions.

This makes it ideal for exterior seals. It’s perfect for outdoor equipment. Automotive components benefit from weather resistance. These parts often face constant environmental stress.

- Excellent Electrical Insulation

Silicone rubber blocks electricity well, and it has high dielectric strength. This makes it perfect for protecting wires and plugs. It’s great for electronics housing.

The material works safely around electricity. This keeps delicate equipment protected. It lasts long without breaking down.

- Non-toxic and Biocompatible

Silicone is completely body-safe and non-toxic. Doctors use it for medical implants. It’s approved for food surfaces and baby items. It works safely even at high heat.

The material won’t cause allergies or reactions. Extended skin contact won’t cause problems. The purest silicone has no added chemicals. This makes it perfect for food storage.

Medical silicone passes tough cleaning tests. It meets all health and safety rules. Hospitals and kitchens trust these special grades.

Medical-grade silicone undergoes strict sterilization testing. It meets rigorous FDA and ISO 10993 standards. These specialized grades ensure safety for healthcare and consumer use.

Which Watch Strap is Best for You?

| Use Case | Best Material | Why? |

|---|---|---|

| Daily Casual Wear | Silicone | Lightweight, soft, and colorful |

| Professional Appearance | FKM Rubber | Sleek, matte finish; premium look |

| Sports & Fitness | Silicone | Sweat-proof and flexible |

| Diving & Water Sports | FKM Rubber | Superior chemical and water resistance |

| Harsh Environments | FKM Rubber | Industrial-grade durability |

| Cold Weather Use | Silicone | Remains flexible in freezing temps |

How to Choose Between FKM Rubber and Silicone Rubber

Choose your rubber material based on application needs. FKM (fluoroelastomer) and silicone rubber excel in different environments. Each offers unique advantages for specific uses. Below, we compare their key properties.

1. Temperature Range Requirements

FKM rubber resists extreme heat. It handles short bursts up to 300°C (572°F). For continuous use, it withstands 250°C (482°F). This makes it ideal for high-temperature applications.

Automotive systems benefit greatly from FKM properties. It performs reliably during prolonged high-temperature exposure. Common applications include oilfield equipment components. Turbine gaskets frequently use this durable material.

Special formulations endure extremes beyond 300°C. It maintains functionality from frigid –60°C to intense 260°C.

While its heat resistance appears moderate, its flexibility stands out. Both high and low temperature extremes are manageable. Such versatility makes silicone uniquely valuable.

Silicone rubber stays flexible even in extreme cold, unlike FKM. This cold flexibility makes it ideal for sensitive electronics. Medical devices enjoy reliable performance in low temperatures.

When to choose:

- FKM Rubber for high-heat machinery (engines, refineries, aerospace).

- Silicone Rubber for wide thermal cycling (electronics, freezers, outdoor seals).

2. Chemical Resistance Needs

FKM rubber provides excellent resistance to aggressive chemicals. It handles fuels, oils, acids, and solvents effectively.

Silicone rubber resists oxygen, ozone, and UV light well. It performs well against moisture and weathering. Yet, it struggles with fuels and strong chemicals.

Silicone excels in food-grade applications. Medical devices use it for their safe properties. Outdoor uses favor silicone for weather resistance. It works best when chemical exposure remains limited.

When to choose:

- FKM for fuel lines, chemical handling, oil & gas applications.

- Silicone for outdoor seals, medical equipment, and food-safe products.

3. Mechanical Strength and Flexibility

It’s incredible how long FKM lasts under mechanical stress. Instead of being flexible, FKM is stiff. Because it is stiff, it can’t be used in high-flex situations. When strength is most important, FKM does its best. Silicone works better for uses that need to move around. Each material is used for different engineering tasks.

Silicone rubber’s softness and elasticity make it perfect for flexible components. While its natural tear strength falls short of FKM, it maintains superior pliability. Reinforced silicone formulations address these limitations. Such versatility explains silicone’s widespread industrial adoption.

When to choose:

- FKM for high-pressure seals, industrial valves, and heavy-duty mechanical parts.

- Silicone is used for flexible gaskets, medical tubing, and soft-touch components.

4. Environmental and Outdoor Conditions

If it wasn’t carefully made with UV stabilisers, FKM rubber doesn’t do well in the sun for long periods of time. It is very resistant to chemicals but can wear easily, so it works best indoors or in a protected area where sunshine isn’t an issue. For outdoor use, FKM needs covers or coats that protect it from wear and tear.

Silicone rubber can naturally handle UV rays, ozone, and changes in temperature without any extra help. Because it doesn’t react to weather, it’s the best material for outdoor parts that will be exposed to it, like seals, gaskets, or protection covers.

When to choose:

- FKM for indoor industrial equipment (chemical reactors, engine compartments)

- Silicone for outdoor components (lighting gaskets, solar panel seals, exterior electrical enclosures)

5. Biocompatibility and Regulatory Compliance

FKM rubber isn’t safe for medical or food uses. It lacks proper safety approvals. Stick to industrial jobs where people won’t touch them.

Silicone rubber meets strict medical safety rules. It’s non-toxic and body-safe. Doctors and food companies trust it. Use silicone when people will touch the product.

When to choose:

- Silicone for medical devices, food packaging, and baby products

- Avoid FKM for any application involving ingestion or prolonged skin contact

6. Cost and Budget Constraints

FKM rubber costs more because it handles heat and chemicals better. The extra cost makes sense for tough jobs where failure isn’t an option.

Regular silicone rubber usually costs less. But medical-grade or extra-pure types cost more. Different silicone rubber grades impact their cost. These give the best value when you need stretchy, skin-safe materials.

When to choose:

- FKM for critical systems (aerospace, chemical processing) where performance outweighs cost

- Silicone for consumer goods, medical devices, or high-volume production, needing safe, flexible materials

7. Industry-Specific Application Scenarios

Industry applications determine the suitability of FKM or silicone rubber. The following table encapsulates the primary applications:

| Industry | Best Choice | Why |

|---|---|---|

| Automotive | FKM Rubber | Withstands fuels, heat, and oil – ideal for engine seals |

| Medical & Healthcare | Silicone Rubber | Biocompatible, sterilizable, flexible |

| Aerospace | FKM Rubber | Resists jet fuel, heat, and pressure |

| Consumer Products | Silicone Rubber | Safe, soft, good for kitchenware or toys |

| Electronics | Silicone Rubber | Excellent insulation and heat resistance |

| Chemical Processing | FKM Rubber | Superior chemical and corrosion resistance |

8. Quick Decision Checklist

- Extreme chemical resistance needed? Choose FKM rubber watch straps

- Medical or food contact required? Choose Silicone straps

- Outdoor UV or weather exposure? Choose Silicone straps

- High heat and fuel exposure? Choose FKM rubber watch straps

- Low-temperature flexibility needed? Choose Silicone watch straps

- Cost-sensitive consumer product? Choose Silicone watch straps

- Industrial-grade sealing under pressure? Choose FKM rubber watch straps

Conclusion: FKM or Silicone?

Know the differences between FKM and silicone watch straps. This helps you pick the right material. FKM resists chemicals well. Silicone is soft and hypoallergenic—both last a long time.

Use our Quick Decision Checklist to compare your options. For special needs, like sports or medical use, talk to our experts. We’ll help you find the best strap.

Which Watch Strap Wins for Your Lifestyle?

Hongju Silicone makes strong, reliable straps for many uses. Divers get straps that resist chemicals well. Athletes choose flexible silicone straps for comfort. Professionals trust these straps in tough conditions. Each strap fits specific needs. We focus on quality and performance.

Contact us now and get your Ideal Fit immediately. Our experts will identify the most suitable strap material to meet your requirements.

FAQs

Q1: Is fluoroelastomer the same as silicone?

No, they’re different; FKM resists heat and chemicals. Silicone stays flexible in cold weather. Choose FKM for fuel/oil exposure. Pick silicone for outdoor/skin contact.

Q2: Are silicone bands better than rubber bands?

Silicone bands last longer and stretch better than regular rubber bands. They resist the sun, heat, and water. Rubber bands break faster and crack in the weather.

Q3: What is FKM in rubber?

FKM is a special rubber for extreme conditions. It handles high heat (up to 250°C) and harsh chemicals better than regular rubber.