How does silicone foam compare to traditional foam? No doubt, silicone foam is a highly resilient material best suited for sealing and insulation. We’ll explore key differences in their properties to understand applicability. Follow our expert guide to make the right choice between silicone foam and traditional sponge sheets. Let’s get started!

What Is Silicone Foam?

Silicone foam is derived from synthetic rubber. It has unique properties like lightweight, flexibility, and resilience to harmful chemicals. The silicone foam also performs well in harsh environmental conditions, mainly varying temperatures. These properties make silicone foam suitable for insulation, sealing, cushioning, and sound dampening.

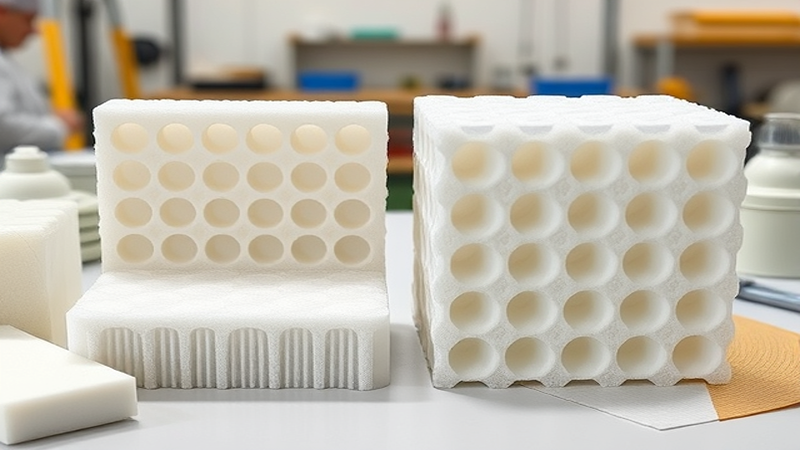

Silicone foam occurs in liquid and solid form. It is produced by vulcanizing silicone rubber with foaming agents. The foam is available in two variants: open-cell and closed-cell structure. The closed-cell silicone foam has a high density and is ideal for sealing and thermal insulation. The open-cell foam has a lower density and is used for cushioning or sound dampening.

Key Properties of Silicone Foam

Sponge vs foam: you can better compare them by understanding the key properties of silicone foam. Let’s explore:

Thermal resistance

Silicone materials have high thermal resistance due to strong molecular bonding. It can withstand extreme temperatures ranging from -60°C to 200°C. The material can retain its properties like flexibility, compressibility, and structural integrity even in varying temperatures.

Weatherproofing

Silicone foam is resistant to UV rays, ozone, and harsh environments. It exhibits excellent weatherproofing due to its closed structure. The material can achieve an IP67 rating and above. It is often exposed to outdoor environments for insulation and waterproofing.

Fire Retardancy

Silicone foam is extensively used for building insulation. It is made of lame retardant to reduce fire hazards and enhance safety. Most manufacturers follow UL 94 V-0 standards to produce fire-retardant silicone foam. It’s a critical property for fire safety.

Excellent Sealing

Silicone foam has a closed cellular structure with tightly packed molecules. It prevents water, air, and dust ingress. The material can be used as a high-performance sealant. It doesn’t deform when exposed to harsh weather or chemicals and maintains a perfect seal.

Flexibility & Compressibility

Silicone foam is made from synthetic rubber, which gives it excellent flexibility and compressibility. The material exhibits a low compression set, which makes it a good option for sealing applications. Its flexibility allows easy adaptation to uneven spaces.

Key Differences Between Sponge and Foam

Let’s conclude the debate on sponge vs silicone. Here are the key differences between silicone rubber foam and sponge foam material.

| Silicone Rubber Foam | Sponge Foam Material |

|---|---|

| Silicone rubber foam is a dense material with a tightly packed structure. It has a solid and smooth appearance. | Silicone sponge rubber is comparatively less dense with a porous surface. However, it can have closed-cell and open-cell structures. |

| Silicone rubber foam is flexible and elastic. It can retain its original shape better. | Silicone sponge rubber has high flexibility and a low compression set. |

| The foam material is lightweight and highly durable. | The sponge foam material can be less durable due to an open structure in similar applications. |

| Silicone rubber foam is temperature-resistant and can withstand extreme heat. | The sponge foam material is temperature resistant but can deform quickly in extreme heat. |

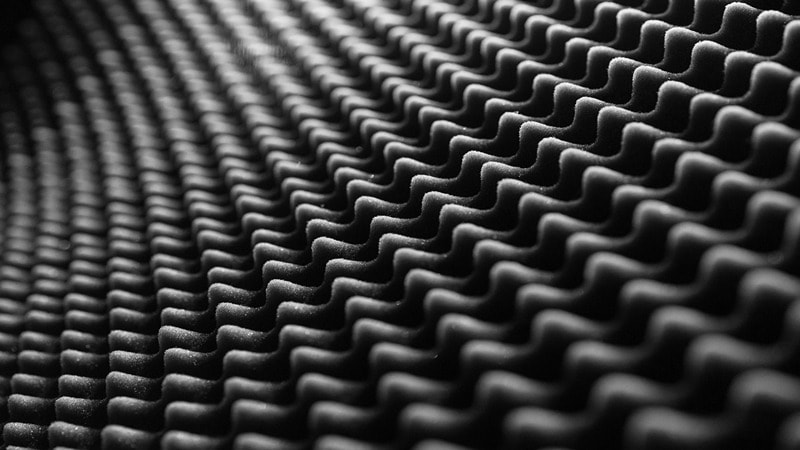

| Used in sealing, gasketing, thermal insulation, weather stripping, and vibration dampening. | Sponge sheets are used in soundproofing, cushioning, and industrial applications requiring excellent compression set resistance. |

Applications of Silicone Foam

Silicone rubber foam is a versatile material that has applications in diverse industries. Different types of silicone foam are used in many industries. Let’s explore:

Automotive Industry

Have you noticed the sealant on your car’s windshield? It’s most likely silicone rubber foam. The material is used for sealing the vehicle’s doors and windows. Moreover, silicone sponge rubber is filled in the door cavity for soundproofing. It’s also the best material for vibration dampening.

Electronics and Electricals

Silicone rubber foam is used for gaskets in electronic equipment, especially panels, and enclosures. It also provides cushioning for sensitive components. The heat resistivity makes it a preferred material for insulation and thermal management in electronics.

Medical Devices

Silicone foam rubber is a biocompatible and chemically inert material. It is extensively used in the medical industry. The sterile seals for different medication containers are made from silicone rubber foam. It is also used in wound dressings and flexible cushions for patients.

Construction and Infrastructure

Different types of silicone rubber foam are designed for insulation and soundproofing. They are used in the construction to insulate and soundproof walls. Since the material is fire-retardant. It is also used in the sealing of doors and windows.

When to Choose Silicone Foam

Silicone foam rubber material has wide applicability. When considering silicone foam for any application, you need to be mindful of its characteristics and compatibility with operating conditions. The material is best suited for applications with limited strength requirements and low pressure. As it can’t withstand heavy loads or high pressure and tends to deform.

Silicone sponge rubber is known for flexibility and compressibility. It is primarily used for sealing; the material can fill any gap to form waterproof seals. The compressibility allows it to be used for gasketing in low-pressure applications. Silicone form can efficiently prevent leakage of liquids, gases, or other substances.

Silicone sponge rubber is also used for cushioning, it shows excellent shock absorption due to high flexibility and compressibility. Electronic devices have silicone foam rubber protective padding to protect sensitive components. The material is also highly resilient and used for thermal insulation in buildings. It helps maintain temperature levels and ensure soundproofing.

So, check your requirements and choose wisely. The material is the best option when you need thermal resistance, shock absorption, flexibility, and fire safety. Silicone sponge rubber is highly durable and long-lasting. It doesn’t degrade over time and stays resilient against harsh weather or varying temperatures and chemical exposure due to its inert nature.

Advantages of Silicone Foam: Silicone Foam vs. others

Silicone foam has unparalleled advantages compared to other polymers like EPDM (ethylene propylene diene monomer) and PU foam (polyurethane foam). It is a cost-effective material with better benefits in terms of thermal resistance, resilience, fire protection, and durability. Whether you opt for silicone foam or silicone rubber sponge, the longevity is next-level.

Silicone foam is highly flexible and temperature resistant, it performs well within the -60°C to 230°C range. Other materials like EPDM foam, PU foam, etc can’t withstand extremely high or low temperatures. Silicone foam is fire-resistant, the material doesn’t catch fire while related materials are prone to fire. It’s also resilient to weathering and chemical exposure.

In the automotive industry, silicone foam is used for soundproofing and cushioning in car cabins. Similarly, most electronic devices have silicone foam seals that absorb vibration and prevent ingression. Silicone foam is also used in the construction industry for thermal insulation and soundproofing in buildings.

Silicone rubber sponge is ideal for sealing doors and windows in vehicles. Different sponge material types are used to form heavy-duty gaskets for use in electrical equipment like transformers. The silicone rubber sponge sheets are also used for weatherproof sealing in houses and buildings. Both materials are highly usable.

How to Choose the Right Silicone Foam

When selecting silicone foam for any application, consider the following attributes. They will help you choose the right silicone foam.

Density

Make sure you understand the density requirements for your application. The density depends on cell structure. You can choose between two options: open-cell structure and closed-cell structure. The former has low density, while the latter has high density. If you want cushioning, a low-density option is better.

Hardness and Thickness

The level of hardness and thickness affects the material’s flexibility and compressibility. Shore values determine hardness and thickness. You should check with your requirements whether you need rigidity to withstand load or flexibility to form efficient seals. Review the material’s compression set resistance for an informed decision.

Heat Resistance

Extreme high temperatures can affect silicone’s properties and cause deformation. Be mindful of the operating conditions and required level of heat resistance. Although silicone rubber foam is highly temperature resistant, it can vary for different sponge material types. Match the specifications before making a selection.

Certifications

The industry you’re operating in may require specific certifications for the use of silicone foam. Check with your compliance and regulatory office for better insights. For instance, you will need RoHS or REACH compliance for environmental and health safety—similarly, FDA Approval for food or medical applications.

Costs

Costs are a critical component when selecting silicone foam. You should explore the market and evaluate the quality of different materials. The costs may rise for materials tailored for specific applications. It’s recommended not to compromise on quality or safety certifications for low costs.

Customization Options for Silicone Foam

Silicone foam is a customizable material that can meet your specific requirements. Slight alterations to chemical composition can modify the thickness and size during production. Manufacturers also offer silicone foam with an adhesive backing option for easy installation. You can directly apply and set the foam for insulation or soundproofing.

Silicone foam can also be treated with additives to enhance performance parameters like flexibility. The material can undergo surface treatments for better adhesion, like plasma treatment. Similarly, silicone foam can be coated with hydrophobic chemicals for better waterproofing. For customization, you can reach out to esteemed manufacturers like Hongju.

Common Questions About Silicone Foam

How is silicone foam different from silicone sponge?

Silicone foam and sponges have different cell structures. Silicone foam has a closed-cell structure without pores, while sponges have an open-cell structure with pores.

Can silicone foam be used for high-temperature sealing?

Silicone foam is ideal for high-temperature sealing. It can efficiently withstand a maximum temperature range of -60°C to 230°C without changing its properties like other polymers.

What is the shelf life of silicone foam products?

Silicone foam is long-lasting and durable, with weather and chemical resistance. If stored in suitable conditions, it can last up to 20 years or more.

Conclusion

Are you finding it difficult to choose the right silicone foam material? Silicone foam is a versatile material with unique characteristics like flexibility, compressibility, and temperature resistance. We’ve explored all the critical properties of silicone foam to better understand its usability. Follow our key considerations in making the right choice for silicone rubber foam.

Do you want top-quality silicone foam products? Hongju offers the best silicone foam products with exceptional durability and longevity at competitive prices.

Hongju: Your First Choice for High-Quality Silicone Foam

Looking for a reliable manufacturer of customized silicone foam products? Hongju is a globally recognized manufacturer of silicone foam. It provides tailored solutions to a variety of industries.

The robust R&D and state-of-the-art manufacturing facility enable the production of high-quality silicone products. Get in touch to get customized silicone options perfect for your specific needs.