What Is Silicone Rubber?

Silicone rubber is a synthetic rubber with silicon, hydrogen, oxygen, and carbon as its constituent elements. Depending on the final product, this elastomer has a chemical composition that includes the silicone polymer, a cross-linking agent, and additives.

Usually, the cross-linking agent used during the manufacture of silicone rubber is platinum or peroxide. This agent is added to the silicone polymer, initiating a chemical reaction that makes the material elastomeric.

Furthermore, the additives used in silicone rubber reinforce its properties. For instance, pigments enhance the final product’s color, while carbon improves the tensile strength of silicone rubber.

Regardless of its additives, this elastomer has excellent electrical properties, high thermal conductivity, and good chemical stability. Furthermore, silicone rubber is easily molded to suit several applications because of its durability and flexibility.

How Is Silicone Rubber Made?

The manufacturing process for silicone rubber is relatively straightforward. The first step in the manufacturing process is to mix and heat the constituents of silicone rubber – silicone polymer, cross-linking agent, and the appropriate additive for the application.

After the ingredients are heated and mixed into a smooth blend. This rubbery material can then be shaped in one of two ways:

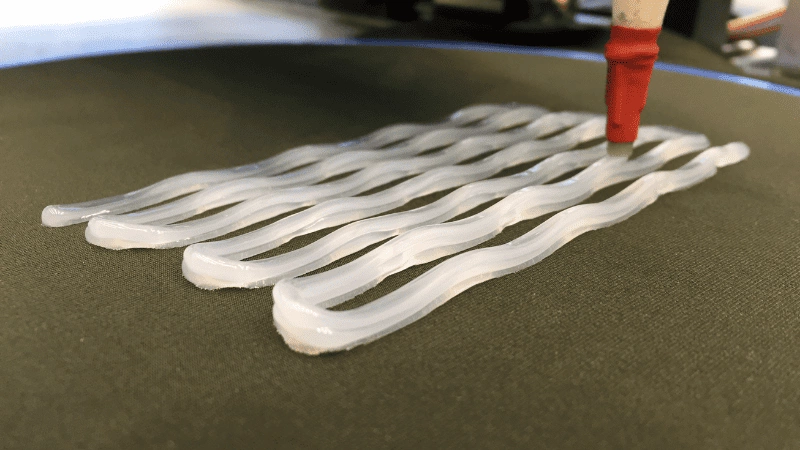

- Extrusion: The mixture is pushed through a shaped opening to create long, continuous parts, like tubes or seals.

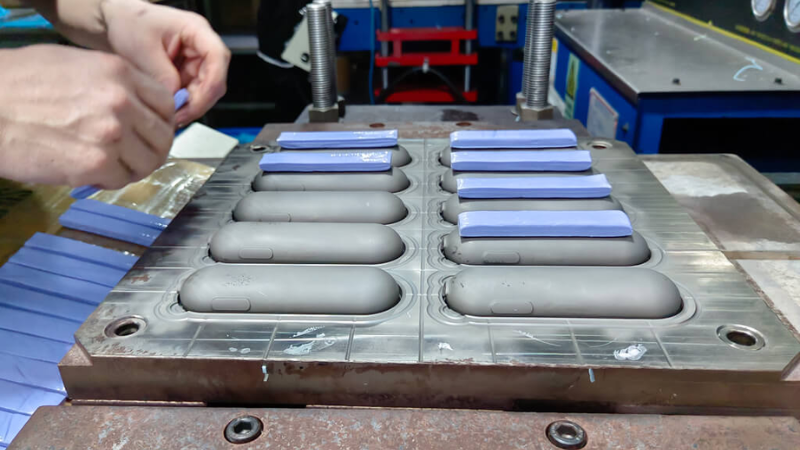

- Molding: The mixture is then injected into a mold and allowed to cure into a specific shape.

During the curing process, a peroxide or platinum catalyst is added to initiate the cross-linking reaction. After the silicone rubber is cured, it is trimmed and cleaned to create the final product.

It is important to note that the hardness of the final product affects the performance of silicone rubber as a damping material. For instance, the hardness of the material affects its vibration-damping effect. Softer silicone rubber materials are better at absorbing shock than harder silicone rubber.

Furthermore, the thickness of the final product also affects vibration damping. The thicker the elastomer, the higher its vibration-damping effect.

Hongju Awaits Your Quote Request!

How Does Silicone Rubber Dampen Vibrations?

Mechanical systems often produce vibrations from the occurrence of friction or mechanical shocks. Leaving these vibrations alone could result in damage to the system, lower efficiency, and noise.

Thus, it is highly important to dampen vibrations. Damping vibrations is a process that eliminates or reduces vibrations in a system.

Because of its elastic and viscous properties, silicone rubber is an excellent vibration dampener. It absorbs the vibrations and dissipates them as heat to the surrounding environment.

As silicone absorbs vibrations, it deforms. The internal frictional forces within the elastomer then dissipate the energy over many cycles. As a result, the elastomer reduces the frequency and amplitude of vibrations in a mechanical system.

Silicone rubber exhibits several vibration-damping characteristics, including;

Hysteresis: Hysteresis is a lag in a material’s response. Its reaction depends on the current force being applied. This happens in materials that absorb energy, like silicone rubber, causing a delayed reaction when a force is repeatedly applied and removed.

Besides, the hardness of the elastomer determines its hysteresis behavior. For instance, soft silicone rubber deforms easily and takes longer to recover. So, it exhibits a more significant hysteresis compared to hard silicone rubber.

Viscoelasticity: Viscoelasticity means a material has both elastic and viscous properties. Under brief stress, it acts like an elastic solid and bounces back. Under prolonged stress, silicone rubber behaves like a thick liquid and will slowly change its shape.

Shear deformation: changes the shape of a material without changing its volume. This phenomenon occurs when forces acting in opposite directions are applied to two parts of a material.

Silicone rubber also undergoes shear deformation. Reinforcing silicone rubber with fillers during manufacture may make it more resistant to shear deformation.

Damping coefficient: It measures the amount of energy dissipated after each deformation cycle. Materials with high damping coefficients reduce the amplitude of vibrations in a system.

Although the damping coefficient of silicone rubber is relatively low, it is still effective in reducing vibrations. The thicker the silicone rubber, the higher its damping coefficient.

Frictional damping: occurs when two surfaces are in relative motion. These surfaces dissipate heat due to the friction between them. Silicone rubber exhibits frictional damping depending on its surface.

If the elastomer has a smooth surface, there is less frictional damping than if its surface is rough. In addition, a coated silicone surface has a lower amount of damping.

Applications of Silicone Rubber as a Vibration-damping Material

Because of its vibration-damping effect, silicone rubber is used in several industries, including;

- Aerospace: Landing gear, propellers, and rotors use vibration dampeners like silicone rubber to reduce noise and improve performance.

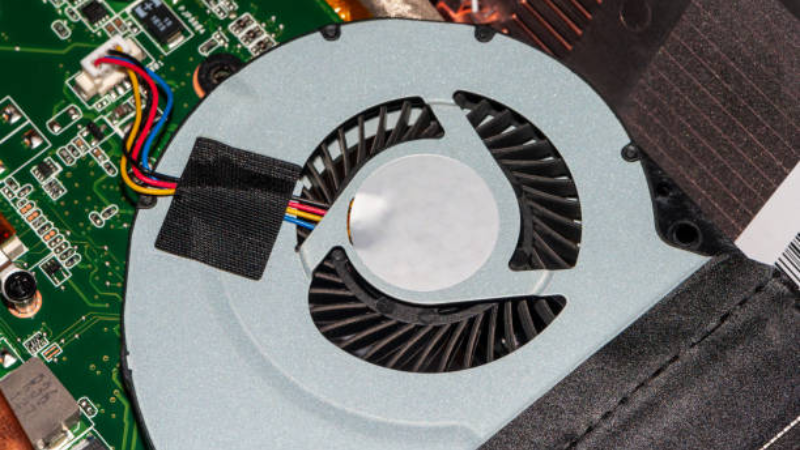

- Electronics: Silicone rubber dampens vibration to protect electronic devices such as printers, copiers, smartphones, and hard disk drives in laptops.

- Automotive: Suspension systems, exhaust systems, engine mounts, and steering systems use vibration dampeners like molded rubber parts.

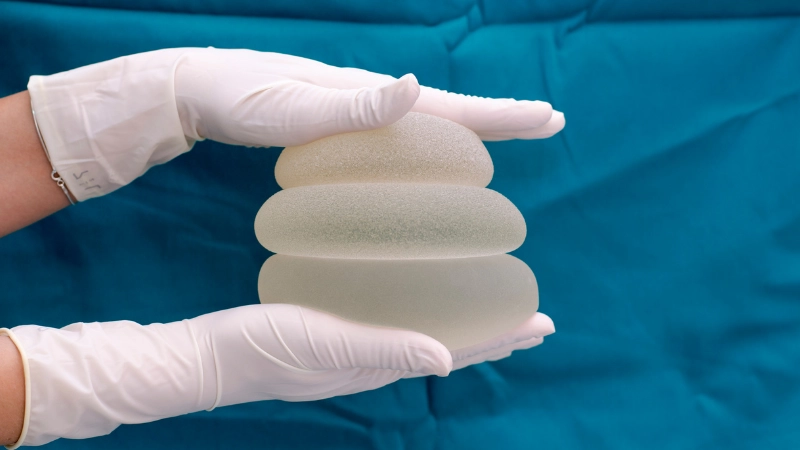

- Medical devices: Silicone rubber dampens vibration in medical devices like prosthetics, MRI, and Ultrasound machines.

Hongju Awaits Your Quote Request!

How to Test and Evaluate Silicone Rubber for Vibration Damping?

Testing and validating the reliability and effectiveness of silicone rubber as a damping material is essential because it helps to prevent unexpected failures and increase overall performance.

Some standard testing methods to evaluate the performance of silicone rubber as a damping material include:

Dynamic mechanical analysis (DMA): DMA tests a material’s viscoelastic properties, including the damping coefficient.

During the test, the material is exposed to a small oscillating force over several temperatures and frequency ranges. The resulting deformation is then measured and used to calculate the damping coefficient.

Impact testing: This test measures the damping properties of a material when it undergoes shock loading. An impact test involves striking the material with a hammer or dropping a weight and then measuring the deformation.

Shear modulus measurement: This test measures the dampening effect of silicone rubber when exposed to shear. During the test, an elastomer sample is placed between two parallel plates. While one plate is fixed, the other moves back and forth.

After measuring the force it takes to maintain the oscillatory movement, it is used to calculate the material’s shear modulus.

Why Choose Silicone Rubber over Other Vibration Dampeners?

Balanced Performance:

Due to its advantages of thermal stability, flexibility, and durability, silicone is one of the most reliable and versatile vibration-dampening solutions available.

Superior Vibration Absorption:

Unlike metals that often transmit vibrations, silicone provides excellent energy absorption and noise reduction.

Wide Temperature Resistance:

Silicone stays flexible and functional from –60°C to 230°C. But natural rubber will harden, crack, or lose elasticity under heat.

Durability Against Harsh Conditions:

Cork or polyurethane may degrade under moisture, UV, or chemicals; while silicone offers long-term resistance to weathering, ozone, and harsh chemicals.

Electrical Insulation & Biocompatibility:

Silicone provides safe electrical insulation and biocompatibility, making it suitable for medical devices, electronics, and other sensitive applications.

Factors Influencing The Vibration Damping Effect

Before choosing silicone rubber as a vibration-damping material, it is essential to note that several factors affect the damping effect of the material. These factors include temperature, vibration frequency, vibration amplitude, and hardness.

Temperature: Temperature affects the damping properties of silicone. With increasing temperature, silicone becomes less stiff, increasing its damping capabilities.

Vibration Frequency: The vibration frequency is another critical factor. The lower the frequency of vibration, the higher the damping properties of the silicone elastomer.

Vibration Amplitude: At low amplitudes, silicone has a low dampening effect. Nevertheless, if the amplitude is too high, the elastomer may reach its deformation limits and become less effective in damping vibration.

Hardness: Softer silicone materials deform easily and absorb more vibrations than hard silicone materials.

Guidelines for Choosing Silicone Rubber as a Vibration-Damping Material

Not all silicones are the same because additives and formulations create different material properties. So your choice should be based on the specific operating conditions of your application.

- Performance Factors: Consider the expected temperature range, vibration amplitude, and frequency. The silicone you select must withstand these conditions while maintaining vibration-damping effects.

- Environmental Resistance: Exposure to weather, moisture, UV, and chemicals can also impact performance. Some silicone materials have enhanced resistance, making them more suitable for outdoor or harsh environments.

- Cost Considerations: While silicone offers excellent durability and performance, it is usually more expensive than others. It is essential to evaluate whether the material provides the right balance between vibration-damping efficiency and budget.

By weighing these factors above, you can select the most suitable silicone rubber that delivers both reliability and value for your vibration-damping needs.

Hongju Awaits Your Quote Request!

Conclusion

Silicone rubber excels at vibration damping due to its excellent viscoelastic properties. It effectively absorbs mechanical shocks and vibrations, converting the energy into heat to protect sensitive components.

With superior performance across extreme temperatures and resistance to harsh environments, silicone has been a durable and reliable solution for applications in the automotive, aerospace, and electronics industries.

Get Your Custom Silicone Solution from Hongju’s Experts

Need the perfect vibration dampener or custom silicone part? Leverage over two decades of Hongju Silicone‘s manufacturing expertise. Our experts will consult with you on your exact specifications, helping you develop an all-inclusive silicone solution.

Contact us today to get your ideal product! Stop searching and start solving.