FFKM and FKM bear many similarities but also have important differences. These differences mean that in some applications, only one of the two should be used.

In this article, we’ll explore the unique nature of these two sealing materials. We’ll examine their chemical properties, the applications each is suited for, and how to choose between them. We’ll also discuss the immediate and long-term costs of FFKM and FKM and why they matter.

What is FFKM Rubber?

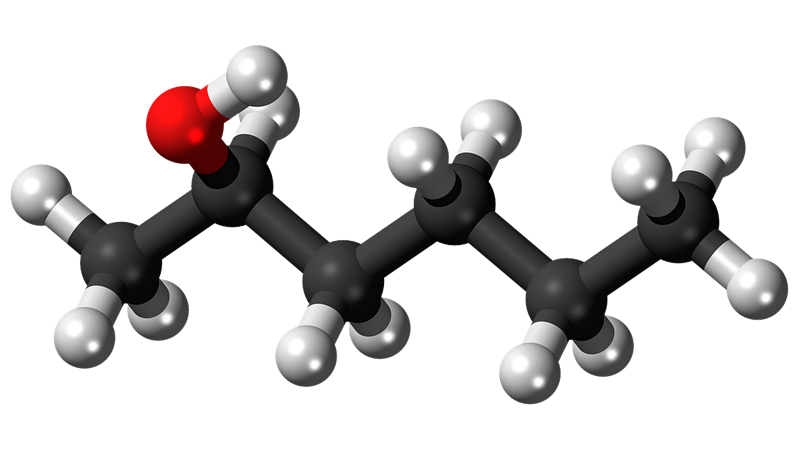

FFKM is a synthetic rubber that was developed in the 1960s. This carbon-based rubber is sometimes referred to as the rubber form of PTFE because it exhibits exceptional resistance to chemicals and heat.

Both FKM and FFKM materials contain a significant amount of fluorine but FFKMs contain more fluorine than FKMs. They were developed because of the need for seals that could perform well under more extreme conditions than FKMs could manage.

The manufacture of FFKM rubber on a grand scale didn’t start until the late 80s due to patent restrictions. Consumers can now choose from several brands of FFKMs in the market.

What is FKM Rubber?

FKM rubber is a fluoroelastomer that first came to market in the 1950s. These synthetic rubbers are made using vinylidene fluoride and contain as much as 69% fluorine by weight. FKMs exhibit excellent high-temperature stability and are chemically resistant to many substances.

There are different types of FKM materials today. Some are good all-rounders but others are developed to have improved high temperature or chemical resistance. This usually sacrifices other qualities such as low-temperature performance.

Viton rubber was the original FKM developed by DuPont. There are plenty of FKM brands to choose from today.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Chemical Properties and Composition

FKMs are fluorinated polymers or fluoroelastomers and FFKMs are perfluoroelastomers. What does this mean and how does this impact their individual properties?

Compositions, Structure, and Properties of FKMs

Different FKMs are made using different monomers. Vinylidene fluoride is present in all FKM materials but other monomers present may include:

The polymer structure of FKMs contains carbon-fluorine bonds. This bond is considered one of the strongest individual bonds in chemistry and is the secret behind both FKMs’ and FFKMs’ increased chemical resistance and thermal stability.

Different processes can be used at the curing stage for FKMs. The main curing processes used today are bisphenol(ionic), diamine, and peroxide cross-linking.

The properties of the FKM will be affected by the curing method. For example, FKMs produced by diamine cross-linking are unmatched in forming rubber-to-metal bonds. However, ionic cross-linking produces FKMs with the best heat resistance.

Common properties of FKMs include:

- Excellent ozone resistance

- Oil and grease resistance

- High density, i.e., >1.8g/cm3

- Higher temperature resistance than most elastomers (260°C/500°F)

- Very high resistance to chemicals including petrochemicals and strong acids

The specific properties of FKMs vary depending on compounding and the curing process used by the rubber seal manufacturer.

Composition, Structure, and Properties of FFKMs

Cyano-functional vinyl ethers are commonly used as the cure site monomer for FFKMs. They are compatible with different curatives including peroxide.

Organic peroxide curing of FFKM materials produces a uniquely high chemical resistance. However, this also makes FFKMs less resistant to oxidative and thermal degradation.

Diamino bisphenol AF is used as the curative instead to get an FFKM with excellent thermal resistance.

This sealing material can be formulated in different ways to achieve different temperature resistances. FFKMs also contain carbon-fluorine bonds but, unlike FKMs and other elastomers, they don’t have any carbon-hydrogen bonds. This gives them superior chemical and heat resistance.

Common properties of FFKMs include:

- Excellent thermal stability at temperatures ranging from -55°C (-67°F) to 350°C (662°F)

- Excellent chemical resistance (better than FKMs)

- Good mechanical properties

- Low-contamination potential

- Very low permeability

- Higher steam resistance

Similar to FKMs, the specific properties of FFKMs depend on the compounding and curing process.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Applications in Industry

FKM and FFKM are used to make seals for applications in extreme operating environments where other elastomers perform poorly. However, because of FFKM’s superior heat and chemical resistance, it is used in even more extreme environments compared to FKM.

Common Applications for FKM and FFKM

FKMs are used to make high-performance seals and o-rings in industries such as:

- Oil and gas

- Chemical processing

- Industrial applications, etc.

- Pharmaceutical industries

- Aerospace and automotive industries

FFKM can be used in similar applications but is typically saved for more extreme conditions that FKM can’t withstand. It’s also used in applications where contamination levels must be kept as low as possible. Examples of applications that are unique to FFKMs are:

- Semiconductor manufacturing – This requires an elastomer that’s less likely to contaminate its surroundings

- Applications with operating temperatures between 260°C and 327°C

- Applications with fluids that are more corrosive than FKM can handle

Limitations of FKM and FFKM

As versatile as FKM and FFKM are, they have their limitations. When FFKMs are used at higher temperatures than they are rated for, they can become brittle, losing their sealing ability. They can also release hydrofluoric acid at very high temperatures.

Similarly, FKMs may release hydrogen fluoride if exposed to very high temperatures.

Seal integrity can be compromised if these two materials are exposed to certain chemicals including fluorinated solvents and gaseous alkali metals. Check for compatibility with specific chemicals when choosing FKM or FFKM seals. Choosing the wrong grade can result in rapid failure.

Cost Analysis of FKM and FFKM

FKM and FFKM are both considered expensive compared to other types of rubber, but FFKM costs even more than FKM.

The most obvious reason for this is the higher cost of raw materials used to manufacture FFKM which can cost several thousand dollars per kg. However, there are additional factors that affect the pricing of FFKM seals such as:

- Rising demand: Demand for FFKM seals has risen recently due to their importance in semiconductor manufacturing.

- Ingredient shortages: FFKMs require specific ingredients with few suppliers. This has led to a limited supply of key ingredients for manufacturers.

- Complicated production process: Producing FFKM is a more involving process than producing FKM.

In addition to their higher cost, customers face longer wait times if they need FFKM seals and o-rings. Therefore, getting FFKM products costs more in terms of both money and time. Even so, many believe they are worth it.

Although they cost more upfront, FFKM seals can save companies more money in the long run because:

- FFKM seals are durable and can outlast other rubber seals.

- FFKM seals are more reliable and fewer resources are spent on inspection and maintenance in the long run.

- Equipment with FFKM seals face fewer seal-related breakdowns resulting in increased uptime and productivity.

- FFKM seals are less likely to contaminate parts, e.g., semiconductor chips, leading to fewer defects.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Choosing Between FFKM and FKM

The best sealing solution between FFKM and FKM will be determined by the operating conditions in your application and your budget. Some important factors are explained below.

1. Chemical and Thermal Environment

Both FKM and FFKM have outstanding chemical and thermal tolerance but they have their limits. FFKM is a better choice if an application has operating temperatures above 260°C or below -26°C.

FFKM is also better for applications with exposure to very harsh chemicals that are likely to degrade FKM.

2. Cost

FFKM is significantly more expensive than FKM. This is an important factor in applications where FFKM’s extreme thermal and chemical resistance is unnecessary, e.g., when the operating temperature is under 260°C.

Although FFKM will perform well, the extra expense will be unjustified if FKM performs similarly well.

3. Availability

Recent supply chain issues have made it difficult to get certain items including seals needed for critical applications in extreme environments. FFKM seals have been particularly impacted by this due to their unique composition.

Some companies may not have the luxury of waiting for an FFKM seal. If an FKM seal will perform reasonably well, it may be necessary to get one as a stopgap until the FFKM seal arrives.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Modern industries have sealing requirements that can’t be met by ordinary rubber seals. This is what led to the development of FKM and FFKM seals. FFKM’s chemical and thermal resistance is unrivaled but FKM seals are still good for many applications and less expensive.

These elastomers have similar chemical properties including strong carbon-fluorine bonds. FFKM performs better because it has no carbon-hydrogen bond. Choosing between these two materials requires careful consideration of the operating environment, cost, and availability.

Why Go to Hongju Silicon for Your FFKM and FKM Seals?

At Hongju Silicone our clients have entrusted their seal manufacturing needs to us for more than 20 years. We use different manufacturing processes including injection molding and have experience working with many materials including FKMs.

If you are puzzled by the choice between FKM and FFKM seals, reach out and discuss your needs with our technical experts today.