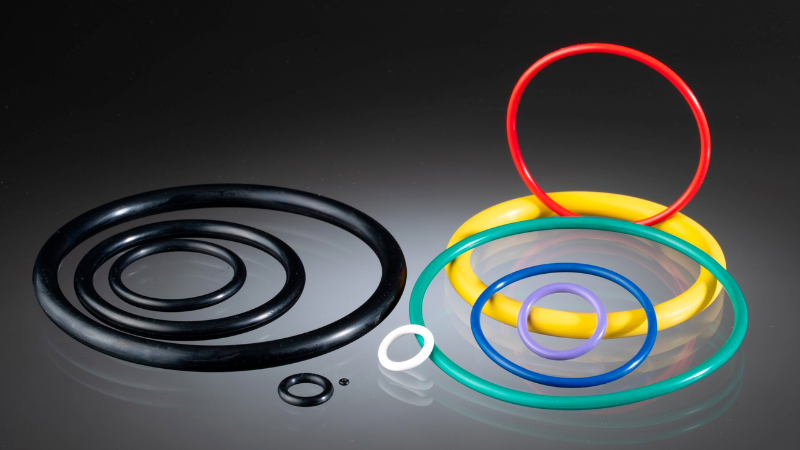

This guide delves deep into the world of nitrile O-rings and seals, exploring their mechanical properties, advantages, applications, and more. Whether you’re a seasoned engineer or just someone curious about material choices, this guide is tailored to provide valuable insights into nitrile’s widespread use in sealing applications.

What are Nitrile O-Rings?

Nitrile o-rings, also known as acrylonitrile-butadiene rubber (NBR) o-rings, are a type of rubber seals commonly used in various industries. These elastomers are composed of a blend of acrylonitrile and butadiene rubber, resulting in their unique properties and applications.

- Definition and explanation: Nitrile o-rings are circular sealing components made from a combination of acrylonitrile and butadiene rubber. They are designed to create a tight seal between two mating surfaces, preventing the leakage of fluids or gases.

- Composition and manufacturing process: Nitrile o-rings are primarily made from synthetic rubbers rather than natural rubber. The percentage of acrylonitrile content in the mixture determines the overall characteristics of the o-ring, such as its resistance to chemicals, oils, and temperature variations.

- Comparison with other types of O-rings

| Material | Advantages | Disadvantages |

|---|---|---|

| Nitrile | Excellent oil and fuel resistance, Good abrasion resistance, Cost-effective | Limited temperature range, Not suitable for exposure to ozone, UV, and certain chemicals |

| Silicone | Wide temperature range, Flexible at low temperatures, Excellent for dry heat applications | Poor tensile strength, Not oil resistant |

| Fluorocarbon (Viton®) | Excellent chemical resistance, Good high-temperature properties | Relatively more expensive, Not as flexible at low temperatures |

| EPDM | Great for outdoor applications due to resistance to UV and ozone, Good chemical resistance | Not suitable for oil-based fluids |

| Neoprene | Good general-purpose seal, Moderate oil resistance, Good UV and ozone resistance | Not suitable for strong acids, ozone, and some other conditions |

Understanding the Properties of Nitrile O-Rings

Nitrile, also known as Buna-N or NBR (Nitrile Butadiene Rubber), is a synthetic rubber material that has carved out its niche in various industries due to its remarkable properties. Nitrile O-rings are among the most popular sealing solutions, and for good reasons. Let’s delve deeper into understanding what makes nitrile O-rings a preferred choice:

- Oil and Fuel Resistance: Nitrile o-rings withstand most hydraulic fluids, petroleum oils, and crude oil. This characteristic makes nitrile O-rings invaluable in automotive, industrial, and certain aerospace applications where oil and fuel exposure is a concern.

- Temperature Range: Nitrile O-rings can operate effectively in temperatures ranging from-40°C to 120°C (-40°F to 248°F). While there are elastomers with wider temperature ranges, nitrile provides a good balance of performance and cost for many common applications.

- Durability: Nitrile exhibits good abrasion and wear resistance, making it suitable for applications where the O-ring may be subjected to dynamic loads or abrasive media.

- Cost-Effective: In addition to their performance characteristics, nitrile O-rings are often more cost-effective than seals made from more specialized materials. This makes them a go-to choice for standard applications.

- Limitations: While nitrile offers excellent resistance to petroleum-based products, it is not suited for exposure to polar solvents, chlorinated hydrocarbons, and strong acids. Its resistance to UV and ozone is also limited, which means it might not be the best choice for outdoor applications.

- Versatility: Due to its wide range of hardness options (from 20 to 90 Shore A), nitrile can be tailored to fit various sealing applications, be it in low-pressure pneumatic systems or high-pressure hydraulic systems.

In summary, NBR can be compounded for enhanced oil and fuel resistance, increased temperature flexibility, high hardness and extrusion resistance, low compression set, and a variety of other attributes. Recognizing these properties can aid in determining where nitrile O-rings excel and where other sealing solutions might be more appropriate. Their balance of performance characteristics and affordability makes nitrile O-rings a reliable choice for many sealing challenges.

The Benefits of Using Nitrile O-Rings and Seals

Nitrile o-rings and seals offer several advantages that make them a preferred choice for many sealing applications. Here are the key benefits:

- Cost-effective solution: Nitrile o-rings and seals provide a cost-effective sealing option, making them an economical choice for various industries.

- Versatility in multiple industries: These seals find utility in a wide range of industries due to their good tear resistance and non-polar solvent resistance. They can be used in automotive, aerospace, manufacturing, and other sectors where effective sealing is crucial.

- Reliable performance in dynamic or static sealing environments: Nitrile o-rings and seals demonstrate reliable performance in both dynamic (moving) and static (stationary) sealing environments. This makes them suitable for diverse applications such as pumps, valves, cylinders, and pipes.

- Compatibility with various fluids: These o-rings and seals exhibit compatibility with different types of fluids, including hydraulic fluids. This characteristic ensures their effectiveness across various systems that require fluid containment.

Common Applications and Uses of Nitrile O-Rings

Nitrile o-rings and seals find widespread use across various industries due to their excellent resistance to oil, fuel, and chemicals. Let’s explore some common applications where these versatile components are utilized:

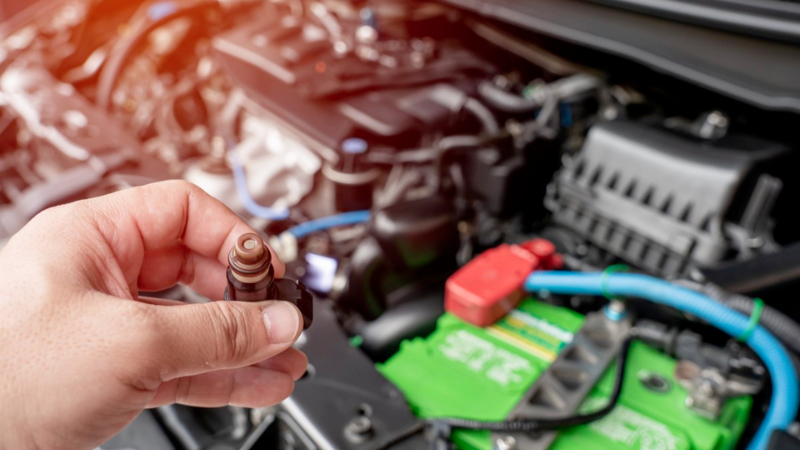

Automotive Industry

- Engine systems: Nitrile o-rings play a crucial role in sealing engine components, such as cylinder heads, oil pans, and valve covers.

- Fuel systems: They are employed in fuel injectors, carburetors, and fuel pumps to prevent leaks and ensure proper functioning. Not recommended for automotive brake fluids.

- Transmissions: Nitrile o-rings help maintain the integrity of transmission systems by sealing fluid passages.

Aerospace Industry

- Hydraulic systems: These seals are essential for ensuring leak-free operation in hydraulic actuators, valves, and pumps.

- Fuel systems: Nitrile o-rings provide reliable sealing solutions for aircraft fuel tanks, fuel lines, and connectors.

Industrial Machinery

- Pumps: Nitrile seals are commonly used in centrifugal pumps, diaphragm pumps, and gear pumps to prevent leakage.

- Compressors: They help maintain optimal pressure levels in air compressors by creating a tight seal between moving parts.

- Valves: Nitrile o-rings ensure tight shut-off in various types of valves like ball valves, gate valves, and butterfly valves.

Plumbing Industry

- Faucets: These rings serve as effective seals between different faucet components to prevent water leakage.

- Toilets: Nitrile o-rings are utilized in toilet flush mechanisms to maintain water-tight connections.

- Pipe fittings: They provide leak-proof connections between pipes and fittings used in plumbing installations.

Common Problems with Nitrile O-Rings and Seals

Nitrile o-rings and seals, although widely used in various industries for their affordability and versatility, can encounter a few common problems. Understanding these issues can help you make informed decisions when choosing the right sealing solution for your application.

- Swelling or degradation when exposed to certain chemicals: Nitrile o-rings and seals may experience swelling or degradation when they come into contact with specific chemicals. It is crucial to consider the chemical resistance of nitrile materials before selecting them for your sealing needs.

- Limited resistance to high temperatures: Another challenge with nitrile o-rings and seals is their limited tolerance for high temperatures. Exposing them to extreme heat can lead to premature failure or loss of sealing effectiveness. If your application involves elevated temperature conditions, it may be necessary to explore alternative materials with higher heat resistance.

- Potential leakage if not properly installed or maintained: Proper installation and maintenance are essential for preventing potential leakage issues with nitrile o-rings and seals. Ensuring correct sizing, adequate lubrication, and regular inspections can significantly reduce the risk of leaks and enhance overall sealing performance.

- Incompatibility with some aggressive fluids: Nitrile compounds may not be compatible with certain aggressive fluids such as strong acids or solvents. It is crucial to assess the fluid compatibility requirements of your application carefully. In cases where aggressive fluids are involved, alternative sealing materials like Viton® or EPDM might offer better chemical resistance.

By being aware of these common problems associated with nitrile o-rings and seals, you can take proactive measures to mitigate potential issues that could arise during operation.

Nitrile O-ring and Seal Maintenance Tips

Regular inspection is essential to ensure the longevity and performance of nitrile o-rings and seals. By following these maintenance tips, you can keep them in optimal condition:

- Inspect for wear, cracks, or damage: Regularly check your nitrile o-rings and seals for any signs of wear, cracks, or damage. Look out for visible tears or deformities that may affect their sealing capabilities.

- Proper lubrication for enhanced sealing performance: Lubricating your nitrile o-rings and seals is crucial to improve their sealing performance. Use a compatible lubricant specifically designed for rubber components to reduce friction and enhance their functionality.

- Store in a cool, dry place away from direct sunlight: Proper storage plays a significant role in maintaining the quality of nitrile o-rings and seals. Keep them in a cool, dry location away from direct sunlight to prevent premature aging or deterioration.

- Replace if signs of deterioration are detected: If you notice any significant signs of deterioration during inspections, it’s important to replace the affected nitrile o-rings and seals promptly. Continuing to use damaged components could lead to leaks or failures.

To assist with maintenance tasks like ring splicing, consider using a ring splicing kit that provides the necessary tools and materials for repairing damaged o-rings efficiently.

By adhering to these simple maintenance practices, you can extend the lifespan of your nitrile o-rings and seals while ensuring they continue to perform effectively in various applications.

Conclusion

Nitrile O-rings and seals have firmly established their position in various industries due to their remarkable resistance to oils, fuels, and other chemicals, combined with their cost-effectiveness and versatile applications. While they may have specific challenges, understanding these issues and their countermeasures can lead to optimal performance and prolonged service life.

Upgrade Your Sealing Solutions with Hongju’s Nitrile O-Rings!

Dive into the world of top-quality sealing solutions with us. At Hongju Silicone, we ensure that our nitrile rubber O-rings or silicone o rings not only meet but exceed industry standards. Let our experts guide you in making the best sealing decisions for your specific applications.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.