What is Liquid Silicone Rubber Injection Molding?

The existence of liquid silicone rubber (LSR) was found in the late 1970s. Injection molding of liquid silicone rubber offered a much better quality of parts than thermoplastic injection molding. Therefore, the process became popular quickly for manufacturing liquid silicone rubber parts.

Liquid silicone rubber (LSR) is a thermosetting elastomer. The molding process for LSR involves heating the mold while keeping the material delivery system cool. This automated process has a short cycle time, which is why parts made from liquid silicone rubber are usually cheap.

Liquid silicone rubber components have excellent mechanical properties. The material has high tensile strength, low viscosity, and elasticity. Moreover, they resist electricity, heat, and chemical reactions. They also have a biodegradable property. Therefore, these components suit medical, automotive, consumer goods, and electrical applications.

Unique Manufacturing Capabilities of LSR Injection Molding

Liquid silicone injection molding is a process capable of many unique manufacturing aspects. Here are a few special properties of the liquid injection molding process

Thin Sections

Silicon molding can create parts with sections as thin as 0.1 mm or 0.004 inches. The parts will have perfect thickness. The quality will be consistent throughout the whole part as well. LSR parts have no pinholes due to the latest technology of molds. The materials used in this production process are ideal for thin sheets or membranes.

No Flash

The manufacturer doesn’t need any secondary deflashing in the production process of LSR parts. A flash-free process is achieved by a combination of high-precision mold design and the LSR material’s low viscosity, reducing the need for secondary deflashing.

Nano/Micro Technology

Liquid injection molding can make minimal parts that may weigh below 10 mg, making it perfect for applications like microfluidic chips and miniature medical implants. The parts for the production process are fully automatic, and the injection system is a needlepoint injection. For this reason, such low-weight parts can be obtained.

Delicate Parts

Very delicate parts can be produced using this manufacturing technology. And every time the operator starts the direct injection process, the parts are formed each time reliably. The unique construction tools and automation allows the production of silicone parts with fine texture and intricate details.

High Precision

The textured surface of the parts is highly polished due to the LSR materials. The manufacturing process is consistent, even if the manufacturer intends to produce millions of parts with the same machine.

Through-Holes and Tube Sections

You can produce plastic parts using the LSR molding process. Every time the machine operates to create a part, through-holes are shaped perfectly each time. The manufacturer can also produce long tube sections accurately without any worries. It is easy to make special tools using this process.

Undercuts

Undercuts in product design are a critical aspect of any manufacturing. However, that’s not the case for Liquid silicone injection molding. Due to the flexible nature of silicone rubber, the parts can be easily removed from the tooling. So, special design considerations are not necessary for undercuts.

8 Steps of Liquid Silicone Rubber Injection Molding Process

The below section shows a step-by-step guide for the complete silicone rubber injection molding process:

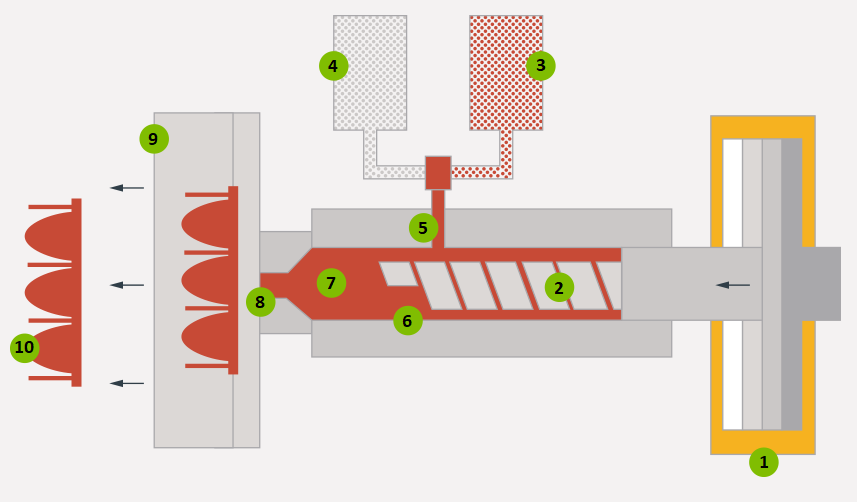

1. Two containers or supply drums hold uncured liquid silicone. One of these containers contains the base-forming material. The other one includes a catalyst.

2. There is a metering unit. It helps to automatically release the two materials in an equal and constant ratio. If there are any pigmentation additives, the metering units also release these.

3. The operator can customize and program the silicone rubber molding machine to make it automatic. The injection is customized to maintain a consistent shot size for each part.

4. Pistons and platens are aligned before closing the mold. The alignment has different settings for the pressure applied, temperature, cycle time, and injection rate, adjustable depending on specifications.

5. After the operator sets all the values, the molding machine gets hot, and the mold temperature rises. A proper level of clamping force is applied to the mold clamp.

6. When the mold is closed and the pump and the injector are ready, the silicone rubber is pushed into the mold cavity with the help of an injection mechanism.

7. To ensure the parts have perfect mechanical strength, the liquid silicone rubbers are cured at an appropriate pressure and temperature until solidification occurs. Curing is a chemical reaction known as cross-linking, which connects linear polymer chains into a 3D network.

8. Once solid, the operator can manually remove the silicone rubber product. An automatic ejection mechanism with gippers can be used as well. But the removal doesn’t require ejector pins as silicone rubber is very flexible.

After finishing the steps above, the manufacturer prepares the mold for the following liquid silicone injection molding cycle.

Note that there are also post-molding processes such as post-curing, cleaning, inspection, and packaging. These steps are equally necessary for the quality assurance of your silicone rubber products.

Practical Benefits of Liquid Silicone Rubber Injection Molding

LSR or liquid silicone rubber parts offer many benefits for users. Here are some of the advantages of this molding process:

Consistency

The silicone molding process is very consistent in producing the same part. The main reason behind this is using the same mold to make the same part. Being consistent provides a lot of convenience to the manufacturer and the customers.

Precision

The liquid silicone molding process ensures excellent dimensional accuracy, with typical tolerances as tight as ±0.05 mm. You can design parts with intricate details and undercuts without worry. Also, you are less likely to need costly post-processing to improve the accuracy of parts.

Quality

If the parts don’t have high quality, the customers won’t be satisfied with the product. In addition, manufacturers use the injection molding process to ensure the high quality of the parts.

Purity

The mixing process of the LSR injection compression molding is exact, and the final product contains minimum impurity. The final product has almost no impurity due to the highly sophisticated manufacturing process.

Limitless Design

If the liquid silicone rubber LSR parts are made of injection compression molding, then there is a chance of designing a part with any design that pops up in the operators’ minds. This is because the raw material is easy to handle, and it is very easy to make the mold.

Reliability

The manufacturers can easily rely on the injection molding process of LSR for product manufacturing. Because this process is straightforward and fast to perform, it is convenient to keep track of the quality of the finished goods.

Cost-effectiveness

The LSR injection molding process is fast, making it highly cost-effective. The automated process can reduce cycle times by up to 50%, significantly lowering the cost per part.

Limitations of LSR Injection Molding

Although liquid silicone rubber injection molding offers so many advantages, it also has some limitations that are important to consider.

High Demands on Material Purity and Environment

LSR is highly sensitive to contamination. Any impurities can negatively affect the final product’s physical properties. So, the whole process from material storage to molding must take place in a controlled, clean room environment to ensure the purity and quality, increasing the overall operational costs.

High Tooling Costs

The initial investment for LSR molds can be significantly higher than for molds used in thermoplastic injection molding. It is because it needs high-precision machining and hardened tool steels to withstand the high heat and pressure of the curing process.

Besides, the mold design must be very precise to prevent flash, which increases more complexity and cost.

Potential Shrinkage Issues

Just like most materials, LSR experiences shrinkage during the curing and cooling processes. The shrinkage rate can be up to 3% to 4%, which is higher than for thermoplastics.

This requires careful consideration during the design phases. Designers must account for this shrinkage to maintain final part dimensions and tolerances.

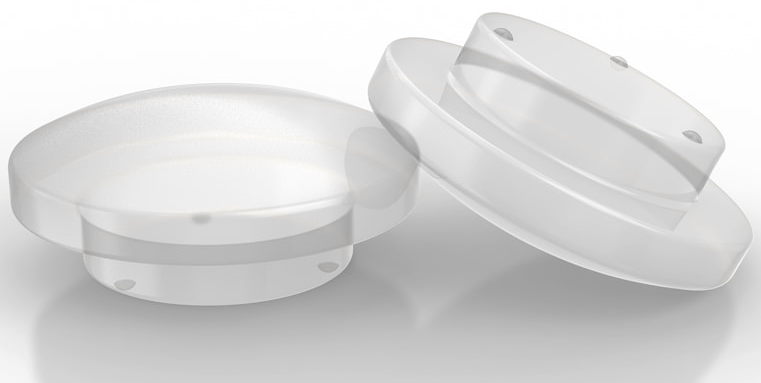

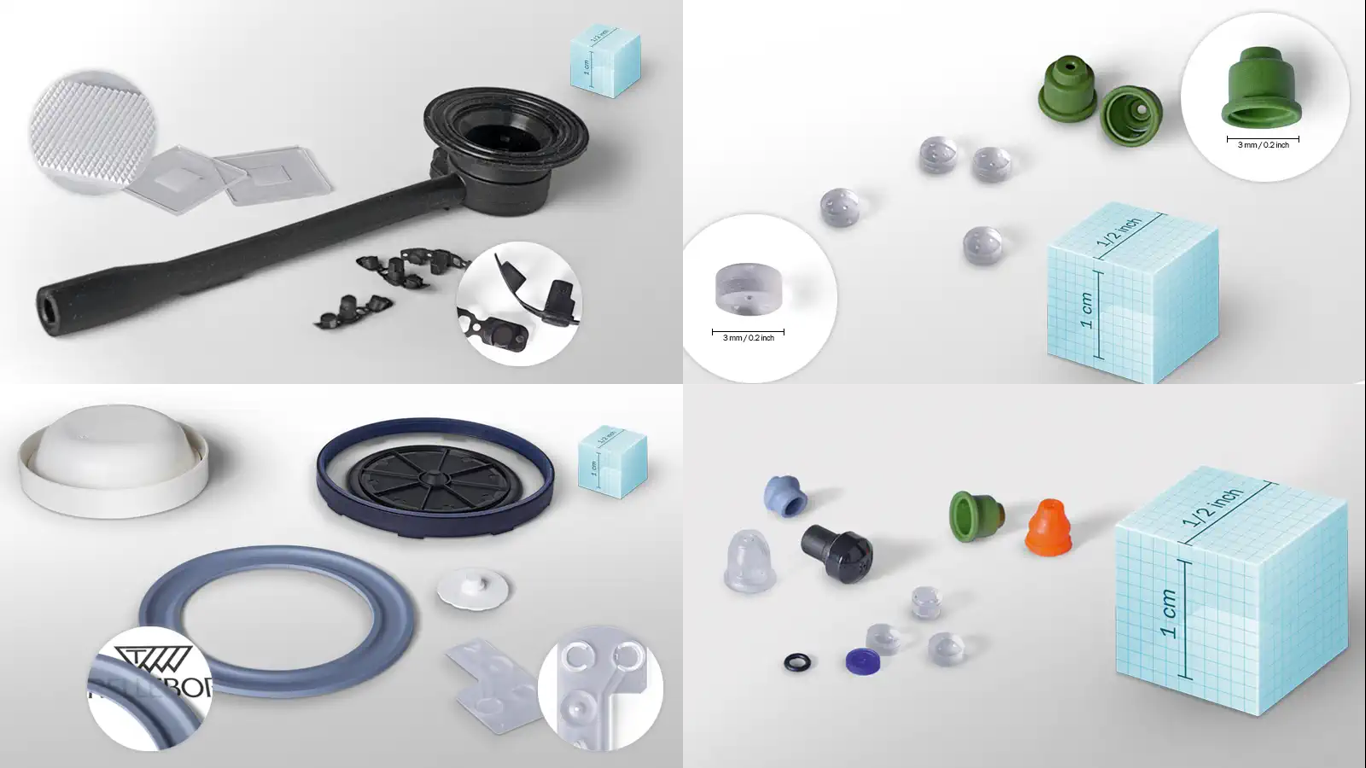

Applications of Liquid Silicone Rubber Molded Parts

Many industries use liquid silicone injection molded parts for many applications. The below list shows a few of those industries:

Medical Devices: Due to its biocompatibility and ability, LSR is preferred to be sterilized using various methods, ensuring patient safety.

Infant and Geriatric Care: The soft, flexible, and hypoallergenic properties make it ideal for parts that will contact sensitive skin.

Electronic Products: It has superior electrical insulation and is flame-retardant, making it safe for seals and gaskets in electronic devices.

Automotive: LSR has excellent resistance to extreme temperatures, UV radiation, and chemicals. So, it is a durable choice for under-the-hood components.

Food and Beverage: With high temperature resistance, LSR is non-toxic and odorless, making it perfect for components that come into contact with food.

Various parts such as silicone rubber keypads, O-rings, seals, wire harness seals, bellows, vibration dampeners, faucets, bacteria-resistant shower heads, electric toothbrushes, hearing aid ear tips, headphone ear tips, baby bibs, rubber grommets, etc. are made of this process for the above-given industries.

Conclusion

LSR injection molding delivers flawless, high-precision products with superior heat and chemical resistance. Its automated process can ensure rapid production, minimal waste, and complex geometries design. In a word, it is truly perfect for medical, automotive, and consumer applications requiring reliability, scalability, and cost-efficiency.

Choose Customizable Precision LSR Components from Hongju!

At Hongju Silicone, we make customized components based on your demands and requirements. Our manufactured goods are FDA and CE-approved, safe to use. For over 20 years, we have been manufacturing components using LSR for various industries.

Contact us today to get further communication! We are dedicated to assisting you in making your vision a reality.