EMI O-rings, a specialized sealing solution, have emerged as a guardian against these electromagnetic nuisances. By ensuring a firm seal and guarding against electromagnetic disturbances, they play a pivotal role in maintaining the performance integrity of countless devices. In this article, we will delve deep into understanding what EMI O-rings are and their indispensable role in the electronic landscape.

What are EMI O-rings?

In the ever-evolving world of electronics and technology, safeguarding devices from external interference is paramount. Among the key players in this protection arsenal are the EMI O-rings. But before diving deep into their unique role, let’s first understand the root of the issue they address: Electromagnetic interference.

Understanding EMI

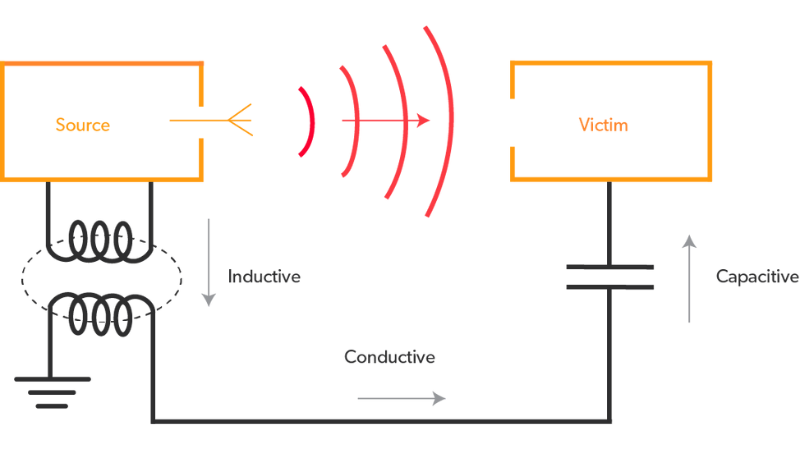

Electromagnetic interference, commonly referred to as EMI, also called radio-frequency interference (RFI) when in the radio frequency spectrum, is an unwanted disturbance generated by external sources that affect an electrical circuit through electromagnetic radiation or conduction. These disturbances can originate from various sources, both man-made, like radio transmitters and cell phones, and natural occurrences like solar flares.

EMI can disrupt the normal functioning of electronic devices. For instance, when you’ve heard static on a radio or seen distorted images on a TV screen, it’s often EMI at work. In more critical applications, such as in aviation or medical equipment, the consequences of EMI can be disastrous, leading to miscommunications, device malfunctions, or critical system failures.

Enter EMI O-Rings

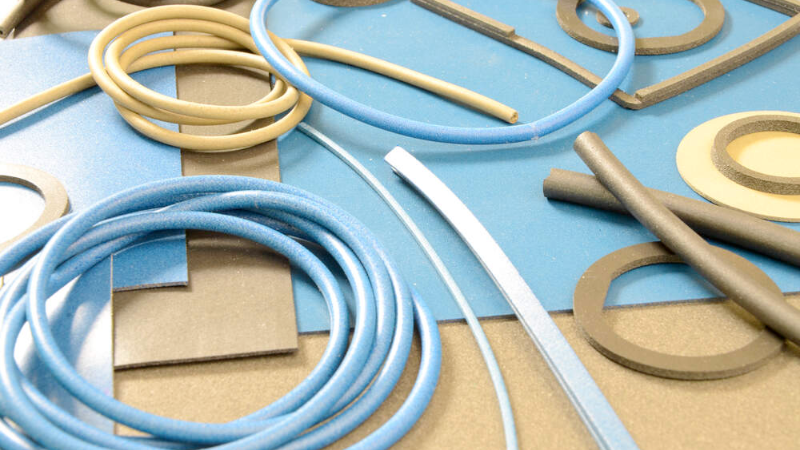

To counter these challenges, the industry has introduced the EMI/RFI O-ring. These are not just typical O-rings; they are crafted using conductive materials, usually infused with metal or conductive fillers, allowing them to serve a dual purpose.

- Sealing: Just like any other O-ring, they prevent the passage of liquids or gases in applications where they’re used.

- Shielding: More uniquely, EMI O-rings offer protection against electromagnetic disturbances. They provide a conductive path that channels the electromagnetic waves away from the sensitive parts of the device, ensuring that the internal electronics remain unaffected by external interferences.

In essence, the EMI O-ring acts as a gatekeeper, ensuring that while unwanted particles, liquids, or gases remain out, so do undesirable electromagnetic waves.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

EMI O-rings Applications

The diverse range of EMI O-rings applications is a testament to their versatility and effectiveness. From critical military communications to everyday consumer electronics, the need for EMI shielding remains paramount. Here’s a closer look at some areas where EMI O-rings play an indispensable role:

- Military and Aerospace Equipment: With devices that often operate in extreme conditions and require precision, the military uses EMI shielding O-rings to ensure the protection of communication devices, navigation systems, and radars. As mentioned, O-rings with the MIL DTL 83528 part specification are frequently employed in this sector.

- Medical Devices: Electromagnetic interference can compromise the function of life-saving medical equipment. Devices like MRI machines, patient monitors, and even some surgical instruments utilize EMI shielding o rings to prevent unwanted disruptions.

- Consumer Electronics: From smartphones to gaming consoles, most modern electronics incorporate Wi-Fi, Bluetooth, or other wireless technologies. To prevent these signals from interfering with one another or external devices, electrically conductive O-rings are often employed.

- Industrial Machines: Factories and industrial setups with multiple machines operating simultaneously can become hotspots for electromagnetic interference. Machines with sensitive electronic components often use EMI O-rings, especially those with dimension A inch or dimension B metric specifications, to ensure smooth operation.

- Automotive Systems: Modern cars are more like computers on wheels. With a myriad of sensors, GPS, infotainment, and safety systems, there’s a need for effective EMI solutions. Nickel graphite in fluorosilicone O-rings often finds applications here due to their dual benefits of conductivity and durability.

In all these applications, it’s crucial to pick the right size ring and seal supplies to specification, often dictated by dimension A metric or dimension B inch values, ensuring that the seal is both effective and durable. As technology continues to advance, the need for robust EMI solutions, like EMI O-rings, will only grow, making them a staple in various industries.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Exploring different types of EMI-shielded O-rings

In the vast world of electromagnetic interference (EMI) shielding solutions, EMI-shielded O-rings occupy a unique niche. They combine the sealing properties of traditional O-rings with the protective capabilities required to prevent EMI and RFI disturbances. To cater to a wide range of applications, various types of EMI-shielded O-rings have been developed. Let’s delve into some of the most popular types:

- Nickel Graphite in Fluorosilicone O-rings: Known for their optimal shielding performance, these O-rings combine the elasticity of fluorosilicone with the conductive properties of nickel graphite. They’re especially useful in environments that demand both fluid resistance and EMI shielding, such as aerospace or automotive systems.

- Conductive Elastomers: These are made by combining conductive fillers like silver, copper, or aluminum with elastomeric compounds. Conductive O-rings created this way offer excellent EMI shielding while maintaining the elasticity of the base elastomer.

- Silver-aluminum-filled O-rings: Ideal for high-frequency applications, these O-rings combine the conductivity of silver with the lightweight properties of aluminum. They are often used in aerospace and satellite communication systems.

- Custom EMI O-rings: For unique applications, custom EMI O-rings are developed to meet specific requirements. They can be designed to have a specific DTL 83528 part number or be made from unique materials, offering tailored solutions for complex problems.

The choice between these types depends largely on the specific application and the environment in which the O-ring will function. Factors like temperature resistance, fluid exposure, and the exact frequency range of interference play a role in determining the best fit.

Choosing the right EMI-shielded O-ring material for your application

Several factors need to be taken into consideration. These factors include the operating environment, temperature range, chemical compatibility, and required shielding effectiveness. By carefully evaluating these aspects and conducting thorough testing, you can ensure that the chosen O-ring material meets all desired specifications and performance requirements.

Operating Environment

The first step in choosing the right EMI-shielded O-ring material is to assess the operating environment. Consider factors such as exposure to extreme temperatures, harsh chemicals, or water, ozone, and UV light. Different materials exhibit varying levels of resistance to environmental stressors. For instance, silicone-based materials are known for their excellent resistance to extreme temperatures and environmental sealing properties.

Temperature Range

Another crucial aspect is determining the temperature range that your O-rings will be exposed to during operation. Certain materials perform better at low temperatures while others excel in high-temperature environments. Fluorosilicone rubber offers a wide temperature range capability, making it suitable for applications that experience both extremes.

Chemical Compatibility

Chemical compatibility plays a vital role in ensuring the longevity of EMI-shielded O-rings. It is essential to verify whether the selected material can withstand exposure to specific chemicals or solvents commonly encountered in your application. Viton® fluoroelastomer exhibits exceptional chemical resistance and is often preferred in industries where contact with aggressive fluids is expected.

Shielding Effectiveness

The primary purpose of EMI-shielded O-rings seals is to provide good shielding against electromagnetic interference (EMI). Evaluate the required level of shielding effectiveness based on your application’s needs. Materials such as conductive elastomers offer high shielding effectiveness due to their inherent electrical conductivity.

To aid you in making an informed decision about which material suits your requirements best, consider consulting experts or manufacturers who specialize in EMI-shielded O-ring materials. Their expertise can guide you toward the most appropriate material choice, ensuring optimal performance and long-term reliability.

Inquire About Our Silicone and Plastic Products!

Tips for Maintaining Your EMI O-ring

Regularly inspecting your EMI O-rings is crucial to ensure their optimal performance in shielding against electromagnetic interference. These small but essential components play a vital role in maintaining the integrity of electronic devices and systems. By following these tips, you can extend the lifespan of your EMI O-rings and preserve their shielding effectiveness.

1. Inspect for Wear, Damage, or Degradation

Frequently check your EMI O-rings for any signs of wear, damage, or degradation that could compromise their shielding effectiveness. Over time, exposure to environmental factors or mechanical stress can cause the O-rings to deteriorate. Look out for cracks, tears, or deformities that may indicate the need for replacement. Pay attention to any changes in conductivity or sealing properties that could impact their overall performance.

2. Follow Manufacturer Guidelines for Storage

To prevent premature aging or deterioration of your EMI O-rings’ conductive properties during storage periods, it is essential to adhere to manufacturer guidelines. Different materials used in manufacturing EMI O-rings may have specific storage requirements due to their composition and sensitivity to certain conditions. For instance, some materials may require temperature-controlled environments while others may necessitate protection from direct sunlight or humidity.

3. Promptly Replace Worn-Out or Damaged O-rings

When you notice signs of wear and tear on your EMI O-rings during inspections, it is crucial to replace them promptly. Delaying the replacement can lead to compromised shielding effectiveness, potentially resulting in electromagnetic interference issues. Keep a stock of spare EMI O-rings on hand to ensure immediate replacement when needed. Promptly addressing any damage or degradation will help maintain reliable electromagnetic interference protection for your electronic devices and systems.

By regularly inspecting your EMI O-rings, cleaning installation surfaces, following manufacturer guidelines for storage, and promptly replacing worn-out or damaged O-rings, you can ensure the longevity and effectiveness of these essential components. Taking proactive steps to maintain your EMI O-rings will contribute to the overall performance and reliability of your electronic devices while minimizing the risk of electromagnetic interference.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.

Conclusion

In today’s technologically driven world, where electromagnetic interference can pose significant challenges, EMI O-rings stand as an invaluable solution. Crafted with precision, these specialized O-rings not only provide the traditional sealing function but also safeguard sensitive electronic equipment from potential disruptions.

Choose Hongju: Your Trusted Source for Premium EMI O-rings!

Discover the Hongju difference when it comes to EMI shielded o-rings gaskets. Our commitment to quality, precision, and customer satisfaction ensures you’re equipped with the best shielding solutions on the market. Reach out to our experts today to find the perfect o-rings and gaskets for your unique application needs.