Do you need a reliable sealant suitable for all kinds of applications? Liquid silicone rubber sealants are the best possible solution. It spreads like plaster and sticks to all shapes and surfaces. Whether you are in construction or manufacturing, silicone is the only sealant that will give the best results.

Let’s explore all the reasons why silicon compounds are the best sealants on the market.

Why Choose Silicone Sealant Over Other Materials?

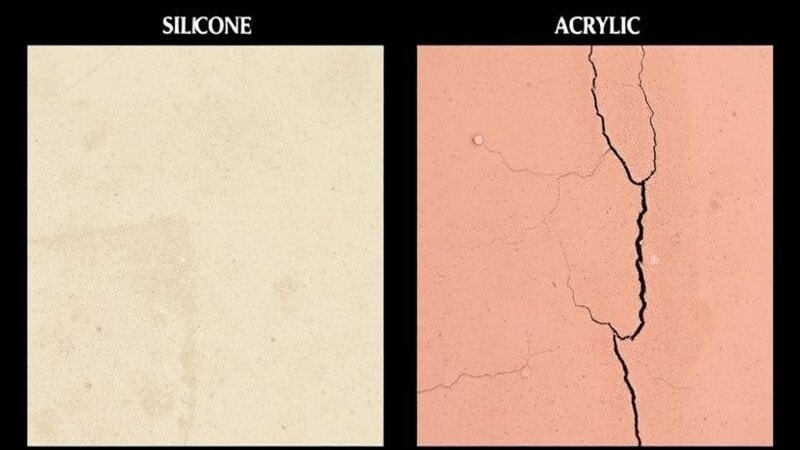

There are a plethora of other adhesives on the market, such as latex, acrylic, and polyurethane. However, silicone products outperform them all. Its thermal stability, durability, and flexibility are unmatched.

Silicone materials are able to maintain performance even under high temperatures and UV exposure. Thus making them ideal for long-term reliable solutions. Whether needed in automotive applications or construction.

Silicone stands apart due to its durability and elasticity. Whereas latex and acrylic sealants crack and degrade over time. Plastic sealants, such as polyurethane, also have demerits. They tend to become yellow and become brittle with prolonged air and UV exposure.

Silicone’s chemical structure, made up of silica and oxygen, supports its longevity. Thus forming permanent waterproof seals without risk of leaks or damage.

There are certain formulations of silicon gels that can tolerate temperatures up to 600°F (315°C) without losing flexibility. Moreover, the viscous nature of silicone grease allows it to adhere to all kinds of surfaces. Whether you want to create a bond between glass, metal, plastic, or ceramic, silicon is your friend.

Its ability to seal in moisture and air and deter vibrations are some reasons it is revered as the superior sealing solution for all industries.

Here is a comparison table of silicone properties with other adhesive materials.

| Feature | Silicone Sealant | Latex Sealant | Acrylic Sealant |

|---|---|---|---|

| Flexibility | Excellent | Poor | Moderate |

| Durability | High | Low | Moderate |

| Water Resistance | Excellent | Low | Moderate |

| Adhesion Strength | Strong (bonds to various materials) | Weak | Moderate |

| Temperature Resistance | High (withstands extreme heat and cold) | Low | Moderate |

| Chemical Resistance | Excellent (resists chemicals, UV, and moisture) | Poor | Moderate |

What is an All-Purpose Silicone Sealant?

All-purpose silicone sealant is a polymer of simple silica and oxygen compounds. It turns into a chemical element that is a versatile and durable adhesive for bonding and waterproofing. It is able to maintain its flexibility and resilience even in extreme conditions.

Key Properties of All-Purpose Silicone Sealant

As a manufacturer or industrialist, it is important to research the properties of any sealant you are using. It is perhaps the most crucial aspect of any project. If the sealant fails to perform its job, it can produce catastrophic failures. Let’s see why silicone is the savior sealant of your project.

- Flexibility: It expands and contracts without cracking. Thus making it perfect for surfaces that experience movement.

- Durability: It resists UV radiation, moisture, and temperature changes. Thus ensuring long-term performance.

- Weather Resistance: It is ideal for outdoor use because it can endure rain, humidity, and temperature changes.

- Easy to use: It comes in cartridges, tubes, and squeezable form. It also easily attaches to most non-porous surfaces, such as glass, metal, plastic, and ceramics.

Use Cases

We are not only claiming that silicone can be used in all kinds of projects. We will also prove it. Here are examples of industries using this legendary sealant in main and other applications. Currently, it is being used in:

- Sealing gaps is ideal for preventing leaks around windows, doors, and plumbing fixtures.

- Waterproofing is used in bathrooms, kitchens, and roofing to prevent moisture entry.

- Insulation helps to seal air gaps in HVAC systems, electrical enclosures, and construction joints.

- DIY and Repairs, as it is suitable for craft projects, home repairs, and vehicle sealing.

Common Uses of Silicone Sealant in Various Industries

Whether you are from construction, manufacturing, or niche industries, you are going to use silicone one way or another. Here is the breakdown of all industries that use silicone and how.

Construction and Home Improvement

Silicone sealant is commonly used to seal windows, doors, and seams in buildings. Its moisture resistance makes it suitable for use in bathrooms, kitchens, and plumbing fittings. Since it prevents leaks and mold formation. It is also effective on flat ceilings, plaster, and plastic surfaces, providing long-term protection.

Automotive Applications

Silicone sealant is widely used in the automotive industry. It is used to seal gaskets, engine components, and windshields. Its ability to endure high temperatures and vibration assures longevity in harsh driving situations. Silicone-based adhesives and lubricants also aid in vehicle performance.

Electronics and Electrical Components

Silicone protects electrical components, circuit boards, and cables from moisture and temperature changes. It minimizes dust and air exposure, lowering the chance of short circuits. Many silicone gels and coatings are utilized to insulate and protect sensitive electronics.

Industrial and Manufacturing Uses

Silicone sealant is used extensively in the food processing, pharmaceutical, and chemical sectors to seal molds, pipes, and machinery. It acts as a mold release agent, facilitating the seamless production of rubber and foam goods.

Consumer and Medical Products

Silicone is used in cookware, medical devices, and personal care products. Its non-toxic, flexible, and heat-resistant properties make it suitable for bakeware, baby bottles, and prosthetics. Silicone grease and lubricants are also used in skincare and industrial applications to achieve the best results.

Materials All-Purpose Silicone Adheres To

While silicone adheres to almost all kinds of materials. It does not hurt to be diligent when it comes to sensitive projects. Here is an itemized list of surfaces compatible with silicone.

- Granite

- Cultured marble

- Ceramic

- Natural stone

- Cement board

- Metals (e.g., aluminum, stainless steel)

- Glass

- Drywall

- Wood

- Porcelain tile

Caution with Vinyl

Vinyl is one of very few materials that does not bond well with silicone. Some chemical reactions between the two materials cause them to become brittle or lose adhesion over time. However, there are many vinyl-based materials that suit well with silicone. So, it is up to you to verify the compatibility before bulk buying.

Tips for Selection

Even though we have covered all the bases, if you are still confused about sealants, then follow these tips. Before purchasing, check the silicone packaging or product specifications to confirm material compatibility. Some surfaces may require a primer or surface treatment for best results.

Sourcing Silicone Sealant for Bulk Purchases

If you are considering purchasing silicone sealants in bulk, then you need to consider a couple of factors. It is important to evaluate supplier reliability, product quality, pricing, and customization options. Here is a brief guide on sourcing silicone for bulk purchases.

Where to Buy Silicone Sealants

Let’s start with where to buy silicone sealants. The most reliable suppliers for bulk silicone sealants are direct manufacturers. They allow you to source the sealant at factory prices while ensuring quality control. You can also alter product specifications when working with manufacturers.

Alternatively, there is the option of suppliers and online marketplaces. At times you can get pretty good deals with these two options as well. However, you have to be pretty diligent when it comes to buying from online platforms. Be very thorough while checking reviews and repute of the company you choose to work with.

If your project is due shortly, then you will want to partner with someone that provides quick service. In this situation, local wholesalers are the best. They provide competitive pricing and faster delivery than anyone else.

Factors to Consider When Buying Silicone Sealants in Bulk

If you are making a bulk purchase, you will be spending major bucks. To keep your investment safe, it is important that you consider the following factors:

- Pricing and Minimum Order Quantity: Negotiate a discounted deal for a bulk order. Most suppliers offer tiered pricing based on order value, so take advantage of it.

- Quality and Certifications: Ensure the company and product are certified. You can look for certifications such as ISO, ASTM, or FDA-grade for food applications.

Conclusion

Selecting the appropriate silicone sealant is critical for guaranteeing durability, flexibility, and long-term performance in industrial and commercial applications. If you require reliable, high-quality all-purpose adhesion, then silicone is the right choice for you. However, make sure you purchase your goods from a reputable supplier, as it can make all the difference.

Looking for the Right Silicone Sealant for Your Business?

At Honju Tech, we specialize in premium silicone solutions tailored to all industries. With over 15 years, bring expertise in silicone to your project. Whether you need custom formulations or expert guidance, we are here to help you find the best sealant for your needs.

Explore our product catalog or contact us for a consultation today!