We’re about to unveil the elite features of the top 10 neoprene gasket manufacturers and suppliers in China for 2024, guiding you to make an informed choice for your specific needs.

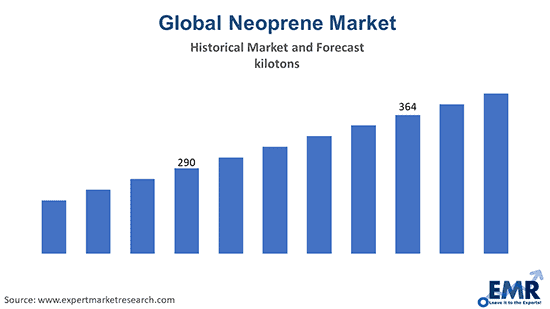

An Overview of the Neoprene Gaskets Industry

Neoprene gaskets are essential for creating strong, flexible seals in a wide range of industries, valued for their resilience to temperature fluctuations and chemical exposure. They are increasingly preferred for their durability and versatility.

Factors to Consider When to Choose Neoprene Gasket Manufacturers

When selecting a neoprene gasket manufacturer, several nuanced factors are essential to consider, to ensure a choice that aligns perfectly with your specific requirements:

1. Market Reputation and History

The longevity and standing of a manufacturer in the market often reflect their reliability and expertise. Investigating their history, including customer testimonials and past projects, provides insights into their reputation and ability to sustain quality over time.

2. Diverse Product Ranges

A manufacturer offering a variety of neoprene gaskets demonstrates their adaptability to various requirements. Assess whether they have a comprehensive range of neoprene gaskets, indicative of their expertise in catering to different needs and manufacturing challenges.

3. Quality Certifications

Certifications like ISO standards signify adherence to high industry standards and quality benchmarks. Ensure the manufacturer’s certifications are up-to-date and relevant, reflecting their commitment to quality and safety in your specific industry.

4. Technological Capabilities and Manufacturing Precision

The technology and machinery a manufacturer employs are crucial. Advanced manufacturing technology typically leads to higher precision in gasket production, essential for optimal performance and sales. A manufacturer that invests in modern technology is likely more capable of innovation and responding to new market demands.

5. Customer Service and Support

Good customer service, including pre- and post-purchase support, is vital. This includes their responsiveness to inquiries, support in custom design, rapid prototyping, and logistical assistance. The level of customer service can greatly influence the overall satisfaction and success of your business engagements with them.

Therefore, a comprehensive evaluation of these aspects will guide you to a neoprene gasket manufacturer that not only provides quality products but also aligns with your business’s strategic and operational needs.

Top 10 Neoprene Gaskets Manufacturers and Suppliers in China

Dive into the dynamic world of neoprene gasket production with our insider look at China’s top 10 manufacturers. These industry leaders are setting the standard with their cutting-edge solutions and best-quality products.

| Position | Brand Name | Year Established | Location | Employee Size |

|---|---|---|---|---|

| 1 | Hongju Silicone | 1999 | Hongju | 50-100 |

| 2 | Sweebond | 2023 | Zhaoqing | 60 |

| 3 | Zhongde | 2014 | Beijing | 8 |

| 4 | Ruichen Seals | 2006 | Jiangxi | 300-340 |

| 5 | Hagoin Group | 1998 | Shandong | 46 |

| 6 | Jiang Yin (No. 3) Rubber | 2017 | Jiangsu | 74 |

| 7 | Milesun | 2002 | Milesun | 400-450 |

| 8 | Galaxy | 2020 | Jiangsu | 50-70 |

| 9 | Dongguan Bright | 2015 | Guangdong | 33 |

| 10 | JinSeal | 1997 | Cixi | 40-60 |

This table highlights the leading neoprene gasket manufacturers in China, evaluated on quality, price, product range, market share, estimated revenue, and customer service. Each entry is a concise snapshot of the company’s unique selling propositions, showcasing their standout contributions to the neoprene gasket sector. As you delve deeper, you’ll uncover a detailed exploration of these key industry players.

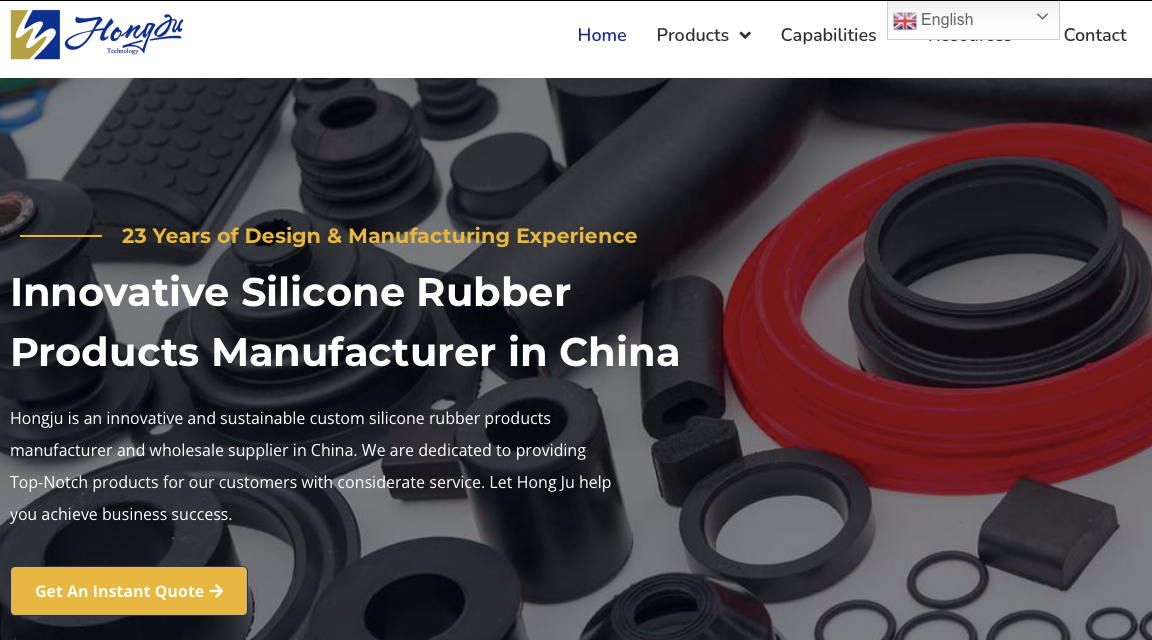

1. Hongju Silicone Co. Ltd.

Hongju Silicone, established in 1999, stands out for innovation and sustainability in the silicone industry. Recognized for its advanced equipment and commitment to quality, Hongju has become a leading producer of neoprene rubber, nitrile rubber, and various rubber products, serving many industries with a dedication that’s hard to match. The company’s best products, including neoprene gaskets, silicone O-rings, and other rubber molded products, speak to its versatility and capability.

Pros:

- Hongju Silicone provides low MOQ, catering to businesses of all sizes for quality products.

- Their prototyping services and expert craftsmanship manufacture products to specific customer needs.

- Hongju’s competitive prices and short lead times enhance its global market appeal, ensuring quality and efficiency.

Cons:

- The company’s vast custom solutions can be overwhelming for those seeking standard options.

- Emphasis on customization and advanced production may prolong design finalization.

- As a leading producer, high demand could extend lead times in peak periods.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

2. Guangdong Sweebond Sealing System Co., Ltd

Founded in 1999, Guangdong Sweebond Sealing System has established itself as a prominent name in the world rubber industry, particularly in the production of neoprene rubber and natural rubber gaskets. As one of the key companies in China, Sweebond has mastered its production processes such as rubber extrusion, and plastic extrusion, leveraging advanced equipment to deliver rubber products that serve various industries with a focus on quality and precision.

Sweebond’s growth trajectory suggests significant future development prospects, as they continue to adapt to the evolving market competitive situation, aiming to meet the unique needs of their diverse clientele.

Pros:

- Sweebond’s neoprene gaskets are highly sought after by customers around the world, thanks to their superior sealing properties, catering to the global market’s strict standards.

- With a strong foothold in market development, the company’s rubber products, especially the gaskets, are renowned for their durability and performance in the competitive landscape.

- They have fostered enduring partnerships with leading companies, gaining a huge market share as a leading producer of neoprene gaskets and other rubber products.

Cons:

- The company’s extensive range may not be appealing to clients looking for more specialized rubber products.

- As they cater to the global market, the total volume of orders can lead to longer lead times for new clients.

- The competitive price point may present a barrier to entry for smaller businesses seeking high-quality neoprene rubber solutions.

3. Zhongde (Beijing) Machinery Equipment Co., Ltd.

Zhongde (Beijing) Machinery Equipment founded in 1999, stands out as a high-technology enterprise in rubber and neoprene products. Their advanced production process, utilizing sophisticated equipment, positions them as a leading producer in the global market of rubber materials products, including neoprene gaskets, spiral wound gaskets, and various sealing solutions. The company produces multiple rubber products, such as rubber bumpers, vibration mounts, and sealing products, catering to various industries, demonstrating their versatility and adaptability.

Zhongde’s role in the industry is significant, as it contributes to estimating market sizes and shaping the market’s competitive situation. Their products are designed to meet the sealing and gasket needs of various industries.

Pros:

- Zhongde’s diverse product range addresses the unique needs of different global customers, highlighting their ability to innovate in the competitive landscape of rubber manufacturing.

- Their commitment to quality products is evident in their extensive testing and inspection measures. They ensure the high standards expected in various industries through both quantitative and qualitative analysis.

- The company’s ability to produce bespoke solutions enhances its market development prospects, as it continues to adapt to changing market sizes and demands.

Cons:

- While their diverse range is commendable, it may present a challenge in maintaining consistency across all product lines.

- Their focus on a broad market share could potentially dilute their specialization in specific product categories like neoprene rubber and oil seals.

- As a key player in a rapidly evolving market, keeping up with the latest development plans and trends could be demanding.

4. Shangrao Ruichen Sealing Co., Ltd.

Established in 2006, Ruichen Seals has solidified its reputation in the global market as a formidable player in the production of neoprene rubber gaskets and other sealing products. With its main base in China, the company has shown substantial growth over the forecast period, as evidenced by both qualitative and quantitative analysis. This growth reflects the company’s responsiveness to the current marketplace and its commitment to delivering comprehensive presentations of its main products.

Pros:

- The company’s latest development plan indicates a strong focus on expanding its range of gaskets and neoprene materials, highlighting its development potential.

- Ruichen’s production facilities, capable of manufacturing thousands of k units of gaskets, position it at the same level as other leading manufacturers in the main countries and regions, including the Middle East and beyond at a country and regional level.

- The company’s response to recent global events, such as the Russia-Ukraine war, showcases its adaptability and foresight in acquiring information and diversifying its materials portfolio.

Cons:

- JinSeal’s dedication to producing top-quality neoprene and Teflon gaskets presents a challenge in maintaining competitive prices globally.

- Their focus on diverse products, including gaskets for industries like food and services, necessitates ongoing innovation.

- Managing the high demand for their premier products while ensuring efficient production is crucial, particularly in the forecast period.

5. Qingdao Hagoin Rubber and Plastic Products Co., Ltd.

Founded in 1998, Qingdao Hagoin Rubber and Plastic Products has established itself as a significant manufacturer in China, producing high-quality rubber parts, plastic parts, and metal parts. It produces rubber products and components including the assembly of fluid transfer systems, industrial hoses, and seals. Serving various sectors such as automotive, aerospace, and agriculture, the company has made a mark among both domestic and international manufacturers, particularly in the USA and Europe.

Pros:

- Certifications like CE, RoHS, REACH, UL, FDA, and LFGB highlight Hagoin’s quality commitment.

- Their advanced facilities enable significant production, including millions of k units of gaskets.

- Hagoin’s global market experience and diverse product range cater to varied customer needs worldwide.

Cons:

- Maintaining consistent quality across their wide material range presents challenges.

- High demand for top-quality products, particularly gaskets, may result in longer lead times.

- Balancing innovation and cost-effective pricing is crucial as they expand in the global market.

6. Jiangyin No.3 Rubber Manufacturer Co., Ltd.

Jiangyin No.3 Rubber Manufacturer, a pioneering company in China’s rubber industry, specializes in producing high-quality oil seals and O-rings. They mainly focus on the production of silicone rubber seals. With 35 years of experience, the company stands as a notable rubber materials manufacturer, offering an impressive annual output of 20 million k units of seals and 50 million k units of O-rings, showcasing its significant production capacity.

Pros:

- Jiangyin No.3 Rubber’s location near Shanghai Port enhances its global market reach, especially in key areas like the Middle East.

- Their ISO9001: 2008 and RoHS certifications signify a commitment to delivering high-quality products, including neoprene gaskets.

- The company’s development potential is showcased through its comprehensive analysis of the current market and future trends.

Cons:

- Ensuring consistent quality across diverse materials like neoprene and Teflon demands strict control.

- Continuous innovation is essential to remain competitive with their extensive range, including gaskets.

- Adapting to events like the Russia-Ukraine war is challenging for maintaining market position and report objectives.

7. Guangzhou Milesun Rubber & Plastic Technology Co., Ltd.

Milesun Rubber and Plastic, established in 2002, is a prominent player in the rubber and metal gaskets industry. As part of the Milesun Group, this key company has carved out a significant place among other competitive manufacturers. Their extensive facility, staffed with over 400 professionals, is pivotal in manufacturing a diverse range of products, including oil seals and metal rubber gaskets.

Pros:

- Milesun’s wide product range, including oil seals and metal gaskets, serves all kinds of customers.

- Their significant market size and accurate market size estimation suggest growth in the forecast period.

- Advanced production highlights its role as a key industry company.

Cons:

- The diverse range of products might challenge those customers specifically looking for specialized oil seals or metal gaskets.

- In the rapidly evolving market competitive situation, keeping up with the latest trends and technologies could be demanding.

- Balancing the production of both oil seals and metal gaskets might require complex management, potentially impacting efficiency.

8. Changzhou Galaxy Rubber and Plastic Technology Co., Ltd.

Changzhou Galaxy Rubber and Plastic Technology, a dynamic company in China, is renowned for its specialized production of various foaming materials, including PE, EVA, CR, and EPDM. These materials are essential in creating neoprene gaskets, which the company produces in significant quantities, contributing notably to the rubber gaskets market. Constant development and research keep them in the top group of rubber gasket manufacturers.

Pros:

- With its advanced production capacity, Galaxy produces over 250,000 k units of foam materials annually, including neoprene rubber gaskets, addressing the needs at the country level and in international markets.

- The company’s competitive price strategy and efficient sales services have made it a favored choice in industries like packaging and fitness equipment.

- Galaxy’s commitment to innovation is evident in its recent developments in the production of neoprene and other products, enhancing its market position.

Cons:

- Specializing in a range of materials, including neoprene for gaskets, poses challenges in maintaining quality consistency across all products.

- Balancing the high production volume, with 36000 m³ of various sheet foam annually, requires continuous optimization of their production processes.

- As the company expands its market reach, adapting to different country-level regulations and market demands remains crucial.

9. Dongguan Bright Rubber and Plastic Products Co., Ltd.

Dongguan Bright Rubber and Plastic Products, a key company in China’s rubber products market, specializes in silicone rubber and neoprene, contributing significantly to the market share and sales of synthetic and natural rubber products, particularly gaskets. With 10 years of experience, they have become a prominent supplier in the industry, known for their quality production of gaskets in thousands of k units annually.

Pros:

- Their diverse material range, including neoprene, enables them to cater to a variety of market needs, solidifying their position as a key supplier of gaskets.

- The technical team’s proficiency ensures the production of high-quality gaskets, positively impacting their sales and market size.

- Their competitive price strategy enhances their reputation as a leading manufacturer of rubber products.

Cons:

- Managing a broad range of materials for gaskets, especially neoprene, requires stringent quality control to maintain consistent standards.

- As a prominent company in the market, innovating while keeping prices competitive poses a challenge.

- Adapting to recent developments in the market, particularly for food-grade and other specialized gaskets, demands ongoing innovation and adaptation.

10. JinSeal Sealing and Material

Founded in 1997 in Cixi, China, JinSeal has grown into a leading manufacturer in the sealing industry, specializing in a wide array of gaskets. Their commitment to quality has established them as a top manufacturer of gaskets and other products, catering to diverse markets including food and pharmaceuticals.

Pros:

- JinSeal’s extensive production capacity allows it to efficiently produce large quantities, thousands of k units, of gaskets, maintaining a competitive edge in both price and sales.

- Their ability to offer customized solutions for gaskets has expanded their client base globally, boosting sales in various industries.

- The company’s competitive pricing strategy for gaskets and other products secures its position among the top manufacturers in China.

Cons:

- Ensuring consistent quality across their broad range of gaskets and other products remains a significant challenge.

- Meeting the specific demands of various industries, including food and pharmaceuticals, requires ongoing innovation in gasket production.

- Balancing market demands with maintaining competitive prices for their range of gaskets and other products is an ongoing endeavor.

Final Thoughts

In your search for the right gasket manufacturer, consider the detailed table of key companies and their main products. It helps compare their manufacturing expertise and range of gaskets. Each listed company, producing k units across scales, impacts the market significantly. Evaluate their gaskets, price, and market influence to choose a manufacturer that meets your business needs in the competitive neoprene gasket market.

Why Choose Hongju for Your Neoprene Gaskets Need?

In China’s gasket market, Hongju is a key company known for its diverse, high-quality gaskets. Catering to multiple industries, our main products excel in quality and price.

We invite you to explore our website and discover why Hongju is the preferred choice for neoprene gaskets in numerous industries. Let us be your partner in success, providing gaskets that align with your project requirements. Choose Hongju, where quality meets innovation in the world of neoprene gasket manufacturing.