These specialized sealing solutions are designed to be easily detected by X-ray and metal detection systems, significantly ensuring product safety and minimizing customer complaints. In this article, we will delve into what metal and X-ray detectable seals and gaskets are, their applications, and why they could be a critical component in your effective inspection program.

What are Metal And X-Ray Detectable Seals/Gaskets?

Metal and X-ray detectable seals and gaskets are specialized sealing components made from high-density plastics or other detectable materials. Unlike conventional seals, these are formulated to be easily identified by X-ray and metal detection systems, thereby reducing the risk of product waste and contamination.

In essence, these seals and gaskets are designed to enhance product safety by ensuring that any piece that becomes detached or worn can be readily detected and removed from the production line, ensuring product safety.

This innovative feature significantly reduces the likelihood of missing or broken products packaged, making it through to the final package, thus safeguarding package integrity and minimizing risk. The inclusion of this technology also helps maintain package mass consistency.

Metal/X-Ray Detectable Gaskets Material

Metal and X-ray detectable seals or gaskets play a crucial role in various industries, ensuring product safety and preventing contamination.

These specialized seals/gaskets are designed to be easily identified by metal detectors or x-ray machines, allowing for quick detection and removal if they were to accidentally enter the production line. But what exactly are these seals/gaskets made from? Let’s take a closer look.

Metal Detectable Gaskets/Seals

Metal-detectable seals/gaskets are typically crafted from materials like silicone, EPDM (ethylene propylene diene monomer), or PTFE (polytetrafluoroethylene) infused with metal fillers.

- Silicone-based metal detectable seals/gaskets offer excellent flexibility and resistance to extreme temperatures, making them suitable for use in diverse environments. They can withstand both high and low temperatures without compromising their sealing capabilities.

- EPDM is another popular material used in the production of metal detectable seals/gaskets. It provides exceptional resistance to chemicals, ozone, and weathering, making it ideal for applications where exposure to harsh substances is common.

- PTFE-infused metal detectable seals/gaskets are known for their outstanding chemical resistance and low friction properties. They can withstand aggressive chemicals and maintain an effective seal even under challenging conditions.

X-Ray Detectable Seals/Gaskets

X-ray detectable seals/gaskets contain additives that enhance visibility under X-rays. Two commonly used additives include barium sulfate and stainless steel fibers.

- Barium sulfate is a white crystalline powder that is highly opaque to X-rays. When mixed with seal/gasket materials such as silicone or rubber, it enables easy identification during routine inspections using x-ray equipment.

- Stainless steel fibers are another additive used in the production of x-ray detectable seals/gaskets. These fine metallic fibers are integrated into the seal/gasket material, providing enhanced visibility under X-rays. The presence of stainless steel fibers ensures that even small fragments or particles can be easily detected and removed.

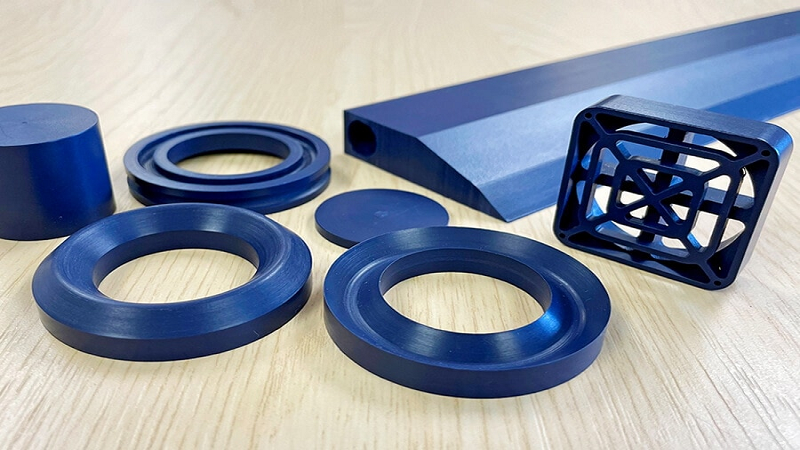

Types of Metal and X-ray Detectable Seals/Gaskets

Metal and X-ray detectable seals/gaskets are essential components used in various industries to ensure product safety and prevent contamination.

These seals and gaskets are designed to be easily detectable by metal detectors and X-ray machines, making them ideal for applications where food or pharmaceutical products are involved.

Let’s explore the common types of metal and X-ray detectable seals/gaskets, their shapes, sizes, and customization options.

Common Types

Metal and X-ray detectable seals/gaskets come in a variety of forms to cater to diverse industrial requirements. Some common types include:

- O-rings: These circular seals with a round cross-section are widely used in sealing applications due to their versatility.

- Gaskets: Gaskets are flat or ring-shaped components placed between two surfaces to prevent leakage.

- Flat washers: These thin discs distribute the load, reduce friction, and provide a seal between fasteners and surfaces.

- Diaphragms: Diaphragms are flexible barriers that allow for pressure regulation or separation between different media.

- Extruded profiles: These custom-designed profiles can be manufactured in various shapes (e.g., tubes, cords) based on specific requirements.

Shapes and Sizes

Metal and X-ray detectable seals/gaskets come in different shapes and sizes to accommodate diverse industrial needs. The availability of various configurations ensures compatibility with different equipment or machinery setups.

Seals/gaskets can be found in round, square, rectangular, or irregular shapes, depending on the application requirements. They are available in a range of sizes, such as small-sized O-rings used for sealing pipes or larger gasket sheets employed for sealing large flanges.

Benefits of Metal and X-ray Detectable Seals/Gaskets

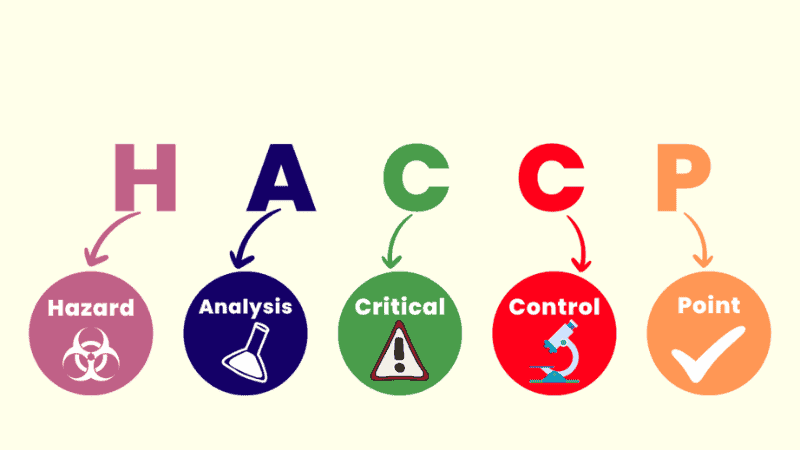

Metal and X-ray detectable seals/gaskets offer several advantages that can significantly enhance production line safety and compliance with food safety certifications such as HACCP.

These specialized seals provide an extra level of protection against foreign object contamination, reducing the risk of product recalls, customer complaints, and potential legal issues.

Enhanced Protection Against Foreign Object Contamination

Metal and X-ray detectable seals/gaskets act as a crucial barrier in production lines, preventing foreign objects from entering the final product.

By incorporating these seals into equipment and machinery, manufacturers can minimize the risk of contamination caused by loose parts or fragments that may accidentally enter the production process.

These specialized seals are designed to be easily identifiable by metal detectors or X-ray machines commonly used in food processing facilities. This enables swift detection and removal of any seal material that may have become dislodged during production, as well as detecting packing voids.

By promptly identifying and addressing such issues, companies can prevent contaminated products from reaching consumers, safeguarding their reputation for quality and safety.

Compliance with Food Safety Certifications

In today’s highly regulated food and pharmaceutical industries, compliance with stringent safety certifications like those outlined by the Food Safety Modernization Act and Hazard Analysis Critical Control Point(HACCP) systems is crucial.

HACCP, in particular, mandates businesses to implement preventive measures to identify and control potential hazards throughout the entire production process.

X-ray and metal detection systems offer a robust solution in this regard, enhancing product safety and integrity by swiftly detecting and removing any seal material or foreign objects that may compromise the production line.

Metal and X-ray detectable seals/gaskets play a vital role in fulfilling these requirements, thus ensuring product safety for both food and pharmaceutical manufacturers. Their implementation aligns with HACCP principles, facilitating efficient certification while safeguarding consumer safety.

Risk Reduction

Product recalls not only damage a company’s reputation but also incur significant financial costs. Metal and X-ray detectable seals/gaskets help mitigate the risk of recalls by providing an additional layer of protection against foreign object contamination.

By minimizing the chances of seal fragments or other contaminants entering the production process, these specialized seals reduce the likelihood of product defects that could trigger customer complaints or lead to potential legal issues.

Comparison of Metal and X-ray Detectable Seals/Gaskets

Here’s a table to compare the key features of Metal and X-ray Detectable Seals/Gaskets:

| Feature | Metal Detectable Seals/Gaskets | X-Ray Detectable Seals/Gaskets |

|---|---|---|

| Detection Mechanism | Easier to detect with conventional metal detectors | Reliable for detecting smaller or irregular fragments via X-ray |

| Material Composition | High-density plastics infused with metal particles | Specialized high-density plastics are visible under X-ray |

| Cost | Generally less expensive | Typically more expensive |

| Industries Used | Food, Pharmaceutical | Food, Pharmaceutical, Medical, Aerospace |

| Limitations | Not as effective with metallic products or high-temperature conditions | Cost and need for specialized X-ray systems can be barriers |

| Product Safety | Excels in ensuring product safety | Excels in ensuring product safety |

| Versatility | Customizable for specific requirements | Customizable for specific requirements |

| Reduced Waste and Downtime | Aids in lowering product waste and costly downtime | Aids in lowering product waste and costly downtime |

By understanding the particularities of each type of seal/gasket, you can better decide which is more suitable for your specific needs and industrial applications.

Benefits of Using Metal Detectable in the Food and Beverage Industry

Metal detectable seals/gaskets are a crucial component in ensuring food safety within the food and beverage industry. With strict regulations in place to prevent contamination incidents, these detectable products play a vital role in safeguarding both consumers and businesses.

Let’s explore the benefits of using metal detectable seals/gaskets in this industry. Helps meet strict food safety regulations by preventing contamination incidents

One of the primary advantages of metal detectable seals/gaskets is their ability to help businesses comply with stringent food safety regulations. These regulations are put in place to protect consumers from potential health hazards caused by foreign objects entering their food or beverages.

By incorporating metal detection technology into seals and gaskets, any accidental presence of metallic particles can be quickly identified and removed during production or packaging processes.

Metal detectable seals/gaskets act as an additional layer of defense against contamination incidents. They are designed with special properties that allow them to be easily detected by standard metal detectors used throughout the industry.

This ensures that any product containing a faulty seal or gasket can be swiftly identified and isolated before reaching consumers. Protects brand reputation by ensuring product integrity throughout the supply chain.

In today’s competitive market, maintaining a brand reputation is crucial for businesses operating in the food and beverage industry. Any instance of contaminated products reaching consumers can have severe consequences, including damage to brand image, loss of consumer trust, and potential legal implications.

By utilizing metal detectable seals/gaskets, companies can significantly reduce the risk of contaminated products entering the supply chain. These specialized components act as an effective barrier against foreign object contamination, providing an added layer of protection for both manufacturers and consumers alike.

Enhances consumer trust and confidence in the safety of food and beverage products. Consumer trust is paramount. In recent years, there has been an increased focus on transparency within the industry, with consumers demanding greater assurance regarding the safety and quality of the products they consume.

By incorporating metal detectable seals/gaskets into their manufacturing processes, companies can enhance consumer trust and confidence. These detectable components demonstrate a commitment to food safety and provide reassurance that thorough measures are in place to prevent contamination incidents.

Case Studies: Real-Life Applications of Metal and X-ray Detectable Seals/Gaskets

Metal and X-ray detectable seals/gaskets are really important in industries like pharmaceuticals, food processing, and packaging. They help stop contamination during production. Let’s look at some examples that show how useful these seals are.

Case Study 1: Dairy Processing Plant Implements Hongju’s Metal Detectable Seals

A dairy processing plant facing frequent downtime due to seal failure partnered with Hongju to implement metal detectable seals. The Hongju seals provided an immediate solution, leading to a significant reduction in costly downtime and product waste. These seals were easily detected during quality checks, thereby ensuring product safety.

Case Study 2: Beverage Manufacturer Switches to Hongju’s X-ray Detectable Gaskets

A leading beverage manufacturer experiencing customer complaints about package integrity switched to Hongju’s X-ray detectable gaskets. This transition allowed their x-ray inspection systems to easily identify missing or broken products, resulting in a substantial decline in customer complaints related to product and package integrity.

Conclusion

Metal and X-ray detectable seals and gaskets serve a critical function in ensuring product and packaging reliability across a multitude of industries.

From their material composition to the broad range of applications, these specialized seals have proven to be indispensable. These seals are becoming the top choice in industries like food and beverage and high-tech because they reduce risks and make a big impact.

Get Industry-Leading Metal and X-ray Detectable Seals from Hongju

At Hongju Silicone, we specialize in high-quality metal and X-ray detectable seals and gaskets that meet the stringent demands of various industries.

With our state-of-the-art technology and rigorous quality control, we ensure that you receive products that not only enhance your operational efficiency but also guarantee product safety. Contact us now and get our free suggestions. We promise that we will try our best to meet your needs and improve your business.