What is Compression Molding?

Compression molding compresses raw plastic or silicone rubber into a heated mold with the final product’s shape. The combination of heat and pressure makes it possible for the material to form a new shape by filling out the space inside the mold.

Usually, the mold has two parts, the upper and lower halves. The upper mold is movable, while the lower one is stationary.

During production, the raw plastic is put on the heated lower mold. The equally heated upper mold is then put on top of the plastic, exerting enough pressure to get the plastic into the right form.

The mold stays together long enough to ensure that the heat and pressure will enable the plastic to maintain the integrity of the shape as it forms. This is the curing process.

Once everything cools, the upper mold lifts to reveal the new form of the plastic. This is when the new plastic product is removed from the mold.

Pros and Cons of Compression Molding

Here are the pros and cons of compression molding.

Pros

Easy color changeovers: The process makes switching colors simpler and more convenient.

Preserves material properties: It helps maintain the mechanical and chemical qualities of the material.

Cost-efficient: The simple process enables the production of inexpensive plastic parts quickly and effectively.

Versatile design capability: Products can be made in different lengths, thicknesses, and with complex designs.

Strong and durable: Since it uses high-strength material, the final product offers excellent durability and resiliency.

Cons

Not ideal for large-scale production: This method is better suited for smaller runs rather than mass manufacturing.

Visible parting line: Because the mold has two sections, the finished product may show a noticeable line down the middle.

Different Applications of Compression Molding

Compression molding can be optimal for creating durable plastic products. Most of the time, this method is excellent for appliance and automotive parts.

The typical applications include the following:

Automotive Industry:

- Engine Seals: Cylinder head gaskets, oil pan gaskets. These require high temperature and oil resistance.

- Vibration Damping Components: Engine mounts, chassis bushings. They utilize the elasticity and durability of rubber.

- Simple Sealing Strips: Seals for doors and luggage compartments.

Industrial & Mechanical Components:

- Large Sealing Rings (O-Rings): Especially those with large cross-sections used for static sealing.

- Wear-Resistant Liners & Pads: Rubber liners for mining machinery and conveyor equipment.

- Equipment Base Vibration Pads: Rubber feet and anti-vibration platforms for large machines.

Consumer & Household Goods:

- Kitchenware: Lid seals for pressure cookers, silicone baking mats.

- Simple Miscellaneous Items: Erasers, door stoppers, sink drain seals.

- Footwear Materials: Rubber soles for work shoes or casual footwear.

Construction Materials:

- Rubber Tiles & Mats: Gym shock-absorbing floor mats, rubber paving bricks for sidewalks.

- Building Expansion Joint Seals: Used to fill joints in concrete structures to accommodate thermal expansion and contraction.

What is Injection Molding?

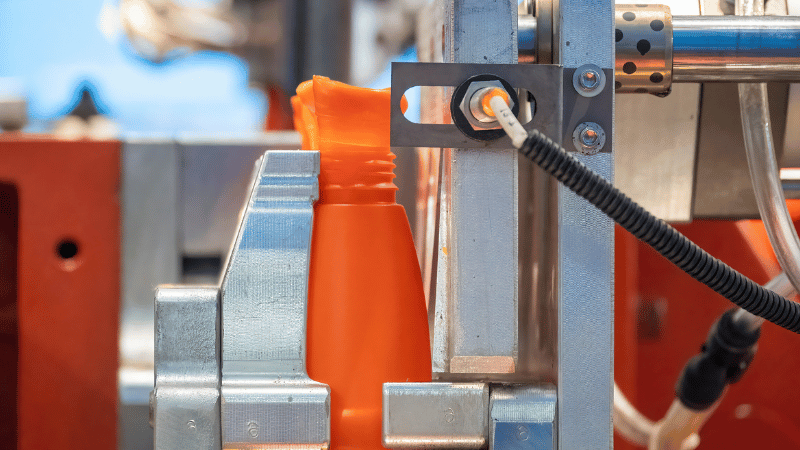

Injection molding is a process that involves injecting the raw material into the cavity of a mold. The raw material starts from a feeder hopper with a screw below it. This screw rotates and takes the material from the hopper into the mold.

A heating process happens simultaneously as the screw injects the material into the mold. This makes the material soft enough to take the shape of the cavity.

The tool has various parts, including the feed hopper, injection unit, heater, hydraulic cylinders, clamping unit, etc.

This molding method makes it possible to create more complex and intricate designs. Since an injection process happens, producing a more consistent end product is more accessible. There’s more accuracy when it comes to meeting the design requirements.

Pros and Cons of Injection Molding

Pros

- Ideal for intricate designs: Perfect for products that require complex and detailed geometries.

- High-volume production efficiency: The process is designed for mass production, making it highly scalable.

- Low cost-per-part at scale: The simple injection process becomes highly cost-efficient for large runs, as the cost per unit decreases with volume.

- High versatility in design: It is easy to create molds in various styles, shapes, and sizes, offering great design flexibility.

- Customization through additives: Resins or additives can be incorporated to achieve specific material properties or colors.

- Production of strong and durable parts: The process yields robust products capable of tolerating different materials and stresses.

Cons

- Not economical for low-volume production: Due to the high upfront investment, it is not cost-effective for small production batches.

- Requires high volume to maximize investment: To justify the tooling expense, a large number of parts must be manufactured to amortize the cost.

Different Applications of Injection Molding

Thanks to the versatility of injection molding, it’s possible to use it in various applications. Whether it’s a small product or a very intricate design, it’s easier to accomplish using this molding method.

The different applications for injection molding include:

- Aerospace components

- Automotive parts

- Avionics products

- Cable assemblies

- Elements for windows and doors

- Packaging for food and beverages

- Dental and medical products

- Engineering prototypes

- Healthcare laboratory components

- Point of purchase (POP) display parts

Similarities Between Compression and Injection Molding

Even if the process of molding is different, there are similarities between compression and injection molding.

Both use molding tools to shape the raw materials into the right design. They both use heat to help make the material flexible enough to take the shape of the design. They also use cooling methods to make the final product durable and sturdy.

But beyond that, here are other notable similarities.

Allows Customized Colors

Customizing the colors is easy for both compression and injection molding methods. You must blend the color you want into the raw plastic resin before feeding it into the mold.

This allows you to create an incredibly colorful, aesthetically pleasing product. Manufacturers usually have these ready colors to mix for you. This can be through dry pigment mixing, where plastic resins mix with dry pigment powder. This mixture happens in the hopper.

There’s also the option of solvent dye. This is a mixture of pigment oil with solvent. You spray this over pellets with no color. This coating happens before the injection.

Has Low Labor Costs

Another similarity between compression molding and injection molding is the low labor cost. Since the process is very straightforward, very little manual intervention happens. The operator of the molds only needs a basic understanding of the process to get this done.

It’s done in automation, so there’s no need to get too much labor.

Cheaper Cost of Parts

Creating the rubber molding with the design of the product is one that changes every time. But for the rest of the tools, it remains the same. This is why the parts are very cost-efficient.

Even if the molds use low-cost materials like steel, they can still be very effective in creating the right shape. Not to mention that you can reuse the molds, which usually last a long time.

Key Differences Between Compression and Injection Molding

There are several considerations when it comes to differentiating the two molding methods. The primary difference lies in the processes they both follow.

In compression molding, the top half of the mold compresses the raw material into the lower half of the mold to create the right shape. In injection molding, a screw injects the raw material into the mold cavity to create the end product.

Beyond this, there are other differences to consider so you’ll know what to choose between the two.

Precision

The die for injection molding uses durable materials with high strength and hardening capabilities. That means there’s a lower chance of deformity in the final product.

This isn’t true for compression molding. The pressure of the upper mold can affect the shape and final design of the product.

Model Complexity

Complex models are more applicable to the injection molding method. It’s easier to manipulate the mold and make it as intricate as possible. This also allows you to test how the design will look – and make changes when necessary.

Compression molding is better for simpler designs without a lot of intricacies.

Lead Time

Compression molding takes longer to complete. This is why you must ensure you give it enough time to produce the number of products as promised.

Injection molding can be faster. This method allows time to test prototypes and make revisions when needed.

How to Choose Between Compression and Injection Molding

Choosing between compression molding and injection molding will depend on the product’s application and the ideal completion time.

For some, injection molding has the advantage over compression molding because it allows intricate designs and the creation of prototypes.

However, compression molding still has its benefits. The straightforward process can be ideal for some production requirements.

Make sure you talk to your manufacturer and give them the complete details of what you want to produce. That way, they can give you the options available to get the best result.

Conclusion

Compression and injection molding are essential processes for creating high-quality rubber or plastic parts. Compression molding excels with larger, simpler designs and lower tooling costs. And injection molding offers superior precision, faster cycles, and complex designs.

Understanding their differences ensures optimal selection for durability, efficiency, and cost-effectiveness to choose one suitable for your needs.

Accelerate Your Project with Hongju’s Agile Silicone Solutions!

Hongju Silicone empowers your innovation with rapid 3-5 day prototyping and flexible low MOQs, eliminating development bottlenecks. Backed by 20+ years of expert craftsmanship, we deliver precision-molded rubber parts that ensure quality from prototype to production.

Our main products include custom silicone rubber keypads, rubber O-rings, gaskets and seals, rubber feet, etc.

Contact us now to bring your project into reality!

Check out our services:

- Silicone Rubber Compression Molding

- Liquid Silicone Rubber (LSR) Injection Molding

- Silicone Rubber Die Cutting

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.