This article aims to cut through the confusion, offering a comprehensive guide to demystifying the types and applications of silicone sealants. Whether you’re sealing gaps, adhering materials in extreme temperatures, or tackling specialized construction applications, we’ve got you covered with expert advice and insights.

What is Silicone Sealant?

Silicone sealant is a versatile material commonly used for sealing, bonding, and filling gaps. It is a type of adhesive that offers excellent resistance to extreme temperatures, UV radiation, and moisture, making it ideal for a wide range of indoor and outdoor applications.

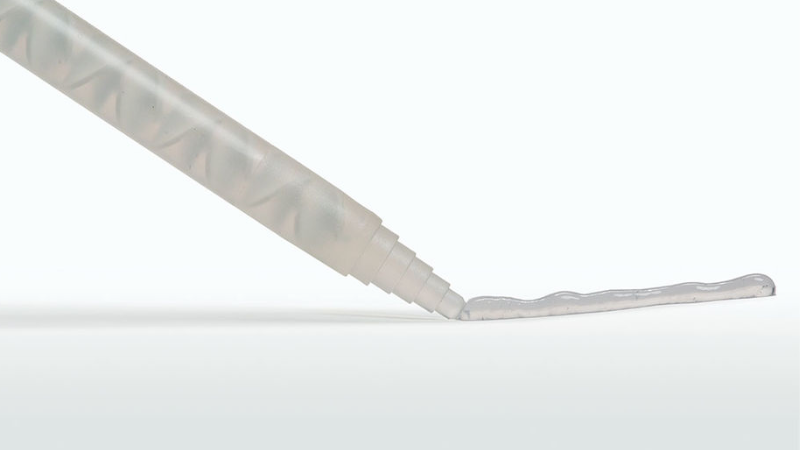

Silicone sealants typically come in liquid form in tubes and are applied using a caulking gun.

Once applied, they undergo a curing process, often facilitated by exposure to air or moisture, to form a durable, rubber-like material that adheres strongly to a variety of surfaces such as glass, metal, wood, and ceramic.

Historical Context of Silicone Sealants

Silicone sealants have come a long way since their initial introduction. Originally developed in the early 20th century, silicone sealant technology has advanced significantly over the decades, broadening its range of applications and capabilities.

During the early years, most silicone sealants were basic formulations with limited adhesive properties, primarily used in less demanding environments like simple household tasks.

With the advent of high-quality sealants, neutral-cure silicones, and acid-cure silicones, these products have been increasingly used in a variety of settings, from construction applications to industrial maintenance applications.

The evolution has been spurred by the understanding of the sealant’s chemical composition and curing process, and the requirement for better adhesive properties that can withstand both high and low temperatures.

Today, silicone sealants are indispensable in various sectors, serving multiple purposes beyond just sealing gaps. They have become a crucial part of window seals, sanitary applications, and even in sealing baths with non-porous surfaces.

The vast array of types—including low-modulus sealants, high-modulus sealants, and specialty neutral-cure silicone products—demonstrates the adaptability and effectiveness of silicone sealants in today’s world.

Basic Chemistry Behind Silicone Sealants

Silicone sealants are a versatile and widely used product, known for their exceptional flexibility and resistance to extreme temperatures. To demystify the types of silicone sealants, it’s essential to understand the basic chemistry behind them.

Chemical Composition

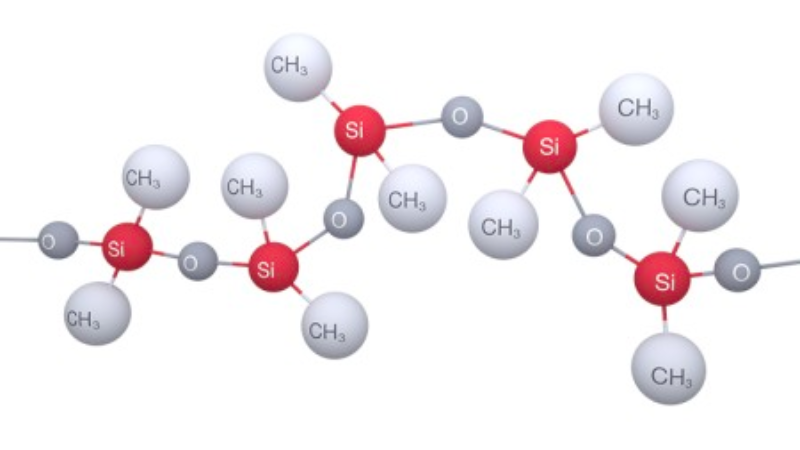

Silicone sealants are primarily composed of polymers that contain silicon, oxygen, carbon, and hydrogen atoms. This unique chemical structure is what sets silicone sealants apart from other types of adhesives or sealants.

The presence of silicon in the polymer chain gives silicone sealants their remarkable properties. Silicon atoms are surrounded by oxygen atoms, creating a backbone with alternating silicon-oxygen bonds. This backbone provides stability and durability to the sealant.

Exceptional Flexibility

One key characteristic of silicone sealants is their exceptional flexibility. The presence of organic groups attached to the silicon atoms allows for easy movement within the polymer structure.

As a result, silicone sealants can withstand significant elongation without losing their adhesive properties.

This flexibility makes silicone sealants ideal for applications where materials may expand or contract due to temperature changes or structural movements.

Whether it’s sealing gaps in windows or bonding dissimilar materials together, silicone sealants can accommodate such movements without cracking or breaking.

Resistance to Extreme Temperatures

Another notable attribute of silicone sealants is their high resistance to extreme temperatures.

The presence of silicon-oxygen bonds contributes to the thermal stability of these materials. Unlike many other adhesives or sealants that degrade under heat exposure, silicone-based products retain their integrity even at elevated temperatures.

This ability to withstand both high and low temperatures makes silicone sealants suitable for various environments and applications.

From sealing joints in automotive engines exposed to intense heat to insulating electronic components subjected to freezing conditions, silicone-based products offer reliable performance across a wide temperature range.

Cross-Linking Reactions

During the curing process, cross-linking reactions occur within the silicone sealant. This chemical transformation is what ultimately creates a durable and elastic bond.

The cross-linking reactions involve the formation of additional bonds between polymer chains, resulting in a three-dimensional network.

The cured silicone sealant forms a rubber-like material that can stretch, compress, and recover its original shape.

General Categories of Silicone Sealants

Silicone sealants can be broadly categorized based on their curing mechanism, modulus, and specific application areas. Here’s an overview:

Based on the Curing Mechanism:

- Acetoxy Silicone Sealants: Cure by releasing acetic acid. Suitable for non-porous surfaces like glass, but might corrode some metals.

- Neutral Cure Silicones: Known for their versatile applications, they don’t release acidic compounds during the curing process. Ideal for materials sensitive to acids, such as metals or clear polycarbonate materials.

Based on Modulus:

- High Modulus Sealants: These sealants have a high elastic modulus, meaning they are stiffer and less stretchy. They provide robust strength and are typically used in construction applications where rigidity is needed.

- Low Modulus Sealants: These are more flexible and can accommodate more movement. They are preferred for window seals or joints that might experience expansion and contraction.

Specialty Types of Silicone Sealants

Beyond the general categories, there are specialty types of silicone sealants that are engineered for very specific applications. These sealants are formulated with unique chemical compositions to meet the demanding requirements of particular tasks.

- Fire-Resistant Sealants: These sealants are designed to resist high temperatures and are ideal for use in environments that are exposed to heat or flames. They’re commonly used in industrial settings and safety installations.

- Food-Grade Sealants: Safe for incidental food contact, these sealants are often used in the food and beverage industry, as well as in household kitchenware. They meet stringent health and safety standards.

- Aquarium Sealants: These are explicitly designed for underwater applications, providing robust adhesion to glass and other non-porous surfaces in aquatic environments.

- Electronic Grade Sealants: Formulated for adhesive properties suitable for electronic components. They resist moisture and ensure the integrity of sensitive electronic assemblies.

- Automotive Sealants: Created for use in vehicles, these sealants have superior resistance to oils, coolants, and other automotive fluids. They also exhibit better adhesive properties compared to general-purpose sealants.

- Quick-Curing Sealants: These are formulated for rapid curing, often within a few minutes, and are used in time-sensitive applications or for industrial maintenance applications.

Factors Influencing Sealant Choice

Choosing the right type of silicone sealant is crucial for ensuring effective sealing and long-term performance. Several factors come into play when making this decision, including substrate compatibility, environmental conditions, and aesthetic requirements.

Substrate Compatibility

One of the primary considerations when selecting a silicone sealant is its compatibility with the substrate it will be applied to. Different types of materials require specific sealants to achieve optimal adhesion and durability.

For instance, if you are sealing a joint between two different materials, such as glass and metal, you need a sealant that can bond effectively to both surfaces. In such cases, using a multi-purpose sealant that adheres well to various substrates would be ideal.

Environmental Factors

Environmental conditions also play a significant role in determining which silicone sealant is most suitable for your project. Exposure to ultraviolet (UV) radiation can cause degradation over time, leading to decreased performance and potential failure of the sealant.

If your application will be exposed to direct sunlight or other sources of UV radiation, it is essential to choose a UV-resistant sealant specifically designed for outdoor use.

Moisture levels are another critical environmental factor to consider. High humidity or constant exposure to water can compromise the integrity of certain silicone sealants over time.

In situations where moisture resistance is crucial, opt for waterproof or marine-grade sealants that provide enhanced protection against water intrusion.

Aesthetic Requirements

While functionality is paramount when choosing a good sealant, aesthetic considerations may also come into play depending on the application.

Some projects require color-matched or transparent sealants that blend seamlessly with the surrounding materials for an aesthetically pleasing finish.

For example, when sealing joints in bathroom tiles or kitchen countertops, you might prefer clear or white silicone sealants that do not disrupt the overall appearance.

Practical Scenarios: What to Use and When

Knowing the specialty types of silicone sealants is only part of the equation. The real test comes when you have to apply this knowledge to practical scenarios. Here are some common situations and the types of sealants best suited for them:

- Home Construction and Renovation: For most DIY applications, such as sealing gaps in windows and doors or sealing baths, a neutral cure or acetoxy silicone sealant will usually suffice. If the surface is porous, opt for a neutral silicone sealant.

- Automotive Repairs: For scenarios that involve exposure to engine heat and automotive fluids, automotive sealants with high-temperature resistance are your best bet.

- Aquarium Building: If you’re creating a custom aquarium, an aquarium-specific sealant is crucial. These are safe for fish and plants and adhere well to non-porous surfaces like glass.

- Electronics: Use electronic-grade sealants to protect sensitive components from moisture and heat. These offer better adhesive properties for tiny components.

- Medical Equipment: For any medical devices or equipment, a medical-grade sealant that’s sterilizable and biocompatible is a must.

Understanding the practical implications of different types of silicone sealants will not only save you time but also ensure the durability and effectiveness of your project. Make sure to choose wisely based on the specific conditions and requirements you face.

Potential Pitfalls of Silicone Sealants

While silicone sealants offer a wide range of benefits, including adaptability to extreme temperatures and strong adhesive properties, they’re not without their challenges.

Common Mistakes in Choosing and Applying Silicone Sealants

- Wrong Type for the Application: One of the most frequent errors is using acetoxy silicone sealants where neutral silicone sealant would be better, or vice versa. The consequences can range from poor adhesion to adverse chemical reactions with the substrate.

- Ignoring Surface Prep: Silicone sealants work best on non-porous surfaces, but they can fail if the surface isn’t clean or dry, leading to compromised adhesive properties.

- Incorrect Curing Time: People often underestimate or overestimate the curing process time, which can lead to problems like smudging or incomplete sealing.

- Overapplying: The use of excessive product doesn’t necessarily mean better adhesion. Instead, it can result in wastage and messy finishes.

- Lack of Tools: Proper application often requires specialized tools, like a caulking gun, which people often overlook.

Solutions and Best Practices to Avoid These Mistakes

- Type Selection: Always refer to the manufacturer’s guidelines or consult professionals to choose between high-modulus sealants, low-modulus sealants, or other types of silicone.

- Surface Preparation: Ensure the surfaces are clean, dry, and possibly primed before application to maximize the adhesive properties of silicone sealants.

- Cure Time: Adhere to the recommended curing time specified by the product guidelines, as some neutral cure silicones may require longer or shorter times compared to others.

- Proper Application: Use the correct amount of sealant, ensuring even distribution for optimal results.

- Right Tools: Invest in the necessary tools like a caulking gun or specialized nozzles for construction applications or sanitary applications.

By adhering to these best practices, you can prevent many of the common pitfalls associated with using silicone sealants, thereby ensuring a more successful and durable application.

Conclusion

Silicone sealants have come a long way since their introduction, serving as an indispensable tool in a multitude of applications. Understanding the different types, from neutral cure silicone to high modulus sealants, is crucial for making an informed choice tailored to your specific needs.

Partner with Hongju for Your Silicone Sealant Solutions

Unlock a world of superior quality and performance by partnering with Hongju for all your silicone sealant needs. From comprehensive technical support to custom formulations that meet your specific requirements, Hongju is your one-stop solution.

Don’t compromise—choose Hongju and ensure the success and longevity of your sealing and bonding projects, and improve your business.

Send Your Inquiry Now!

Quality Meets Affordability. Inquire Now for High-Quality Products at Low Volumes.