First manufactured by DuPont, Viton is a fluoroelastomer, and it is known as the rubber of choice when all others fail.

In this definitive guide, we will tell you what Viton rubber is, how it’s manufactured and processed, and why this elastomer is so popular. We will also explain how you can choose the right type of Viton rubber for your needs. Read on to find out why this material is worth the hype.

What is Viton Rubber?

Viton is a synthetic rubber that is based on fluorocarbons. It is classified as a fluoroelastomer. Like most fluoroelastomers, Viton exhibits resistance to a wider range of chemicals than other elastomers.

Although these rubbers are commonly referred to as Viton, they are officially called Fluorine Kautschuk Materials, usually shortened to FKM. Viton is the brand name given to the original product by DuPont.

The Chemours Company, a spinoff of DuPont, still manufactures the original Viton rubber. However, FKMs are now produced by other companies worldwide, including 3 M.

DuPont created the original Viton rubber to meet the aerospace industry’s needs. Still, the excellent heat resistance of the elastomer, plus its ability to withstand exposure to strong chemicals and fuels, has made it a popular choice in other industries, including:

- Chemical processing

- Automotive

- Semiconductor manufacturing

- Aviation

- Petroleum refining

- Food and pharmaceutical manufacturing.

Chemistry of Viton Rubber

There are different types of Viton rubber compounds, but they all contain vinylidene fluoride (VDF). VDF is a gas, and when combined with hexafluoropropylene or HFP, the result is a Type-1 FKM.

VDF can be combined with other chemicals to produce other types of FKMs. For example, when combined with HFP and tetrafluoroethylene (TFE), the result is a type-2 FKM. These have better temperature and chemical resistance, but exhibit diminished low-temperature flexibility.

Apart from chemical composition, the cross-linking mechanism used for curing FKMs also plays a crucial role in creating different types of Viton rubber. The three cross-linking mechanisms in use today are:

- Diamine cross-linking: Relatively uncommon, but results in better rubber-to-metal bonding characteristics.

- Ionic cross-linking: Most commonly used curing method. Compared to diamine cross-linking, it results in better heat resistance, compression set, and hydraulic stability.

- Peroxide cross-linking: This curing method was developed for type-3 FKMs. Type-3 FKMs have higher flexibility at low temperatures compared to type-1s and type-2s.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Advantages of Viton Rubber

Viton rubber has a long list of advantages compared to other elastomers, including:

- Superior heat resistance: Viton rubber can operate reliably in temperatures as high as 260°C and survive occasional exposure to more extreme temperatures. Nitrile rubber (NBR), a cheaper alternative, can only be used reliably at an operating temperature of 100°C.

- Excellent oil and chemical resistance: Viton is highly resistant to degradation by many chemicals, fuels, solvents, and petroleum oils. This material also repels water and isn’t easily penetrated by water-based liquids due to its hydrophobic nature.

- Outdoor use: Viton remains relatively unaffected by UV rays and, as stated earlier, isn’t affected to a significant degree by water. This means it retains its properties including color when used outdoors. It’s also resistant to oxidation, mold, and ozone.

- Flexibility and elasticity: Viton’s tensile strength is good, and it demonstrates greater flexibility and ability to retain its form under stress compared to some synthetic rubbers.

- Slow Aging: Viton is not easily degraded by many liquids, even under prolonged exposure. This is one of several factors that make the material resistant to aging.

- Low gas permeability: Viton has a low gas permeability, making it excellent for sealing, especially where the gases are likely to degrade other materials.

- Low compression set: Even after prolonged compression, Viton products will regain much of their original size and shape. Many elastomers are permanently deformed by prolonged compression.

- Long service life: Thanks to FKMs’ excellent chemical resistance and good mechanical properties, these rugged rubber seals can serve for a long time even in the harshest environments. This results in fewer breakdowns and greater operational efficiency.

Applications of Viton Rubber

The properties of Viton make it the ideal material for many applications. However, this material costs a lot more than others. It is typically used where the unique demands of the application can justify the high cost as seen below.

1. Aviation and Aerospace

Both the aviation and aerospace industries demand materials that can withstand temperatures that can range from low to very high.

Additionally, the materials used for o-rings and other seals must be able to withstand fuels and harsh chemicals such as hydraulic fluids used in these applications. Viton outperforms other elastomers in meeting these demands.

2. Chemical Processing

In chemical processing, Viton is important for preventing the leakage of harmful chemicals. This synthetic rubber can withstand many chemical interactions and can be used on equipment used to process acids, solvents, and other chemicals.

Viton can also be used to create coatings that can protect surfaces that might come into contact with damaging chemicals.

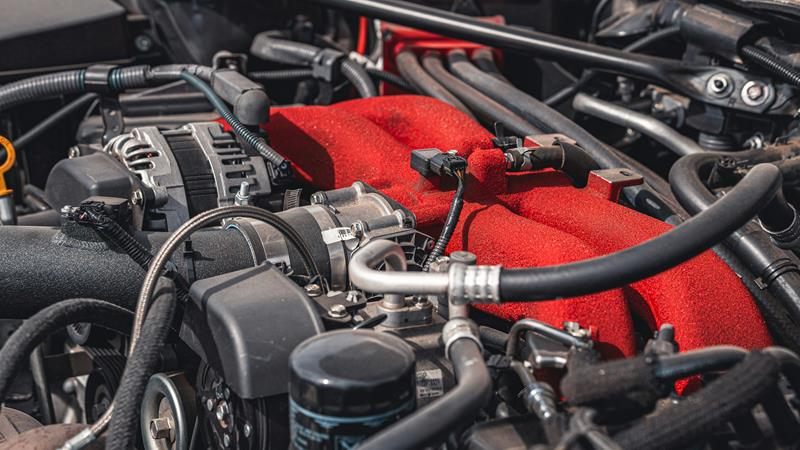

3. Automotive Industry

Important equipment in vehicles is protected from exposure using Viton rubber seals. O-rings made from the material are used for seals that are exposed to lubricants, oxygenated automotive fuels, and high temperatures. For example, Viton o-rings can be found in the fuel pump and fuel injector.

4. Food and Pharmaceutical Industry

Exposure to animal fats can cause cracking, swelling, and softening of rubber. This degradation can render some seals useless. Viton is highly resistant to animal fats and is highly recommended for applications in the food industry where animal fats and other fluids are a concern.

5. Instrumentation

Instruments used in many applications require a strong and reliable seal to protect sensitive internal parts from exposure. Viton rubber is used to manufacture gaskets, diaphragms, hoops, separators, and other components for instruments used for critical applications in harsh environments, e.g., in the military.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Types of Viton Rubber

The simplest way to classify FKMs is by their chemical composition. This results in five different types of FKMs as explained below:

- Type-1: Composed of VDF and HFP. 66% of the weight of these FKMs is fluorine.

- Type-2: Composed of VDF, HFP, and TFE. 68 – 69% fluorine content. Better heat and chemical resistance than type-1.

- Type-3: Contain VDF, TFE, and Perfluoromethylvinylether (PMVE). Fluorine weight content ranges between 62% and 68%. Materials have better flexibility at low temperatures compared to types 1 and type-2.

- Type-4: Composed of Polypropylene, VDF, and TFE. Fluorine content is about 67%. Materials have higher base resistance but have poor swelling properties.

- Type-5: Contain VDF, TFE, HFP, PMVE, and ethylene. Higher base resistance and improved resistance to hydrogen sulfide at high temperatures.

Manufacturing and Processing of Viton Rubber

The manufacture of Viton is similar to that of other synthetic rubbers. The key raw materials are mixed with curing agents, processing aids, accelerators, and other components to form the raw rubber.

The rubber is formed into the shape of the seal or other products using processes such as extrusion and compression molding. The extruded parts are taken through another curing and hardening stage i.e. vulcanization, which gives the material properties such as increased hardness and toughness.

Many components can be added to the rubber during processing, depending on the desired properties of the final product. This is why Viton rubber products can have many different qualities.

How to Choose the Right Viton Rubber

The application should guide your choice of Viton rubber. The different types of Viton rubber have different properties. Some will offer exceptional chemical resistance at a high temperature but may not form a good seal at low temperatures.

You should also consider the manufacturer of the FKM to ensure you’re getting a good quality material at a great price.

FKMs are more expensive than other synthetic rubbers. You should check with an expert to ensure you don’t choose an expensive FKM when a cheaper one will serve you just as well.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

Viton rubbers, or FKMs, make some of the best seals in the world today. Their ability to withstand such a broad range of chemicals and high temperatures makes them an ideal material in many industries.

All FKMs contain fluorine, but other compounds can be added to improve certain qualities. This fluoropolymer elastomer can be divided into 5 different classes. It is a durable material, but its high cost and many variations mean you should talk to an expert to assess your needs before making a choice.

Ask the Experts at Hongju Silicone About Viton Rubber

Viton is an excellent material, but you need to work with an excellent manufacturer to get the best out of it. Hongju Silicone has over 20 years of experience producing seals, gaskets, and other rubber products.

We have worked with synthetic rubbers, including Viton and EPDM, and our experts can help you choose the right material for your application. Reach out and find out how we can start making your Viton rubber products today.