The terms “elastomers” and “rubber” are often used interchangeably; however, it is essential to note that these terms are not synonymous. This article explains what elastomeric rubber is and how it differs from other types of rubber. Read it till the end to make the right choice while choosing rubber for your industrial applications:

What Is Elastomeric Rubber?

Elastomeric rubbers are highly flexible materials with excellent elasticity and strength. Owing to their high resilience, elastomeric rubbers are widely used in seals and gaskets.

The word “elastomeric” is derived from the combination of “elastic” and “polymer.” This explains that elastomers are a plastic-like substance with rubber-like flexibility.

When considering elastomeric rubber, it is essential to note that “elastomers” and “rubbers” are not interchangeable terms. It can be said that all rubbers are elastomers, but not all elastomers qualify as rubbers.

Elastomers include all polymers that return to their original shape after being stretched. Whereas, elastomeric rubber refers to rubber materials that have these elastic properties.

What Are Elastomers?

One cannot understand what elastomeric rubber is without understanding what elastomers are. An easy way to define elastomers is that they are long-chain polymers that can return to their original shape after being stretched.

The molecular structure of elastomers consists of flexible chains cross-linked at regular intervals. This unique structure gives elastomers flexibility and strength.

The key traits processed by elastomers include high elasticity, resilience, and flexibility. Having high elasticity, elastomers can stretch without breaking.

Resilience refers to a material’s ability to absorb and release energy quickly and efficiently. Having high resilience, elastomers can bend, twist, stretch, and return to their original shape. The key traits of elastomers make them ideal for use in nearly all industrial applications.

People of the Amazon first used elastomers for waterproofing and footwear. In the 1730s, the first rubber sample was brought to Europe. Later, Charles Goodyear discovered that heating rubber with sulphur makes it fit for use in industries.

In the 20th century, neoprene, the first synthetic rubber, was formed. After it, synthetic elastomers like EPDM and silicone became popular.

Elastomer vs. Rubber vs. Plastic: What’s the Difference?

Elastomers, rubbers, and plastics are polymers, but all have distinct characteristics. Polymers are composed of long chains of molecules formed by the frequent bonding of smaller molecules called monomers.

Elastomers are highly flexible materials that can be extended and revert to their original shape easily. Elastomers are either natural or synthetic materials and are used in flexible seals, gaskets, and tubes.

To answer the most commonly asked question of what rubbers are, we can say that rubbers are a type of elastomer. Rubber offers high elasticity and is best suited for use in gloves, tires, and industrial parts.

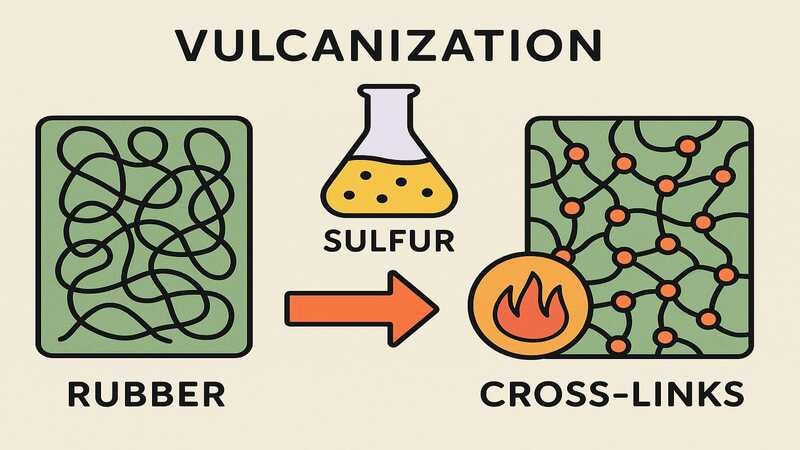

Rubber’s strength is improved, and it is made durable and weather-resistant through a process called vulcanization. In vulcanisation, the rubber is heated with sulfur; the heating process forms cross-links between polymer chains, which increases the durability of the rubber.

Many people wonder, is rubber plastic? Well, the answer to this question is no. Both plastic and rubber are polymers, but they are distinct from each other. Plastic is not very flexible and cannot return to its original shape.

Plastic is used where strength is more important than flexibility. Containers and other packaging parts are often made from plastic.

In short, we can say that all rubbers are elastomers, and can stretch and return to their original shape. The side-by-side comparison of all these polymers is given below. This comparison will help product designers to choose the type that meets their requirements:

| Property | Elastomer | Rubber | Plastic |

|---|---|---|---|

| Flexibility | Highly flexible | Highly flexible | Not much flexible |

| Elasticity | Excellent | Excellent | Poor |

| Processing | Moulded or extruded | Vulcanized | Injection molded |

| Usage | Seals, gaskets | Tires, gloves | Packaging, Containers |

Types of Elastomeric Materials

There are two main types of elastomeric materials, natural and synthetic. A detailed explanation of both these types is given below:

Natural Elastomers:

Natural elastomers are rubber-like materials that are derived from natural sources. Natural elastomers are most commonly extracted from the Hevea brasiliensis, the natural latex tree.

Natural elastomers offer high flexibility, elasticity, and resilience. Natural rubber is the most common example of natural elastomers.

Synthetic Elastomers:

Synthetic elastomers are man-made rubber-like materials. The chemical synthesis of petroleum-based monomers forms them. These monomers are specifically designed to provide high oil resistance, UV resistance, and weather resistance.

Some common types of synthetic elastomers include:

- EPDM – This synthetic elastomer is weather-resistant.

- Nitrile Rubber (NBR) – Nitrile Rubber is an oil and fuel-resistant synthetic elastomer.

- Neoprene – Neoprene is a synthetic elastomer that is designed to be chemically resistant.

- Silicone – This type of synthetic rubber is heat-resistant and of medical-grade quality.

- Viton – Viton, too, is a chemically resistant synthetic elastomer.

- Butyl – This type of synthetic rubber is airtight and durable.

Properties of Elastomers

From the automotive to the medical sector, elastomers are widely used in all industries. The unique physical properties of elastomers make them highly suitable for a wide range of industrial applications. Some of the key properties of elastomers include:

Mechanical Properties:

Mechanical properties refer to how a material behaves under pressure, i.e., when stretched, bent, or twisted. Elastomers possess outstanding mechanical properties, including high elasticity, strong tensile strength, and excellent resistance to abrasion.

Elasticity is the property of an elastomer that allows it to return to its original shape after being stretched or deformed. Tensile strength refers to the maximum force an elastomer can withstand before it breaks.

Abrasion resistance indicates how well the material resists deformation caused by friction.

Chemical Properties:

Chemical properties explain how a material reacts to chemicals, fuels, and oils. Elastomers’ chemical resistance varies by their type.

Some elastomers can resist oil, chemicals, fuel, and solvents. Whereas some elastomers, i.e, silicone and Viton, perform well under high heat or chemical exposure.

The chemical properties make elastomers great for use in fuel hoses and seals. Chemical-resistant gloves and medical tubes/devices are also made using elastomers.

Thermal/Electrical Properties:

Thermal properties describe how a material responds to changes in temperature or electrical current. Some elastomers perform well in both cold and hot temperatures.

Some elastomers do not let electricity pass through them. The electrical insulation makes elastomers best suited for use in cables, seals, and insulators.

Common Applications of Elastomeric Rubber

As mentioned above, elastomeric rubber is used in multiple industrial applications. Some of the common applications of elastomeric rubbers are:

1. Seals and Gaskets

In the automotive, aerospace, and plumbing industries, elastomers are used to create leak-proof seals and gaskets.

2. Flexible Hoses and Tubing

Hoses and tubes made from elastomers can withstand pressure and safely transport oils, gases, and chemicals.

3. Diaphragms, O-rings, Valve Seals

O-rings and valve seals are made using elastomers. Using elastomers ensures tight, responsive sealing in dynamic and high-pressure applications.

4. Medical & Food-Grade Uses

Many silicone elastomers are considered safe for human contact. Food-grade and medical-grade silicone are commonly used to manufacture cookware and feeding tubes.

5. Consumer Goods

Elastomers are durable and are therefore widely used in consumer goods, such as keychains, grips, and wearable devices.

It is essential to note that elastomers are often preferred over plastics in numerous industries. This is because elastomers offer higher flexibility. Having high flexibility, elastomers are ideal for environments where rigid plastics may crack.

Advantages and Limitations of Elastomeric Rubber

Like other types of rubber, elastomeric rubber also has its pros and cons. The advantages and limitations of elastomeric rubber are given below:

Advantages of Elastomeric Rubber

There are many advantages of elastomeric rubber, some common ones include:

- Elastomers are highly flexible and can be stretched multiple times their original size

- Elastomers are durable and can handle pressure easily.

- Many elastomers can handle low or high temperatures without compromising their performance.

Limitations Of Elastomeric Rubbers

Some of the limitations of elastomeric rubbers are:

- Elastomers are soft; thus, they have limited load-bearing capability.

- Some elastomers can degrade when exposed to UV rays, ozone, or strong chemicals. However, by adding certain additives, one can prevent the degradation.

Despite their limitations, elastomers continue to be widely used in industrial applications.

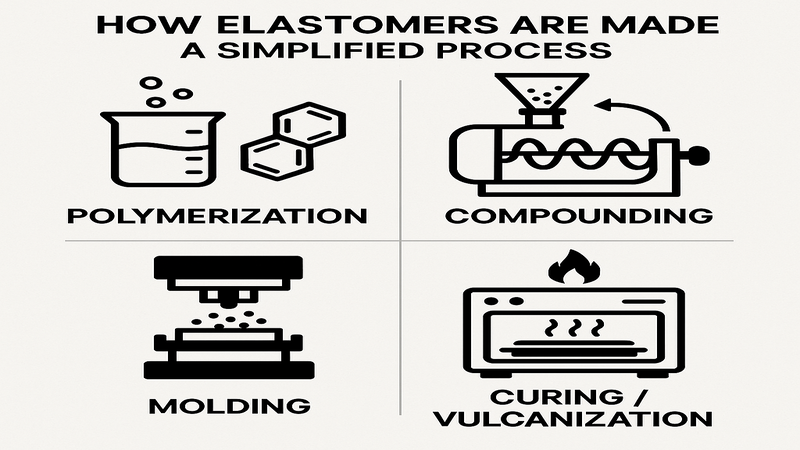

How Elastomers Are Made – A Simplified Process

Making elastomers is not complex at all. A step-by-step process of making elastomers is given below:

1. Polymerization:

The first step of making elastomers is polymerization. In polymerization, small molecules bind to form long polymer chains. There are different methods of polymerization. You need to choose the one that is according to your elastomer type.

2. Compounding:

After polymerization, the raw polymer is mixed with various additives in a process known as compounding. Compounding is done to enhance the physical properties of the polymers. Elastomers are mostly combined with:

- Fillers (like carbon black) to improve strength

- Plasticizers and oils to improve flexibility

- Antioxidants and UV stabilizers to prevent degradation.

3. Molding:

The third step of making an elastomer is molding or shaping. In this step, the compounded elastomer is shaped into a specific form. To shape polymer, different methods are used. These methods include injection molding, compression molding, and transfer molding.

4. Curing / Vulcanization:

The final and most crucial step of making elastomers is the vulcanization process. In this step, the shaped elastomer is heated with sulfur, which forms cross-links between polymer chains. Vulcanized elastomers are strong, elastic, and heat-resistant.

Elastomeric Rubber in Comparison with Rubber-like Materials

The comparison of elastomeric rubber with other rubber-like materials is given below. This comparison will help you better understand the difference between elastomers and rubber-like materials:

| Material | Characteristics | Common Uses |

| TPE | Thermoplastic, recyclable | Grips, toys |

| PU | Tough and abrasion-resistant | Wheels, foams |

| Silicone | Extreme temp resistance | Medical devices, baking tools |

| EPDM | UV/weather resistant | Roof seals, gaskets |

Final Verdict

Elastomeric rubbers are highly flexible and are utilized in a wide range of applications. There are some limitations to elastomeric rubbers. However, despite the constraints, elastomeric rubbers are commonly used in multiple sectors.

It is essential to note that elastomers, rubber, and plastics serve different purposes. Industrial buyers need to choose the one that is suitable for their needs.

Regardless of the type of rubber, ensure that you select the right supplier. Doing this is cost-effective and efficient in the long run.

Hongju Silicone – Your Trusted Partner For Custom Silicone Rubber Parts

Looking for a reliable partner to assist you with your custom silicone product parts? Well, your search ends here. Hongju Silicone, with over 23 years of experience in manufacturing silicone rubber products, is ready to meet your needs.

With our low MOQ and fast delivery, we are sure to transform your rubber designing and manufacturing experience. Get in touch with us now to get a quote tailored to your unique requirements.

FAQs

Q1. What is the difference between elastic and elastomeric?

Elastic refers to the ability of a material to return to its original shape after it has been stretched. Elastomeric, on the other hand, refers to a rubber-like material that is highly elastic, flexible, and durable.

Q2. What is an elastomeric material used for?

Elastomeric materials are utilized in a wide range of industrial applications. In the automotive industry, elastomeric materials are used to make seals, gaskets, and O-rings.

In the medical sector, elastomeric materials are used in medical tubing, catheters, and other health devices. Elastomeric materials are also used in food-related applications and other consumer goods.

Q3. Is elastomeric the same as silicone?

No, elastomeric is not the same as silicone. Silicone is a type of elastomer known for its high heat resistance. Silicone is used in many food-grade applications. Some other types of elastomer include EPDM, nitrile, neoprene, and others.

Q4. What is the difference between polymers and elastomers?

Polymers refer to a class of materials that are composed of long chains of molecules. Polymers include rubber, plastic, and more.

Elastomers, on the other hand, are a set of polymers that have high elasticity. This means that elastomers can be stretched without permanently ruining their shape.