Rubber plays a critical role in industries from automotive to medical. Its properties—tensile strength, heat resistance, elasticity, and durability—directly determine whether it is suitable for a specific application. This guide compares natural and synthetic rubber in detail, helping you choose the right material for your needs.

What is Rubber?

Rubber is an elastomer (polymer with elastic characteristics) categorized as natural rubber and synthetic rubber. The major difference is in their composition.

Natural rubber comes mainly from Hevea brasiliensis trees grown in tropical regions, composed primarily of polyisoprene. It is harvested as latex and processed into sheets or blocks.

Synthetic rubber is made from petroleum byproducts like butadiene and styrene through controlled polymerization, allowing tailored performance for heat resistance, oil resistance, or weathering.

Both natural and synthetic rubber are widely used, but synthetic types can be engineered for specific needs such as higher heat resistance, oil resistance, or weathering performance.

In the automotive sector alone, tires, seals, gaskets, hoses, and belts are made from rubber. It also has critical use in the medical sector; surgical gloves, catheters, etc, are rubber-made. Other applications involve sports equipment, electrical insulation, adhesives, and sealants.

Natural Rubber vs. Synthetic Rubber – Quick Comparison

| Property | Natural Rubber | Synthetic Rubber (Range) |

|---|---|---|

| Hardness (°Shore A) | 25–95 | 10–95 |

| Temp Resistance (°C) | -40 to +80 | -70 to +180 (up to 350 short-term) |

| Tensile Strength (MPa) | ~25 | 8–30 |

| Elongation (%) | Up to 800 | 150–800 |

| Oil/Fuel Resistance | Poor | Poor–Excellent |

| Ozone Resistance | Moderate | Moderate–Excellent |

| Sustainability | Renewable, biodegradable | Petrochemical-based, partially recyclable |

Physical Properties of Rubber

The physical properties of rubber are critical in determining its suitability for various applications. These rubber characteristics describe its interaction with the environment.

Let’s discover the physical properties of rubber and how you can measure them.

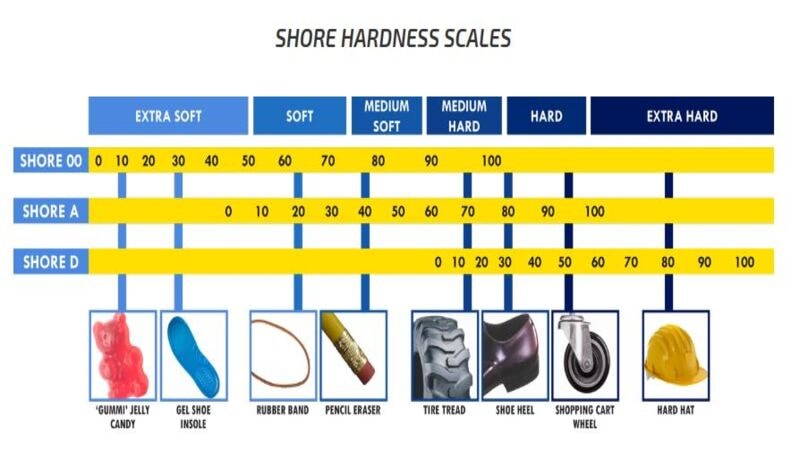

1. Hardness

Hardness is the resistance to deformation upon the exertion of a force. It is an inherent property of rubbers due to their chemical structure. Every rubber type has a different level of hardness, which is set according to the intended application.

The hardness level can be modified through chemical compounding. Commercially available rubbers have different hardness levels. Hardness determines the load-bearing capacity of a rubber. It is a crucial performance parameter when selecting rubber for different applications.

Example: EPDM roofing sheets are usually Shore A 60–70 for a balance between flexibility and impact resistance.

2. Tensile Strength

Tensile strength is the material’s ability to withstand a force to the point it breaks when being stretched. Simply put, tensile strength in rubber is resistance to breaking when pulled apart.

SBR typically offers 15–20 MPa tensile strength, making it common in automotive tires. When compared to natural rubber, synthetic rubber, like styrene butadiene rubber (SBR), has a high tensile strength.

3. Thermal Resistance

Thermal resistance is the ability to withstand heat without property loss. EPDM, silicone, and fluorocarbon outperform NR, handling up to 180–300 °C.

Mechanical Properties of Rubber

The mechanical properties of rubber dictate its behavior in different operating conditions. Understanding these rubber characteristics is necessary to see how rubber reacts when exposed to a variety of forces and stresses.

4. Elongation

Elongation is the stretching of a material due to tensile stress, increasing its original length. Rubbers are highly elastic materials and tend to elongate three to four times their original length. This property enables the application of rubber in different settings.

Elongation is the % stretch before breaking. Silicone: 300–700%; NR: up to 800%. Critical for gaskets, gloves, and flexible seals.

5. Resilience

Resilience is the material’s ability to absorb energy when stretched and release it to retain its original shape without deforming. Resilience in rubber is a property that enables it to regain its original size and shape after undergoing deformity due to compressive, tensile, or bending forces.

Resilience is the rebound ability after deformation. NR has high rebound; neoprene retains resilience outdoors. Measured as % rebound (ASTM D7121).

Durability Properties of Rubber

Durability increases the usability of rubber for a variety of applications. When selecting a rubber type, you must understand its specifications to ensure efficient operations. The following properties are critical to maintaining rubber’s structural integrity and performance levels for better durability.

6. Tear Resistance

Tear resistance is a property of a material that prevents rupture when experiencing high tension. Rubber projects a good tear resistance due to its elastic nature. It prevents any tears or cuts caused by rough metal edges or sharp objects. The propagation of cuts and nicks is also prevented to maintain operability.

Tear resistance is measured in kilonewtons per meter (kN/m) or pound-force per inch (lbf/in).

7. Abrasion Resistance and Compression Set

Abrasion resistance is a material’s ability to resist abrasion (damage due to scraping or rubbing against itself and other objects) without deforming. A compression set refers to the material’s inability to decompress to its original shape and size after experiencing a compression load.

Both are critical rubber characteristics that impact durability. Ideally, rubbers should have high abrasion resistance and low compression set for optimal performance.

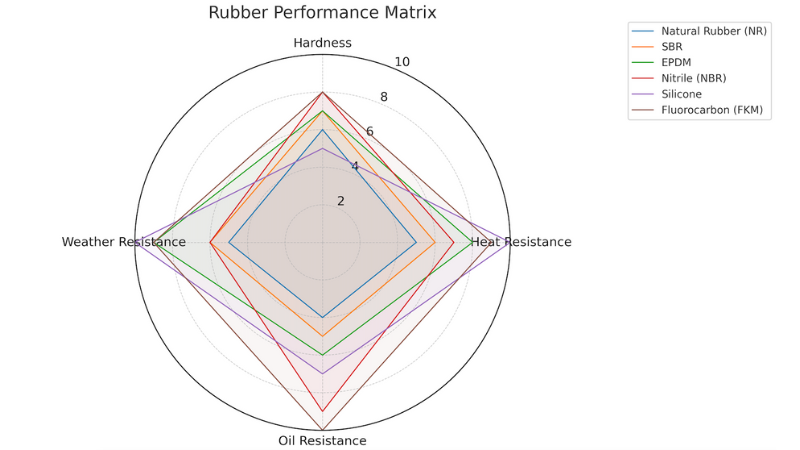

Types of Rubber Materials

Let’s explore different types of rubber materials and their key characteristics. Usually, rubbers are in two categories, i.e., natural and synthetic rubbers, with the addition of specialty rubbers.

Natural Rubber (NR)

Natural rubber comes from tropical and subtropical trees found in countries like Brazil, India, Indonesia, Malaysia, and Sri Lanka.

In most field tests, NR still outperforms many synthetics when it comes to raw strength and flexibility. Mechanics like it for parts that need to “give” under pressure — think truck suspension bushings or heavy-duty conveyor belts.

It’s renewable and biodegradable, but you’ll see it break down faster if it’s constantly exposed to oil, heat above 80°C, or harsh chemicals.

You’ll find NR in everything from latex gloves in hospitals to army boots (soldiers like the grip in wet terrain). Even some spacecraft gaskets still use NR for its elasticity — but only in areas shielded from direct heat or chemical exposure.

Synthetic Rubber

Synthetic rubber is artificially produced through the chemical synthesis of petroleum or natural gas byproducts. Typically, the copolymerization of butadiene with another monomer yields synthetic rubber.

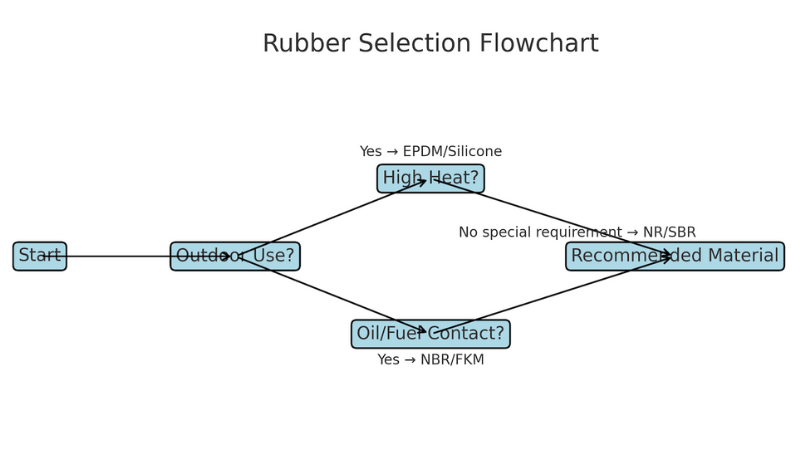

The whole point of synthetics is to copy NR’s flexibility but fix its weaknesses. For example, EPDM laughs at UV and ozone, making it the go-to for car door seals and roofing membranes, while nitrile stays strong even after months in oily machine parts.

The popular synthetic rubber types include styrene-butadiene rubber (SBR), butyl rubber, neoprene, nitrile rubber, and EPDM.

Each has its niche:

- SBR — cheap, tough, perfect for car tires.

- Butyl — unbeatable air retention, so it’s in most inner tubes.

- Neoprene — resists weather and moderate oils, used in wetsuits and cable jackets.

- Nitrile (NBR) — excellent with oils and fuels, common in engine gaskets.

- EPDM — best for outdoor seals, still flexible after years in the sun.

Specialty Rubber Materials

Specialty rubbers are where manufacturers get creative. They’ll tweak formulas or add cross-links (vulcanization) to hit very specific goals — more heat resistance, less swelling, or extreme elasticity. Think of it like “custom-tuning” rubber for a job site or factory line.

Some common types of specialty rubbers include silicone rubber, fluorocarbon rubber, and nitrile rubber.

Silicone handles -55°C to 300°C without turning brittle, which is why you’ll see it in oven seals, aerospace O-rings, and even baby bottle nipples. It stretches like crazy (up to 700%) without tearing, and it doesn’t yellow under UV.

Similarly, fluorocarbon rubber and nitrile rubber offer exceptional chemical resistance to petroleum oils and fuels, solvents, acids, etc.

Fluorocarbon (like Viton®) is common in oil & gas valves — it holds up even when bathed in hot crude or corrosive solvents. NBR is the workhorse in factories where hydraulic oil leaks are just part of the job.

Applications of Rubber Materials

Rubber is used to manufacture a variety of products. From car tires to toys, you will find rubber almost everywhere. Let’s explore rubber material properties and applications:

- Industrial and Automotive Applications

In factories and under the hood, rubber earns its keep. EPDM seals keep rain out of car cabins for over a decade, nitrile hoses carry fuel without softening, and SBR tires grip asphalt through summer heat and winter cold.

Similarly, high abrasion resistance and low compression set enable rubber application in industrial settings. On conveyor lines, NR or SBR rollers absorb shock and protect products. In heavy equipment, vibration dampers made from neoprene stop bolts from shaking loose.

- Consumer Applications

In homes, you’ll spot rubber in yoga mats, smartwatch straps, and the soles of running shoes. Parents trust silicone for baby pacifiers because it doesn’t crack or absorb odors.

Its water and chemical resistance also make it perfect for bath toys, kitchen spatulas, and sports gear that sees constant sweat and sun.

Conclusion

Rubber is an essential material used across various industries. Its unique blend of properties like tensile strength, elasticity, heat resistance, etc, makes it an indispensable material. There are a multitude of applications of rubber in medical, automotive, industrial, aerospace, fashion, and other sectors.

Understanding rubber material types and characteristics helps you make efficient use. We have provided you with an in-depth analysis of critical rubber characteristics. You are in a good position to select the right material type with the required specifications as per your needs.

Get Tailored Solutions for Your Rubber Material Needs

Need a rubber compound tailored to your performance requirements? We, Hongju, customize NR, SR, and specialty blends for automotive, medical, and industrial applications.

What are you waiting for? Get in touch with one of our representatives for queries, ordering mechanisms, or anything you want.

FAQs

Q1: What are the benefits of rubber?

Rubber is a versatile material with unique properties like tensile strength, heat resistance, elasticity, and compression. It is used in the manufacturing of a variety of materials, including tires, seals, toys, shoe soles, etc.

Q2: What is the difference between natural and synthetic rubber?

Natural rubber is extracted from trees through indigenous techniques, while synthetic rubber is produced from the chemical synthesis of petroleum byproducts. Both rubber types have comparable properties but different chemical compositions.

Q3: What are the properties of synthetic rubber?

Synthetic rubber has similar properties to natural rubber; it’s highly elastic, durable, resistant to heat and chemicals, and offers excellent impermeability to water.

Q4: Which rubber lasts longer in outdoor conditions?

EPDM synthetic rubber generally lasts the longest outdoors. It resists UV, ozone, and extreme weather far better than natural rubber, making it ideal for roofing, automotive seals, and other long-term outdoor applications.

Q5: Which rubber is more eco-friendly?

Natural rubber is more eco-friendly because it’s renewable and biodegradable. However, its environmental impact depends on sustainable plantation practices, while synthetic rubber comes from petroleum and is non-biodegradable.