What is Liquid Silicone Rubber (LSR) Injection Molding?

Liquid Silicone Rubber (LSR) injection molding is a highly precise manufacturing process of producing parts from a two-component liquid silicone material. This process involves injecting the original material into a heated mold cavity, and then it undergoes a chemical reaction called vulcanization. Last, the material cures into a solid, elastic, and durable part.

LSR injection molding is now widely used to create a variety of products in the medical, automotive, consumer, and aerospace industries.

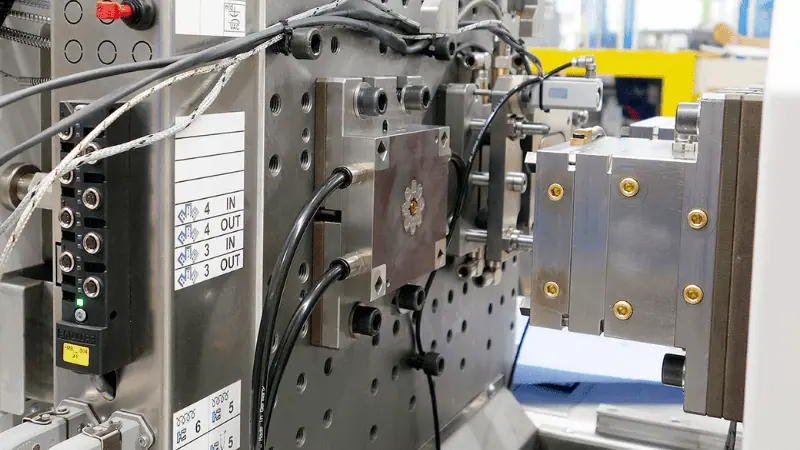

The characteristics of the LSR injection molding process are technical precision and efficiency. It is highly automated and ensures the consistent production of high-quality parts with complex geometries. The process’s speed and reliability make it an ideal choice for mass-producing parts that meet strict quality control standards.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

What are the Benefits of Using Liquid Silicone Rubber?

LSR is a thermosetting elastomer known for its exceptional properties. Its elasticity is high, with commercial grades exhibiting up to 1200% elongation at break. Besides, LSR has good biocompatibility, making it safe for skin contact, hypoallergenic, and implantable applications.

The following are the main benefits of liquid silicone rubber.

Versatility:

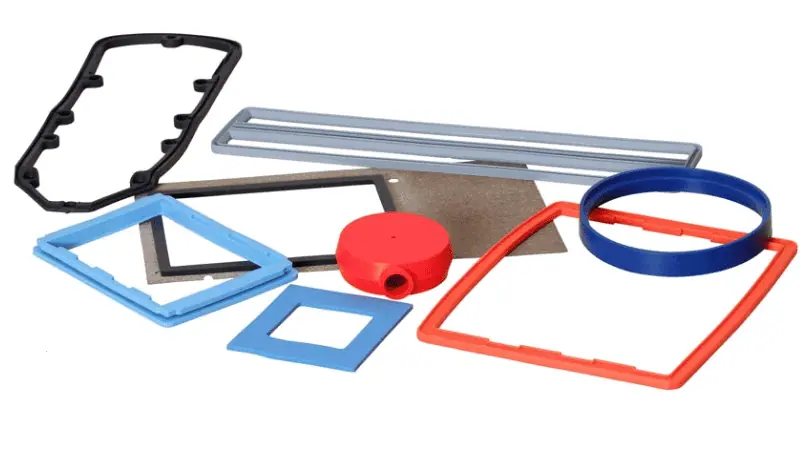

Liquid silicone rubber is a favorite for automotive tools, medical equipment, electrical materials, kitchen, and other household tools. LSR can be molded into a single or dual-sided injection. LSR mold cavities can be used to create a wide range of products, from regular parts like gaskets to complex instruments.

Temperature resistance:

LSR has outstanding temperature resistance. It doesn’t lose shape when subjected to high temperatures and can withstand extreme cold. LSR can remain flexible even at temperatures below -40°C and stable at temperatures up to 200°C. This is why it is now embraced for various consumer products like ice trays, complex industrial tools, muffin trays, etc.

Hygiene:

Liquid silicone rubber is now used for many kitchen utensils. The non-porous nature of this rubber makes it a favorable choice. The use of LSR in the kitchen removes the burden of bacteria pile-ups, hence its usefulness in beverage and food storage. Silicone is non-toxic and water-resistant. It can be recycled at designated plants.

Moisture resistance:

LSR molds can be thrown into boiling or warm water without fearing negative impacts. It can also resist oils and other chemicals without dissolving or losing shape with time. These are some of the reasons that make it desirable for tubings, medical applications, and other equipment that need regular steaming or chemical sterilization.

Low compression set:

This means that it is opposed to complete deformation when subjected to consistent strain. The compression set of LSR molds ranges from 15% to 20%. They retain their shape and flexibility even when suppressed for a long time and subjected to temperatures.

Electrical insulators:

Liquid silicone rubber is also more desirable because it resists corona discharge, hence a perfect insulator. However, it isn’t out of place for LSR to have conductive properties, which makes it great for keyboards and other electronic components.

Flexibility:

LSR can be molded into nearly any desired shape, making it a versatile material for complex designs. Its exceptional flexibility means that a finished part can be stretched, compressed, or bent and will always return to its original form without damage.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

How Does Liquid Silicone Rubber Molding Work?

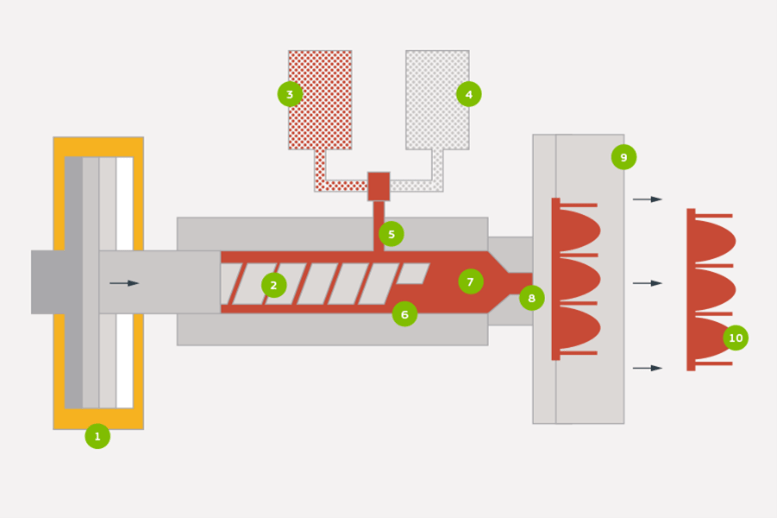

LSR injection molding is a highly precise and efficient process that transforms a liquid, two-part silicone into a solid, finished product. Unlike thermoplastic molding, where material is heated and then cooled to set, LSR molding operates on a unique principle of “cold-to-hot”.

The process begins with two separate components of liquid silicone rubber, typically labeled Part A (polymer) and Part B (catalyst), stored in sealed drums. They are kept separate and cool to prevent premature vulcanization.

A metering unit accurately pumps both parts in a precise 1:1 ratio into a static mixer. Then, they are blended thoroughly with any added color pigments. After mixing, the mixed liquid is injected into the cold runner system of the mold to ensure the silicone rubber remains in its liquid state until it reaches the mold cavity.

The change happens when the liquid silicone enters the heated mold cavity. The heat, ranging from 170°C to 200°C, triggers a chemical reaction known as platinum-catalyzed vulcanization. This process rapidly cross-links the polymer chains, making the material solidify and take the shape of the mold within seconds.

Once fully cured, the solid, elastic part will be ejected. The cross-linked structure is permanent, making the final result impossible to remelt or reshape.

This gives LSR the outstanding durability, elasticity, and resistance to extreme temperatures. For these advantages, it is ideal for demanding applications in the medical, automotive, and consumer goods industries.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

LSR Molding Design Considerations

Creating a suitable mold is one of the most important factors to consider if you must get the most accurate LSR product of high quality. To meet production standards, here are some of the things you must consider:

Function:

What will the mold or part be used for? This is the first consideration of the design process. Are you designing a medical device that’ll be inserted into the body for many years? Is it a button on a device, an automobile, or a knob part? Will it be used in a disposable material or a high-endurance tool?

The purpose of the design determines the level of exposure it will face, which affects its material selection, shape, and other aspects. This requires a thorough assessment of the requirements of the product and the production process at the very beginning of the development process.

It’s crucial to have a clear picture of the design’s purpose and its intended use to ensure its optimum performance and quality.

Size:

The manufacturing process of liquid silicone rubber parts is also influenced by the size of the part and the production volume of the LSR molding process. Mass production needs more time to cure silicone instead of smaller productions.

The size of the mold design also determines the ejection and manufacturing process. Fragile parts, for instance, may end up with dents and disfigured surfaces during the production process. You may then decide to use finishes to guard against this.

Sterilization Requirements:

Will the part require sterilization? Liquid silicone rubber molds that will be sterilized with steam will require high resistance to hydrolysis and heat.

What’s more, Gamma, e-beam, and UV sterilization demand that you use other materials. Note that only a few materials for parts need sterilization with different methods during use.

Shot Size and Multi-Shot Molding:

In LSR injection molding, shot size is an important factor. Some manufacturers set a minimum of 10 cubic centimeters. However, advanced mold construction techniques can allow for processes such as LSR Multi-Shot Injection and 2-Shot molding, which are key to creating complex parts.

Multi-shot injection molding is a process where LSR is molded directly onto a thermoplastic substrate. This procedure happens in a single molding machine, with the LSR being injected onto the pre-formed plastic part within the same mold.

This technique offers apparent advantages. It makes the permanent combination of different materials possible, creating a single component without additional assembly. This not only enhances the final product’s functionality but also improves its cosmetic appearance, saving overall costs.

Take the First Step:

Requst for an Inquire

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

In conclusion, LSR injection molding has revolutionized manufacturing with exceptional properties. LSR’s durability, chemical resistance, and long-lasting performance can prolong the lifespan of critical products, making it a worthwhile choice to enhance quality and safety.

As a result, LSR injection molding is a worthwhile investment to improve product quality without compromising cost efficiency.

Precision LSR Solutions– Trust Hongju’s Expertise!

Unlock the full potential of LSR with Hongju Silicone’s end-to-end LSR injection molding services. From medical-grade products to complex automotive components, we deliver superior products for high-volume production.

We also offer a wide range of trustworthy OEM and ODM services. Our team will guide you from design to mass production with fast prototyping, strict compliance, and cost-efficient tooling.

Request a free design review and quote now! Transform your vision into a high-performance reality!