Depending on the manufacturer and the supplier, the quality of plastic injection molds is not always consistent. There are several factors to consider when choosing a reliable and reputable manufacturer or supplier.

But don’t worry because we have done everything for you and compiled a list of the top 10 plastic injection mold manufacturers and suppliers in China. So, let’s dive in!

An Overview of the Plastic Injection Mold Industry

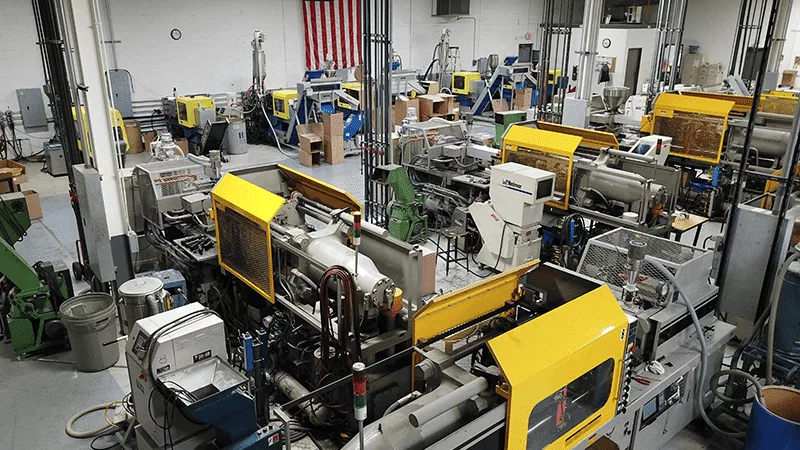

Injection molding is a complex and detailed process that is known for producing parts by injecting molten material into a mold. In this process, you get to see versatility, which means you can use different materials.

For example, you can use metals, elastomers, and, notably, thermoplastic and thermosetting polymers in plastic injection molding machines.

So, what is the significance of the plastic injection molding industry? Almost all the products that we use daily are made using this technique.

From wire spools and bottle caps to complex automotive components and electronic gadgets, all these items are made using a certain type of injection molding machine. This shows that plastic injection molding is not limited to just one industry; it covers many!

If we talk about the economic significance, the injection molding industry was valued at 11,385 million US dollars in 2021. Experts say that injection molding companies have a bright future ahead of us, estimating it to hit 15,734 million US by 2030.

This growth trajectory, characterized by a compound annual growth rate (CAGR) of 4% during the 2022–2030 forecast period, underscores the technology’s expanding role in modern manufacturing. This growth is obvious because almost every industry is opting for plastic-related items.

Factors to Consider When Choosing a Plastic Injection Mold Manufacturer

Before selecting the right plastic injection mold manufacturer, you have to consider different factors. The factors we are about to list below are the ones that we considered when making this list of the best plastic injection molding companies in China. So, have a look:

Quality & Efficiency

The foremost consideration should be the manufacturer’s commitment to quality and efficiency. This is visible in their track record of producing durable molds by using quality injection molding equipment that meets precise specifications without compromising on the speed of delivery.

High-quality molds are essential for producing parts that meet your standards and reduce waste. Efficiency in manufacturing processes also ensures that your project stays on schedule.

Volume Specialization

Volume specialization is another vital factor. Whether your project is high-volume or low-volume, the manufacturer’s capabilities should align with your needs. High-volume projects require strong, durable systems and machinery capable of consistent output over long periods, whereas low-volume projects may require more flexibility and customization.

Services & Technology

The technological capabilities and additional services offered by the manufacturer also affect the outcome of your project.

Advanced CAD/CAM software, 3D printing for prototypes, and precision CNC machining are examples of technologies that enhance mold accuracy and quality. Comprehensive services, including mold repair, maintenance, and design consultation, can provide added value.

Material Knowledge

Understanding different materials and their properties is fundamental. The manufacturer should offer guidance on material selection based on the product’s application, durability needs, and cost constraints. Their expertise in thermoplastic, thermosetting polymers, and any other materials pertinent to your project can improve the product’s performance.

Customer Service & Communication

Effective communication and friendly customer service are of supreme importance for husky injection molding systems and companies. You can’t get the results you want if there is a communication gap or the customer support is not friendly.

The designing and manufacturing process is complex and requires ongoing dialogue between you and the manufacturer. Good manufacturers are proactive in communication, offering regular updates and being responsive to your questions and modifications.

Top 10 Plastic Injection Mold Manufacturers and Suppliers in China

| Position | Brand Name | Year Established | Location | Employee Size |

|---|

Here is our handpicked list of the top 10 plastic injection mold manufacturers and suppliers in China, based on their experience, reputation, and technological capabilities.

1. Hongju Silicone Co, Ltd.

Hongju is by far the leading and most trusted plastic injection mold manufacturer and supplier in China. If you want high-quality silicone, rubber, or plastic products, this is your go-to supplier and manufacturer in China.

Company Business Overview

Since its foundation in 1999, the company has made its name for producing silicone rubber products of superior quality that meet international standards. Hongju caters to the needs of diverse industries such as electronics, household appliances, and the automotive industry, offering different services including mold development, fast prototyping, and extensive production capabilities.

Pros

- Eco-friendly: Unlike other injection molding companies, Hongju is known for making eco-friendly materials that are easy on your wallet and the environment.

- Unique Designs: In addition to focusing on quality assurance, you get unique designs, ensuring that the products meet current standards.

- Quick Delivery Time: Hongju promises to deliver within 3-5 working days, showing its expertise as one of the world’s largest plastic injection molding manufacturers.

Con

- Custom Designs Might be Expensive: This is because you want to make things that are custom-made just for you, making them expensive.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

2. Guangdong Yizumi Precision Machinery Co., Ltd

Yizumi specializes in both custom and standard machines, catering to a wide spectrum of manufacturing needs. Yizumi’s commitment to innovation is evident in its honors, including the 2020 National Leading

Enterprise in the High-tech Zone and the annual Advanced Enterprise of Scientific and Technological Innovation.

Company Business Overview

Founded in 2002, Guangdong Yizumi Precision Machinery Co., Ltd has made its name not only in China but around the world. The company’s remarkable scale, with over 3,000 employees and production bases that span almost 600,000 square meters worldwide, underscores its significant presence.

Yizumi became China’s first injection molding company to be listed on the A Shares of the GEM of Shenzhen Stock Exchange on January 23, 2015.

Pros

- Global Presence: The company demonstrates its capability to serve many clients internationally, which shows how reliable it actually is.

- Durability and Precision: All the products by Yizumi are very durable and created with precision, ensuring you get only the best.

Con

- Expensive: When there are over 3,000 employees, you set the prices high to pay their wages.

3. Dongguan Runsheng Plastic Hardware Co.

Located in the heart of China’s manufacturing hub, Dongguan Runsheng Plastic Hardware Co. has established itself as a leading entity in the plastic injection molding industry.

Company Business Overview

The company was founded in 1996 in Dongguan City of Guangdong Province. Known for its keen attention to precision in mold design and assembly, this company boasts a team of highly qualified managers and seasoned technicians dedicated to creating innovative products that push the boundaries of quality and design.

Pros

- Customization: The company offers customization options, allowing clients to tailor products to their specific needs, enhancing product relevance and application success.

- Precision and Uniqueness: Runsheng’s commitment to high precision and innovative product design is supported by an extensive suite of core services, including rapid prototyping injection molding, tooling, die-casting, and CNC machining.

Con

- Pay Premium for Customizations: Of course, with the customized die-casting machines, you get to pay extra for the customizations.

4. TK Mold Ltd.

This esteemed company specializes in producing plastic molds and parts, which are integral to the assembly of finished products across a broad spectrum of industries, including medical appliances, smart home devices, mobile phones, precise electronics, and more.

Company Business Overview

Founded in Hong Kong in 1983, TK Mold has established itself as a pioneering force in the plastic injection molding industry, renowned for delivering revolutionary plastic solutions.

An independent marketing research firm, IPSOS, has highlighted that TK Mold’s revenue from its plastic mold segment is unparalleled, positioning it at the apex among Chinese MT3-level suppliers.

TK Mold boasts an expansive operational footprint, with five production facilities, four strategically located in China—including its headquarters in Shenzhen—and one in Germany.

Pros

- Sustained Growth: TK Mold is recognized as a leading authority in the plastic molding industry, capable of delivering complex, high-quality plastic parts.

- Multiple Industries: The company covers multiple industries, from medical to household, making it a go-to option for everyone.

Con

- Not for Specialized Options: It covers versatile industries, so you can’t expect much specialization into a particular thing.

5. Rilong Mold Co., Ltd

Since its foundation, Rilong Mold Co., Ltd has firmly positioned itself as a significant player in high-precision plastic injection products.

Company Business Overview

Founded in 1990, this Chinese industry titan boasts a team of 300 dedicated professionals. These skilled craftsmen and women excel in engineering, production, and rigorous testing, ensuring that every product meets and exceeds client expectations.

Rilong sets itself apart by offering comprehensive in-house manufacturing solutions. It navigates the entire product development cycle from innovative concept to final product with a keen focus on customization per each client’s unique needs.

Pros

- Proper Testing: Their detailed injection molding process ensures the final product is up to the mark.

- Diverse Offerings: They cover things ranging from essential automotive components and cutting-edge optical products to security cameras, etc.

Con

- Time-Consuming Process: The manufacturing process and testing might take time, resulting in more delivery time.

6. JMT Automotive Mold Co., Ltd

JMT Automotive Mold distinguishes itself through its specialized production and design of mold parts predominantly for the automotive sector, while also showcasing masterful proficiency in SMC (Sheet Molding Compound) mold, along with molds for home appliances and household products.

Company Business Overview

Founded in 2005, JMT spans an impressive 23,000 square meters, making it one of the most expansive and pioneering plastic injection molding enterprises in China.

Their commitment to maintaining a cutting-edge facility is evident in their investment in world-class processing equipment, for example, their Taiwan high-speed milling machining centers, more than 10 Haitian injection molding machines, a five-axis high-speed machining center, etc.

Pros

- High-Quality: The firm’s expansive facility and investment in top-tier processing equipment enable it to handle large-scale projects and maintain high-quality standards.

- Specialization: The company specializes in several sectors, such as automotive, home appliances, etc.

Con

- Premium Prices: You have to pay a good amount for their quality products.

7. Sositar Mold Co., Ltd

Catering to an extensive range of applications, from home appliances and electronics to sporting and medical equipment, automotive parts, and general industrial OEM applications, this company demonstrates versatility and expertise that meets the varied needs of its clients.

Company Business Overview

Founded in 1998, Sositar Mold Co., Ltd has firmly established itself as a leader in producing diverse mold parts. Operating from a 3,800m² production base and supported by a dedicated team of over 150 professionals, Sositar Mold is capable of delivering between 60 and 80 molds monthly.

Pros

- Handle Large Injection Moldings: It can handle injection moldings up to 1,500g or for machines with a capacity of 650 tons.

- Consistent Production Output: It can deliver a significant number of molds monthly, highlighting the company’s efficiency and scale of operations.

Con

- Slow Response: The impressive scale could potentially affect the company’s agility in responding to smaller-scale projects.

8. Shenzhen Silver Bass Technology Co., Ltd.

Recognized for its specialization in the development, production, and precision technology fabrication of molds, this company has made significant contributions to precision structural components and large precision injection molds.

Company Business Overview

Since opening its doors in 1993, Shenzhen Silver Bass Technology Co., Ltd. stands out as a pillar in China’s injection molding industry. Shenzhen Silver Bass has forged strong partnerships with international brands, including Peugeot and ZTE.

Pros

- Trust: Collaborations with global brands indicate a high level of trust in Shenzhen Silver Bass’s quality and delivery capabilities.

- Strategic Location: This enhances its accessibility to key markets and supply chains in the fast-paced automotive industry.

Con

- Expensive for Some: The high precision and complexity of molds might reflect in the pricing, potentially placing it above the budget for smaller projects.

9. Richfields Plastics Ltd.

The company extends beyond mere molding, offering many secondary services including assembly, packaging, and spray painting to ensure a comprehensive solution for clients.

Company Business Overview

Established in 2001, Richfields Plastics Ltd. has positioned itself as a powerhouse in the Chinese plastic injection molding market, operating from an expansive 18,000-square-meter facility and employing a dedicated workforce of 250.

Its diverse range of plastic products serves multiple sectors such as household items, sports equipment, automotive components, toys, and various consumer goods.

Pros

- Product Diversity: Its diverse range of plastic products serves multiple sectors such as household items, sports equipment, automotive components, toys, and various consumer goods.

- Different Services: It offers a broad spectrum of services, from molding to post-production processes like assembly and packaging, facilitating a turnkey solution for clients.

Con

- Specialization Issue: The wide focus on various industries might dilute the specialization in any single sector, potentially affecting the depth of custom solutions for niche applications.

10. Haitian International

Haitian International offers products tailored for both the every day and peak demands of the plastic processing industry. The company prides itself on its straightforward, energy-saving technologies that meet and exceed client expectations.

Company Business Overview

Celebrating over 50 years of exemplary service, their product line is impressively diverse, featuring hybrid, electric, and traditional hydraulic injection molding machines.

Its continuous innovation and adaptation to market dynamics ensure that its products remain at the forefront of technology, offering clients high-quality, cost-effective solutions.

Pros

- Eco-friendly: All their products are high-quality and eco-friendly at the same time.

- Range of Products: The broad product range caters to various customer needs across the plastic processing industry.

Con

- Initially Expensive: The focus on advanced and energy-efficient technologies may come with a higher initial cost.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

These are the top 10 plastic injection mold manufacturers and suppliers in China. Check them out by visiting them and select the one that fits your needs. Remember, it is you who can make the best decision for your business. So, plan if you don’t want to regret it later!

Hongju – Everyone’s Highly Recommended Brand

Hogju will never let you down with its exceptional quality products and friendly customer support. Be it swimming caps or rubber silicone products, you can be sure you are buying what you are paying for. Still thinking that you have to know more? Visit Hongju Now!