Nowadays, silicone rubber products are sought-after because of their resistance to high temperatures, non-toxic nature, chemical resistance, oil resistance, durability, flexibility, and cost-effectiveness. Whether you’ve just recently switched to rubber washers or you’re looking for a new silicone rubber supplier, we’ll be featuring the top 10 silicone rubber washer manufacturers you can source from in China. We’ll also talk about the key things to consider when choosing the right supplier for your business.

An Overview of the Silicone Rubber Washers Industry

Although regular rubber washers are generally good enough, silicone rubber washers are way more durable. Especially for items that need to be extra heavy-duty like car parts and industrial machinery, it’s best to choose silicone rubber washers. They’re weather and ozone-resistant and also highly durable since they aren’t prone to condensation effects. Plus, they’re more customizable because of their malleability.

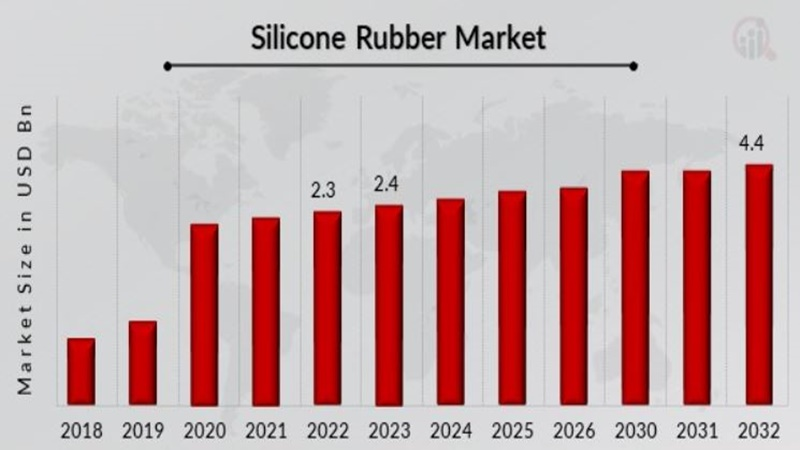

With the growing demand for electric vehicles and construction materials, the silicone rubber market is sustainably growing. Year after year, its market size is increasing with an expected annual growth rate of 7.5% from 2023 to 2032.

5 Things to Consider When Choose Silicone Rubber Washers Manufacturer

While cheap is good– no doubt. Cheaper isn’t always better. You shouldn’t readily go for the first cheapest supplier you come across. There are other important aspects to consider besides pricing. After all, you’re choosing silicone rubber washers to ensure precision and performance. You need the right silicone rubber washer manufacturer that can guarantee quality without breaking the bank.

Here are key factors to consider when choosing a silicone rubber washer manufacturer in China.

1. Quality Control

Look for a manufacturer that can offer both quality and consistency. Every batch of silicone rubber washers you receive should achieve your desired dimensions and project requirements. Competent manufacturers focus on a process-oriented quality management system that highlights product improvement, waste reduction, and defect prevention. World-class silicone mold facilities use sophisticated technology to ensure solid quality. Look for suppliers with accreditations and certifications like ISO 9001 and IATF 16949.

2. Proven Track Record

It’s best to work with silicone manufacturers that have been in the business for several years now. They most likely have already established and fine-tuned their manufacturing processes and quality control measures. Their technical knowledge is also time-tested, and they already have a network of raw materials suppliers to ensure stability and scalability. You may also look for testimonials and customer reviews to gain more insights and make an informed decision.

3. Customization

You most likely have exact requirements in mind in terms of shape, size, and even color. The right silicone rubber washer manufacturer can help you bring to life the exact items you need for your production. Whether you require small washers for delicate electronic rubber parts or large ones for heavy-duty industrial equipment, the chosen supplier should be able to offer flexible sealing solutions with competence and accuracy. That way, you can work with a genuine one-stop shop for all your future needs.

4. Prototyping Services

You need to be able to test and validate designs before you proceed to mass production. Find a manufacturer that offers excellent testing services. Especially in the case of liquid silicone rubber washers that require flawless precision and functionality, prototyping is a very important step. It’s crucial to work with a manufacturer that’s willing to refine the design until you’re satisfied. If you don’t want costly errors during mass production, make sure to include this as a benchmark in your search.

5. Competitive Pricing

Check the overall expenses from tooling to setup to production costs. Also, check if the manufacturer offers more discounts for bulk or larger orders. However, don’t compromise quality for affordability. Although the cheapest ones may be the most tempting choice, do your due diligence in checking their reviews and quality control measures. It may only lead to more costly repairs or worse, tarnished reputation if your product’s performance is compromised as a result.

The last thing that you want is subpar components, especially if you’re looking to build high-quality liquid silicone rubber products that can stand the test of time. To fortify your supply chain, make sure to choose the right manufacturers that you’ll be happy to work with over the long term. Here are the top 10 China-based silicone rubber washer manufacturers you can source from.

Top 10 Silicone Rubber Washers Manufacturers in China

The Chinese market has a plethora of rubber parts manufacturers; it can sometimes be challenging to take a pick. Every factory has core strengths, but you need to find one that matches your needs and budget. From quality control to customization to affordability, weigh all essential factors before you dive right in.

| Position | Company Name | Year Established | Location (City) | Employee Size |

|---|---|---|---|---|

| 1 | Hongju Silicone | 1999 | Dongguan | 50-100 |

| 2 | Shengda Rubber | 2011 | Quanzhou | 10-50 |

| 3 | Savvy | 2008 | Ningbo | 100 |

| 4 | Hongjie Sealing | 2001 | Shenzhen | 300 |

| 5 | Seal Smart | 2005 | Shanghai | 10-50 |

| 6 | QL Rubber | 2000 | Haining | 100-150 |

| 7 | Ruichen Sealing | 2006 | Dongguan | 200 |

| 8 | Better Silicone | 1998 | Xiamen | 11-50 |

| 9 | Brother Rubber | 1996 | 50-100 | |

| Qingdao | ||||

| 10 | Tongxiang Spring Rubber & Plastics | 2009 | Tongxiang | 70-80 |

There are a lot of silicone rubber washer manufacturers in China, but these ten options are a good place to start. Let’s examine each alternative according to its product quality and main selling points.

1. Hongju Silicone Co. Ltd.

Hongju Silicone has a solid 23 years of experience in product design and manufacturing. It’s a sought-after silicone rubber supplier in China that offers custom and sustainable solutions. There’s no minimum order requirement, so you can order the volume that you need while expecting lightning-fast delivery.

You also don’t have to worry about safety since all materials are FDA and CE-approved. The factory offers liquid silicone rubber products and services to various markets across Japan, Korea, Europe, North America, and all over the world. Their product catalog is extensive and everything is 100% customizable.

Pros:

- Fast prototyping (in just 3-5 days)

- No minimum order requirement

- 23 years of design and manufacturing experience

Cons:

- Lead time varies depending on the order quantity and complexity

- Quotation takes up to 3 days (although you can also request an instant quote)

Send your inquiry for prompt quotations!

2. Quanzhou Shengda Co. Ltd.

Shengda Rubber also offers custom silicone rubber parts and supports clients both locally and internationally. Established in 2011, the company is a relatively new player (as compared to other competitors) but does offer low-cost and good-quality products.

Their commitment to research and development makes them a great manufacturer to source from. They offer a wide range of silicone rubber products with low MOQ.

Pros:

- Offers a wide range of products

- Provides customization

- Reasonably fast lead time

Cons:

- The website lacks resources and product info

3. Savvy Co. Ltd.

The company manufactures silicone rubber products for both small and large businesses. They produce O-rings, oil seals, rubber gaskets, die-cut gaskets, and other custom liquid silicone rubber parts. They have already delivered more than 10,000 projects worldwide, serving different industries from aerospace to military to laboratories.

They use a wide range of manufacturing processes including vacuum/compression, transfer molding, large-part forming, low-temperature deburring, and so on.

Pros

- Experienced in mass production

- ISO9001 certified

- Any defective product is promptly replaced for free

Cons

- Has minimum order quantity for goods not in stock

- For products not in stock, lead time takes 20-30 days

4. Hongjie Sealing Co. Ltd.

The company’s main products include backup rings, diaphragms, washers, grommets, and other custom rubber components. They produce various silicone products and washers, be it flat washers, sealing washers, beveled, spherical washers, and so on.

They also offer customization, so they can use various materials depending on your required silicone products– from printing silicone rubber to silicone foam and other custom silicone products and services.

Pros

- Supports emergency production

- Good customer support

- IAFT 16949 certified

Cons

- Lead time is around 5 weeks

- Free tooling is available for large orders only

5. Seal Smart Co. Ltd.

Seal Smart produces molded silicone rubber products for various industries like automotive, electronics, plumbing, chemical processing, oil and gas, and so on. You can choose from their wide range of silicone rubber products from rubber silicone gaskets to X-rings to rubber balls. The rubber washers available in their catalog include the EPDM rubber washers, VMQ (SI( rubber washer, FKM (VITON) rubber washer, NBR rubber washer, and CR rubber washer. The company has 15 years of experience in the industry and also offers customization and has its mold manufacturing department.

Pros

- FDA and SGS-approved

- Wide range of silicone rubber products

- 15 years of industry experience

Cons

- With minimum order quantity

6. QL Rubber Co. Ltd.

From rubber seals to rubber dampers and other molded rubber parts, the Haining Qianlang Rubber Products Factory supplies different kinds of rubber products. You can choose from any versatile material and processing methods like water treatment, plastic injection molding, compression molding, die cutting, and silicone injection molding, among other liquid silicone rubber services. The factory offers standard parts as well as customized rubber components depending on clients’ specifications.

With its 20 years of experience in the industry, QL Rubber has already established customers across the globe.

Pros

- Small orders accepted

- The website has an extensive resource page on rubber plastic products and other silicone rubber parts.

- Responsive customer support

Cons:

- Some customers received the wrong dimensions

7. Ruichen Sealing Co. Ltd.

The company was established in 2006, serving clients in their production of auto parts, electronics, power tools, connectors, toys, and pneumatic components. The company’s main products are rubber seals with over 4000 molds for o-rings and a wide range of materials and colors available. Their production equipment is advanced, and they invest in research and development to experiment and test various properties and rubber components to improve product performance. They support both domestic customers as well as clients from other countries including Canada, Britain, India, Russia, Singapore, and the US.

Pros:

- Specialization in rubber seals

- Certified by FDA, ISO9001, RoHs, and IATF 16949

- Customizable molded rubber products

Cons

- With minimum order requirement

- Delivery time may take 7-45 days depending on the scope

8. Better Silicone Co. Ltd.

Although they have a smaller manpower, Xiamen Better Silicone is another reliable factory for molded silicone products, rubber plastic, and other rubber items. From medical-grade silicone injection molding to liquid silicone rubber products, Better Silicone has a wide range of rubber components especially for medical facilities.

The factory produces medical silicone sealing gaskets, liquid silicone rubber molding, silicone vacuum suction cups, and more. The company specializes in medical silicone products, so if you’re looking for expertise in this niche, Better Silicone is the place to go.

Pros

- FDA and SGS-approved

- Offers factory tour service

- Provides sample order services

Cons:

- Catalog is limited (especially to medical products)

9. Brother Rubber Co. Ltd.

Brother Rubber has been around since 1996. They have an extensive product catalog and offer custom silicone and standard rubber parts. They have harnessed their injection, compression, and transfer molding capabilities over the years. They work with various industries and have established relationships with shipping companies, helping you receive better shipping deals.

Their factory has grown from just 10 molding machines to 15 automatic rubber molding machines, 20 semi-automatic machines, 5 liquid injection molding devices, 8 extrusion machines, and other mold-making equipment. The company has established over 100 standard products over the years yet still offers maximum customization to customers around the world.

Pros

- 100% customizable

- Timely delivery

- Flexible payment methods including Western Union, PayPal, T/T, and small-amount payment

Cons

- Custom orders may take longer

10. Tongxiang Spring Rubber & Plastics Tech. Co., Ltd

The company offers silicone rubber products, plastic products, and hardware solutions as well. Established in 2009, the factory is a relatively new player as compared to its counterparts. The team is composed of 5 mold design engineers and their hub is located just 100 kilometers from Shanghai. Their quality control measures are pretty solid, and they have been a trusted supplier for clients in different countries.

Pros

- Great quality control and inspection

- ISO9001 and SGS-certified

- Has an extensive product catalog

Cons

- The average lead time may take a month

Summary

The reliability and longevity of your systems and equipment depend on the caliber of your chosen silicone factory. You shouldn’t choose a manufacturer haphazardly and must take the time to verify each supplier’s capabilities in terms of quality control, scalability, customization, customer support, and pricing.

Another crucial factor is consistency. You need a stable supply chain, and if the supplier delivers on a hit-or-miss basis, that could jeopardize your production and cause costly delays. Choose a proven and tested silicone rubber washer manufacturer to make sure that every little thing in your production is covered. A supplier with decades of experience has already refined their manufacturing processes and lead times and can also better handle emergency orders and demands for scalability.

Why Choose Hongju Silicone Co. Ltd. for Your Projects?

If you need straightforward and smooth transactions from start to finish and if you’re looking for a reliable manufacturer that you can work with long-term, Hongju Silicone is the pick of the litter. Visit Hongju Silicone to explore its robust manufacturing capabilities and highly comprehensive solutions.