What does Rubber Compression Molding Mean?

Maybe you heard that rubber compression molding is a “miracle weapon” in the global rubber industry with tremendous flexibility, ideal for all small to large and even thick parts.

Is that correct?

I’m not sure, but I know that rubber compression molding has proven its worth with the strong growth of all businesses that need compression rubber.

The automotive rubber molding components market alone reached a market size of US 40.5 billion in 2020.

So, if you want to deep-knowledge about what rubber compression is and its benefits, let’s move on to the following guide to learn more.

What is Compression Molding?

Compression molding is a manufacturing process of using compression (force) to change the shape of the molding material by placing it into an open heated mold. Then, the final finished product will be put out with the support of temperature and pressure.

Compression molding appeared in the early 1900s and was the fastest-growing first technique with many outstanding features and advantages.

And this technique is generally used to manufacture thermoset plastics, rubber, and synthetic materials, such as phenolic, melamine, phthalate, and epoxy.

What about the Meaning of Rubber Compression Molding?

In short, it is a combination of rubber and compression molding.

For example, you put a preformed rubber piece into the cavity of a mold, close it, and wait for the heat and pressure to cure the rubber.

silicone rubber products

And the perfect cured rubber product finally appeared.

However, you must understand how to create high-quality, beautiful rubber pieces.

Next, I will show you the most basic rubber compression molding process; even if you are not an expert in compression molding, you can understand it easily.

Rubber Compression Molding Process

The process has 4 steps:

Natural or synthetic rubber will often promote and enhance its usefulness in many shapes and forms.

Let’s see how this process works and how we got the final product of rubber.

Rubber compression molding process (4 steps)

Here are four basic steps you should know:

Step 1: Prepare rubber and mold plates

Step 2: Put rubber into the compression molds

Step 3: Compressing

Step 4: Opening the mold

Let me explain the details of each step.

Step 1: Prepare rubber and mold plates

Prepare a piece of uncured rubber before performing compression molding.

Calculate the required amount of rubber before putting it in the compression mold.

If the amount of rubber put into the mold is less, it will not be able to produce the desired shape.

Therefore, you should calculate the amount of rubber loaded in the correct mold to create the best product.

Different molds create various parts with unique thicknesses, lengths, and detail levels.

In this step, you might need to heat the mold’s lower half to maintain the rubber’s heat during the molding process.

Step 2: Put rubber into the compression molds

Now, it’s time to put the rubber into the heated mold.

Well, this step has some points you should keep in mind.

Put on protective gloves and keep a safe distance from the machine when it is hot.

Then you put the rubber piece into the compression mold and close the lid.

The perfect precision of the rubber will ultimately depend on the exact proportions of the material you made in step 1, as well as the quality of the mold design.

Step 3: Compressing

Rubber compression molding by compression molding machine requires the support of temperature and pressure.

Heat will harden the material while pressure fills the cavity and removes air voids.

The innovative rubber compression molding machine will have a logic controller that makes it easy to handle and monitor important parameters during operation.

When compressing the mold, you need to maintain a hot heat.

Step 4: Opening the mold

The final part of this process is opening the molded door.

When reaching the firm, pressure and heat compress the rubber.

With the cycle time complete, the compression-molded rubber part will be ejected from the mold cavity.

When opening the mold, the excess rubber or flash products that do not fit the mold can be cut off, and a new molding process continues.

Rubber types for rubber compression molding include:

Whether natural or synthetic, each rubber form demonstrates unique properties that make it suitable for particular applications.

Here are some common types of rubber and their properties:

Natural Rubber (NR)

Natural rubber from the latex from the rubber tree (Hevea brasiliensis) or other.

Natural rubber is an excellent physical material for Vibration dampers, O-rings, Coatings, Mountings, and Diaphragms because it has high tensile and surface friction properties.

Butyl or Isobutylene Isoprene (IIR)

Butyl consists of small amounts of isoprene and isobutylene.

IIR works well with excellent resistance to water, alkalis, and oxygenated solvents.

In addition, it can reduce the sound, making it ideal to use as a bumper for equipment.

Styrene Butadiene (SBR)

The copolymerization of butadiene and styrene produces SBR.

SBR is capable of organic acids, water, chemicals, and aldehyde

One of the most common uses of styrene-butadiene is in automotive parts. For example, drive couplings.

Also, you may quickly find it in several applications, such as belting, hoses, gaskets, metal adhesion, and cabling.

Ethylene Propylene Diene Monomer (EPDM)

Mixing ethylene and propylene can create an EPDM with excellent heat resistance up to 150°C.

In addition, it also performs well when used in steam systems, outdoor products, or automobile systems.

Silicone Rubber

Silicon rubber is an elastomer containing carbon, hydrogen, and oxygen silicon.

In addition to being resistant to extreme temperatures, fire, and ozone, silicon rubber is also resistant to ultraviolet (UV) radiation.

It is available in liquid and solid forms and in various colors.

Silicone Rubber is suitable for products that need biological compatibility ( such as gloves) and chemical resistance (such as cosmetic applicators or food containers).

Neoprene Rubber

Neoprene comes from the polymerization of chloroprene.

Neoprene is a versatile material with weather and temperature resistance, fire resistance, and abrasion resistance.

Its capability to maintain good mechanical properties over a wide heat range may also be used as gaskets, belts, and seals for windows and doors.

Nitrile or Buna – N (NBR)

Nitrile rubber, composed of acrylonitrile and butadiene, is the most commonly used for rubber molding.

NBR possesses exceptional mechanical and chemical properties, such as resistance to compression, heat, oil, various fluids, and solvents.

This makes it suitable for automotive gaskets, O-rings, and engine hoses.

Fluorosilicone (FVMQ)

Fluorosilicone is one of the silicone variations that contain trifluoropropyl. It is highly adaptable to a wide range of heat.

Good heat resistance in (-100 to 350 degrees Fahrenheit), oil, fuel, synthetic lubricant, fire, and transmission fluids ozone.

It is widely used in the aerospace industry because of its durability and resistance to petroleum products.

Application of rubber molding in practice

As you know, we all live in an integrated and thriving economy.

Therefore, the demand for rubber-molded products is increasing rapidly.

The rubber molding market will reach $52.0 billion in 2026, according to the IndustryARC report.

Asia Pacific (APAC) dominated the rubber molding industrial market with a market share of more than 36% in 2020.

Examples of compression molding in many industries:

- Aerospace: To ensure passenger and aircraft safety, rubber gaskets and seals must withstand rub gasses, fire, and oil.

- Automotive: The auto industry handles rubber parts in many sections of cars, such as brake, clutch, and battery gaskets.

- Print: A metal core, a rubber bonding material, and a rubber covering are essential to the printing industry’s molded rubber products.

- Electrical: The products can include outlet covers, protection from shock, chemical resistance, methods for reducing electromagnetic interference, and sealing connections from dust and moisture.

- Agriculture: Rubber gaskets and seals supply the safety and protection required to handle various chemicals and pesticides.

- Medicine: Rubber molding products work wonderfully, from providing incoming fluids via tubes to every aspect of medical treatment.

- Food and Beverage: The Food and Drug Administration (FDA) specifies that we can use types of acceptable rubber in the production of parts and components for the food and beverage industries.

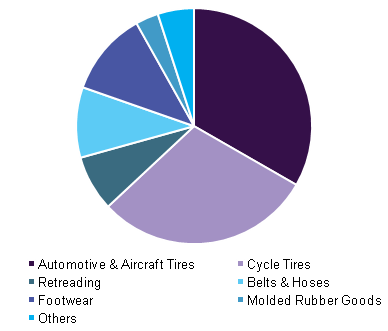

Compared with other industries, the auto manufacturing industry is applying more rubber molding with custom rubber parts to concentrate on producing tires to meet the increasing demand for vehicles.

Rubber market share

Cycle tires are an important segment, with a volume share estimated to reach 29.14% by 2025.

However, footwear in the fashionable segment is also growing with high demand for heels, shoe soles, and liners.

Advantages of Rubber Compression Molding

Unlike other metal parts, rubber compression has more advantages with the light amount, high intensity, good hardness, excellent corrosion resistance, and more.

Here are the top ten benefits of rubber compression molding when comparing it with metal and other methods like injection molding.

- Tooling savings

- Short setup time (saves on short production runs)

- The capacity to process stiff, high durometer materials

- Least amount of waste

- Lower expense than injection molding and transfer molding

- Simplified process to create low-cost rubber components with ease and high efficiency.

- Get all forms of elastomers

- Perfect for extended curing time with large parts

- Increasing the number of cavity count

- Cost-effective

Conclusion

With such a very high global rubber supply and demand, the compression molding technique will help you get a great ticket that can generate huge profits and compete fairly with other caliber competitors in the distribution of compressed rubber products.

But the concern that lots of people like you’re facing is that they don’t know how and where they may pick a manufacturer who can understand your requirements and provide the perfect solution and technique.

Or you’re wondering about the rubber injection molding for your company and in need of discussing custom rubber molding with a professional.

Hongju could be the best fit for you if you’re in an unwanted situation or don’t have much time for it.

Work with the Experts at Hongju for Your Rubber Compression Molding Needs

If you’re stuck dealing with a heap of custom machine parts, we’ll help you with whatever you want.

Whether in the UK, the US, China, or any other country, you can be assured of high-quality products that meet international standards in Hongju with FDA and CR-approved certificates.

You will be delighted to cooperate and work with professionals with more than 23 years of experience in rubber compression molding.