Types of Rubber Materials for Medical Devices

You must already know that rubber comes in different types. Hence, it makes sense that manufacturers use other rubber materials to produce medical device parts. The most commonly used rubber materials in this industry include:

- Nitrile Rubber: This synthetic rubber features excellent oil resistance and resistance to fuels and certain chemicals.

- Silicone Rubber: famous for its high biocompatibility and temperature resistance, it is an excellent material for catheters or implants.

- EPDM: EPDM works great for outdoor medical equipment. Why? It performs exceptionally well against outdoor elements, including ozone, weathering, and heat.

- Natural Rubber: Natural rubber offers a good compression set and high elasticity. As a result, it is excellent for medical tubing and gloves.

- Fluor-elastomer: it has excellent temperature, chemical, and ozone resistance. Hence, it is often used in sterilization equipment.

Benefits of Molded Rubber Products in Medical Applications

Since rubber has wide use for medical device parts, it must offer many benefits. Let’s have a look at the best ones:

- Moldable: rubber has high moldability, meaning manufacturers can shape it into the exact form needed by medical device manufacturers.

- Versatile: rubber offers incredible variations of properties. This includes different rubber materials and alternations, such as vulcanization, that help design rubber products with customized properties.

- Cost-effective: Rubber manufacturing is a relatively inexpensive process. Moreover, it does not take much to produce rubber products in bulk quantities.

- Customizations: Rubber is a highly customizable material. You can ask the manufacturer to add color, texture, or measurements to your custom-molded rubber components.

- Insulation: since rubber offers good insulation, medical devices greatly benefit from it. Especially when it comes to protection against heat.

- Sterilization-friendly: sterilization friendly rubber makes it one of the best materials for medical device parts and surgical instruments.

Common Custom Molded Rubber Parts

The medical device industry uses a variety of rubber products. These include gaskets, seals, tubing, and bellows.

- Seals: rubber seals help prevent liquids, gases, or other materials from leaking out of a device or container, such as syringe cups.

- Gaskets: this rubber part helps create tight seals between two surfaces. The most common use of gaskets is in vacuum pumps, respirators, pressure monitors, etc.

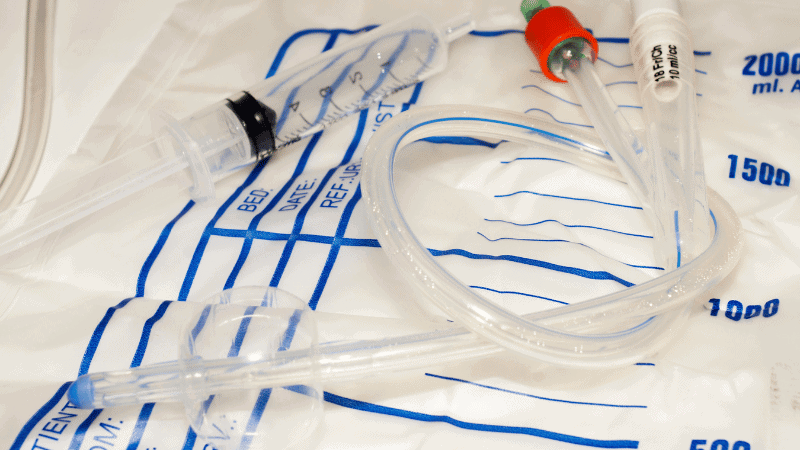

- Tubing: rubber tubing helps transport gases, liquids, and other materials in medical devices such as IV pumps, catheters, etc.

- Bellow: Bellows help create flexible connections between two medical devices. A good example would be a medical ventilator.

Why Silicone Rubber Is the Preferred Choice

Undoubtedly silicone is the most widely used rubber material in medical applications. But why? For starters, silicone has excellent durability, flexibility, and biocompatibility. Hence, it does not cause an adverse reaction when in contact with living tissue.

Also, silicone resists extreme temperatures as well as UV light. This makes it ideal for sterilization. Additionally, silicone rubber’s flexibility allows for comfortable use in medical devices such as catheters and tubing.

Moreover, silicone also makes a perfect material for sterilization equipment. Given its heat resistance, silicone rubber medical parts are reusable. On top of it, the chemical and oil resistance comes in handy in various applications.

How to Choose the Right Molded Rubber Part

Several factors go into deciding the right custom-molded rubber parts for your need. Hence, it would be best if you considered the following:

Budget

You must find the right price for the products. Hence, you have to keep in mind the budget. This can affect which manufacturer you work with and the quality of rubber products you get.

Conditions

Conditions mostly have to do with the choice of rubber material. For instance, you don’t want to get natural rubber medical parts for extremely high-temperature conditions. Similarly, EPDM that performs well outdoors must not be considered for indoor components.

Compatibility

This factor has more to do with the product size, type, color, and texture. Make sure whatever rubber products you order are universal or work well with your medical devices.

FAQs

Q1: How is the rubber component molded?

There are different techniques of rubber molding. These include transfer molding, injection molding, compression molding, and die cutting. Each method has its pros and cons. Hence, manufacturers use them based on customer demand and the nature of the product.

Q2: What is medical rubber?

Different from food-grade rubber, medical rubber is a particular grade of rubber that is suitable for medical equipment and process. It does not contain any toxins that can harm the human body.

Q3: Why is silicone rubber widely used in medical applications?

Silicone has many excellent properties, such as flexibility, temperature resistance, and biocompatibility, that make it suitable for medical applications. Moreover, silicone is also a cost-effective material.

Q4: What rubber materials are used in medical devices?

Different rubber materials are used to produce specific parts for medical devices. The most common ones include nitrile, EPDM, silicone, and natural rubber.

Conclusion

To conclude, rubber has a significant role in the medical industry. It has solved many problems and made many applications efficient and more accessible. Hence, the growing market always looks for reliable manufacturers and suppliers. Moreover, the benefits and uses discussed above clearly indicate the industry will only grow as we move further.

Custom Silicone Rubber Solutions Designed for Your Business

At Hongju, we deliver silicone rubber products with speed, flexibility, and precision. Enjoy rapid prototyping in just 3–5 days, low MOQ to reduce risks, and 20+ years of expert craftsmanship.

Contact Hongju today for tailored solutions that accelerate your production and meet your exact needs. Request a quote now!