Platinum-cured silicone is reshaping custom manufacturing with its purity, durability, and exceptional performance. From medical devices to high-end consumer products, its advantages far surpass traditional peroxide-cured silicone.

This guide explores how platinum-cured silicone is made, where it excels, and how to choose the right manufacturer to ensure consistent quality. Keep reading!

What is Platinum-Cured Silicone?

Platinum-cured silicone is a high-quality silicone rubber that is used in a variety of industries such as medicine, food and beverage products, processing, and electronics.

When compared to other curing process methods, it is manufactured using platinum as a catalyst in the curing process, ensuring minimal impurities and a higher level of purity. As a result, the silicone product is extremely clean, biocompatible, and chemically stable.

Platinum-cured silicone is non-toxic and resistant to heat, UV rays, and chemicals. These properties make it ideal for applications with strict hygiene requirements.

It is therefore widely used in medical implants, food and beverage products, and kitchenware. Because of its dependability and versatility, it is a popular choice for critical applications.

Benefits and Applications of Platinum-Cured Silicone

Platinum-cured silicone offers numerous advantages across diverse applications. Its high purity and biocompatibility make it ideal for medical and pharmaceutical uses, including surgical implants, tubing, and seals.

In the food industry, the material’s non-toxicity, temperature resistance, and ease of sterilization support its use in food-grade gaskets and molds.

For electronics, it serves as a reliable insulator and sealant, effectively protecting components from moisture and contaminants.

Additionally, the durability and UV resistance of platinum-cured silicone make it suitable for outdoor applications such as solar panels and automotive components.

These combined benefits continue to make it a versatile and widely adopted material across multiple sectors.

Inquire About Our Silicone and Plastic Products!

Manufacturing Processes for Platinum-Cured Silicone

Silicone rubber, particularly platinum-cured silicone, is a versatile material known for its exceptional purity, biocompatibility, and resistance to extreme temperatures.

Custom manufacturing processes play a critical role in shaping this material into a diverse range of intricate components that meet the specific needs of various industries.

We will look at three primary custom manufacturing processes for platinum-cured silicone here.

Injection Molding

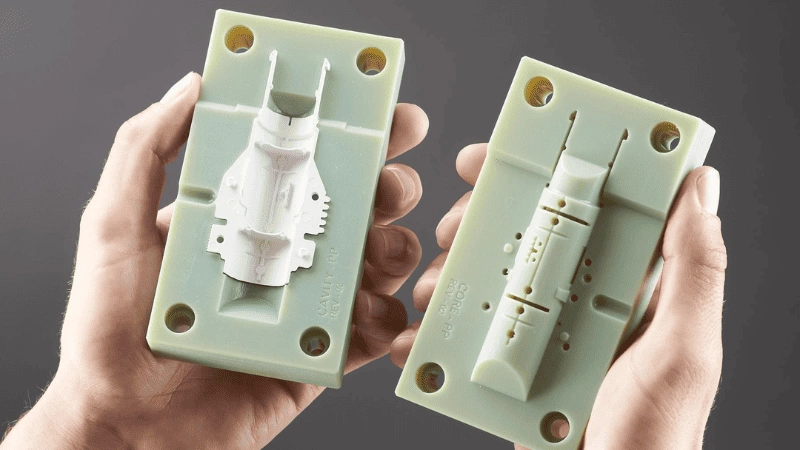

Injection molding is a popular method for custom manufacturing of platinum-cured silicone products. This method involves heating the silicone until it becomes molten, then injecting it under high pressure into a precisely designed mold cavity.

When the silicone has cooled and solidified, it takes the shape of the mold.

Benefits of Injection Molding:

- Precision: Injection molding can produce intricate and precise shapes with tight tolerances, making it ideal for complex silicone components.

- High Production Rates: It enables rapid production, making it ideal for large quantities of silicone parts for low viscosity.

- Consistency: The procedure ensures consistency across multiple parts.

Applications

Injection molding is widely used in the medical industry for the manufacturing of medical devices such as surgical implants, tubing, seals, and a variety of silicone components.

Other industries use it to make silicone gaskets, automotive parts, and specialized equipment.

Extrusion

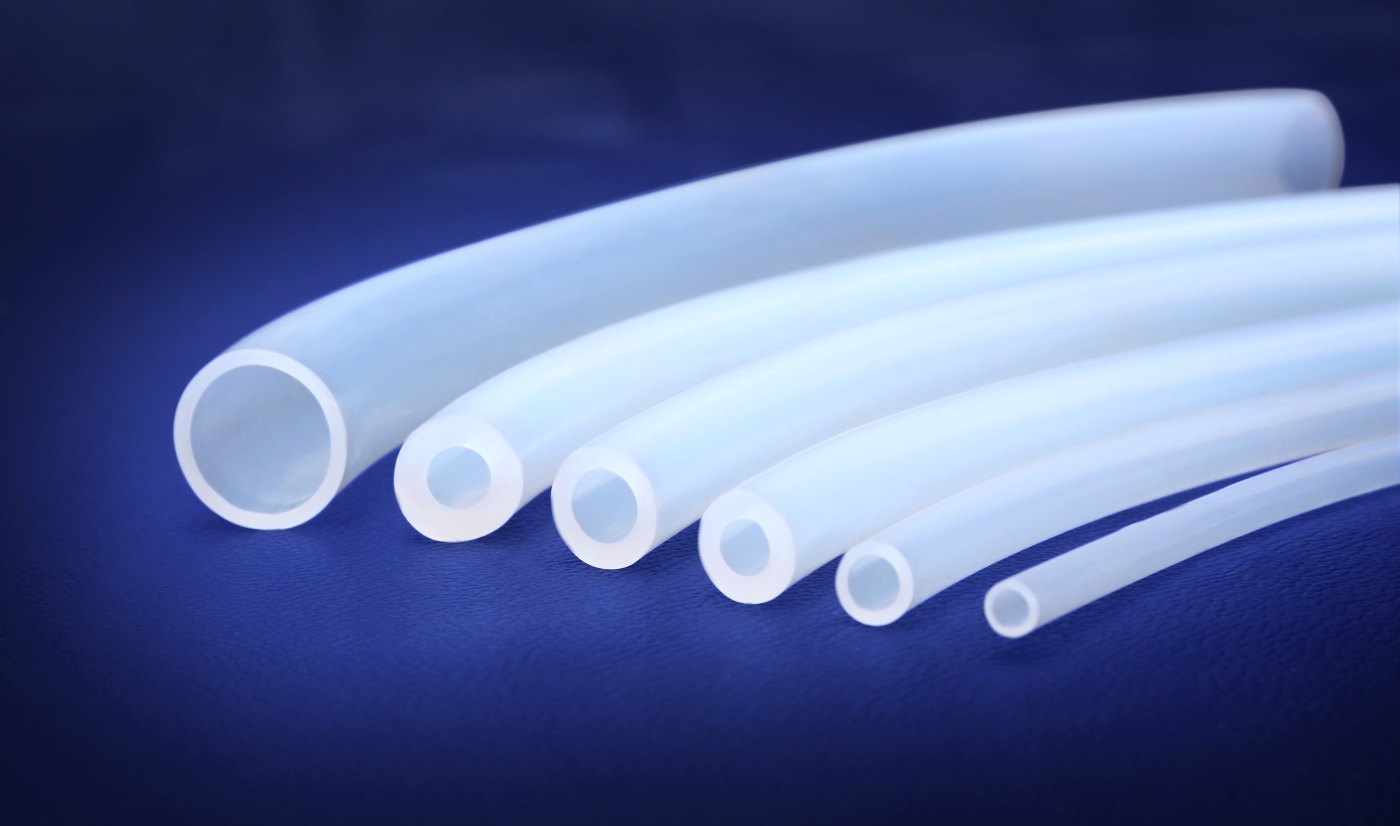

Extrusion is a process of another platinum-cured silicone custom manufacturing process that is commonly used to create continuous profiles, tubing, sheets, and other linear shapes.

The silicone material is forced through a shaped die or extrusion head, imparting heat into the desired cross-sectional profile solid form, in this method.

Benefits of Extrusion:

- Continuous Production: Extrusion enables the continuous, uninterrupted production of silicone products.

- Versatility: It allows you to shape the silicone into a variety of shapes and sizes.

- Uniformity: It allows for flexibility in molding silicone rubber into different shapes and sizes. Extrusion guarantees uniform dimensions and characteristics throughout the product.

Applications

Extrusion is widely used to make silicone tubing for use in medical and pharmaceutical applications, food storage products, and beverage products as well as gaskets, seals, weather stripping, and profiles for use in industrial and construction settings.

3D Printing

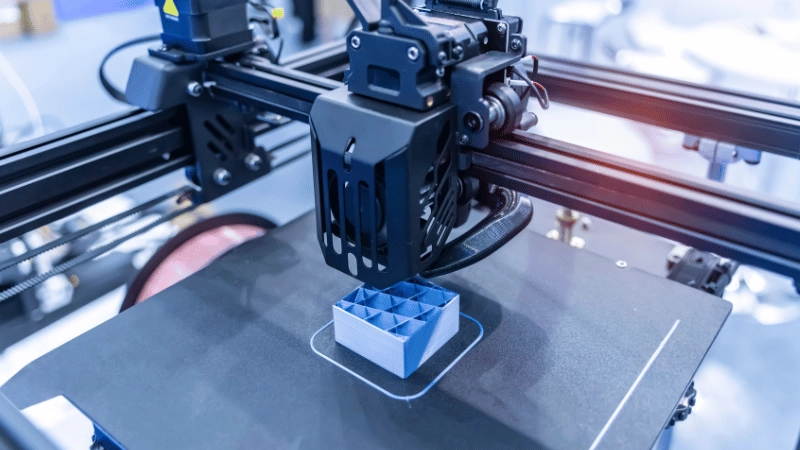

Beyond traditional processes such as injection molding and extrusion, custom manufacturing of platinum-cured silicone has expanded into novel areas such as 3D printing.

In 3D printing, silicone material is deposited layer by layer to create complex three-dimensional objects.

Benefits of 3D Printing

- Customization: 3D printing allows for highly customized designs and prototypes.

- Complex Geometry: It can create intricate, geometrically complex silicone components.

- Low-Volume Production: Ideal for producing small quantities of specialized silicone products.

Applications

3D printing with platinum-cured silicone has a wide range of uses, from the rapid prototyping of unique, medical applications and devices to the production of intricate silicone parts.

Inquire About Our Silicone and Plastic Products!

A Look Into Platinum-Cured Silicone Production

Platinum-cured silicone production is an appealing process that results in a highly pure and versatile material. It starts with blending silicone polymer with a platinum-based catalyst to ensure minimal impurities.

This mixture is then carefully molded, extruded, or even 3D printed, depending on the desired product.

Injection molding provides precision for complex shapes, extrusion allows for continuous production of tubing and sheets, and 3D printing allows for complicated customization.

The end result is a biocompatible, non-toxic material that is resistant to extreme conditions.

Whether for medical implants, food-grade applications, or aerospace components, platinum-cured silicone production indicates the remarkable adaptability and purity of this silicone variant.

Key Features of Platinum-Cured Silicone for Custom Manufacturing

Platinum-cured silicone stands out in custom manufacturing due to its exceptional properties. First and foremost, its exceptional purity, achieved through the platinum catalyst, ensures a clean, biocompatible material.

Its non-toxicity makes it ideal for medical implants and food-grade applications.

Furthermore, its versatility shines in complex manufacturing processes such as injection molding, extrusion, and 3D printing, allowing for precise customization.

Platinum-cured silicone’s key characteristics make it an excellent choice for crafting customized components in a variety of industries.

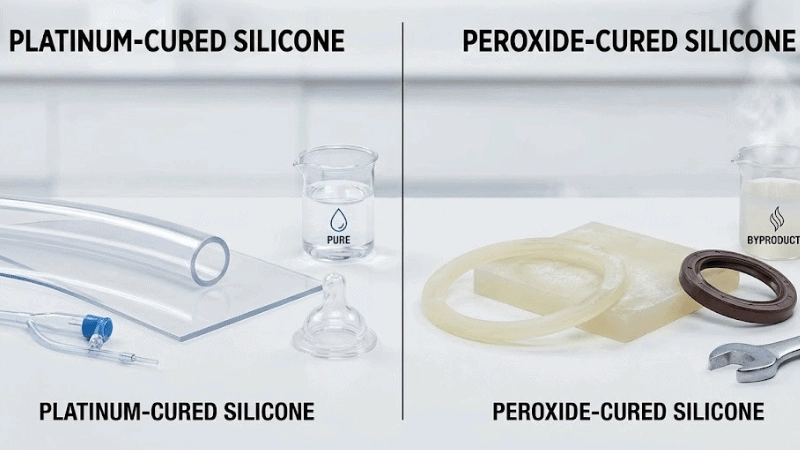

Comparison: Platinum-Cured Silicone vs. Peroxide-Cured Silicone Rubber

| Properties | Platinum-Cured Silicone Rubber | Peroxide-Cured Silicone Rubber |

| Biocompatibility and Minimal Impurities | Preferred choice for applications requiring | May contain impurities. |

| Purity | Renowned for exceptional purity. | May contain impurities. |

| Temperature Resistance | Excellent resistance to high temperatures | less demanding temperature requirements |

| Toxicity | Non-toxic. | Generally non-toxic. |

| Chemical Stability | Exhibits chemical stability. | Provides good chemical stability. |

| Applications | Ideal for 3D printing and precision molding | A dependable option for many general-purpose applications |

How to Choose a Custom Manufacturer for Platinum-Cured Silicone

Choosing the right custom manufacturer for platinum-cured silicone products is critical to ensuring your project’s quality, precision, and cost-effectiveness.

Here are ten important factors to consider before making your decision.

Expertise and Experience

Consider manufacturers with a proven track record of working with platinum-cured silicone, as experience in the platinum-curing process often translates to a better understanding and expertise in handling this material.

Material Knowledge

Ensure the manufacturer has in-depth knowledge of platinum-cured silicone’s unique properties and manufacturing requirements, such as platinum, platinum curing process, curing agents used, process methods, and mold design.

Quality Assurance of Platinum-Cured Silicone

Find out about their quality control measures, certifications, and adherence to industry standards, particularly if your application requires stringent quality requirements, such as medical or food-grade standards.

- Customization Capabilities: Examine their ability to customize products to your specific requirements, including intricate shapes, sizes, and quantities.

- Prototyping Services: Manufacturers that provide prototyping services like Hongju Silicone can assist you in testing and refining designs before full-scale production, potentially saving time and money.

- Technology and Equipment: Verify that the manufacturer uses up-to-date technology and equipment suitable for platinum-cured silicone rubber production, ensuring efficiency and precision.

- Cost Transparency: Seek pricing transparency, including material, labor, and any additional costs, to get high transparency and ensure there are no surprises.

Platinum-cured silicone custom manufacturers should be chosen after a careful evaluation of their capabilities, adherence to quality standards, and suitability for your project’s particular requirements.

Inquire About Our Silicone and Plastic Products!

Conclusion

Platinum-cured silicone sets the standard for custom manufacturing, offering exceptional purity and durability. Its lack of toxic by-products makes it essential for critical medical and food-grade applications.

To leverage these superior properties, selecting a manufacturer with rigorous quality assurance and advanced production capabilities like Hongju Silicone is crucial for ensuring reliable, high-performance results.

Accelerate Your Projects with Hongju’s Platinum-cured Silicone

Hongju Silicone is renowned for its expertise in platinum-cured silicone manufacturing. Leverage our 20+ years of craftsmanship, ultra-fast 3-5 day prototyping, and flexible low MOQs to get your high-quality products without compromise.

Contact our experts now to start your custom solution!

FAQs

Q1: Why is platinum curing preferred for medical and food-grade silicone?

Platinum curing creates the purest, most inert silicone without byproducts. It meets strict FDA and USP Class VI standards, ensuring zero contamination risks for medical devices or food contact applications.

Q2: How does platinum curing enhance product performance?

It yields superior clarity, extreme temperature resistance (-60°C to 250°C), and exceptional tear strength. The result is durable products that maintain flexibility and transparency through repeated sterilization cycles.

Q3: Can you achieve complex geometries with platinum-cured silicone?

Yes. Its low viscosity before curing enables reproduction of micron-scale details, making it ideal for precision components like microfluidic chips and complex sealing interfaces in custom manufacturing.

Q4: What industries benefit most from this material?

Medical (implants, tubing), pharmaceutical (drug delivery), food processing, and infant care products benefit from its non-toxic stability and easy sterilization compatibility.