Are you a product designer struggling to find the right silicone melting point? Well, you are not alone, as many DIY enthusiasts and product designers find it tricky to get answers to what temperature does silicone melt?

In this article, we will explain the melting point of silicone, factors that influence its heat resistance, and answer does silicone burns, so read on!

Why Silicone Does Not Have a Traditional Melting Point?

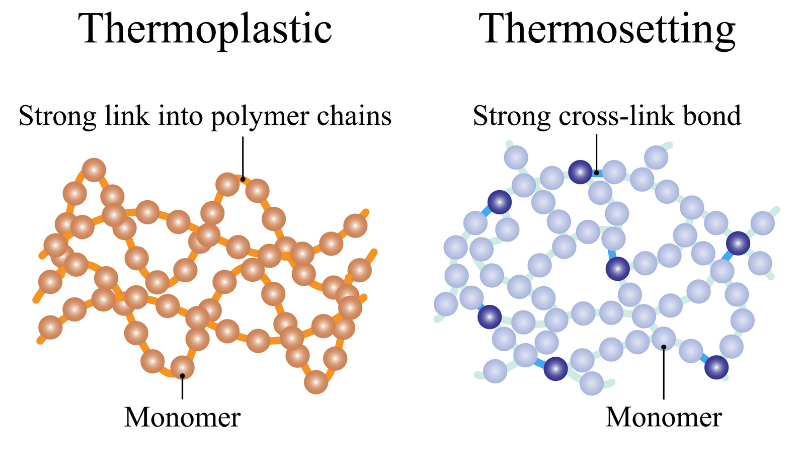

Silicone does not have traditional melting points because of its chemical structure and material composition. It is essential to note that silicone belongs to a class of materials called thermoset and not thermoplastic.

Thermosets are polymers that form a permanent cross-linked network during the curing stage. Once the network is formed, it does not break or weaken by reheating. Alternatively, the thermoplastics have lightly branched chains that can melt when heated.

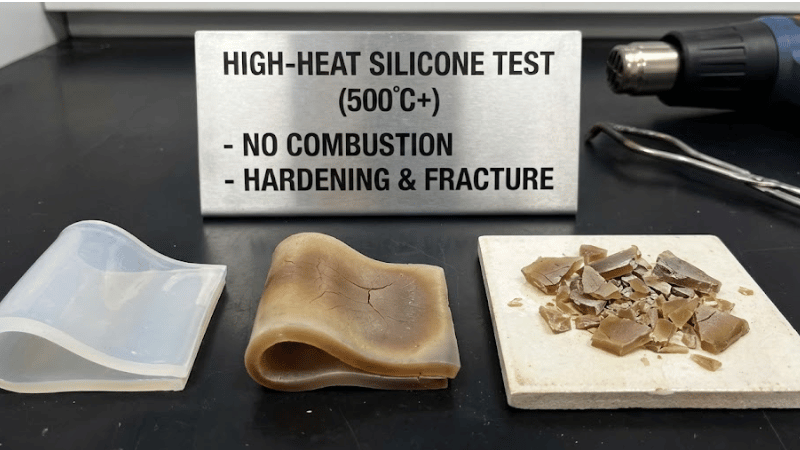

Even though silicone does not melt, it begins to decompose at extreme temperatures, such as 400 degrees Celsius. This is called the decomposition temperature.

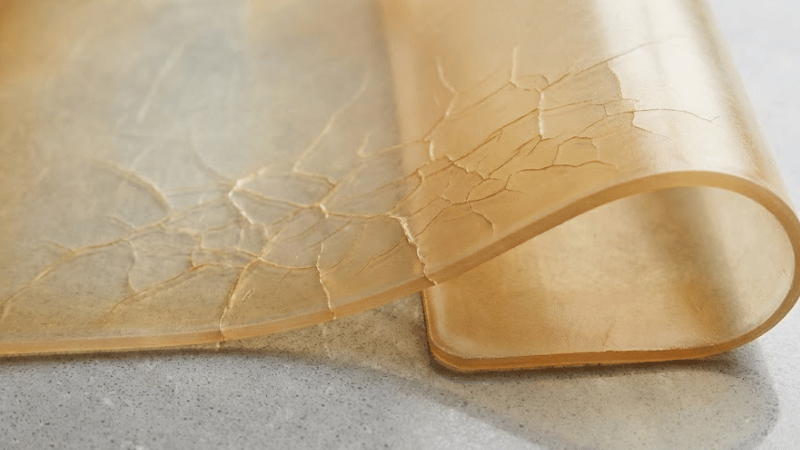

At this temperature, the polymer chains began to break down chemically, and this process is called thermal decomposition. Thermal decomposition hardens, cracks, discolors, or breaks silicone but does not liquidify it.

As per thermal analysis studies, silicone rubber degradation occurs in stages, typically between 220 °C and 570 °C. Within this temperature range, the polymer backbone breaks down rather than liquefying, which explains why silicone is highly heat-resistant but can never become a flowing liquid.

What Happens When Silicone Gets Too Hot?

When silicone is heated beyond a certain temperature, it will not melt, but will experience chemical breakdown. Silicone loses its elasticity when it is exposed to high continuous temperatures.

Similarly, you may experience the surface of silicone hardening, cracking, or discoloring upon overheating.

So we can say that the answer to the question of does silicone melts is that no, it does not melt, but when heated beyond the silicone melting point, it may harden or discolor.

Factors That Affect Silicone Heat Resistance

Heat resistance refers to the ability of a material to tolerate high temperatures before it starts to deform, degrade, or lose its shape. Many factors affect silicone’s resistance to heat, some of them include:

Chemical Formulation

Chemical formulation refers to the combination of chemicals and additives used to create a material. Standard silicone has a very good heat tolerance. However, the silicone made with high-temperature additives, e.g, iron oxide, has increased resistance to heat and stability at extreme temperatures.

Environmental Factors

Exposure of silicone to oxygen, oils, and steam can accelerate the degradation process, thereby reducing heat resistance.

Curing Method

Curing is the process of turning liquid or soft silicone into a solid material. Platinum-cured silicones have better heat resistance as compared to peroxide-cured silicones. Peroxide-cured silicone discolors or loses its strength faster when exposed to high temperatures.

Duration

Prolonged exposure to heat can affect the lifespan of silicone, leading to hardening or weakening of the silicone.

The table explaining the factors affecting the heat resistance of silicon is provided below:

| Factor | Affect On Silicone |

| Chemical Formulation | High-temp additives (e.g., iron oxide) increase stability |

| Curing Method | Platinum-cured resists heat better; peroxide-cured may discolor or weaken |

| Environmental Factors | Oxygen, oils, or steam accelerate degradation |

| Duration | Prolonged heat can cause hardening or brittleness |

What Temperature Can Silicone Withstand? Ranges & Grades

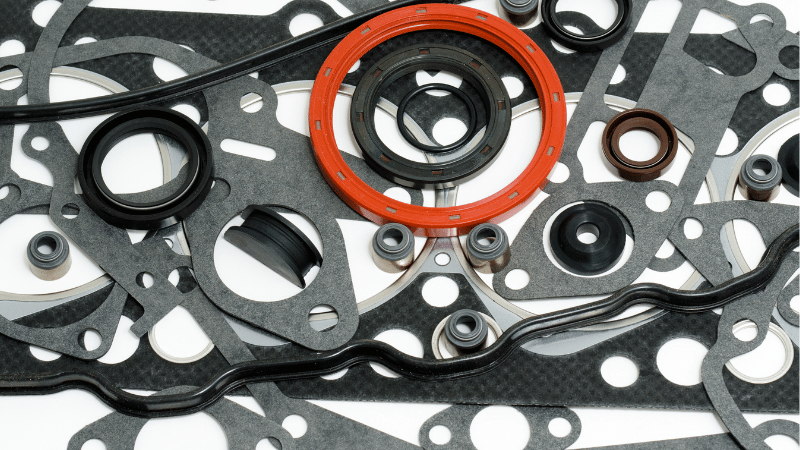

Silicone is commonly used in cookware, industrial seals, and automotive applications due to its mechanical properties to withstand extreme temperatures. To choose the silicone as per the needs, product designers and engineers need to understand the silicone melting temperature range and different grades.

The General Operating Range

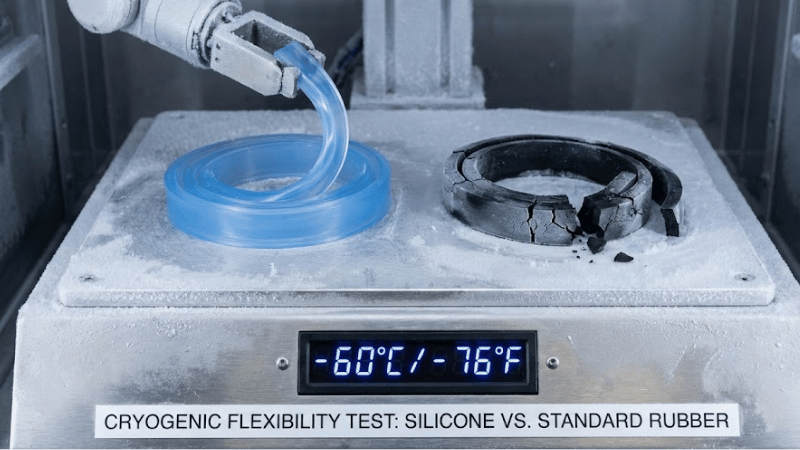

The commercial silicone rubber (the standard cured one) can safely operate between the temperature range of -60°C to 230°C (-76°F to 446°F). This range is much wider than natural rubber and many other materials.

Natural rubber can crack in cold weather. Whereas when exposed to elevated temperatures, it can soften, melt, or degrade. On the other hand, standard silicone doesn’t melt, but loses its properties when it is subject to temperatures beyond its limit.

Continuous vs. Intermittent Heat

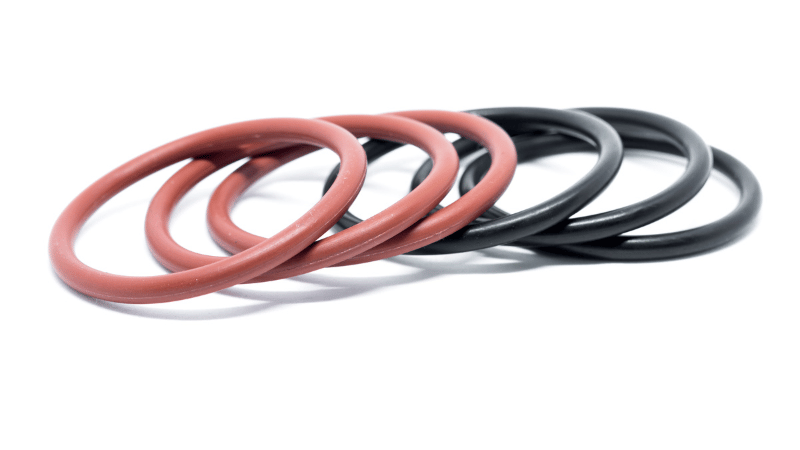

Silicone parts can handle 200°C–230°C of temperature continuously. This property makes silicone rubber ideal for use in oven gaskets, bakeware, and high-performance applications where continuous heat is applied.

For product designers, it is important to note that silicone rubber can only tolerate temperatures exceeding 250°C for a short time. If heated beyond this temperature limit repeatedly, it may experience:

- Loss of elasticity

- Surface hardening or cracking

- Brittleness over time

Understanding the difference between continuous vs. intermittent heat is important for product engineers and DIY enthusiasts to design silicone products and to choose the right silicone rubber type.

High-Temperature Grades: Breaking the Limit

Standard silicone is heat-resistant and does not melt, but it sometimes isn’t heat-resistant enough for all the industrial applications.

To address such issues, high-temperature grade silicone, which is often reddish-orange in color, is designed especially to withstand conditions that standard grades cannot.

These high-temperature upgrades have heat-stabilizers such as iron oxide and other transition metal oxides. These heat stabilizers increase the thermal stability and prevent degradation.

The high-temperature grades maintain elasticity, shape, and performance even when exposed beyond decomposition temperature.

With the advanced formulations, the unique chemical structure of silicone can now withstand temperatures of 250 degrees Celsius continuously, and can bear short-term spikes up to 300 degrees Celsius without deforming, deshaping, or losing its properties.

The high-temperature grade silicone is ideal for automotive gaskets, industrial seals, and aerospace components where exposure to extreme heat is constant.

Food-Grade & Medical-Grade Silicone: Safety at Heat

Silicone is a widely used material in the medical and food industries. The medical-grade silicone is used for making catheters, medical tubing, syringes, and pumps. In the food industry, it is used for making kitchen utensils, silicone cookware, bowls, and spatulas.

For use in medical applications and food-related applications, production engineers consider not just the heat resistance and specific grade but also the safety and chemical stability.

Product designers need to ensure that the silicone will not leach any harmful chemicals that affect the taste of food when exposed to heat. Medical and food-grade silicone must be in compliance with FDA and LFGB standards to ensure that they are safe for use.

The ability of silicone to withstand autoclave sterilization at around 134 degrees Celsius, without losing its shape, makes silicone materials ideal for use in both the medical and food industries.

Low-Temperature Flexibility

Similar to high temperature, silicone’s unique properties make it highly flexible at low temperatures, too. This means that the silicone melting point logic applies to cold as well.

Even when exposed to low temperatures, silicones do not become brittle like PVC, standard rubber, and other rubbers.

This makes silicone ideal for applications in freezing or below-zero environments. For use in extreme conditions, specialized Phenyl silicone grades are ideal as they maintain flexibility down to -100°C (-148°F).

These silicones are used in industries where maintaining elasticity and preventing cracking in the cold is critical. The common examples of such industries are aerospace, laboratory equipment, and low-temperature sealing.

A table comparing different materials based on their heat resistance is given below. Read it to choose the right material:

| Material | Typical Temperature Range | Heat Behavior | Notes |

| Silicone | -60°C to 230°C (-76°F to 446°F) | Maintains flexibility; degrades slowly at extreme heat | High heat resistance; self-extinguishing; does not melt |

| PVC (Polyvinyl Chloride) | 0°C to 60°C (32°F to 140°F) | Becomes brittle in cold, softens or melts in heat | Low heat resistance; prone to cracking and deformation |

| Standard Rubber | -40°C to 120°C (-40°F to 248°F) | Can crack in cold, softens at high heat | Moderate heat resistance; less durable than silicone |

Does Silicone Burn?

The definitive answer to this question is that silicone is heat-resistant and does not burn easily. Unlike plastic, which can catch fire very easily, silicone behaves differently, and regardless of how hot can silicone get, it never burns.

In case silicon is exposed to extreme heat, it can harden or break, but won’t burn. Due to this property, silicone is used widely in bakeware, baking mats, kitchen utensils, medical implants, hair tools, and silicone sealants.

However, it is important to always use it within the rated silicone rubber temperature range, as prolonged exposure beyond this limit can shorten its lifespan and compromise performance.

Silicone and Flame Resistance

Silicone is naturally self-extinguishing, which means it will not continue to burn once the heat source is removed. It has a high ignition temperature of around 450 degrees Celsius, making accidental combustion rare under normal conditions.

Unlike plastics, when exposed to external heat, silicone does not drip or produce flaming liquids. In fact, it forms stable ash or silica residue. This property makes silicone ideal for insulations, seals, and gaskets where flame resistance is critical.

Is Silicone Fireproof or Just Heat Resistant?

The question is silicone fireproof is a commonly asked one. One definitive answer to this question is that it is not fireproof; it can burn if exposed to temperatures above its ignition point. However, it does offer excellent flame resistance, making it safer than plastics and rubbers in high-heat applications.

Unlike other materials that drip flaming liquids, silicone is self-extinguishing. Its high ignition temperature, paired with self-extinguishing properties and heat resistance, allows it to bear critical industrial uses.

Is Silicone Safe for Electronics?

Is silicone safe for electronics? Yes, provided you choose the right grade.

While standard silicone is naturally flame-resistant, specialized flame-retardant grades can achieve a UL 94 V-0 rating.

- What is V-0? This certification from Underwriters Laboratories (UL) means that if the silicone is set on fire, the flame will self-extinguish within 10 seconds, and there will be no flaming drips.

- Application: This is a mandatory requirement for silicone components used in electric vehicle (EV) battery seals and aerospace avionics.

Conclusion

To sum up, we can say the silicone shows excellent heat-resistant properties. With the advent of high-temperature grade silicon, silicone can now be used in any industrial application that involves continuous heat contact.

The better heat-resistance makes silicone a perfect material for use in medical equipment, food-grade applications, and much more. No matter the application, always make sure to choose a reliable and trustworthy supplier like Hongju Silicone for your silicone rubber needs.

Invest In High-Quality Silicone Rubber Parts – Contact Hongju Now

At Hongju, we have more than two decades of experience inmanufacturing custom silicone products. Our Low MOQ allows us to produce quantities according to our clients’ needs.

Our ability to quickly create models of products within 3-5 days with CNC machining gives us an edge over our competitors.

Just contact us today and get a bulk quote tailored to your requirements now.