What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process of mass fabrication in which plastic parts are made by injecting molten material into molds. These plastic products are further used in numerous industries. The mold is made up of the same design in which the final product is required.

Top Plastic Injection Molding Manufacturers and Suppliers in China

The following table shows the most prominent manufacturers and suppliers in China ranked by various indicators. These performance indicators include product quality, reliability, estimated annual revenue, workforce, and many other factors. Let’s have a look at the table below.

| Position | Company Name | Year Established | Location (City) | Employee Size |

| 1 | Hongju Silicone | 1999 | Dongguan | 50-100 |

| 2 | Daxin Rubber | 2012 | Dongguan | 300-400 |

| 3 | OTTSilicone | 2010 | Guangzhou | 50-100 |

| 4 | Melon Rubber | 2017 | Zhongshan | 50-100 |

| 5 | Haotian Silicone | 2015 | Dongguan | 50-100 |

| 6 | Hong Ye Silicone | 1998 | Shenzhen | 60-70 |

| 7 | ABIS | 1996 | Shenzhen | 100-200 |

| 8 | Newtop Silicone | 2015 | Xiamen | 50-100 |

| 9 | Insilicone | 2007 | Dongguan | 100 |

| 10 | DeYu Silicone | 2008 | Dongguan | 30-50 |

Company Summaries

Below we will describe each company in detail so you can better understand the best one for you. For your convenience, these are already ranked.

1. Dongguan Hongju Silicone Rubber Products Co., Ltd.

Hongju Silicone is at the top of the list due to its quality manufacturing process. It has a vast and extensive manufacturing experience of over two decades, founded in 1999. Its quality manufacturing is reflected in its adherence to international standards like FDA, ISO 9001, and CE.

Hongju specializes in liquid silicone rubber injection molding and other services like compression molding, die cutting, metal or rubber bonding, and transfer molding. It has one of the finest and most advanced machines and qualified engineers to make quality-oriented products.

They have one of the largest product delivery networks in the world and a quick turnaround time. You can get most of your products, like plastic molds, within a week. Moreover, the price rates are also quite economical and comparative.

Company Advantages:

- High-Quality Parts and Manufacturing

- Internationally Certified through FDA, ISO, and EU

- Fast-Paced Delivery Network

- Economical Price

- Reliable After-Sales Support

Main Products and Services:

- Rubber Grommets

- Silicone Rubber O-Rings

- Plastic Injection Molds

- Rubber Molds

- Swimming Caps

Inquire About Our Silicone and Plastic Products!

2. Rilong Precision Mold Co. Limited

Rilong is a prominent Chinese manufacturer founded in 1990 and has rich experience in plastic-based products. Its injection molding process is one of the best due to quality-based CNC machining.

It comprises 150 staff members, including professional engineers, researchers, and usual workers. It has quality management certifications of ISO, IATF, and RoHS. Its project management team enables it to provide finalized products within 1-2 weeks.

The packaging and prototyping of Rilong are also very reliable and quality-oriented. Numerous customers around the world have admired the surface finishes.

Company Advantages:

- Low Minimum Order Quantity Requirements

- ISO, IATF, and RoHS Certified Manufacturer

- After-Sales Support

- Reliable Quality Products

- Quality Raw Materials

Main Products and Services:

- Multi Cavity Molds

- Thermoplastic Resins

- Plastic Injection Molds

- Rubber Molds

3. Dongguan Daxin Rubber Electronic Co. Ltd.

Daxin Rubber is a state-of-the-art manufacturer and supplier of plastic injection molding based in Dongguan. The factory is installed on a wide area of 15,000 sq. meters and has around 400 employees.

Thermoplastic injection molding is one of its primary capabilities. Daxin has a vast experience of more than a decade and has a network of global shipments to more than 80 countries.

Alongside being a good plastic molding company, Daxin Rubber also manufactures silicone molds and other silicone-based products. It has international quality certifications of BSCI, SEDEX, ISO, and IATF. The production time for its manufactured products is almost 1-2 weeks.

Company Advantages:

- After-Sales Support and Meaningful Collaboration

- Free Prototyping

- Quality Material

- Capacity to Produce a High Volume of Products

- Rich Manufacturing Experience

Main Products and Services:

- Gas Assist Injection Molding

- Thermoplastic Resins

- Custom Plastic Parts

- Automotive Components

- Molded Plastics

4. Huizhou Hongyejie Technology Co. Ltd.

Hong Ye Silicone is a leading manufacturer of injection molded products. It offers injection molding, HTV, RTV-2 silicone rubber, and LSR. It also has a vast experience of more than two decades which is why it is considered one of the top plastic injection molding companies.

It exports all silicone, plastic, and rubber-based products to Southeast Asia, Europe, and America. Various consumer products are made through manufactured items. From mold design to finalizing and producing parts, 150 members R&D Team work diligently.

You will always find consistent results, as adhering to international standards is its top priority. Along with other services, it also produces liquid silicone rubber. From production to packaging, every step is evaluated by quality testers.

Company Advantages:

- High-Quality Raw Material

- Customized Surface Finishes

- Fast and In Time Delivery

- Smooth Production Process

- Economical Price

Main Products and Services:

- Custom Injection Molded Plastics

- Automotive Parts

- Liquid Silicone Rubber

- Silicone Gel

5. Bluestar Technology Group Co. Ltd.

Bluestar Technology Ltd. is a big name in the industrial marketplace as it has provided injection molding services for over two decades since 2003. Its primary focus is to develop in-house plastic molding parts for the automotive industry. Due to its delivery network, you can get your plastic molded parts within 1-2 weeks.

Bluestar has an experienced R&D Center having around 100 employees consisting of engineers. The manufacturing processes are of high-quality and internationally recognized methodologies. Custom plastic injection molding is one of its specialties.

The entire process, from production to packaging, takes up to one week for an average volume of plastic molds.

Company Advantages:

- Fast-Paced Delivery

- Specialized in the Automotive Industry

- After-Sales Support

- Vast Experience

Main Products and Services:

- Custom Plastic Injection Mold

- Automotive Parts

- Rubber Molded Parts

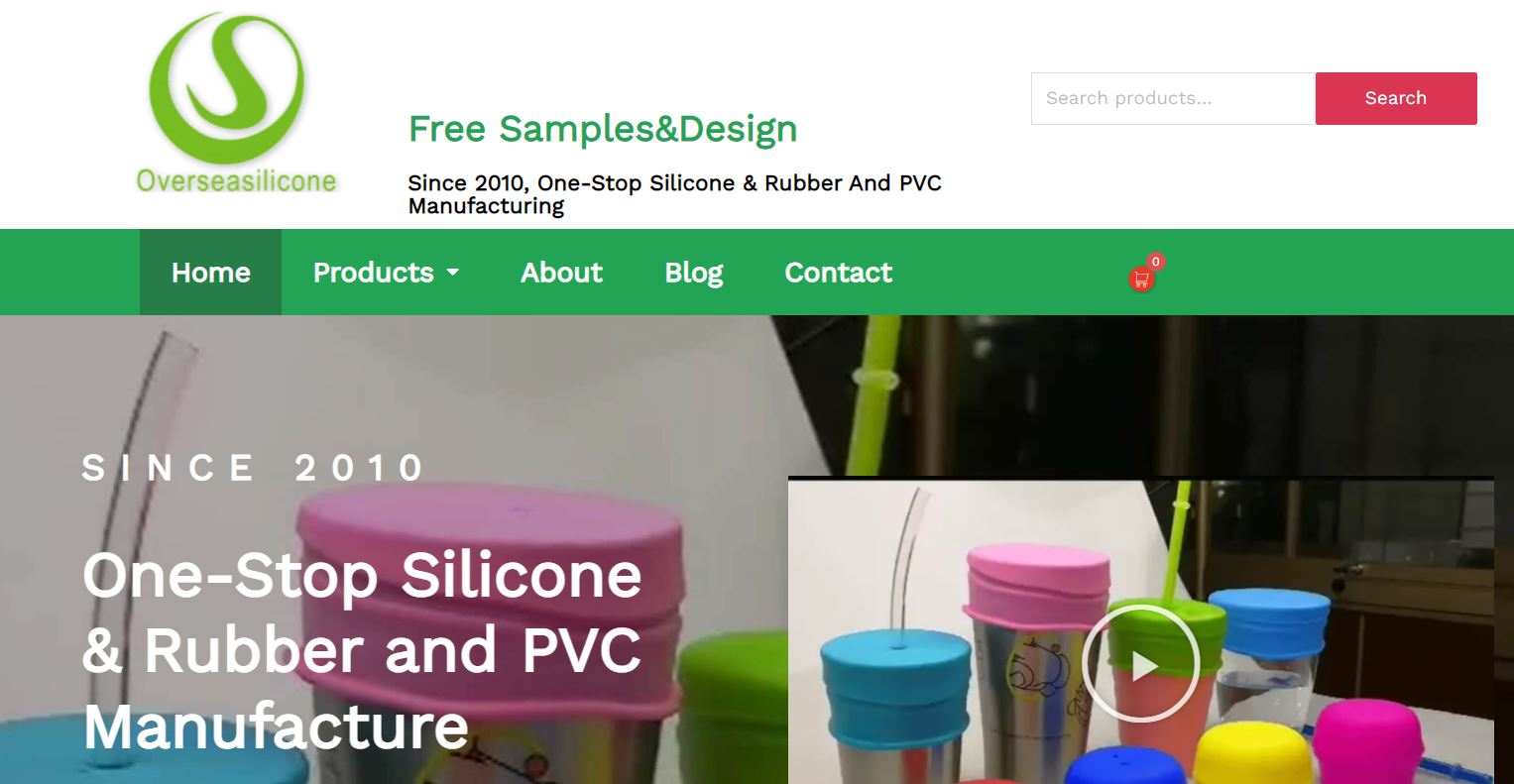

6. Guangzhou OTT New Materials Co. Ltd.

OTT was founded in 2010 and specializes in silicone, rubber, and plastic-oriented products. The entire plastic injection molding process becomes quality-oriented through state-of-the-art manufacturing machines.

It has around 100 employees, including 12 fully qualified engineers. Ìt also offers custom injection molded parts through advanced prototyping, along with injection molding services, LSR, RTV-2, high transparent silicone, and numerous other products.

Moreover, OTT Silicone also offers free design services for all of your bulk orders. The custom injection mold will contain the required mold cavity and other specifications. The price range for all OTT’s products is also quite competitive.

Company Advantages:

- High-Quality Injection Molding Process

- Economical Price

- International Certifications like ISO, EU

- Reliable International Shipment

Main Products and Services:

- Injection Molding

- Silicone Rubber

- Silicone Resin Powder

- Electronic Potting

7. Melon Rubber Industry Co. Ltd.

Melon Rubber Industry is a well-known manufacturer and supplier of plastic injection molding. It has a vast product catalog covering almost all plastic-oriented products. It was founded in 2017, but their CNC machines are of exceptional quality.

Melon Rubber Industry always uses quality raw materials to manufacture its products. They also quickly respond to all of their customers worldwide within 24 hours. The price range is also very economical and affordable.

It has a 100-member team of professional staff who ensure precision parts and quality control till final packaging. Through their advanced inventory control mechanism, you can expect your injection molded products to be delivered within 1-2 weeks.

Company Advantages:

- Qualified Workforce and Professional Engineers

- Advanced CNC Machining

- After-Sales Support

- Low MOQ Requirements

- Competitive Price

Main Products and Services:

- Injection of Molded Plastic Parts

- Tooling and Resin Powder

- Silicone Rubber

- Silicone Molds

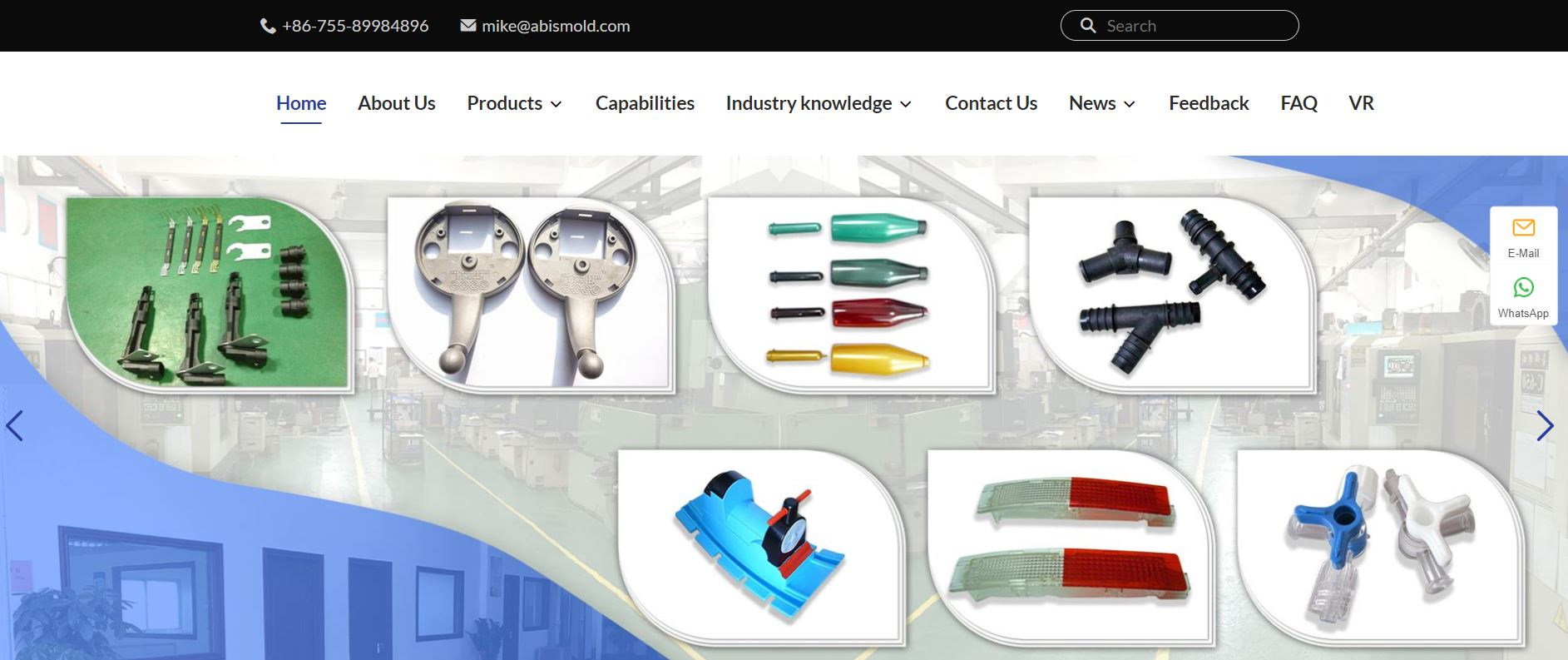

8. ABIS Mold (HK) Technology Co. Ltd

ABIS Mold Technology Co. Ltd. has been a renowned injection molding company since 1996. The total area of the factory is 12,000 sq. meters, with advanced development facilities. It offers injection molding, rubber molding, die casting, and silicone molding.

As an ISO 9001:2015 certified manufacturer, ABIS adheres to international quality standards throughout the manufacturing period. It is undoubtedly one of the finest injection molding companies due to its experience and manufacturing mechanisms.

ABIS always uses export-quality raw materials, which FDA also grades. Its product delivery network is spread worldwide. Moreover, it manufactures products such as plastic mold, tooling, and resin for almost all industries.

Company Advantages:

- Vast Manufacturing Experience

- 24/7 After-Sales Support

- Low MOQ Requirements

- Quality Raw Material

- State-of-the-art Tooling and Injection Molding Process

Main Products and Services:

- Injection Molded Plastics

- Rubber Mold

- Silicone Mold

- Liquid Silicone Mold

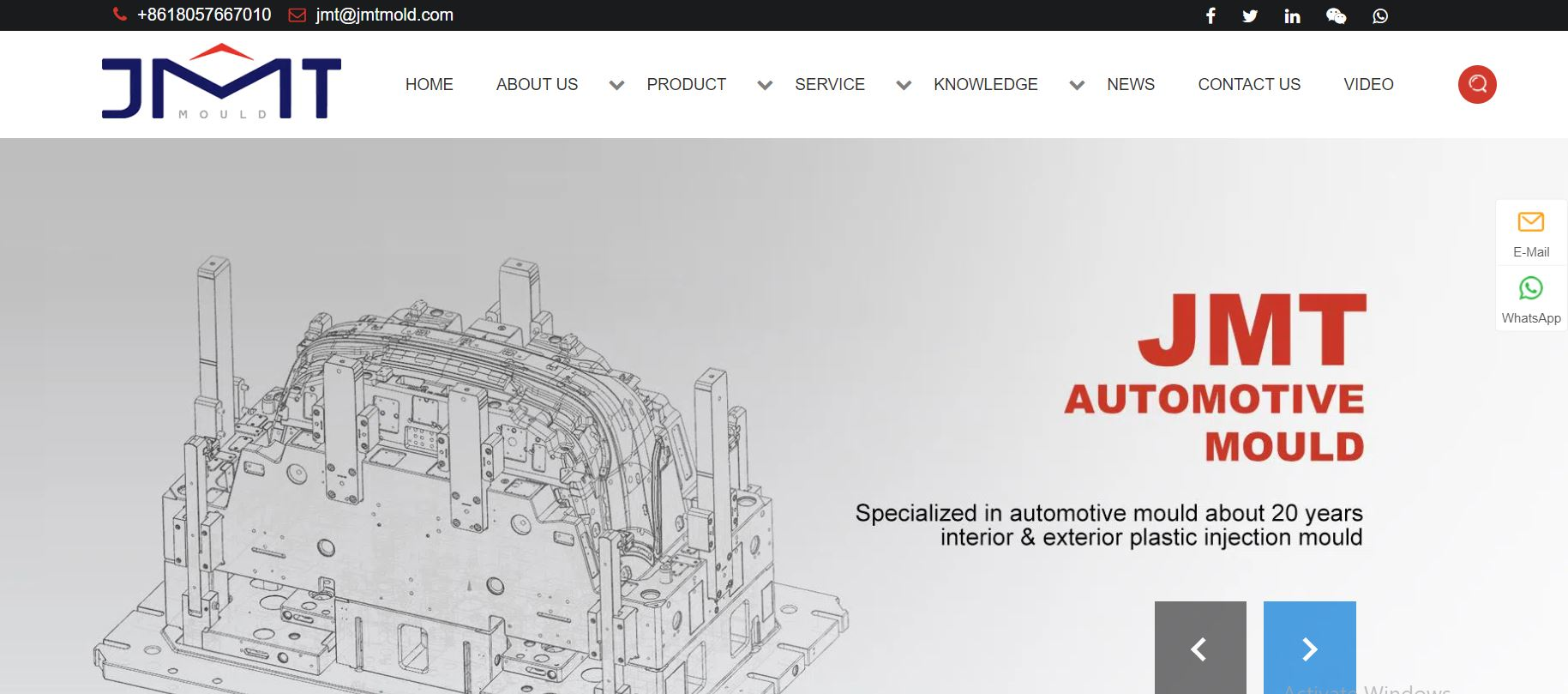

9. JMT Automotive Mould Co. Ltd

JMT has a mold manufacturing experience of more than two decades since its inception in 2000. The main focus of JMT is to manufacture automotive molding material. It also manufactures injection molding plastics through an advanced CNC injection molding process.

JMT is a Taizhou Huangyan JMT Mould Co., Ltd. subsidiary and adheres to international quality standards like ISO 9001:2015 and IATF 16949:2016. It has a workforce of around 150 employees, including engineers and researchers.

Moreover, it has around 30 production lines, making it possible to deliver products within 1-2 weeks. JMT also provides worldwide shipment facilities.

Company Advantages:

- Fast-Track Delivery

- Adherence to International Quality Standards

- Quality Raw Material

- Advanced Manufacturing Process

- Designing Service

Main Products and Services:

- Plastic Mold

- Automotive Molding

- Injection Molding

- Rubber Molding

10. InSilicone Co. Ltd.

Insilicone is also a good manufacturer of plastic injection molding and silicone-oriented products. It was founded in 2007 with a factory area of 3000 sq. meters. It has a comparatively low number of workers, but all are well-professional and experts.

Insilicone also deals in PVC and rubber manufacturing through conventional methods. However, it can provide free design services and price quotes.

The prices of its products are very economical and comparative. Surprisingly, it also adheres to international quality standards like ISO 9001:2015, BSCI, and SEDEX. However, the delivery time is around 3-4 weeks.

Company Advantages:

- Low Price

- Low MOQ Requirements

- ISO, BSCI, and SEDEX Approved

- Customizability

Main Products and Services:

- Injection Mold

- Rubber Molding

- Silicone Baby Products

- Silicone Kitchenware

4 Benefits of Importing Plastic Injection Molding from China

There are numerous benefits to importing plastic-oriented products from China. Some of the most significant ones are as follows.

Quality Products

Chinese manufacturers always pay great attention to the quality of their products; that’s why they adhere to international quality standards. Almost all of the companies adhere to measures like ISO and EU.

Economical Prices

Chinese manufacturers of plastic molding export quality material from China, and the labor costs are also relatively low. Therefore, they always offer quality-oriented products at economical prices.

Free Trade Zone

China has the freest trade zones in the world in many cities, notably Shenzhen, Shanghai, Tianjin, Dongguan, etc. That is why you can get plastic injection mold and other products without direct intervention from customs.

Wide Selection of Manufacturers

Since there are numerous manufacturers in China, you will find diversity and the ability to choose the best one according to your requirements.

Looking for Plastic Injection Molding? Hongju Silicone Can Help You

If you are looking for the best plastic injection molding manufacturer and supplier, please don’t hesitate to contact us. We have a vast experience of manufacturing for more than 20 years. You will find top-quality plastic injection molds with economical prices and lifetime support.