What is Neoprene Rubber?

Neoprene is synthesized by polymerizing chloroprene. Synthetic rubber comes in three types: foam, sheets, and extrusions.

Moreover, it possesses several excellent properties, including oil resistance, ozone resistance, and oxidation resistance, making it suitable for various commercial applications.

Also, many industries, including automotive and telecommunications, use this material for its properties.

Moreover, neoprene offers excellent thermal performance, which paves the way for even more applications. As a result, the industry readily uses this synthetic material as an alternative to more expensive options.

As for types, the material comes in three different forms, which we will discuss in the following section.

Types of Neoprene

Like any other synthetic rubber, neoprene rubber also comes in variations. These varying forms of neoprene make it suitable for a broader range of applications, per the users’ needs. The most prominent variations of neoprene include:

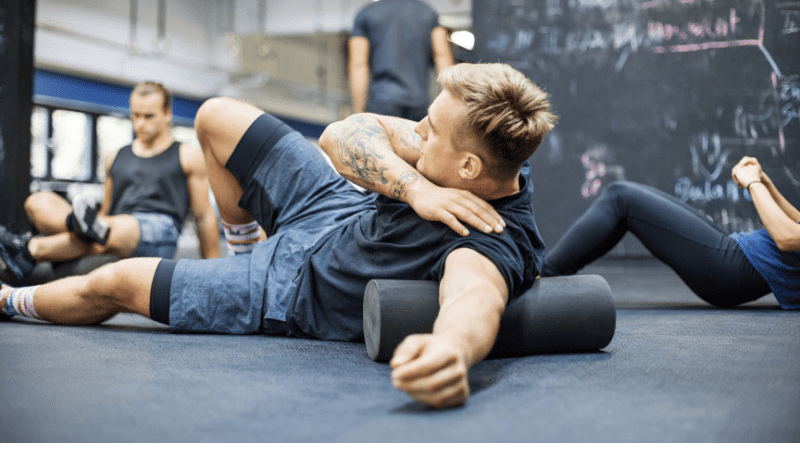

Neoprene Foam

This type of neoprene rubber has a spongy texture. As a result, it works as the foaming agent. On top of it, the thickness of neoprene foam allows it to be used as padding for various equipment, such as elbow pads.

Moreover, several industries also use it as an insulator, as it helps retain heat or keep it out where necessary.

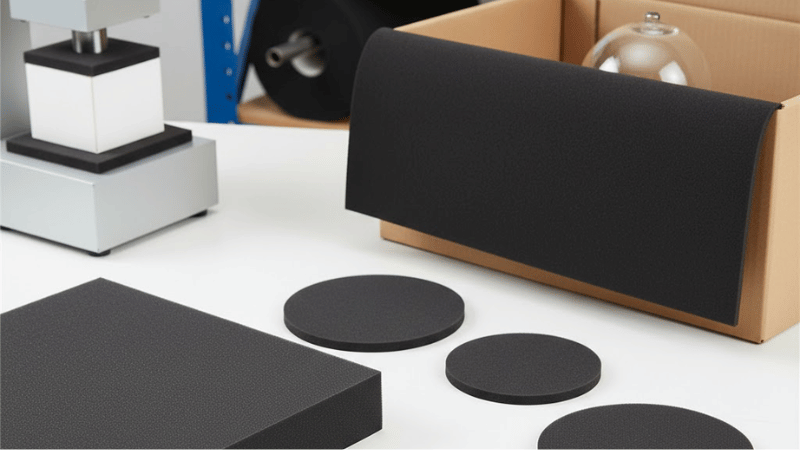

Neoprene Sheets

Neoprene sheets have the ability to act as a protective layer for landfills and other areas. Moreover, these sheets also come in handy for manufacturing safety equipment such as suits, gloves, covers, waterproof boots etc.

Extruded Neoprene

Extruded neoprene is probably the most common type, as it can be used in multiple ways. For instance, neoprene extrusions can be turned into seals and washers.

On top of it, this type of neoprene also makes a suitable material for sealing windows.

Neoprene Rubber: Key Properties

Neoprene has some excellent properties, which explains why the material gained so much popularity quickly. Let’s have a look at some of the most prominent properties it offers to the users and applications:

Abrasion Resistance: Neoprene seals and gaskets are common because the material tends to withstand abrasion. Various dynamic applications use them since the material withstands regular wear and tear, eradicating the fear of mechanical failures.

Moreover, neoprene also regains its original shape after some form of deformation, which makes it even better.

Environmental Resistance: Neoprene delivers excellent performance in outdoor conditions. This includes ozone, oxidation, and UV resistance.

As a result, it works out as a great alternative to natural rubber, which tends to perform poorly outdoors.

Moreover, neoprene also withstands harsh weather conditions pretty decently, hence it keeps strong seals even in unfavorable conditions.

Compression Set: Neoprene also has a low compression set. This means any neoprene product regains its original shape even after prolonged sessions of compressive pressure.

As a result, neoprene is an ideal alternative to natural rubber, which does not perform as well.

Moreover, a low compression set enables neoprene seals and gaskets to maintain tight contact with the surfaces without losing grip, even in the long run.

Neoprene Rubber: Uses and Applications

Neoprene has extensive use in a wide range of industries. We will see how each industry uses neoprene products for their properties in various forms and shapes.

Marine Industry

Neoprene offers incredible thermal and water resistance characteristics. As a result, the marine industry readily uses this material. For example, various marine suits use neoprene rubber for their waterproofing.

Moreover, adding elements during the manufacturing process, such as nitrogen, allows neoprene to become dense. This makes neoprene suitable for diving suits as the higher density keeps the diver deep inside the water.

However, there are certain limits to how deep you can go with a neoprene suit. Talk to the manufacturer about it beforehand.

Electrical Industry

Neoprene is commonly used for wires, bulbs, and transformers. Why? Well, the material displays incredible static resistance. On top of it, neoprene handles fire pretty well, which comes in handy in these applications.

As a result, neoprene’s capabilities as an insulator make it a great rubber material for various electrical equipment.

Industrial Applications

Neoprene performs exceptionally well against abrasions. On top of it, the material shows excellent oxidation resistance.

As a result, it makes for an excellent material for several industrial applications. These include corrosion-resistant coatings as well as sealing gaskets.

You can also ask manufacturers to create neoprene gaskets personalized to your needs.

Medical Industry

Neoprene offers a variety of benefits for the medical industry. These include its ability to retain shape, high flexibility, cushioning ability, and wearability. As a result, it is used to produce various supporting pads in the medical field.

Packaging Industry

Neoprene foam makes an excellent material for packaging and padding. This is especially handy for products that need extra care when in transit.

Construction Industry

Neoprene has several characteristics that make it suitable for outdoor construction applications. These include its ability to withstand harsh weather conditions and temperatures.

Moreover, the low compression set also comes in handy. The most common applications of neoprene in this industry include bearing pads and washers, among other materials.

Automotive Industry

As discussed earlier, neoprene displays incredible abrasion resistance. As a result, the manufacturers produce a variety of automotive neoprene components that experience dynamic conditions.

On top of it, neoprene also resists various oils, solvents, and heat, making it a whole lot better for these applications. As a result, you will often come across neoprene belts, hoses, seals, etc., in vehicles.

Safety Equipment

Different rubber materials have different temperature ranges. Many industries also use neoprene to manufacture safety equipment. This credit goes to neoprene’s ability to withstand temperature and offer high flexibility.

Hence, neoprene in fabric foam is perfect for protective wear equipment.

Neoprene Rubber: Benefits and Advantages

So far, we have talked about the properties and uses of neoprene. But how does this material stand out from the rest? What advantages does it offer? Let’s look at the list below:

- Neoprene rubber offers excellent shock absorption properties. As a result, it has several applications in the automotive industry for suspension systems, bumpers, and vibration mounts.

- Neoprene performs effectively against water. As a result, this waterproof material makes great wetsuits and other equipment for sports and military purposes. Neoprene rubber swim caps are even better than silicone swim caps.

- Neoprene offers excellent sealing performance. As a result, the material has great use in the construction industry.

- Neoprene rubber also has suitable properties for medical use. The material is non-toxic and safe for prosthetic devices.

- Neoprene rubber also displays good insulation performance. As a result, the material is readily used to make boots, gloves, and other protective equipment. Moreover, it also acts as an excellent sealant and insulator on construction sites.

FAQs

Have more questions? Have a look at some frequently asked questions about neoprene:

Q1: Is neoprene toxic to humans?

Neoprene rubber does not cause allergic reactions to human skin like natural rubber. As a result, the material does not fall under the category of toxic materials.

Moreover, neoprene rubber displays good chemical stability, which makes it suitable for human skin contact since the risk of chemical reactions is minimal.

Q2: How waterproof is neoprene?

A standout feature of neoprene is that it is entirely waterproof. As a result, it is widely used in many water-related applications, such as water gear and equipment.

Moreover, neoprene rubber also helps with insulation making it suitable for cold and wet environments.

Q3: What is so special about neoprene?

Neoprene’s best thing is its versatility. So much so that you can find neoprene used for its insulation and phone cases. As a result, the diversity of the material makes it unique in the rubber industry, even better than natural rubber.

Conclusion

To conclude, neoprene has incredible potential as a synthetic material. It can withstand temperature, chemicals, and oils and greatly resist abrasions.

As a result, a wide range of industries use this product, which keeps it in high demand. If you are a rubber business looking for neoprene products, you need a reliable manufacturer.

Contact Hongju For Premium Neoprene Products Now!

At Hongju, we offer a completely customized experience. Get prototypes in 3-5 days and low MOQs tailored to your needs. With 20+ years of expert craftsmanship, we deliver quality silicone solutions that accelerate your success.