Do you have any experience of using liquid silicone rubber? The material is extensively used across industries like healthcare, automotive, and consumer goods. It’s non-reactive, flexible, and highly temperature-resistant. Still, most people question, “Is liquid silicone safe?” In this blog, we will debunk all misconceptions about the safety and toxicity of liquid silicone. Follow us!

What is LSR material? Explore Here!

It is an artificial material that occurs in liquid form at room temperature. It is heat-cured to solidify into a durable and flexible elastomer (rubber-like material). LSR material undergoes additive curing with platinum to achieve a liquid form. The gel consistency of LSR makes it injectable and easily moldable.

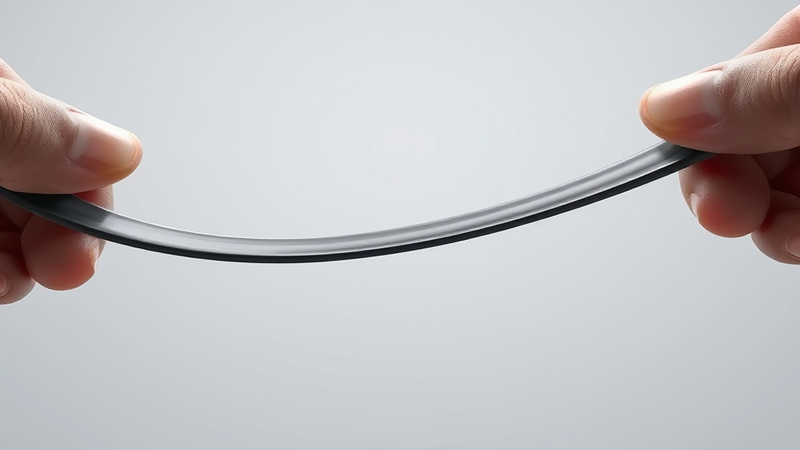

The material boasts unique properties like chemical inertness, resistivity to temperature changes, and water ingress. You will get exceptional elasticity and flexibility in liquid silicone rubber. The material is extensively used in consumer, healthcare, and industrial products. Its injection molding capability makes it highly usable and convenient to manufacture a variety of products.

LSR material is biocompatible and hypoallergenic. It is approved by various drug and food regulatory authorities, such as the FDA (U.S. Federal Drug and Food Administration), for use in medical applications and food products. Liquid silicone is found in implantable devices, food packaging, medical tubing, and other products.

Top 10 Myths About Liquid Silicone Rubber Debunked

Is liquid silicone toxic? If you have similar questions, we’ve got the answers. Let us clear your misconceptions and update your knowledge!

Safety and Toxicity

Liquid silicone is a safe and toxicity-free material. It is synthesized from silicon (commonly known as sand) without any addition of toxic additives or cross-linking agents. Here are the answers to all of your queries:

- Is Liquid Silicone Toxic?

Medical-grade silicone rubber is non-toxic and approved by the FDA (U.S. Federal Drug and Food Administration) for use in medical and food-related products. It is cured following an additive curing process with platinum salt, which eliminates the production of toxic byproducts. The material undergoes rigorous biocompatibility testing to be marked safe.

- Is Burning Silicone Toxic?

Burning silicone doesn’t produce any harmful gases except for some fumes of silicon dioxide. It’s a misconception that silicone combustion releases toxic chemicals.

The material is composed of silicon and breaks down into fine particle-size crystals of sand upon burning. Moreover, liquid silicone is also self-extinguishing and doesn’t pose severe fire hazards.

- Is Liquid Silicone Body Safe?

Liquid silicone is biocompatible and marked body-safe by the FDA. It is extensively used in surgical implants, prosthetics, and medical tubing. The material is tested under ISO standards like ISO 10993-5 (cytotoxicity), ISO 10993-10 (sensitization & irritation), ISO 10993-11 (systemic toxicity), etc., for skin safety and biocompatibility.

LSR Properties

Liquid silicone exhibits unique properties like high flexibility, elasticity, and durability. Some myths about liquid silicone say it turns too soft or too hard when cured. Let’s bust myths!

- Is Silicone Soft?

Silicone rubber is presumed to be a soft material, but that’s not really the case. It can be customized to have different levels of softness for required applications. The softness of a material is measured using a durometer on a Shore scale.

Liquid silicone can have Shore A 5 (soft like gel) to Shore A 80 (rigid but flexible) ratings. Optical silicone for lenses has Shore 70 hardness.

- Does Silicone Harden Over Time?

Liquid silicone rubber doesn’t degrade with time. It has high durability and can withstand rough and tough use. The material performs well against high temperatures, UV rays, and chemical exposure. To avoid hardening, you need to select a compatible liquid silicone material depending on operating conditions.

- Is Liquid Silicone Suitable for Skin?

Liquid silicone is hypoallergenic and skin-friendly. It is free from toxic compounds and doesn’t trigger allergic reactions. It is also chemically inert and doesn’t react to the environment or other chemicals. The smooth surface makes it more safe for the skin. It is ideal for products like menstrual cups, oxygen and CPAP masks, earbuds, bands, tubing, etc.

Environmental Impact

Unlike its counterparts, such as plastic, silicone has minimal environmental impact. For many people, “Is silicone natural?” feels like a mystery. Do you also think so? Let’s uncover the truth!

- Is Silicone Natural?

It is not natural but derived from silica (sand), a natural compound, through a synthetic process. The material is made of silicon, hydrogen, and oxygen atoms. It is a synthetic material produced artificially. The silicone we use is mixed with a variety of additives and chemicals, which gives it its unique properties.

- Is Silicone Biodegradable?

Most people confuse biocompatibility with biodegradability. Silicone is biocompatible, which means it doesn’t react with the human body or living organism; however, it’s not biodegradable. The material can’t be decomposed naturally by bacteria or other living organisms. However, silicone is recyclable in specialized facilities.

Applications

Do you believe our star is less effective than other materials? If yes, you’re under a false impression. The material is used in different industries ranging from aerospace to medical. Let’s explore:

- Can LSR Replace Other Materials?

The material is the best alternative to latex and PVC (Polyvinyl Chloride) for a variety of applications. Latex is known to cause allergic reactions, whereas LSR material is biocompatible and 100% skin-friendly. Similarly, PVC hardens when exposed to UV radiation, whereas LSR offers better weathering resistance.

- Is LSR Only for Medical Use?

Apart from the medical industry, liquid silicone has many other uses. The material has applications in diverse industries, such as automotive, consumer goods, and even aerospace. In the automotive sector, industrial-grade silicone is used to produce gaskets, coverings, hoses, etc. Commonly used consumer goods, from baby products like pacifiers to daily-use utensils are made from liquid silicone.

Uses of Liquid Silicone Rubber

Liquid silicone rubber is a high-utility material that has applications in diverse industries. The biocompatibility and hypoallergenic features allow it to be used in healthcare products like prosthetics, medical tubing, etc. It’s also considered a better alternative to latex due to skin-friendliness.

Also used in electronics as encapsulation and insulation for sensitive components.

Regulatory authorities like the FDA have approved liquid silicone for use in consumer goods. It is used to produce baby products, various parts of wearable devices, and kitchenware. The material’s ability to withstand rough operating conditions enables its use in automotive.

Your car’s gaskets and various other rubber seals are made of silicone. It is also used in vibration-dampening equipment.

Advantages of Liquid Silicone Rubber

No doubt, silicone rubber material is an advantageous material. Here’s what makes silicone rubber stand out:

Customization

You can use the material for injection molding, which helps unlock its true potential. The material can be molded into complex shapes with varying softness, and you can customize it according to your specific requirements.

Durability

Liquid silicone performs exceptionally well under rough operation conditions. It is resistant to UV light, heat, and chemicals. The material can withstand different temperature ranges and doesn’t degrade due to weathering effects.

Safety

The material is non-toxic, hypoallergenic, and biocompatible. It is FDA-approved and manufactured under ISO standards. The material has medical applications whereas food-grade silicone is used in packaging for food products.

Environmental Benefits

Liquid silicone rubber has a lesser environmental impact than plastics and other counterparts. The material is chemically stable and doesn’t react to the environment or form any harmful buy products. It is long-lasting and reduces waste.

Addressing Environmental Concerns

Liquid silicone rubber is a good alternative to plastics and other polymers when it comes to environmental concerns. The material is 100% recyclable and reusable, it can be incorporated in new silicone products. When recycled, the material doesn’t produce any harmful byproducts or toxins.

The material’s long-term usage also makes it more environmentally sustainable.

Here’s how silicone compares to other materials like plastics in terms of environmental footprint:

| Liquid Silicone Rubber | Plastic (PVC, PET, etc) |

|---|---|

| derived from naturally occurring compound silica (sand) | using petroleum byproducts that are harmful to the environment |

| long-lasting generates less waste than plastics and shows good heat resistance | Often single-use and generate a lot of waste, which is an environmental hazard |

| It doesn't degrade into microplastics that pose a danger to humans and the environment alike. | Degrades into microplastic and flows inside living organisms |

| non-toxic and biocompatible | toxic and releases toxic byproducts |

Choosing the Right Liquid Silicone Rubber for Your Project

Planning a market hunt for liquid silicone rubber? Be mindful of the following factors to get the right material as per your needs:

Certifications

If you’re going to use liquid silicone for medical or food products, you must ensure compliance to regulatory bodies. The material must be certified by the Federal Drug and Food Administration and it should be tested under various ISO standards.

Desired Properties

Since liquid silicone rubber is customizable, you can get the desired properties in the material. For instance, what level of softness on the shore scale will suit your needs? You can also change the flexibility of material with the addition of cross-linkers during production.

Application-specific Needs

Understand your operating conditions, especially the temperature and pressure levels the material will be exposed to. You can ask your manufacturer to produce a material that is compatible with the application-specific temperature and chemical resistance.

FAQs

Is Silicone Rubber Safe, and Can It Burn or Be Recycled?

Do you still have any questions remaining? Here are answers to repeated FAQs about liquid silicone:

Is silicone rubber safe for medical applications?

Liquid silicone is medically safe since the material is biocompatible and hypoallergenic. It is FDA-approved and undergoes rigorous testing to ensure biocompatibility.

What happens when silicone burns?

When silicone burns it generates non-toxic silicon dioxide and degrades into fine crystals of sand. The material loses elasticity and turns brittle.

Can liquid silicone be recycled?

Yes. Liquid silicone can be reused and recycled. Recycling silicone is different from other plastics and requires special equipment.

Conclusion

Is liquid silicone safe? Hope that we’ve answered it and all other misconceptions about the versatile material. If you want to use liquid silicone rubber for any application, it’s 100% safe with exceptional features like biocompatibility, hypoallergenic, and non-reactive nature. The material is extensively used in medical and industrial applications with remarkable performance.

Do you want medical-grade liquid silicone rubber? Hongju is a top manufacturer of medical-grade liquid silicone products approved by international regulatory bodies.

Hongju: Unlock Liquid Silicone Rubber’s True Potential

Do you want customized liquid silicone rubber solutions? Hongju has over 20 years of experience in manufacturing medical-grade silicone products. It boasts superior R&D and a state-of-the-art manufacturing facility. Get in touch with our representatives for a one-on-one meeting to find tailored solutions for your needs.