What Is Viton Rubber?

Viton is a type of fluorocarbon rubber (FKM) first developed by DuPont in 1957. It is a synthetic rubber known for its excellent resistance to heat and chemicals. Today, many companies produce and sell FKM under different brand names, but Viton remains the most recognized.

FKM is a group of elastomers that differ based on their fluorine content. DuPont, the originator of FKM, offers over 25 different grades of Viton. Several automotive and chemical industries exclusively use Viton products. Learn more about the difference between FKM and Viton here.

Viton Grades

Viton grades are classified using a series of five letters and numbers. For example, “Viton A-401C“.

- First Character (A) – This indicates the family group of FKM, where each family has slightly different mechanical and molecular properties.

- Second Character (4) – This indicates the Mooney viscosity of the FKM.

- Third Character (0) – This represents the amount of curing agent present in the FKM pre-compound. “1” is the lowest, “2-9” is intermediate, and “0” is the highest.

- Fourth Character (1) – This represents variations on the additives inside the FKM pre-compound. A-402C has one more process aid than A-401C.

- Fifth Character (C) – This indicates the presence of an accelerant or curative in the FKM pre-compound. A lack of a fifth character suggests the product has no curatives but might contain some process aids.

Viton Rubber Compound Examples

A-410C is a common Viton grade containing the curing agent (bisphenol) from the factory. It is suited to several manufacturing processes, including transfer molding, compression molding, injection molding, extrusion, and calendering.

B-601C contained higher levels of fluorine, resulting in excellent chemical protection for the rubber compound. It has limited viability and is mainly used for compressing molded gaskets and injection molded O-rings.

GFLT-301 is a unique formulation of Viton made from peroxide curing and designed for low-temperature performance. It is compatible with extrusion, compression, transfers, and injection molding. All variations of Viton have good mechanical properties and excellent chemical resistance.

Although Viton’s grades seem complex, it is essential to understand their basic properties to ensure that the final selected materials fully meet your application scenarios. Because comprehensive understanding can help you express your requirements more accurately when communicating with suppliers.

Viton Rubber Properties and Advantages

Irrespective of the grade, most Viton (FKM) polymers share similar material properties.

Mechanical Properties

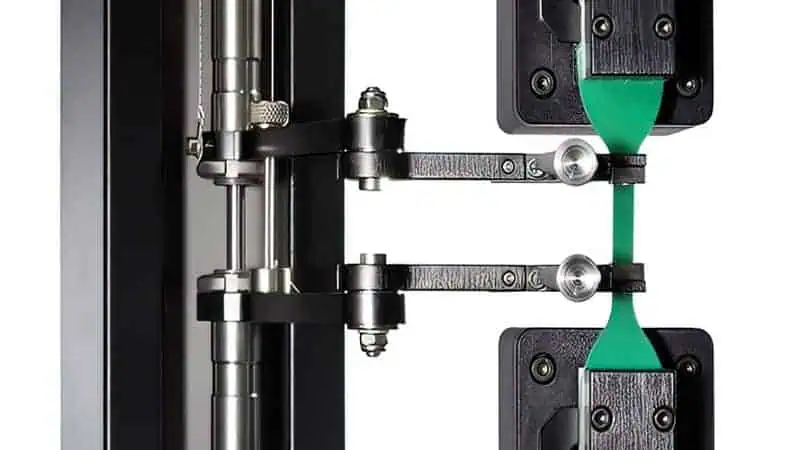

Viton occupies a wide range of mechanical properties, from poor to excellent. Overall it has good material hardness and tensile strength but falls short of tear resistance.

Compression set and metal adhesion are where this magical material shines. Metal adhesion is a prominent reason behind the use of O-rings in the robotics and automotive industries.

Here is a brief table showing the range of FKM’s mechanical properties.

| Durometer Hardness | 50-95 Shore A |

| Tensile Strength | 500-200 Psi |

| Elongation Range | 400%-500% |

| Compression Factor | Excellent |

| Tear Resistance | Good |

| Adhesion Properties | Good |

| Adhesion to Metals | Excellent |

Chemical Resistance

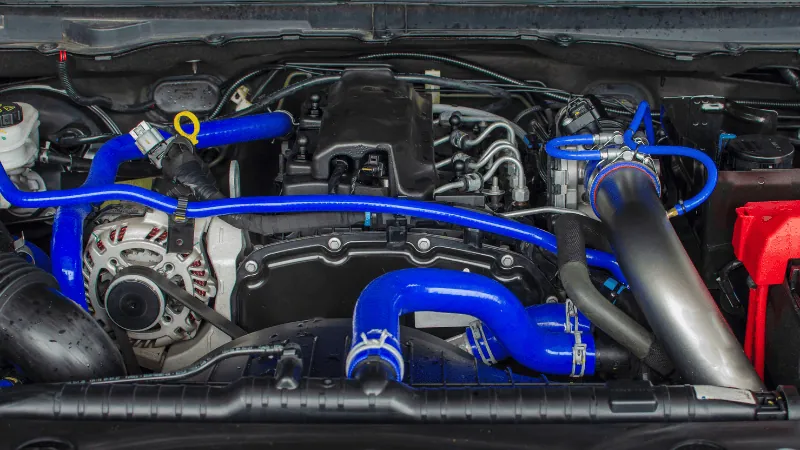

Viton’s resistance to chemicals is excellent. Viton provides a 99% retention of tensile strength after a 7-day immersion in gasoline at 73°F. Compared to other synthetic rubbers, the fluid resistance of Viton truly stands out because of its fluorine content.

Viton’s excellent resistance to oil, acid, and fuel makes it ideal for automotive engine seals. In these high-temperature and corrosive environments, other rubbers fail rapidly, but Viton can ensure the long-term reliable operation of the engine.

The only liquids that can damage Viton products are ketones, ethers, and amines. These top-notch properties are a significant reason for Viton’s use in transportation fuel applications.

Below is a short table showing the range of FKM’s chemical properties.

| Acids | Good-Excellent |

| Alkalies | Good |

| Fuel | Excellent |

| Oil | Excellent |

| Solvents | Excellent |

| Amines | Poor |

| Ethers | Poor |

| Ketones | Poor |

Environmental Resilience

Synthetic rubber materials generally have decent environmental protection, and Viton is no exception. Viton products are resilient materials capable of dealing with even the harshest environments.

Viton has an outstanding environmental resistance, just like an “outdoor expert” in the rubber industry. Even when exposed to strong sunlight or bad weather for a long time, it can maintain the performance without additional protective measures. Viton products are often deployed in outdoor environments as they do not require special protective enclosures.

Below is a short table highlighting the FKM’s ability to withstand harsh environments.

| Flame | Excellent |

| Water | Excellent |

| Ozone | Excellent |

| Oxidation | Excellent |

| Radiation | Good |

| UV Light | Excellent |

| Weather | Excellent |

| Gas Permeability | Excellent |

Operating Temperature Range

Operating temperatures are a problem area for many rubber products. But Viton, a material specially designed for performance applications, has specific properties to deal with temperature extremes.

It has a standard operating range of -30º F to 500º F and can even stand harsher temperatures in certain conditions. Though Viton has exceptional protection against high temperatures, it lacks low-temperature capabilities.

But this is not a significant issue as Viton products are rarely deployed in colder environments. You will commonly see them in car engines or factory equipment, where higher temperature ranges are a more critical factor.

Here is a quick summary of the operating temperature ranges you can expect from FKM.

| Low Temperatures | -30º F to 0º F |

| High Temperatures | 450º F to 500º F |

| Brittle Point | 0º F to -40º F |

What Are Viton Rubber Applications?

Viton is primarily used for high-performance applications where its fuel and oil-resistant attributes can be fully utilized. These high-performance application environments also tend to be hot and corrosive, making most rubbers ineffective here.

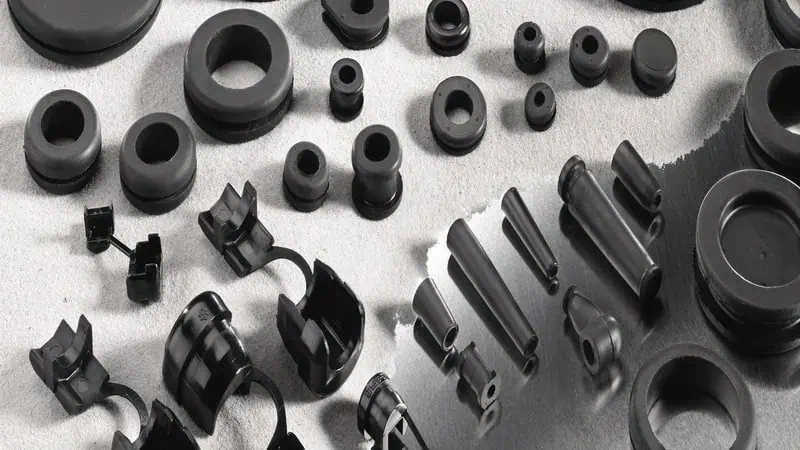

The three most commonly available products are Viton o-rings, gaskets, and seals. It also has other, less-known uses in sealing products. Viton sealants and adhesives are quite popular for metal bonding and electrical device coatings.

The following industries heavily utilize Viton products.

- Chemical – Container seals, adhesives, flame protection, etc.

- Automotive – Engine oil seals, cable sleeving, gaskets, o-ring applications, etc.

- Oil & Gasoline – Pipes & hoses, container seal, container lids for corrosive oils, etc.

- Aerospace – vibration dampers, low-temperature external seal applications, o-rings, etc.

- Heavy Machinery – Vibration & sound dampers, oxidation protection, seal applications, etc.

Difference between Viton and Silicone

Silicone and Viton occupy two different sectors of the rubber market. Where silicone is a jack of all trades, Viton is a specialized rubber product. If you need a general-purpose rubber, then silicone will do the job. But if you want a resilient rubber for high-performance applications, Viton is the gold standard.

Chemical Resistance

Due to its fluorine content, Viton has some of the highest chemical protection. In contrast, silicone has some of the worst chemical properties among all rubbers.

Chemical damage is a significant issue in factories and industrial workspaces. Other rubber products offer similar chemical protection but fall short in mechanical properties. Viton stands out for its outstanding chemical resilience alongside its mechanical properties.

Strength

In terms of intensity, Viton is like a strong athlete. It has a stronger tensile strength and Shore hardness, capable of withstanding high stress and fatigue in heavy machinery, which is something that general-purpose silicone cannot match.

Silicone, in comparison, lags behind Viton in all mechanical properties, except compression set, where it maintains an equal footing.

Abrasion and Tear Protection

Viton has been specially designed to withstand excessive forces and impacts. It will not degrade, shear, or tear under most operating conditions. Though it has weak tear properties, Viton is still miles ahead of silicone.

Applications

Viton o-rings are its most popular product, generally outselling all others. While silicone and silicone fluids occupy so many product categories, you cannot possibly name just one popular product.

It should be noted here that Viton can be used for the same applications as silicone and even outperforms its silicone counterparts. However, as a specialized rubber, it comes with a hefty price tag. It is financial folly to deploy Viton in anything other than the most demanding applications.

Low-Temperature Operation

Low-temperature polymers are rare as most will become brittle and crack in sub-zero environments. Silicone has an unparalleled operating temperature range of -178º F to 550º F.

Cold environments are generally less of an issue in the manufacturing space. So it should not come as a big surprise that silicone is the sole rubber compound able to achieve such feats. This by no means invalidates the cold environment application of Viton. Instead, it merely highlights silicone’s advantage.

Conclusion

Viton rubber excels in resisting acids, oils, and radiation, offering exceptional strength for demanding applications. Although it is limited by solvent vulnerability and higher cost, its versatility and performance make Viton ideal for challenging industrial environments.

Superior Viton Rubber from Hongju: Engineered for Excellence, Delivered with Speed!

Hongju Silicone offers a wide range of high-quality OEM and ODM services. We can empower your projects with industry-leading Viton rubber products that deliver exceptional chemical resistance, extreme temperature durability, and reliable performance.

Contact us to leverage our low MOQs, rapid prototyping (3-5 days!), and decades of molding expertise to accelerate your production timeline without compromising quality.