Gum rubber and chewing gum seem like the same product, but they cannot be far apart from one another. Despite having a similar elastic, stretchy nature, their applications, characteristics, and sources are very different. Let’s examine the main differences between the two materials, from their sources and characteristics to their applications.

What is Chewing Gum?

Chewing gum is a mindless habit that has been around for thousands of years dating back to ancient civilizations including the Mayans and Aztecs. In the past, natural plant-based gums, such as Chicle gum and Jeltong-Pontianak alone or in combination, were used as chewing gums.

European settlers in America learned about chewing gum from Native Americans and started selling it commercially in the 1600s. The first gum to ever be sold commercially in America was the main pure spruce gum.

Modern chewing gum is generally created by mixing elastomers with plasticizers. The elastomers create elasticity and support the gummy texture, while plasticizers provide cohesiveness and chewability to the gum.

What is Gum Rubber?

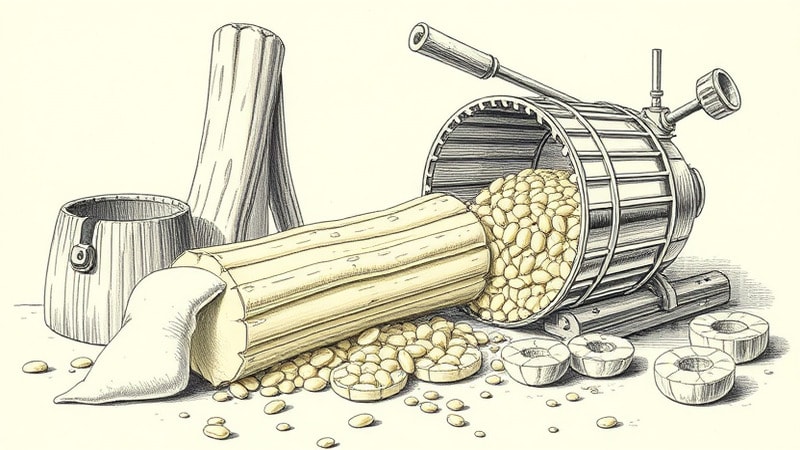

Natural rubber is made by harvesting latex from trees using a technique known as tapping. Tapping is the procedure of making incisions in the trunk of a rubber tree to allow latex material to drain into collection containers. It is then processed to yield the material known as natural gum rubber.

More than 200 plants around the globe produce latex; however, the majority of natural rubber goods are created from latex from Hevea brasiliensis. This makes natural gum rubber an ideal material for eco-conscious consumers.

Gum rubber is a natural product that has been utilized for thousands of years, beginning with ancient Mesoamerican tribes who used it to make a range of tools. On the other hand, synthetic rubber is chemically produced by the gum industry. It is still an essential component of many modern organizations that require flexibility and endurance.

Unlike synthetic rubbers like Neoprene and Nitrile, gum rubber is biodegradable because of its natural origin. The original latex properties also add to the biodegradability of gum rubber as it is subjected to minimal processing.

The primary component of gum rubber is polyisoprene, a polymer made up of repeating isoprene units (C5H8). The polymerization process brings together isoprene molecules to form long, elastic chains. The majority of natural rubber is elastic due to its cis structure.

Properties of Gum Rubber

Gum rubber is also known as natural rubber as it is harvested from trees. Even though it is a natural product, it shows exceptional resemblance to synthetic rubber. Here are some of the properties of gum rubber:

- Elasticity: It is renowned for its exceptional elasticity, allowing it to stretch significantly and return to its original shape, making it ideal for applications requiring flexibility.

- Durability: Gum rubber is highly durable as it exhibits high tensile strength and superior resistance to tearing and abrasion.

- Non-Marking: Leaves no marks or scuffs on surfaces, making it popular in flooring and footwear.

- Temperature Sensitivity: Gum rubber is highly temperature sensitive and performs best at moderate temperatures and may degrade in extreme heat or cold.

The Difference Between Gum Rubber and Chewing Gum

Gum rubber and chewing gum, or bubble gum, are inherently different things, downright from their source to use. Here is a simple table defining the key differences between the two.

| Feature | Gum Rubber | Chewing Gum |

|---|---|---|

| Source | derived from rubber tree (Hevea brasiliensis) latex sap | Made from natural or synthetic gum bases, softeners, flavors, and sweeteners are frequently added |

| Main component | A naturally occurring polymer called polyisoprene | Gum base, which frequently consists of waxes, resins, and elastomers |

| Production process | It is vulcanized (heated with sulfur) after being harvested from rubber trees to increase its strength and suppleness. | It is combined with sugar, flavorings, sweeteners, and softeners, then processed and formed into pellets or sticks. |

| Industrial applications | It is utilized in industrial rubber goods, seals, gaskets, tires, shoes, and more. | It is also utilized in several dental and medical applications (e.g., nicotine gum) in addition to recreational use. |

| Properties | Extremely supple, resilient, weatherproof, and abrasion-resistant. | Flexible and chewy, yet meant for occasional usage, they are typically not as long-lasting. |

| Main use | Commercial and industrial goods that need to be strong, flexible, and long-lasting. | Individual use for enjoyment, flavor, and stress reduction |

Why the confusion?

Chewing gum and gum rubber are sometimes confused since the term “gum” is used to refer to both products. Initially, both the products were made from chicle gum, but modern practices have replaced the natural latex in both products, hence a similarity in the name and basis for confusion.

Characteristics of Chewing Gum

Chewing gum was designed to provide a long-lasting chewing experience without breakdown. Its remarkable flexibility helps in stretching and rebounding, making it ideal for activities such as bubble blowing. The texture of chewing gum is soft and silky before gradually firming when sugars or artificial sweeteners dissolve and only the gum foundation remains.

One of the most important characteristics of chewing gum is the slow release of taste. As you chew the gum, flavors break down and are released, resulting in a powerful taste that fades with time. Now even sugar-free chewing gums are available to be enjoyed by people who do not want to consume sugar.

How Chewing Gum is Made

Making chewing gum requires a simple yet precise set of steps. The gum base is a combination of resin, wax, and elastomers. While originally derived from natural materials such as chicle, modern manufacturing frequently uses synthetic gum bases to ensure consistent quality. The gum foundation offers the flexibility and chewability that distinguish chewing gum from gum rubber.

After the gum base is created, natural or artificial flavors, sweeteners (such as sugar or sugar replacements), and emulsifiers are added to improve flavor and texture. The mixture is heated and kneaded until it has a consistent texture. The dough-like material is subsequently pressed into sheets or blocks, which are chilled.

Depending on the product, it can go through either hard or powdered coating to extend its shelf life and give an appealing texture. Last they are packed in little plastic bags for protection.

Nowadays specialty chewing gums are being created with natural components such as chicle or birch bark tar. These gums use traditional formulas to appeal to customers looking for a nostalgic or environmentally friendly option. These items demonstrate the diversity of chewing gum manufacturing by combining modern technology with traditional processes.

How is Gum Rubber Made?

The process of making gum rubber begins with the extraction of latex from rubber trees. This is done through a method known as tapping, which involves making shallow incisions in the tree bark to collect milky latex sap.

Once collected, the latex is coagulated, which involves adding acids such as formic acid to separate the rubber particles from the liquid. The coagulated rubber is then cleaned, dried, and rolled into sheets, producing gum rubber.

The resulting gum rubber sheets have remarkable elasticity, durability, and non-marking qualities, making them suitable for a wide range of applications, including industrial seals, footwear, and flooring.

Unlike synthetic rubbers, gum rubber is valued for being a renewable and environmentally beneficial material. Its production is based on ecologically friendly forestry processes, which ensure the trees are not injured during latex harvesting. This sustainability element makes gum rubber a popular choice for industries looking for environmentally friendly products.

Uses and Applications of Gum Rubber

Gum rubber is one of the most versatile natural materials, making it extremely useful in a variety of industries. Its high elasticity and durability are critical in the production of flexible and wear-resistant items such as tires, belts, and hoses. Furthermore, gum rubber’s non-marking qualities make it an ideal material for flooring and footwear manufacturing.

The adhesive and sealant industries both rely heavily on gum rubber. Its unique ability to connect surfaces and form a tight seal makes it useful in industrial and commercial environments. Furthermore, gum rubber is used to create coatings that improve the durability and attractiveness of a wide range of products.

Interestingly, gum rubber is also the foundational ingredient for synthetic rubbers like nitrile rubber and styrene-butadiene rubber (SBR). These derivatives are critical in automotive, medical, and industrial uses, proving gum rubber’s importance in both natural and synthetic forms.

Here is a list of products and industries that use gum rubber:

1. Tires: Because of its great flexibility, resilience, and capacity to tolerate wear and strain, gum rubber is frequently utilized in the manufacture of automobile tires.

2. Footwear: It is utilized in the soles of shoes and boots, offering comfort, flexibility, and durability, particularly in work boots and athletic shoes.

3. Gaskets and Seals: Gum rubber is used to make gaskets and seals for industrial equipment, which help to keep things airtight or watertight and stop leaks.

4. Rubber Bands: Rubber bands, which are utilized in homes, workplaces, and industrial settings, are made from gum rubber because of their stretchability.

5. Hoses: Due to its strength, flexibility, and wear resistance, gum rubber is used to make hoses for a variety of industries, including agricultural and automotive industries.

Is Gum Rubber Related to Chewing Gum?

Despite having the word “gum” in their names, gum rubber and chewing gum are two completely different materials. Gum rubber is a natural product made from the latex sap of rubber plants and is mostly utilized in industrial applications.

Modern chewing gum, on the other hand, is made from synthetic polymers that have the elasticity of natural rubber but are specifically engineered for human consumption.

The early forms of rubber were made from chicle, which is similar to latex thus breeding the misconception between the two products. This historical overlap between the two materials explains why they are sometimes mistakenly linked.

Advantages and Disadvantages of Gum Rubber

Gum rubber is a standout material with versatile material properties, making it suitable for a variety of applications. However, like any material, it has its strengths and limitations. Let’s break down the advantages and drawbacks of gum rubber to gain a deeper insight.

Advantages of Gum Rubber

Gum rubber is highly resilient in conditions requiring elasticity. Its natural flexibility allows it to stretch and recover without permanent deformation, making it ideal for applications like seals, gaskets, and shock absorbers.

As a natural material derived from rubber trees, gum rubber has a lower environmental impact compared to synthetic alternatives. Its biodegradability further adds to its eco-friendly nature. Moreover, it does not leave any scuffs due to its non-marking properties making it perfect for surface-sensitive products.

Disadvantages of Gum Rubber

Chemical sensitivity is one of the major drawbacks of gum rubber. It is prone to degradation when exposed to oils, solvents, and harsh chemicals, limiting its use in certain environments. Moreover, it is extremely vulnerable to extreme temperatures.

A variation in temperature to either end can seriously affect its performance, leading to potential cracking or loss of elasticity. Due to its natural sourcing and processing, gum rubber is often more expensive than synthetic rubber options.

Gum Rubber vs. Synthetic Rubbers

While gum rubber is the base material of synthetic rubber, the functionality of the two materials varies greatly. Understanding their differences helps in selecting the right material for your project.

Key Differences

The main difference is the composition. Gum rubber is a natural material sourced from the latex of rubber trees. Whereas synthetic rubbers are man-made using petroleum-derived polymers. While some synthetic rubbers use gum rubber as a base, the addition of polymers makes them synthetic in nature.

The second difference is in durability. While gum rubber is softer and offers excellent flexibility, synthetic rubbers like nitrile or EPDM are more resistant to chemicals, oils, and extreme temperatures.

Lastly, gum rubber is a cost-intensive product as it is natural and requires a very time-consuming farming process. On the other hand, the mass-produced synthetic rubber alternatives are considerably cheaper and readily available.

When to Choose Gum Rubber

Gum rubber is perfect for applications that require great elasticity, non-marking features, and environmentally friendly solutions. A few examples of gum rubber include vibration-dampening pads, non-slip mats, and sensitive surface gaskets.

Synthetic rubbers, on the other hand, should be used in situations where strong chemicals, oils, or extreme temperatures are present since they offer greater resistance to wear and tear.

Frequently Asked Questions (FAQs)

Q. Can Gum Rubber Be Chewed Like Chewing Gum?

A. No, gum rubber cannot be chewed like chewing gum or bubble gum. Even though it contains the common name gum resembling the popular product chewing gum, the gum rubber is not chewable at all. It is non-edible and used for industrial applications only.

Q. Is Chewing Gum Made from Gum Rubber?

A. No, modern chewing gums use a synthetic base with flavorings to create the standard chewing gum. However, historically chicle gum, used for gum rubber, was used as a chewing gum substitute due to its elastic properties and natural origin.

Q. What Makes Gum Rubber Unique Compared to Other Materials?

A. Gum rubber is unique because of its elasticity, resilience, and flexibility, which allow it to stretch and restore its original shape without breaking. It is ideal for heavy-duty applications such as tires and seals because, unlike many other materials, it is abrasion-resistant.

Furthermore, because gum rubber is derived from natural latex, it is more environmentally friendly than synthetic alternatives.

Q. Is gum rubber biodegradable?

Because gum rubber is composed of natural latex, which decomposes over time in the presence of environmental factors, it is biodegradable. However, if the rubber is treated or vulcanized, it becomes more durable but less biodegradable in the short term, and the decomposition process may be delayed.

Conclusion

Gum rubber stands out as a naturally occurring material with remarkable flexibility, elasticity, and non-marking characteristics. Its eco-friendly and biodegradable qualities make it an excellent alternative for industries that value sustainability.

While it may have limits in severe environments, its benefits in applications demanding precision and softness far outweigh its disadvantages. Businesses can make more efficient and effective decisions if they grasp the differences between gum rubber and other materials.

Ready to discover the perfect gum rubber solution for your operations?

At Hongju Technology, we specialize in delivering premium gum rubber products tailored to diverse industrial needs. With years of expertise and a commitment to quality, we ensure our solutions meet the highest standards.

Explore our product range to find what suits your needs or contact our team today for personalized guidance.