What is Buna-n (NBR)?

Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene.

Nitrile Butadiene Rubber(NBR) is a synthetic rubber with excellent physical properties.

It is in high demand because it can be tailored to meet the industry’s unique requirements or the complicated design procedure for an engineering project.

Its physical and chemical properties vary depending on the polymer’s composition of nitrile. The more nitrile there is within the polymer, the higher its resistance to oils but the lower its flexibility.

It is specially processed with Sulphur or Peroxide for demanding projects to manipulate its physical and chemical features, i.e., melting point, chemical resistance, and hardness.

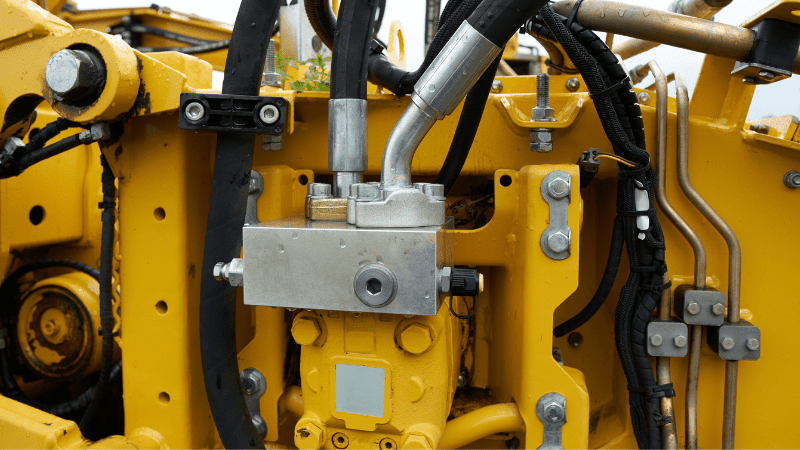

In the rubber industry, nitrile rubber is recognized for its high resistance to heat, pressure, and harmful fluids (mineral oils). This makes it an excellent raw material for O-rings, gaskets, and oil seals in industries such as automotive companies and electrical factories.

Butadiene and Acrylonitrile (ACN), the primary ingredients of Buna-n, are mixed based on the project’s necessities.

Though the formula varies, 34 percent of ACN is responsible for its high tensile strength, abrasion resistance, and oil-resistant applications.

At the same time, Butadiene is accountable for the flexible and elastic nature of the rubber.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Where is Buna-n or Nitrile Rubber (NBR) Used?

Buna-n, also called acrylonitrile butadiene rubber, a synthetic rubber, is used in various applications.

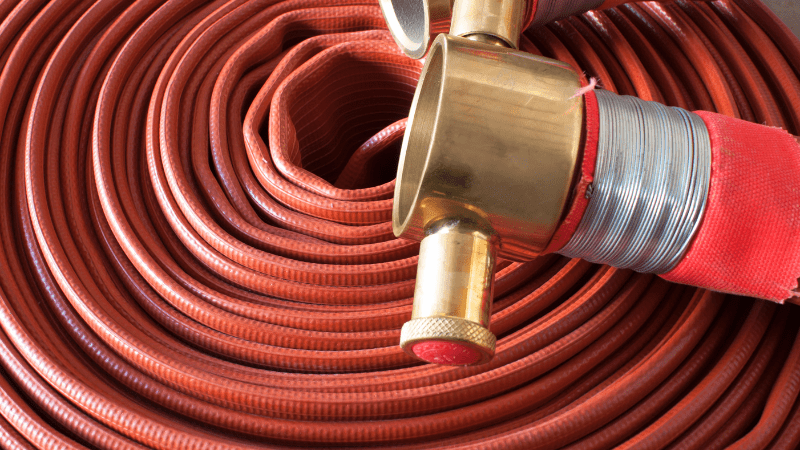

It is used in the construction, automotive and aeronautical industry for O-rings, rubber grommets, and handling hoses.

Buna-N is known for its unusually high resistance to oils, fuels, and other chemicals and its superior strength.

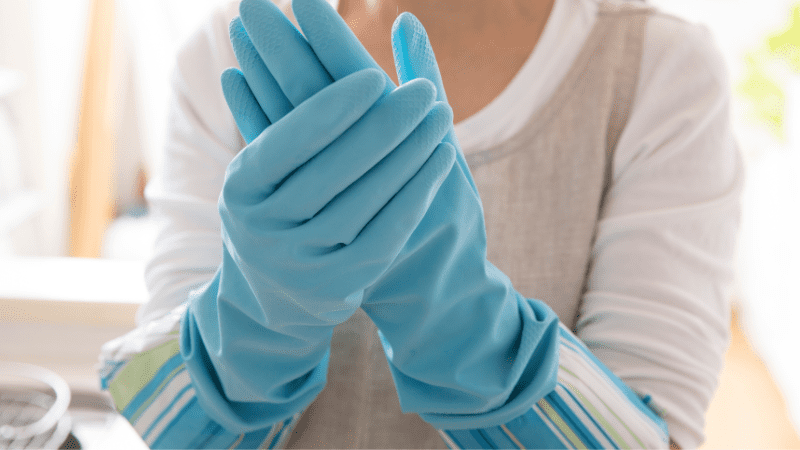

The uses of nitrile rubber include disposable non-latex gloves, automotive transmission belts, hoses, O-rings, gaskets, oil seals, V belts, synthetic leather, printer’s form rollers, and cable jacketing.

It is also used to manufacture rubber adhesives for lamination and as a color pigment binder. It is used to seal pumps and to make protective gloves and boots in nuclear Industries.

Nitrile Rubber is ideal for the most demanding environments, i.e., the medical industry, because it can resist high levels of heat and withstand harmful acids. It is also used in pharmaceutical laboratories.

Nitrile Rubber(NBR) depending on the alteration to the formula can be used in every industry.

How does Nitrile Rubber Differ from Other Rubber Materials?

Buna-n (Nitrile Rubber) differs from other more common materials in terms of better physical and chemical properties.

It is the first base polymer, named after being discovered by scientists in the early 1900s. Nitrile Rubber and Buna-N refer to the same synthetic rubber material — acrylonitrile-butadiene rubber (NBR).

The differences usually come from specific formulations or compounding adjustments made by manufacturers to suit various industrial requirements and performance needs.

Here are some of the key differences between nitrile rubber and other types of rubber materials:

| Property | Nitrile Rubber (NBR) | Natural Rubber (NR) | Neoprene (CR) | Silicone Rubber (SiR) | EPDM Rubber |

| Oil & Chemical Resistance | Excellent resistance to oil, fuel, and hydrocarbons | Poor; swells easily in oils | Moderate; resists some oils | Poor oil resistance | Poor oil resistance, but good against polar fluids |

| Temperature Resistance | −30°C to +120°C | Limited; degrades under heat | −40°C to +120°C | Excellent; −60°C to +230°C | Good; −50°C to +150°C |

| Weather & Aging Resistance | Poor without additives | Poor | Moderate | Excellent | Excellent |

| Mechanical Strength & Elasticity | Good, but less elastic than NR | Excellent; high resilience and tear strength | Good; balanced flexibility | Fair; soft and lower tear strength | Good flexibility, moderate strength |

| Water & Steam Resistance | Fair | Poor under prolonged exposure | Moderate | Good | Excellent; best for water and steam |

| Electrical Insulation | Fair | Good | Moderate | Excellent | Excellent |

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How can You Tell if a Material is Made of Buna-n (NBR)?

You can identify Buna-N (Nitrile Rubber, NBR) by checking its resistance to oil and fuel. NBR does not swell or soften when exposed to petroleum-based fluids, unlike natural or silicone rubber.

It also has a distinctly firm yet flexible texture and often appears black or dark gray.

Another way is through a burn or solvent test—it emits a slightly acrid odor and resists most polar solvents. In industrial use, markings like “NBR” or “Buna-N” on seals, O-rings, or gaskets also confirm the material type.

What are the Benefits of Using Buna-n (NBR)?

There are benefits to using Buna-n for rubber parts. It is a remarkably versatile elastomer used for numerous applications and projects.

It is one of the most widely used raw materials for fluid seals, oil seals, and gaskets.

Nitrile or Buna-n, as it’s commonly known, has an extensive list of valuable features. NBR offers excellent resistance to petroleum-based oils and fuels, silicone greases, hydraulic fluids, water, and alcohol.

It provides a good balance of desirable working properties including low compression set, high tensile strength, and high abrasion resistance. This wide range of benefits makes it enticing. This is also a reason for its popularity among rubber technicians.

- Excellent Resistance: It has good oil resistance and functions well with petroleum oils and other such fluids.

- Tear Resistance: It excels in physical toughness with high abrasion and tear resistance.

- It is hard: Its Shore A hardness rating ranging from 40 to 90 points.

- Cheap alternative: It is more affordable than many other elastomers and fluoroelastomers

Are there any Drawbacks to Using Buna-n (NBR)?

Although, as an elastomer, this is a preferred choice among industry experts, there are a few drawbacks to consider when using Buna-n for rubber accessories.

For instance, Buna-N is susceptive to ozone, ketones, ethers, esters, aromatic hydrocarbons, automotive brake fluid, strong acids, and aldehydes.

It has poor resistance to ozone, sunlight, and weathering, which can cause it to break down and degrade over time.

Butadiene rubber should be used in a suitable environment as raw materials for disposable non-latex gloves and other rubber accessories.

When Buna-n comes in contact with strong oxidizers, the elastomer oxidizes. Depending on the formula used and the presence of acrylonitrile, the flexibility of materials made with Buna-n can also be controlled and manipulated.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Buna-N (Nitrile Rubber) is a versatile, oil-resistant synthetic rubber widely used in automotive, industrial, and sealing applications. Its excellent durability, flexibility, and chemical resistance make it ideal for demanding environments.

Though it has some temperature limitations, NBR remains a reliable, cost-effective choice for manufacturers seeking performance and longevity in rubber components.

Buy High-Quality Nitrile Rubber Products from Hongju

Hongju combines 3–5 day CNC prototyping, flexible low MOQ, and over 20 years of silicone manufacturing expertise to help you bring ideas to market faster. From design to mass production, we simplify your sourcing process with precision and reliability.

Request your quote today and start scaling with confidence!