What is a Membrane Switch?

Membrane switches are simple on/off circuits printed on a plastic sheet using conductive inks. A silicone layer with conductive pads covers the circuit layer and acts as the trigger. When you press the silicone against the circuit layer, a momentary electrical connection occurs, turning the switch on or off.

The printed circuit is the actual membrane switch, and the user interfaces with the membrane switch through the top silicon layer. Lettering and design elements are typically printed on the silicone layer. However, it can be further customized according to customer requirements. And you can look through this blog to learn how to design membrane switches.

Membrane Switch Construction

The core of membrane switches consists of silicone and circuit layers. The circuit and silicone can be customized to create several different membrane switches. But the basic membrane switch technology has remained the same.

So to keep this section simple and easy to understand, let’s focus on the basics of membrane switch construction.

Circuit Layer Construction

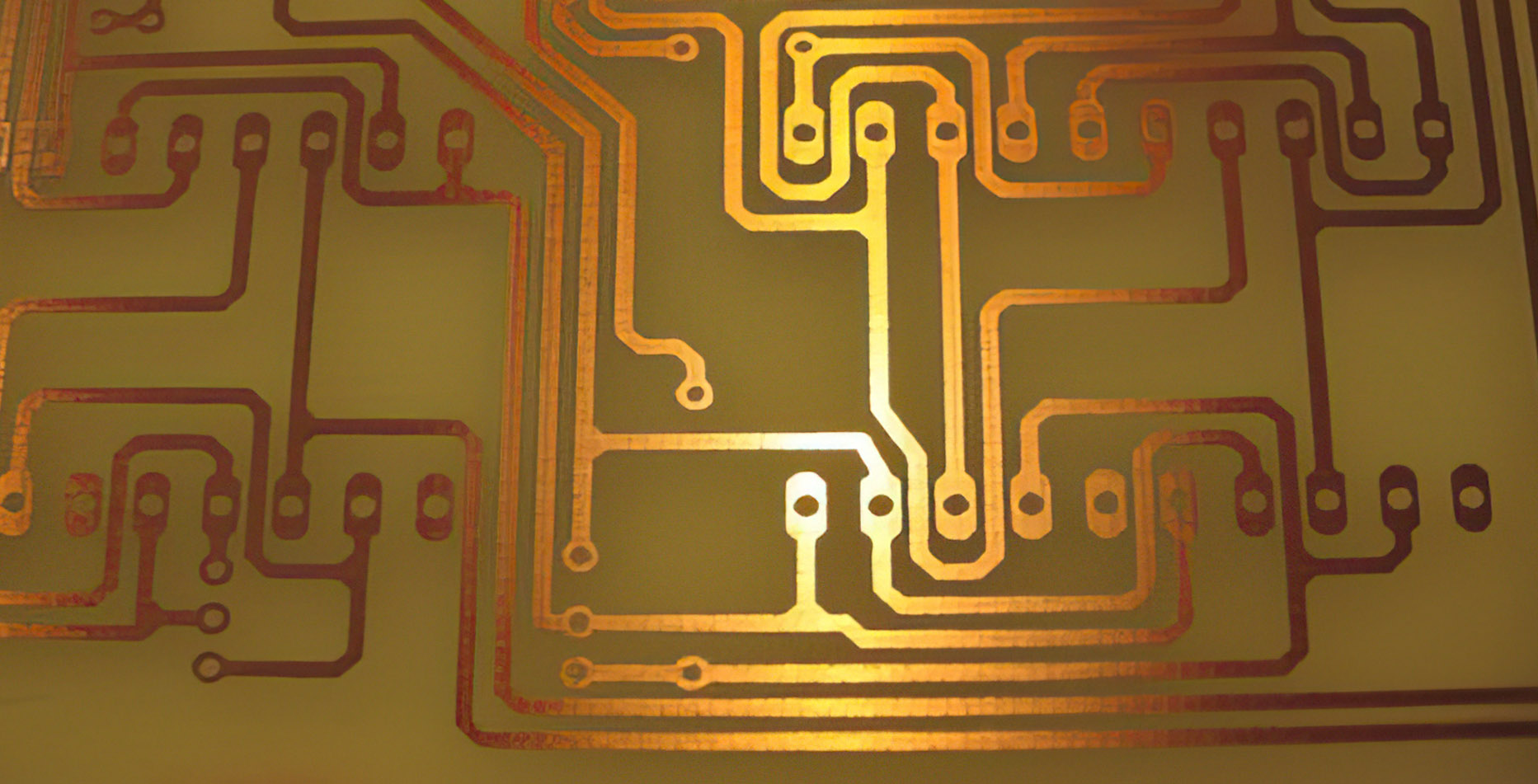

The membrane switch circuit has two elements, conductive inks and non-conductive bases. The ink is printed on the circuit base in a unique pattern. There are small breaks in the printed design. Each break acts as an open circuit; no current flows through them. Pressing the conductive pad (key/button) down closes the circuit and allows current flow.

Tiny particles of conductive material are dispersed throughout the ink. The most common filling used for conductive inks is as follows.

- Copper

- Silver

- Graphite

Copper conductive ink is rarely used in commercial membrane switches, While graphite or silver conductive ink is present in almost all membrane switches.

Depending upon the application, circuit bases can be made of flexible or rigid materials. Here are the most popular materials used for screen printing circuits.

Flexible Materials

- PET (Polyethylene terephthalate)

- ITO (Indium tin oxide)

Rigid Materials

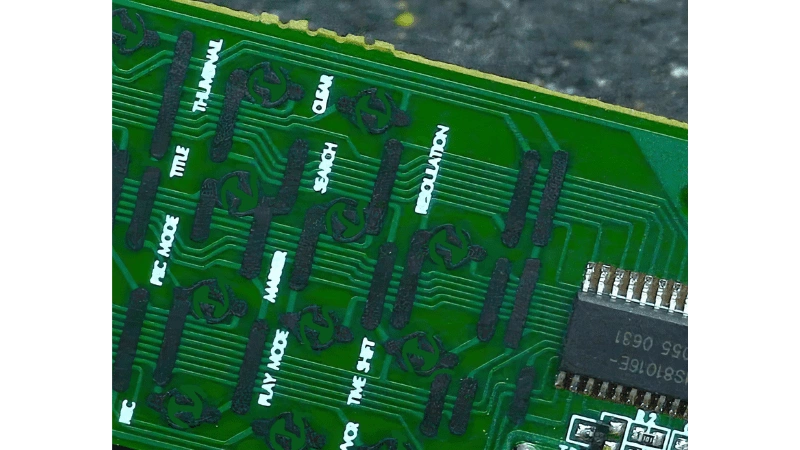

- PCB (Printed circuit board)

- FPCs (Flexible electronics)

Both flexible and rigid circuits can be made up of multiple layers stacked on top of one another. The more complicated a circuit is, the more layers are required. Most layers of membrane switches are hidden underneath the top circuit layer to minimize accidental damage.

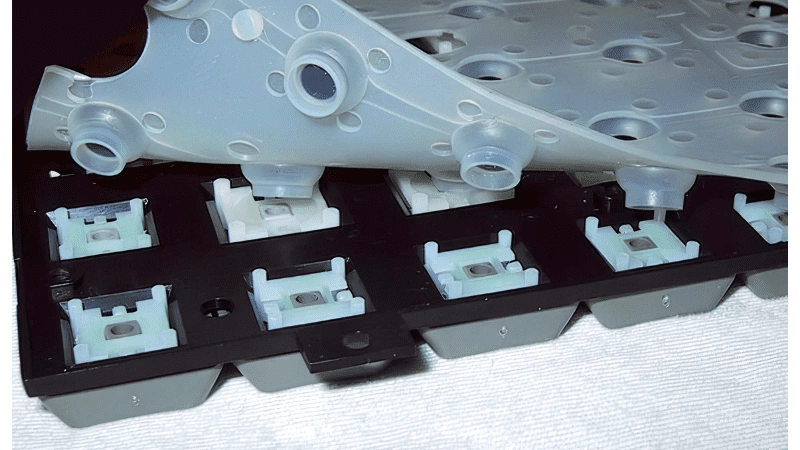

Interface Layer Construction

The interface layer can also be customized using materials similar to the circuit construction. Typically, this layer is made from silicone, a non-conductive soft-touch material.

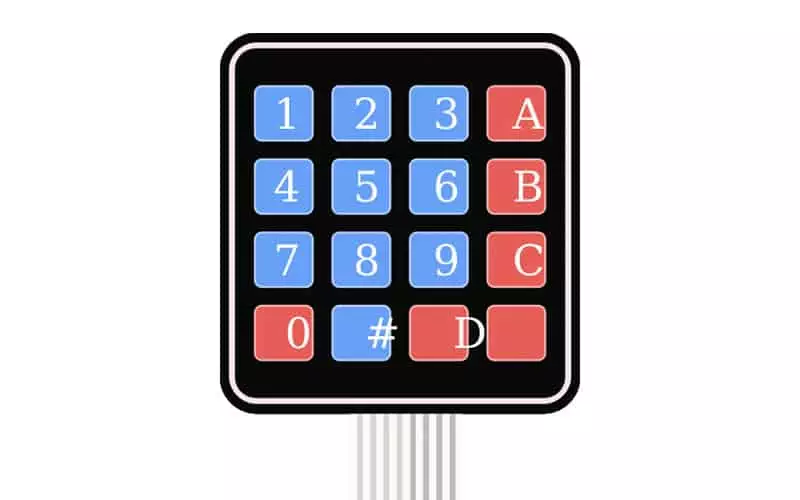

The interface is a thin non-conductive layer with conductive pads on the bottom, responsible for switching on/off the circuit. The dome retainer layer is an alternate name for this layer because some membrane keypads use a dome-shaped conductive pad.

Domes are responsible for the tactile feedback of a membrane switch. Tactile feedback is the little click feel you get when you press a button on a membrane switch.

Tactile Switches

Tactile switches use domes to give better feedback to a membrane switch. Crowns are not essential to working a membrane switch but are typically preferred as they provide tactile feedback for a superior feel.

Tactile membrane switches will typically use non-metal domes to reduce costs. Metal domes have better tactile response and durability but come at an additional cost. A tactile membrane switch will have a slightly thicker profile than a non-tactile switch.

Non-Tactile Membrane Switches

Non-tactile switches use a simple spacer between the circuit and the interface instead of a dome. A non-tactile switch is slightly cheaper and barely thinner than a tactile one. There is a minimal advantage to a non-tactile switch, and it is generally regarded as an inferior membrane switch.

Additional Layers

Graphic Overlays

The graphic overlay is thin polycarbonate or PET layers, with lettering printed on top. Using graphic overlay is an alternative to silicone screen printing.

Some microwave ovens use membrane switches with a graphic overlay. But most products skip the visual layer in favor of silicone screen printing or digital printing.

Spacer Layer

The spacer layer is a support layer primarily used in conjunction with dome switches. When the dome switch is pressed, the air inside is forced out of ventilation holes cut into the spacer layer.

Adhesive Layer

Adhesive layers are present between every two layers of a membrane switch. An adhesive layer keeps the graphic overlay, the dome retainers, and the circuit attached firmly.

Mounting adhesive refers to using an adhesive layer to firmly attach the membrane switch to an electrical device.

LED Indicators

LED (light-emitting diode) is a small light fixture that can be added behind the membrane switch. This light can be used as a passive backlight to illuminate the controls in dark environments. LEDs also act as confirmation indicators for button/key presses.

How do Membrane Switches Work?

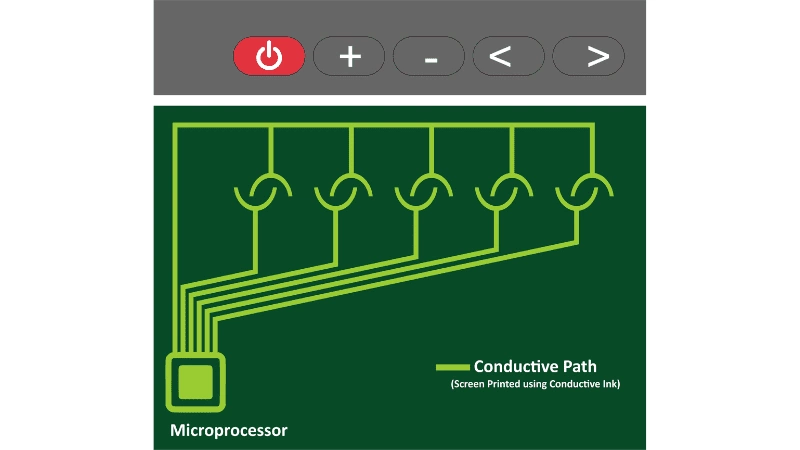

The primary goal of a membrane switch is to create a human-machine interface. Membrane switches use an open circuit screen printed on a flexible PET sheet. When connected to a battery, current flows through the conductive paths but stops at specific breakpoints. These breakpoints are open circuits; no current will flow until the course is complete.

Keys with conductive bottoms are used for actuators. Pressing a key pushes the conductive bottom against the open circuit, completing the conductive path. Now then, current can flow through the course.

A microcontroller is responsible for decoding the key presses. Once the current starts flowing through the circuit, it will go through the microprocessor. The microprocessor will inform the primary device which key has been pressed on the membrane switch.

Example

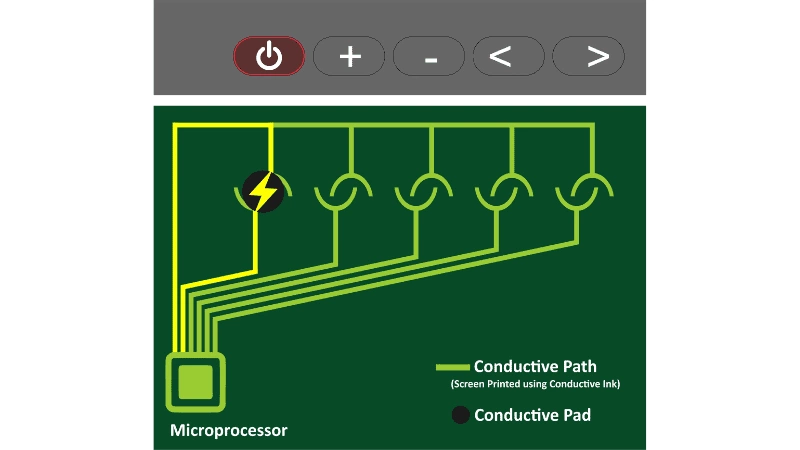

Consider a TV with membrane switches attached to the front. It has five keys, one for on/off functionality, two for volume control, and two for changing channels. The circuit behind the membrane switches is printed on a PET sheet and connected to the TV’s microprocessor.

Here is a simplified circuit diagram of the membrane switches.

When you plug in the TV, it will receive a small electric current, but it will not turn on. To turn on the TV, you must press the On/Off key on the membrane switch. When the key is pressed, the dome underneath collapses, and the conductive pad inside the dome comes in contact with the membrane switch circuitry. The conductive pad has bridged the gap between the printed paths and closed the circuit.

The current will flow from the power source to the circuit and through the microprocessor. The microprocessor will determine that the On/Off key has been pressed and turn the TV on accordingly.

TV remotes contain the same membrane switch circuitry inside. The only difference here is that the microprocessor sends the instructions to the IR (infrared) transmitter on the remote, which sends the signal to the IR receiver on the TV.

Benefits of Membrane Switches

There are several benefits to using a membrane switch. But the three most important advantages are as follows.

- Durability

- Easy Maintenance

- Accessibility

- Water Resistance

- Low Profile

- Cost-Efficient

- Easy Customization

A membrane switch can be sealed using waterproof adhesive, and it can have a protective coating on top of them and still function perfectly fine. Despite all the additional layers, membrane keypads still maintain a thin profile, making them excellent for small electronic devices. Surface-mounted membrane switches are only possible because of this thin profile.

Membrane switch technologies have improved over the past few decades. Membrane switches lack the tactile feel of mechanical switches. But with metal dome switches, this drawback is mostly negligible. We see more versatile human-machine interfaces using a new membrane switch design.

Mechanical vs. Touch Screen vs. Membrane Switches

Membrane switches, mechanical switches, and touch screens offer advantages over others. All three types of controls can have pressure-sensitive, adhesive, and tactile elements. This means you can modify any of these to fit your desired application.

Here is a simple table discussing the properties of mechanical switches, touch screens, and membrane switches.

| Property | Mechanical Switches | Touch Screen | Membrane Switches |

| Durability | Good | Poor | Excellent |

| Easy Maintenance | Good | X | Excellent |

| Accessibility | Good | Excellent | Excellent |

| Water Resistance | Poor | Excellent | Excellent |

| Low Profile | No | Yes | Yes |

| Cost-Efficient | No | No | Yes |

| Easy Customization | Excellent | Excellent | Excellent |

| Versatility | Good | Excellent | Poor |

Mechanical switches are preferred for their excellent tactile feel, quick response times, and better electric circuit design. But mechanical lashes are thicker and more prone to dust and water ingress damage.

Touch screens are preferred for their versatility as you can display a more complex user interface. But high-resolution touch screens are expensive and more prone to impact and scratch damage.

A membrane switch is ideal for custom shapes and sizes. You can modify your existing membrane switch design to be compatible with a PCB or flexible membrane switch. Membrane switch technology requires very few electrical components, so it’s fragile and cost-effective.

However, membrane switches require particular applications to be effective. They do not have the same broad potential as LCD touch screens.

Conclusion

Membrane switches are a type of switch that is used in many different applications. They offer several benefits, such as durability and low cost. If you want a reliable and affordable switch, membrane switches may be the right choice.

Buy Membrane Switches from Hongju

Hongju is a leading silicone rubber products manufacturer in China. We have manufactured custom silicone rubber keypads and membrane switches for our customers since 1999. To glimpse our diverse and high-grade product range, visit our products page.