What is Silicone?

Silicone is a rubber-like material that can be stretched or deformed by force. When the pressure is withdrawn, it comes back to its original shape. So, Silicone is primarily a polymer which is also known as an elastomer.

It has different properties that make them suitable for critical applications. For example, it is non-reactive, which means it will not react in touch with other chemicals. It is pretty flexible and biocompatible. So it can be used without worrying about any adverse effects.

Also, silicone has excellent temperature and water resistance. So it is perfect for use as a sealant or insulator. All these properties make silicone rubber an excellent medical-grade material. Manufacturers use it in various medical applications and medical devices.

What is Medical Grade Silicone?

Medical grade silicone is used by many manufacturers who make medical devices using silicone. Silicone has many benefits and is one of the most suitable medical-grade materials.

Medical grade silicone can refer to two things. One is class VI silicone, which is medical-healthcare grade, specifically. This one is tested for biocompatibility.

It is suitable for various medical applications such as baby bottle nipples, menstrual cups, water pipes, scuba mouthpieces, and skin and food-contact items.

Another thing that medical-grade silicone means is long-term implantable medical materials. It means this type or grade of silicone is suitable to be a part of implantable devices that can stay attached to a human body.

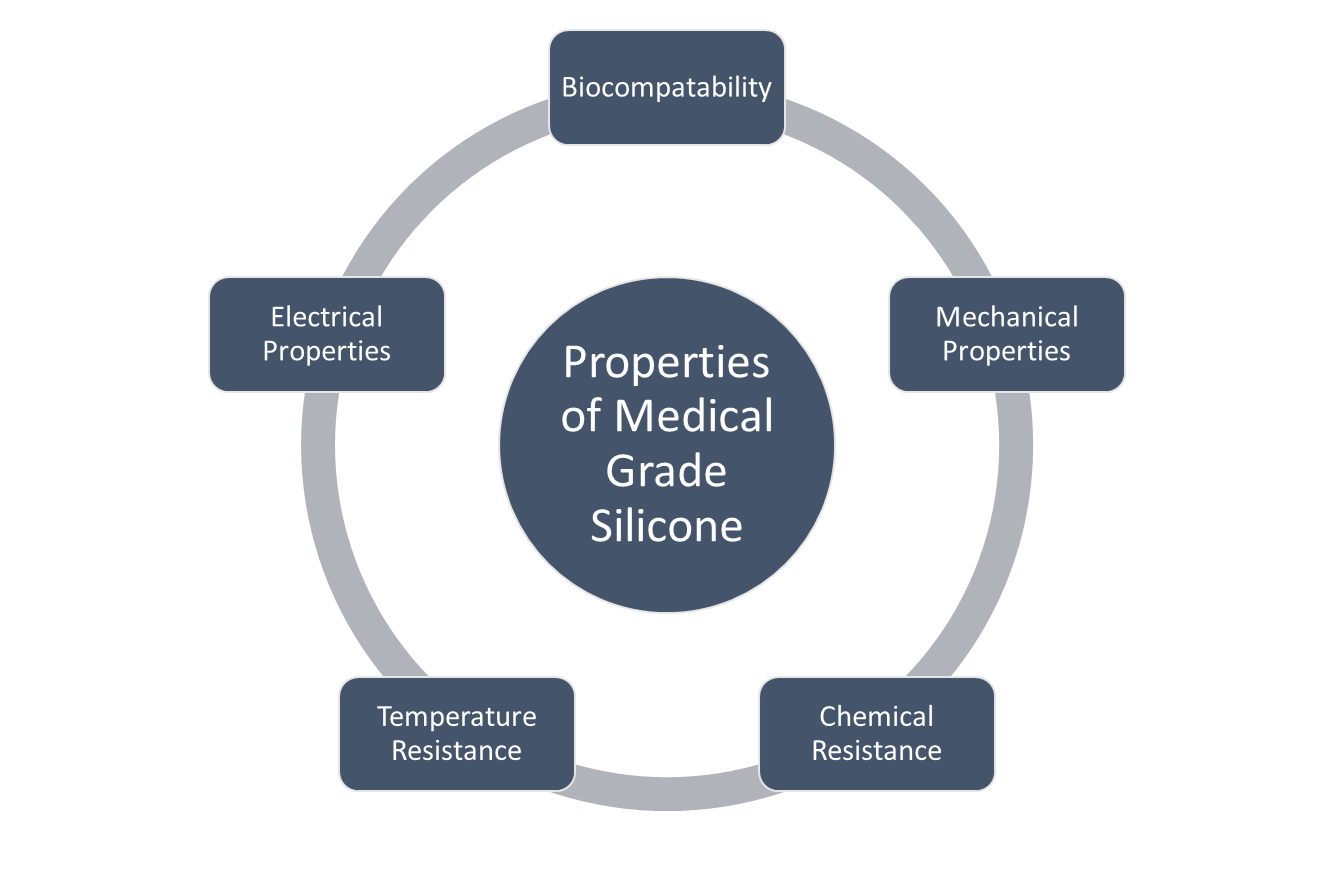

Properties of Medical Grade Silicone

The chemical structure of silicon-oxygen is very strong; because of this structure, medical-grade silicone has some unique performance properties.

The physical properties of medical-grade silicone are discussed below:

Electrical Properties

When it comes to being an electric insulator, no other material is as good as silicone. There are a lot of medical applications where electrical insulation is necessary.

Silicone rubber can be a great choice in this case. Medical-grade silicone is a non-conductive material. It also can maintain dielectric strength at higher temperatures.

This is why medical-grade silicone is suitable for medical devices that generate heat.

Mechanical Properties

The tear strength of medical-grade silicone rubber is 250 PPI. Its tensile strength is 1500 psi. Very few medical-grade materials have elongation and flexibility as good as silicone.

Softer silicone can stay soft over a long period without losing its property. The elongation of silicone can be up to 1250%.

Moreover, it has a low compression set. Such a compression set makes it perfect for a lot of medical applications.

Chemical Resistance

Medical-grade silicone has good chemical resistance. First of all, silicone is an excellent water-resistance material. This is why it is perfect for making sealants for various medical devices.

Secondly, it can resist many other chemicals, for example, oxidizing chemicals, acids, isopropyl alcohol, and ammonia.

But manufacturers should remember that silicone cannot handle alkalines, concentrated acids, and solvents.

Temperature Resistance

Silicone is a type of elastomer capable of withstanding a broad range of temperatures compared to most other elastomers.

It can remain stable at temperatures ranging from –75° F to 500° F. For this reason, its heat resistance properties are excellent.

The only way to sterilize medical-grade silicone is by using E-beam or gamma irradiation, EtO gas, steam autoclaving, and a few other methods.

Biocompatibility

There are many tests that show that silicone is a very good elastomer that is compatible with human tissue. The response is relatively low when implanted in human tissue as it is compatible with our bodily fluids.

Silicone is non-reactive without any taste or odor, and therefore there is no possibility of bacteria growth. Moreover, silicone doesn’t corrode other materials to which it is attached.

These are frequently designed to meet ISO, FDA, and Tripartite biocompatibility standards for a medical device.

Types of Silicone Rubber

There are several types of silicone rubber, but there are four significant types. These four types are discussed below:

Liquid Silicone Rubber (LSR)

Liquid silicone rubber is mainly medical grade. The injection molding process makes this.

Injection molding is the process of manufacturing components by injecting molten material into a mold. Injection molding is reasonably practical for medical-grade liquid silicone rubber.

The main reason why most medical device applications require LSR is that it is directly injected into the mold cavity without any chemical modifications.

Sometimes colors are added to liquid silicone rubber based on different application requirements in the medical industry.

High Consistency Rubber (HCR)

High Consistency Rubber (HCR) is a similar material to Liquid Silicone Rubber (LSR) but with some unique properties. The compression molding process is used for manufacturing medical products with HCR.

In compression molding, HCR is put into a mold after passing through a two-roll mill and then compressed to get silicone components for the medical industry. HCR can be mixed with different fillers and additives to manipulate its physical characteristics.

For this reason, medical device manufacturers use this to manufacture medical products according to their requirements.

Fluorosilicone Silicone Rubber (FSR)

The Fluoro silicone rubber is primarily used in the automobile industry because of having high flame and brake fluid resistance. The benefits of using FSR for medical purposes can be stability, resistance to compression, resistance to solvents, and chemical resistance.

Room Temperature Vulcanized Silicone (RTV)

At room temperature, RTV Silicone vulcanizes or solidifies. Silicone caulks fall into this group and is commonly utilized in prototype parts.

Before going into high-volume production of the final product for the end-user, medical silicone parts manufacturers often use these materials to make prototypes.

Importance of LSR for Medical Use

LSR is a highly versatile material that is used in the medical field. It works at wide temperature ranges, so manufacturers use it to make various components.

Different types of medical usage for LSR are medically unrestricted implantable, medically restricted implantable, and medically non-implantable.

Many medical components, such as hydrocephalic shunts and pacemakers, are made using LSR or liquid silicone rubber. The primary reason for using LSR materials in the medical sector is the biocompatibility of silicone.

Many researchers in the material science field have developed ways to improve the hardness level of LSR. For this reason, manufacturers can use LSR materials to make various medical components with different hardness levels.

There are three categories of medical-grade LSR:

Permanent Contact

Permanent contact LSR is also known as long-term implantable LSR. This type of LSR requires a lot of testing before it can be used practically.

Different types of testing on this LSR include:

- Chronic Toxicity

- Carcinogenicity

- Developmental Toxicity

Prolonged Exposure

The prolonged exposure to LSR material is popular as healthcare grade. It can stay in contact with human tissue for more than 24 hours and up to 28 days without risk.

Different types of testing on prolonged LSR include:

- Intramuscular Implantation with Histopathology

- Hemolysis

- Toxicity

- Genotoxicity

Limited Exposure

This type of LSR is used to make devices that come into mucosal membranes, skin, or breach surface contact in the medical sector. It should not stay in contact for more than 24 hours.

Medical Fields Where LSR Is Used

The highly versatile material LSR is used to make a variety of medical devices. These devices are mainly made using the process of injection molding.

This process is suitable for LSR materials because it saves a lot of time and, at the same time, produces multiple components.

Below is a list of medical fields where LSR is used broadly for various applications

- Cardiology

- General Surgery

- Bariatric Surgery

- Oncology

- Ophthalmology

- Plastic Surgery

- Dialysis

- Wearable Health Monitoring Devices

- Ear, Nose, and Throat

- Neurosurgery

Advantages of Medical Grade LSR

Medical-grade LSR offers a lot of advantages. For example,

- Because of part geometry and usability, many components can only be made using LSR.

- The final products made by LSR material are of high quality without any flash and don’t leave any waste.

- Product dimensions have the highest consistency if it is made using LSR.

- The overall quality and precision are also quite promising because of the lean manufacturing processes.

- The cycle time for manufacturing LSR components is concise, so they can be produced in high volumes.

- The TCQ, or “Total Cost of Quality,” is the lowest for medical-grade liquid silicone rubber.

Conclusion

In summary, medical-grade silicone offers valuable properties, like durability, biocompatibility, chemical and heat resistance, and flexibility. These properties enable it to function as an implant material, surgical instrument, and protective barrier in medical applications.

Its ease of use, low cost, and long-lasting properties make medical-grade silicone a popular material for medical devices and equipment. The unique properties and versatility of medical-grade silicone contribute to its broad usefulness in medical technology.

Looking for Medical Grade Silicone?

Hongju Silicone Can Help You

At Hongju, we can assure you of the highest quality medical grade silicone and expertise to help you find the most suitable solution for your specific needs.

Visit our website to discover more about Hongju Silicone and our expertise in providing high-quality silicone rubber products. Whether you need custom solutions or have specific requirements, contact us; our team is here to assist you.