Why Rubber Feet Matter for Cutting Boards?

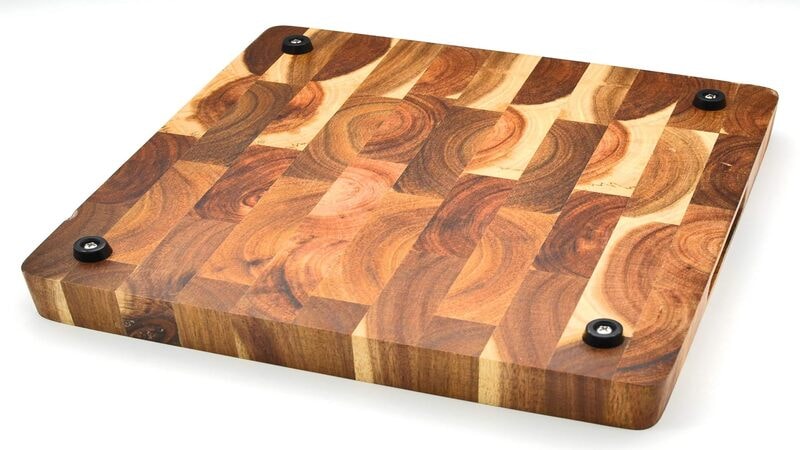

Rubber feet are helpful in preventing slipping during intense cutting. These feet improve the overall board stability and elevate it, allowing airflow from beneath.

These feet also protect the countertops as they won’t scratch them, and improve the overall hygiene, too.

You can use rubber feet on a cutting board to enable either one-sided or dual-sided usage. There are many innovative design options that allow for dual-sided feet embedding and also let you stick or remove the feet as per your convenience with magnetic adhesion.

We’ve multiple rubber colors and several sizes of feet available, meant to be suitable for everyone!

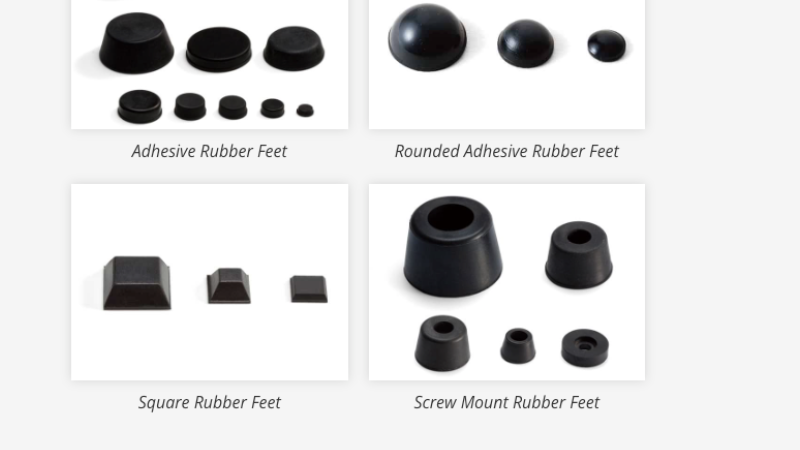

Types of Rubber Feet for Cutting Boards

It’s important to be clear on your usage and needs when choosing the right rubber type for your cutting board manufacturing or upgrade. If you’re using a wooden cutting board and need its feet to be strong and durable, we suggest going for the screw-in rubber feet.

Adhesive rubber feet are perfect for those who want to use their cutting boards occasionally and are looking for an easy-to-install option.

Some cutting boards are marketed for commercial usage and come with pre-drilled holes for foot installation. Push-in feet are a good quality option for such cutting boards.

To avoid slipping on the counter surface, we suggest using anti-slip silicone pads under your cutting boards. These small rubber feet are non-slip and hence ideal for use on damp marble counters.

If you expect exceptional strength for your cutting boards, we suggest you stock up on feet with a metal ring insert. The metal ring on these feet acts like a glue, avoiding pull-outs even with intense usage.

All in all, each of the above foot types comes with its own unique points that make it perfect for one user or another. Just make sure you invest only in quality options, tailored to the perfect size and use for your cutting board.

How to Choose the Rubber Materials for Cutting Board Feet

There are several material options when it comes to choosing feet extensions for cutting boards. Some of the most common ones in today’s markets include silicone, EPDM, TPR, soft rubber options, and others. Selecting the right silicone cookware material lets you enjoy your board for longer and with ease.

Silicone feet offer heat-resistance, non-slip advantages, flexibility, and safety in the kitchen. If you invest in food-grade silicone, you can be doubly sure of your cutting board feet being safe for your home cooking.

EPDM feet are a good quality elastomer option for those who want tall cutting boards with durable feet, but are not ready to invest too much into their DIY cutting boards.

EPDM is also a safe material to use in labs and hospitals because of its chemical resistance, and when comparing it with neoprene, EPDM often proves more suitable for environments requiring high durability and safety.

Thermoplastic rubber feet (TPR) are currently the best seller because of a number of reasons. These feet offer a balance of flexibility and toughness, making it easy to move the cutting board around but also ensuring it avoids slipping on slippery and wet countertops.

If you are not a fan of stiff and hard rubber feet, having rubber bumpers on the surface, you might want to try out the soft durometer rubber options for your board’s feet. These soft feet offer flexibility and ease of use in the kitchens where intensive cutting isn’t often required.

| Feet Material | Grip Abilities | Strength / Durability | Water Resistance | Offer The Best Use In |

|---|---|---|---|---|

| Silicone | Strong | Very High | Fully Resistant | Home Kitchens, Slippery and Wet Countertops |

| EPDM | Good | High | Good Resistance | Affordable, DIY cutting board projects |

| Thermoplastic Rubber | Strong | Very High | GoodResistance | Versatile use for all kinds of commercial boards |

| Soft Durometer Rubber | Moderate – Low Profile | Moderate | Decent Resistance | Low-scale, comfort-focused kitchens |

Best Sizes for Rubber Cutting Board Feet

The size of your cutting board’s feet is an important determinant that stabilizes it. Typically, most boards use feet with a diameter ranging between 10 and 20 mm. This is ideal for feet that support the board without being bulky.

If you want a properly lifted and yet balanced board for cutting, you should consider the height of the feet, too. The ideal height is 6–12 mm, as it allows enough lift and keeps the board balanced. Low-profile feet work great for lightweight boards, while tall feet work best for heavy wooden boards.

If you have any type of plastic board, we suggest using smaller feet. Compared to these, wooden boards need sturdy and bigger feet.

If you’re a wholesaler, we suggest investing in bulk options from a reliable supplier , such as Hongju Silicone, to ensure that all the boards are consistently constructed, and you also save on sourcing the feet.

| Feature | Recommendation |

|---|---|

| Typical Diameter | 10–20 mm |

| Avg. Height | 6–12 mm |

| Low vs. Tall | Light vs Heavy Boards |

| Small vs. Sturdy | Plastic vs. Wooden Boards |

| Bulk-Buy Options | Ideal for Makers |

How to Install Cutting Board Feet

Installing rubber or silicone feet on your cutting board is very easy. Just make sure you have the needed tools ready. Necessary hardware for DIYs includes good quality, stainless steel screws, screw drivers, drill machine, washers, adhesives, and nuts.

Firstly, you need to remove the old feet that need replacement. If these are screw-in feet, undo the screws and clean everything before installing the next pair. If the feet are adhesive, pry off the dry glue using a sharp and flat tool. Then, clean the dry adhesive with alcohol before installing new feet.

Now, here is a simple step-by-step process to reinstall the new screw-in feet:

- Step 1: If the previous holes are loose, fill them using a wood filler.

- Step 2: Let the filler dry and re-drill the holes

- Step 3: Use a drilling machine to install the new screws and feet. Do not over-tighten anything.

If you want to install fresh adhesive feet, here is what to do:

- Step 1: On a clean and dry surface, spread an even and thin layer of the adhesive.

- Step 2: Gently put the feet on the adhesive, hold for a few seconds, and leave.

- Step 3: Let the adhesive dry so the feet can stick properly.

Tips to Keep the Board Level and Balanced

Here are some tips for balanced and properly levelled cutting boards:

- Countersink Holes for Stability: This helps push in the feet so they can sit tightly in one place, avoiding movements or shaking of the board during speedy cuttings.

- Check Flatness After Installation: After the feet have been installed, place the board on a level surface. It shouldn’t wobble or swing.

- Use Quality Hardware: The screws, nuts, adhesives, and everything used during the feet installation must comply with certain quality standards.

Common Mistakes to Avoid

Here are some mistakes to avoid with your rubber feet for cutting boards:

- Uneven Drilling: Will make the board unstable and wobbly.

- Using Weak Adhesives Alone: The feet will detach repeatedly and will have a bad grip.

- Mixing Different Foot Heights: Leads to an uneven and wobbly cutting board.

Maintenance & Replacement of Cutting Board Feet

No matter how sturdy the rubber bumpers or feet you use for your cutting boards are, proper maintenance and repair are essential to ensure longevity of the equipment. We advise carrying out a thorough inspection every few months to check if there’s any wear or tear needing attention.

If the cutting board is used frequently, it is easy to spot signs like flattening, cracking, and reduced grip on the surface of countertops. Such things require immediate attention and repair if you want the board to last.

Fortunately, keeping silicone feet clean is very easy. To ensure hygiene, use a combination of mild soap or dishwashing liquid and waterto clean the feet after a few uses. We strongly condemn using abrasive and harsh chemicals that can damage the flexibility of the rubber.

Sometimes, slimy and oily buildup on the feet can cause slipping. It is suggested to use a soft cotton cloth or a brush to clean the buildup, followed by wiping the feet with a damp cloth. This helps restore rubber’s traction, keeping the board firm and non-slippery.

If you want to replace the feet and throw the old ones out, consider taking an environmentally conscious approach to disposal.

Conclusion

Rubber cutting board feet aren’t only sturdy and long-lasting, but they also enable hygienic and food-safe practices in your kitchens. Whether you’re an individual cutting board owner or a kitchenware wholesaler, make sure to invest in quality rubber feet for cutting boards that are firm and sturdy.

Upgrade Your Cutting Boards Today – Buy The Best Seller Rubber Feet In Bulk!

At Hongju Silicone, we have mastered the art of creating rubber feet and silicone items that can elevate your kitchenware without compromising on hygiene. Seek our professional services with decades of capability in creating rubber products that last.

Reach out to us today to place orders for bulk rubber feet options in your desired quantity, color, and style. Customization is possible as well!

FAQs

Q1: What size cutting board feet are best?

For wooden cutting boards, 12–15mm diameter screw-in feet are the best. If the board is small, you can use 10-12mm adhesive feet. We also have stainless steel screws and custom feet options.

Q2: Can I order custom-colored or branded rubber cutting board feet?

Yes, Hongju Silicone offers customized silicone rubber feet, especially for wholesalers and kitchenware suppliers. You can order any color, hardness level, and embossing style you want.

Q3: Do you offer bulk supplies of food-grade rubber feet for commercial or OEM projects?

We certainly do! Food-grade silicone feet are one of our best products. Place bulk orders for consistent quality.

Q4: What’s the MOQ (Minimum Order Quantity) for custom rubber cutting board feet?

At Hongju Silicone, we don’t believe in binding our clients with specific MOQ requirements for standard rubber feet. You can order as much as you need without worrying about inventory and storage.